Operations Optimization: Strategies, Examples, and 6 Steps for Process Optimization

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

The idea of making consistent, regular, and incremental enhancements to work is everywhere. Toyota introduced Kaizen, Motorola created Six Sigma, and Agile engineering teams use continuous improvement.

The overarching theme is constant improvement to prevent stagnation in your business.

These improvements take many forms. They could be as simple as moving certain products to the impulse purchase counter at a supermarket or rearranging the entire assembly line to reduce waste.

Either way, there is always room for improvement. You can create significant process efficiencies by paying attention to your processes and optimizing them regularly.

Read on and learn how to use process optimization strategies and methods to streamline your business operations.

Operations optimization is the continuous activity of observing, understanding, improving, testing, and streamlining business processes to maximize desired business outcomes such as throughput, efficiency, productivity, profitability, or cost/waste reduction.

Teams can choose from different approaches to optimize processes depending on their specific requirements.

Depending on the process, scale, impact, steps involved, and business goals, there are various process optimization methods. We’ve listed down some of the most common types of process optimization for you:

Here is an overview of the most common process optimization techniques and frameworks used across different industries and organizations.

Lean focuses on eliminating waste (anything not adding value) and creating more value for customers. Its key principles include value stream mapping, just-in-time (JIT) production, and continuous improvement (Kaizen).

Common applications:

This data-driven process improvement methodology minimizes defects and process variability to achieve near-perfect quality (3.4 defects per million opportunities). It focuses on the DMAIC framework (Define, Measure, Analyze, Improve, Control).

Common applications:

This business process optimization technique analyzes event logs from IT systems to identify inefficiencies and bottlenecks.

Common applications:

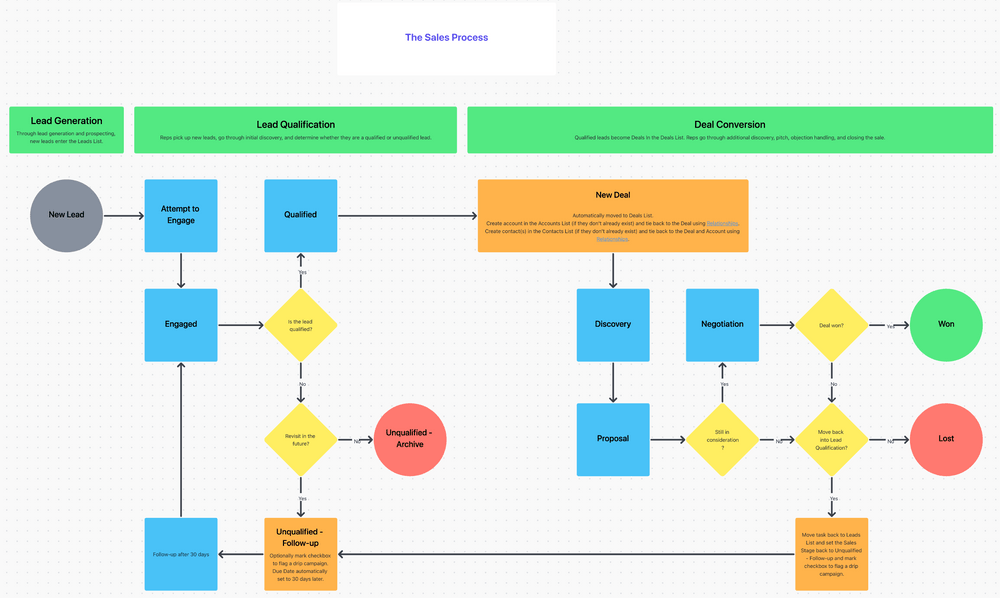

This process improvement technique visualizes processes using flowcharts or software tools and simulates different scenarios for operations optimization.

Common applications:

The optimization technique involves a radical redesign of business processes to achieve dramatic improvements in performance.

Common applications:

TQM is a holistic approach to long-term success through customer satisfaction and continuous improvement across all organizational levels.

Common applications:

TOC, or the Theory of Constraints, was developed by Dr. Eliyahu Goldratt, an Israeli physicist turned management guru. It focuses on identifying and addressing the most significant limiting factor (bottleneck) in a process.

Common applications:

Agile is a flexible and iterative approach to optimizing processes, primarily used in software development.

Common applications:

Root cause analysis is a problem-solving method to identify the underlying causes of process inefficiencies or failures.

Common applications:

Also Read: Root Cause Analysis Templates

Value stream mapping is a Lean tool for visualizing processes to identify non-value-adding steps and optimize workflows.

Common applications:

Every process has the potential to be optimized. A good business analyst will know what to optimize and when. As a best practice, begin by asking the following questions to the project teams.

These questions should give you a list of processes that need to be optimized. Once you have this, begin prioritizing. While doing so, consider three factors: effort involved, disruption expected, and potential outcomes.

If you’re just beginning to optimize business processes in the organization, you might want to prioritize those that need moderate effort, cause minimal disruption, and deliver medium to high outcomes.

💡Pro Tip: ClickUp’s Impact Effort Matrix Template is designed to help you quickly and accurately evaluate the impact and cost so that you know which processes to prioritize.

If you have a mature workflow optimization program, you might choose business processes that require high effort and cause high disruption while delivering high outcomes. The risk of disruption might be worth considering the results it will deliver.

While performing the previous step, you might have understood the basics of what the process entails. Now, it’s time to analyze it more thoroughly.

List every step of the process in as much detail as possible. Speak to the project teams. If they collaborate with other departments, speak to them, too.

💡Pro Tip: Visualize how tasks flow into each stage of the project and categorize them into goals, activities, and action items with ClickUp’s Process Map Template.

Note down every inadequacy/inefficiency in each step. For example, in an accounts payable process, uploading invoices to the ERP system might be taking too long, making it ripe for automation. In the marketing department, some designs might be off-brand, requiring better quality control measures.

Ask why the process is the way it is. Often, operations teams change existing processes without clearly understanding the current process.

This can have disastrous effects on other parts of the process or other connected processes.

Once you’ve documented this analysis, map the processes visually. Include related processes to understand the entire landscape.

💡Pro Tip: Use a Gantt Chart to spread it over some time. This helps us see these processes clearly and lays them over various scenarios.

Think of various improvements you can make to the inefficient business processes. Ask the project team for suggestions—often, they know best what they need.

Take inspiration from other departments that might have already solved this problem. Explore all possible solutions.

A sound mind map is a great way to document all these ideas without fearing a blank page or constraints of rows and columns.

💡Pro Tip: Brainstorming tools like ClickUp Whiteboards help you collaboratively ideate with team members and turn ideas into action at a single click.

Once you have a list of possible process optimizations, discuss each in detail. Identify the most likely to solve the problem and deliver the desired outcome while staying within the operational and budget constraints.

For example, if the problem is delays caused by the manual uploading of paper invoices to the ERP, the potential process improvement might be:

Based on your priorities and constraints, choose the solution that’s right for you.

💡Pro Tip: Use Task Priorities in ClickUp to clearly plan next steps

Before you implement the process improvements, test them on a smaller scale. You might do this by applying the changes to a small set of users or for a short period.

Monitor the user responses to the improvements and measure the outcomes. Collect qualitative and quantitative feedback from all stakeholders to ensure your intentions are met.

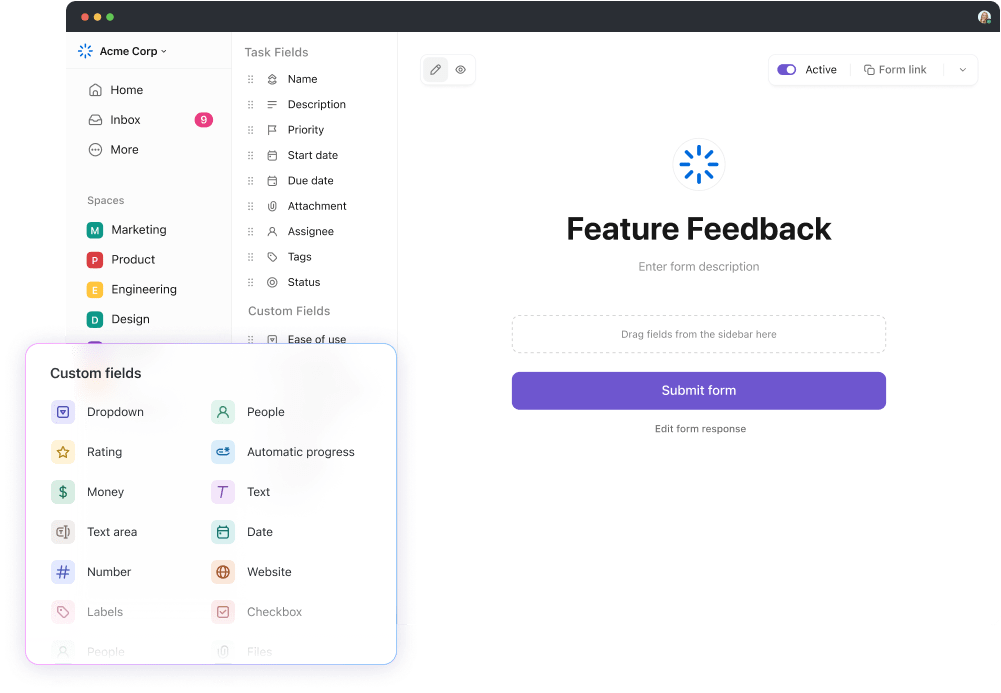

💡Pro Tip: Custom Fields in ClickUp help you compile data as granularly as you wish.

If your test succeeds, implement it for the entire organization while preparing for change management.

Most importantly, monitor how each user is adopting the new process. Identify potential opportunities to optimize it further. Keep your inbox open to feedback.

💡Pro Tip: Make this step easier with change management templates.

Problem: Inefficiencies and waste in the production process

Solution: Toyota developed the Lean Manufacturing approach, emphasizing:

Results:

Problem: High defect rates and process variability in manufacturing and service operations

Solution: GE adopted the Six Sigma framework to reduce process errors and improve efficiency

Results:

Problem: Long waiting times during peak hours in stores

Solution: Starbucks optimized workflows in stores to improve speed and efficiency.

Results:

Process optimization can be a complex endeavor. It involves making small yet significant changes to processes people follow daily, often subconsciously. Every process optimization has some level of disruption.

The only difference between the successful ones and others is that the former’s results outweigh the disruption’s effects. Good process optimization can benefit you in any of the following ways.

An operational intervention that can deliver such exceptional benefits does not come without challenges. Let’s explore what you will likely encounter in your process optimization journey and how to overcome them.

As you can see, these challenges are not in process optimization itself but in the implementation of it. With the right process improvement tools, you can overcome these challenges and streamline operations. Here’s how.

We live in a world of tool overload. There are dozens of tools for project management, collaboration, communication, and so on. Leverage the right tool stack to improve the outcomes of your process optimization efforts.

Data collection is not a one-time activity. Therefore, you need a systematic approach from multiple perspectives to make your data collection effective.

Run surveys to understand the team’s concerns with the process you’re looking to optimize. ClickUp’s conditional formatting Form view helps you create smarter forms to collect ideas and feedback.

Use a time tracker to measure how long each step in the process takes. The ClickUp time tracker is an excellent tool to do this. You can start/stop the timer or manually add the time spent. You can do this anywhere—mobile, browser, or native apps.

Look at completed project archives to learn more about how the tasks are performed. Go through comments and checklists to analyze current processes. Or just ask the AI Project Manager in ClickUp Brain to find this information for you.

No process can be successfully optimized without collaboration, whether when collecting data, brainstorming ideas, implementing the change, or measuring results. Modern collaboration tools make this possible.

Use ClickUp Notepad to take notes and share them with the team. What’s more? Use the AI tools to proofread and summarize them as well.

Use tools like the ClickUp Whiteboards to visualize business processes. Drag and drop steps, add dependencies, and make it visible for everyone to comment. This creates comprehensive visibility, bringing everyone on the same board!

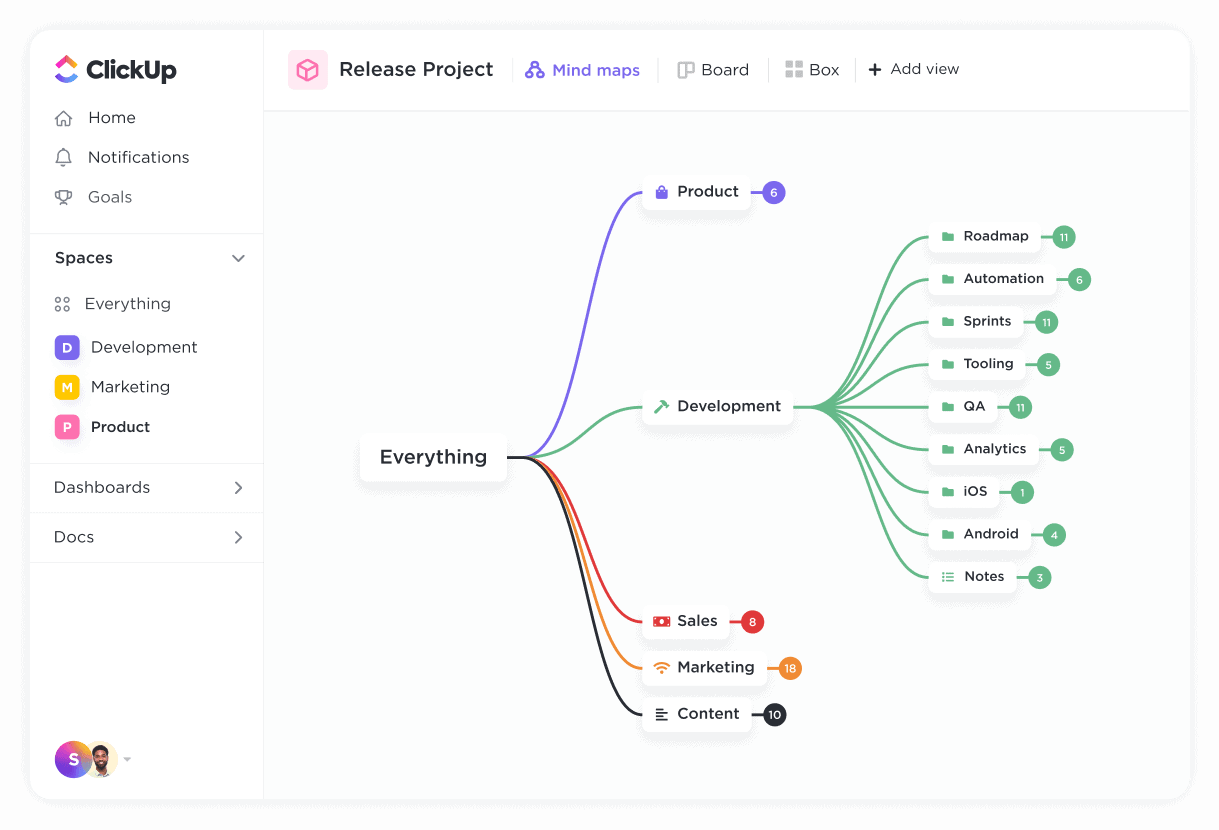

You can also use ClickUp Mind Maps to simulate potential improvements and let teams annotate too.

Debate ideas. Propose changes on a shared document with ClickUp Docs, inviting team members to review and offer feedback. Use the comments feature to debate any improvements you suggest, exploring the pros and cons asynchronously.

Or, get the whole team on a single chat thread to exchange ideas. With ClickUp Chat, you can do this through async chat threads or audio or video calls.

Better planning, presentation, and communication can address challenges related to resistance to change and leadership buy-in. We’ve also got tools for that!

Use the ClickUp Gantt Chart View to visualize the process over time. Create before and after views to show the difference process optimization makes. This will help teams imagine the potential upside to accepting the change.

Streamline connected processes with ClickUp Dependencies. Link-related tasks, customers, orders, deals, users, bug reports, documents, etc. View all relationships and dependencies in one place to make the right decisions.

Use ClickUp Automations to do the busy work. Automatically change assignees and priorities, and apply tags to accelerate the process optimization program. Trigger tasks based on any action or condition.

Here’s how a ClickUp customer felt about the tool’s efficacy in process optimization:

ClickUp’s time tracking functionality enabled accurate monitoring of resource allocation and task duration. This data-driven approach allowed for better resource management, identifying areas for optimization and enhancing overall project efficiency.

ClickUp is the only productivity platform that brings all your work in one place. With interconnected tools for communication, collaboration, and task management, it is the only solution you need to plan, execute, analyze, and optimize your processes.

With the power of various AI-powered features, automation, and smart templates designed to give you control over your processes, it’s the best place to begin optimizing business processes.

Try ClickUp for free today for your next process optimization efforts.

© 2026 ClickUp