Sales & Operations: Planning, Benefits, Challenges, and Best Practices

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

High-quality products lead to positive customer experience, but creating an effective sales and operations strategy goes beyond asking yourself what the customer wants. Department collaboration and positive team dynamics are as important for successful sales and growth.

An effective sales and operations planning (S&OP) process can be a game-changer in this regard—it aligns supply, demand, and financial planning, enabling you to make an efficient production plan. Plus, it helps you maintain supportive interdepartmental relations by encouraging cross-functional collaboration.

In this article, we’ll dive deeper into the S&OP (sales and operations planning) process by exploring its benefits, potential drawbacks, and best practices to help you implement it smoothly. We’ll also introduce you to the main steps of the S&OP implementation process and reveal the metrics you should track to drive growth. 📈

Sales and operations planning (S&OP) is an integrated, cross-functional supply chain planning process that aligns product supply and demand with the company’s financial plan by comparing the expected demand with the available resources. The presented trade-off aids executives in strategic decision-making on matters like:

The process can be conducted monthly, yearly, or every two or three years, depending on company goals.

The success of the sales and operations planning process depends on the strong collaboration and synchronization of product development, manufacturing, marketing, sales, and finance departments. The input of all relevant teams is the only way to have a solid and functioning S&OP, which also boosts teamwork and dedication to the same goal.

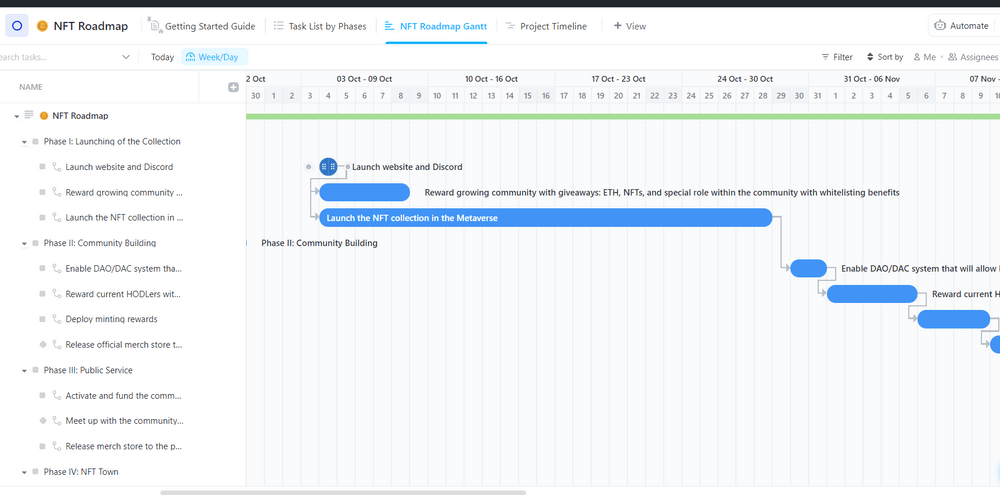

Kick off your sales and operations planning process with the ClickUp Sales Plan Template! Easily track the progress of your plan and accompanying achievements through the List view, Timeline, or Gantt Chart, and share the template across departments to keep everyone in the loop.

Implementing S&OP can help your sales and operations teams in numerous ways. For starters, it streamlines sales and operation processes and minimizes production costs, but its benefits extend beyond this. Here’s a breakdown of the most important advantages of the S&OP process.

A successful S&OP process strongly relies on cross-functional collaboration for better decision-making. The input from relevant teams is necessary for the S&OP design because their data is what helps the leadership develop an efficient plan in the first place.

Strong collaboration encourages the team to look at the bigger picture—the overall productivity and growth of the company—instead of only their department objectives. This allows teams to share ideas and information across different departments, ensuring everyone is updated on current trends and upcoming challenges, which is crucial for the plan to succeed.

S&OP matches supply and demand to ensure there’s no excessive inventory, so you’ll avoid the loss of revenue brought by stock-outs or warehousing inventory costs.

Kickstart your inventory management with the ClickUp Inventory Management Template! Review historical data for market trends and forecasting, adjust inventory levels based on sales, and get visibility into everyday operations using the template’s Timeline and List views.

S&OP assists you in delivering products that meet customer demand on time. It also helps you price your product properly by providing deep insights into the balance between supply and demand.

Effective S&OP processes help you forecast product demand better and create a plan accordingly. With increased awareness of the supply chain needs, you can respond to customer demands quickly. This prevents clients from waiting for your products or services, which can drive them to competitors. Plus, it helps you reduce overproduction costs. 💰

Scenario planning in S&OP processes helps in responding quickly to changes in supply and demand. Having plans for various scenarios assists businesses in preparing alternative solutions to potential issues beforehand so they don’t miss revenue opportunities or lose customers.

Now, let’s explore the main challenges you may encounter with the S&OP process and see how you can overcome them effectively.

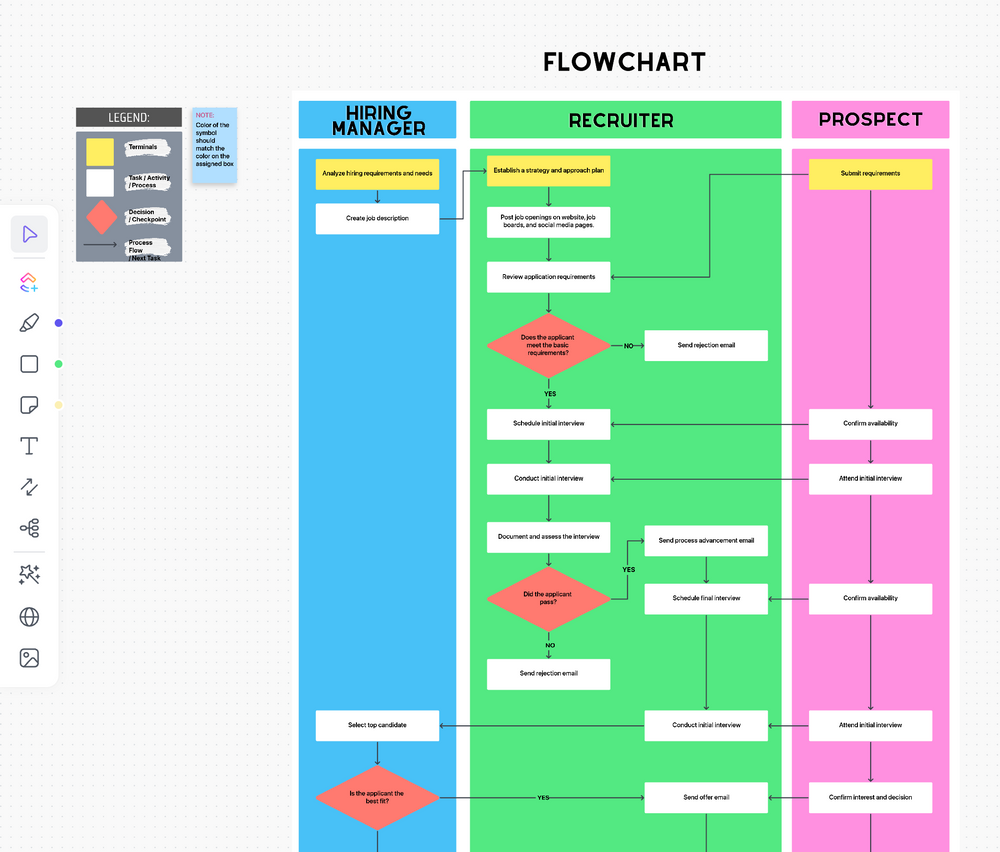

The S&OP may seem complicated because it includes many variables that must run smoothly to ensure successful supply chain management. The complexity of the process may make it hard to comprehend and can result in confusion among stakeholders.

To overcome this challenge, keep your process flow charts straightforward and clean. Using a project management solution like ClickUp is a great way to easily build collaborative flow charts. Create the perfect flow chart for your S&OP process with the ClickUp Process Flow Chart Template—a pre-designed, fully customizable framework, ideal if you want to hit the ground running ASAP! 🏃

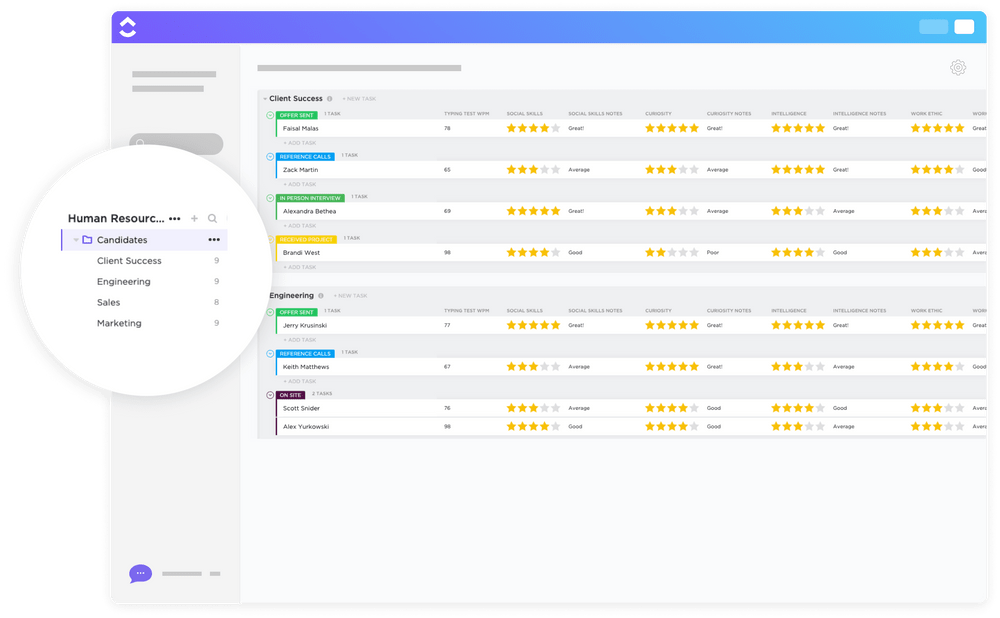

Hiring supply chain operators requires careful consideration as you’ll need employees with strong technical and analytical skills. The people you hire must also be familiar with all supply chain operations to ensure smooth collaboration.

Choosing the right candidate can be time-consuming, so streamline it with the ClickUp Hiring Candidate Template, which lets you review, compare, and prioritize candidates to find a perfect fit for your S&OP team. 👌

S&OP requires multiple departments to work together to align your supply and demand plans. This means that your sales, marketing, logistics, manufacturing, and finance departments must always be informed of process changes and updates. However, checking up on so many departments’ activities can be challenging.

You can overcome this challenge by digitizing all your documents and keeping them in a centralized location. That way, all departments can access it to view updates, news, changes, or any other important information.

Start your database without the hassle of creating a document from scratch using the ClickUp Wiki Template! Document anything you need in the template’s pre-made pages and sections, and customize it to fit your business needs. 📝

A successful S&OP process requires six simple steps that must be implemented in a fixed order. Let’s dive deeper into each step to see what they entail!

The data collection step is the foundation of the S&OP process, as it helps organizations develop a realistic action plan. It involves gathering data related to:

The main goal of data collection is to create a forecast for future sales by gaining deep insight into the business’s current situation and potential future demand.

Demand planning is the most important step in the S&OP process. It requires analyzing consumer trends, sales forecasts, and historical data to create a demand plan that tells you how many units of the product can be sold and when and where to meet demand.

Essentially, this step provides the quantifiable demand amount according to your customer’s needs, and you can measure it in units or terms of revenue. Since demand changes quickly, you should review its forecast regularly and consider factors like seasonality that may affect the estimates.

In this step, you should determine whether the company can match supply and demand. The capacity is evaluated by representatives from materials, operations, and finance, who then determine whether there are any constraints on suppliers, machinery, or employees.

For example, if you and your team identify any capacity constraints, you can make adjustments by hiring more people or enlisting different suppliers.

This step is all about collaboration between leaders from sales, operations, marketing, finance, materials, product management, and HR. They meet to compare the forecasts to the demand and supply plans and review the plan’s financial impact. Their expertise helps pinpoint potential issues and ensures that all pieces of the puzzle fit before launching the production plan.

The purpose of the executive meeting is to approve the final sales and operation plan. Executives meet to analyze the plans, forecasts, and recommendations discussed in the pre-S&OP meeting. The plan is then refined by exploring different scenarios related to the changes in supply and demand to ensure quick responses to sudden market changes.

When the sales and operations plan is approved and shared with all external and internal stakeholders, it’s ready for implementation. Once the plan is up and running, the S&OP process is evaluated regularly to ensure functionality and growth. 🌱

Start tracking your S&OP process right away with the ClickUp Sales Process Template! Use its pre-designed task list to define steps your sales team must take for a successful S&OP process and use the Roadmap Gantt Chart to ensure all tasks align with the overall schedule.

Tracking S&OP metrics can help organizations assess performance, mitigate risks, and ensure continuous improvement. Here are the key sales metrics you should track to achieve your S&OP goals more efficiently:

📮ClickUp Insight: 83% of knowledge workers rely primarily on email and chat for team communication. However, nearly 60% of their workday is lost switching between these tools and searching for information. With an everything app for work like ClickUp, your project management, messaging, emails, and chats all converge in one place! It’s time to centralize and energize!

Now that you’re familiar with how the S&OP process works, it’s time to learn how to make the most of it! Let’s dive into the S&OP best practices to help you align your sales and operations and promote teamwork across different departments.

The success of the S&OP process depends on proper guidance and direction since the leader must create a positive dynamic among teams that may have conflicting priorities. For example, some tension between the supply and demand team can be expected due to time constraints and similar issues.

That is why having clear ownership of your S&OP is essential to set standards for the involved parties to collaborate more efficiently. This person should be someone of firm executive status, like a CEO or a manager.

The S&OP process requires all departments to be equally involved in the process, so cross-functional collaboration is vital to its success. If you only consider the sales department’s contributions but ignore operations and finance, your sales and operations planning won’t be effective or productive.

To ensure all parties involved are updated and on the same page, you should boost visibility across your organization. A great way to do so is by relying on the ClickUp Tasks feature, which helps you plan, organize, and collaborate on any project in real time. It allows you to manage tasks through multiple views like List, Kanban board, and Timeline, making it easy to know exactly which tasks are In progress, Done, or on the To-do list. ✅

You can share your ClickUp workspace with all your employees so they’re always caught up on the latest changes. The task feature also supports cross-functional collaboration because it lets you:

Since balancing supply and demand is at the core of the S& OP process, You should understand the impact your supply and demand changes may have on your business. Running what-if scenarios can help you gain a better understanding of market trends and assist you in preparing for potential market changes.

For example, if you have to increase production due to higher demand, modeling different scenarios can help you pinpoint the long-term benefits and figure out the short-term financial setbacks that might occur. You can then use this data to make informed decisions.

In the past, S&OP was conducted through siloed applications and spreadsheets, which didn’t enable running what-if scenarios, support planning across multiple divisions and locations, or help businesses respond to market changes quickly.

Today, S&OP executives rely on modern software solutions that include smart technologies like AI and machine learning. S&OP teams can use real-time data related to market changes and user behavior to manage their supply and demand. Software designed for this kind of planning also supports what-if simulations and advanced analytics, allowing teams to create theoretical situations without testing and compromising their plan in the real world.

If you’re looking for a user-friendly AI tool, ClickUp Brain will be your best friend! 🧑🏼🤝🧑🏻

This tool can serve as an AI Project Manager that helps you automate your work, team updates, progress reports, and individual standups. You can also ask any questions and get contextual answers from your docs, tasks, and projects or use it to generate emails for quick and consistent responses.

Learning from past mistakes drives progress in the S&OP process, so keeping detailed records of your past plans is crucial. Document as many aspects of your S&OP efforts as possible so you can look back at your notes as the market evolves and identify which plans and processes were successful in the past, which weren’t, and why. You can determine which plan works best for your business and adjust your current strategies accordingly.

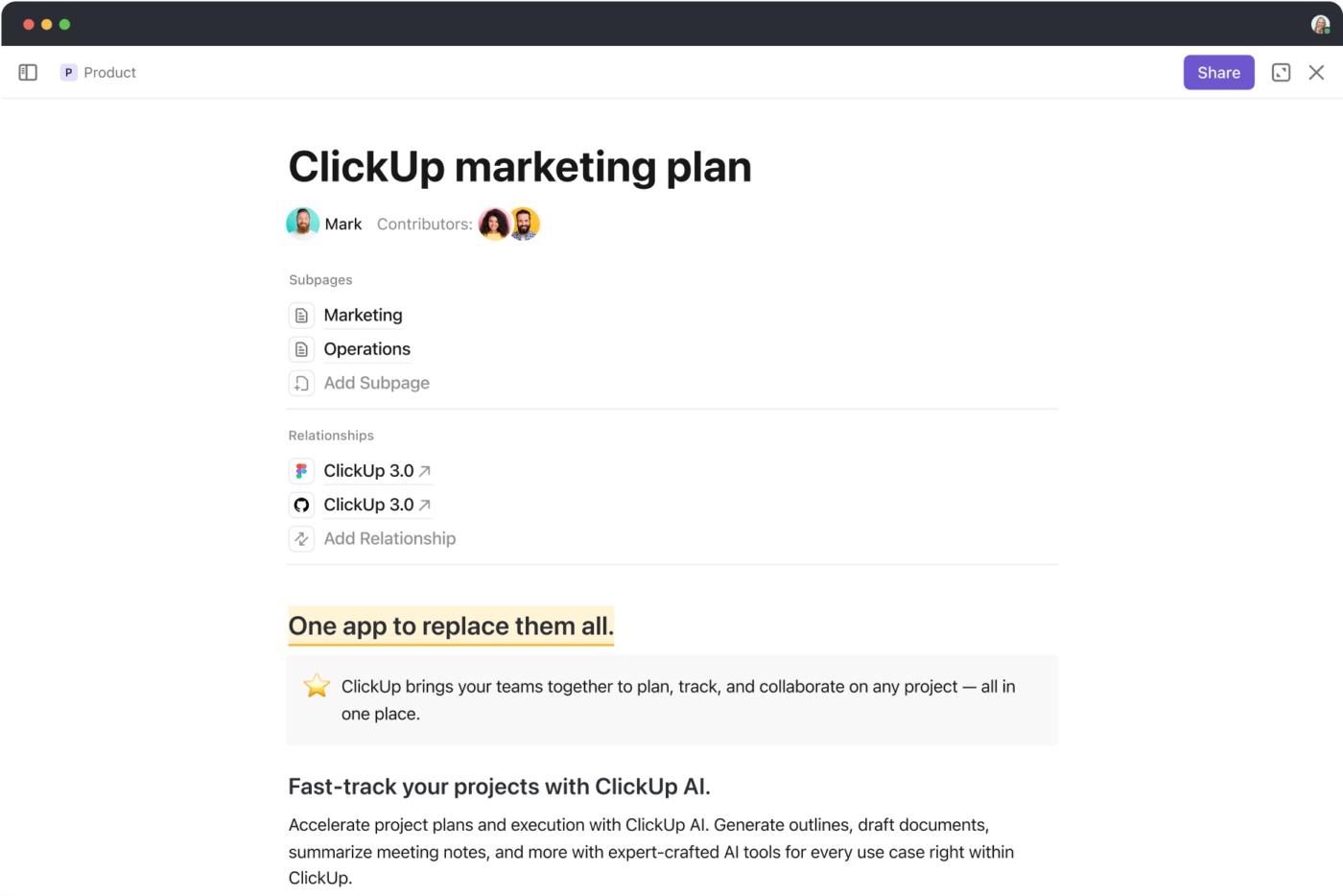

The best tool to keep records of your sales and operation plans is ClickUp Docs—fully customizable documents let you add pages, sub-pages, tables, and images to fit your business needs perfectly! ✨

Docs also supports collaboration by allowing real-time in-doc editing and commenting. Plus, it includes permission control, so you can keep your past S&OP processes private and provide access only to relevant team members.

Adding a customer relationship management (CRM) tool to your S&OP toolbox can help you increase operational forecast accuracy. An effective CRM tool provides insights into when the expected product demand should occur and can indicate which customers are expected to impact the production volume. That way, you can ensure supply chain decisions are based on the most accurate demand assessment.

CRM tools help you create a 360° view of your customers, focusing on their interactions with your business and finding the information needed for better customer communication. You can deepen your relationship with your customers and gain control over customer acquisition and retention.

Improve your CRM by relying on ClickUp CRM—the best customer relationship management solution on the market! It lets you visualize all your customer data in one place through 50+ Dashboard cards, including pie, line, or bar graphs. 📊

Manage your customer engagement, sales pipeline, and orders using multiple project views like Kanban Board, List, or Table view, which allow you to:

You can also automate your sales process using the ClickUp Sales feature. It lets you keep track of your whole sales funnel and helps you keep leads moving through your pipeline by automatically assigning tasks in each process stage.

Implementing a sales and operation plan properly can help increase your business revenue, minimize production costs, and keep your customers satisfied. To simplify the S&OP process implementation, sign up for ClickUp for free and enjoy its wide selection of CRM tools, pre-designed sales plan templates, and powerful project management features—all designed to help your business thrive! 🙌

© 2026 ClickUp