How to Leverage Value Chain Analysis to Boost Competitive Advantage and Business Longevity

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

A business may survive okay in varying market conditions, but for it to thrive, you need to optimize its value chain activities to ensure superior performance. Established businesses are often those that constantly enhance the value they deliver to customers and shareholders, as well as other stakeholders involved.

It’s not just about improving products and services, though—you must also micro-analyze your inbound and outbound logistics, human resources management, and other operational processes to widen profit margins.

That’s precisely why forward-thinking managers rely on value chain analysis (VCA) to gain a true competitive edge in their niche. The practice requires constantly improving primary and support activities in a business with a vision to build customer loyalty and enjoy cost savings, all leading to competitive advantage through stable value creation. 🌱

In this article, we’ll explore:

Prominent economist and Harvard Business School professor Michael Porter first explored the concepts of value chain and value chain analysis in his book The Competitive Advantage: Creating and Sustaining Superior Performance.

Value chain refers to all the processes throughout the entire product or service lifecycle, starting from the R&D stage all the way down to the distribution and sales phases. Each process in the chain can be analyzed for the incremental value it adds to the final product or service, which is exactly what value chain analysis is all about.

It’s the process of analyzing the primary and support activities involved in delivering the product and maintaining business. The purpose is to determine which processes contribute reasonably to the value delivered by the final product or service.

A careful value chain analysis helps businesses unlock new insights that enable them to deliver maximum value to their customers and stakeholders. By the end of a successful analysis, managers should be able to:

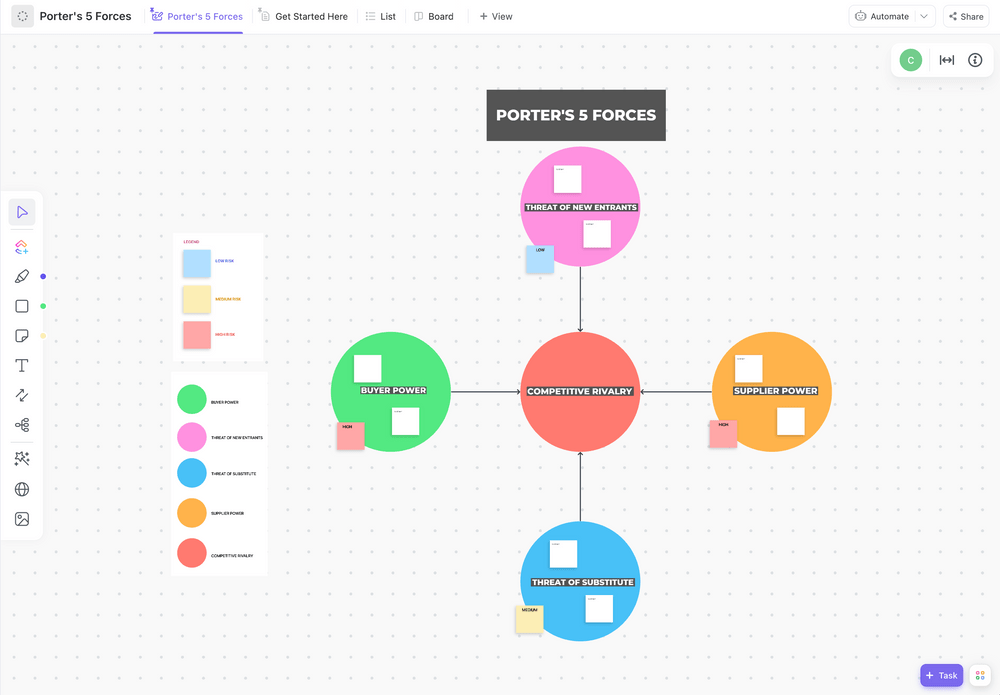

Tip: Looking for a Porter-style analysis of competitive forces in your market and their impact on your value chains? Try out the ClickUp Porter’s 5 Forces Template for quick visualizations. 🌹

Some of the key benefits derived from Porter’s value chain analysis include:

All in all, you get to achieve operational differentiation, which generates distinct advantages that your competitors find difficult to replicate. And in the long run, this translates to stronger brand perception and improved year-on-year profitability. 📆

Value chain analysis encompasses exploring processes across two main categories: primary and secondary activities.

Primary functions or activities consist of core processes for developing and distributing any product or service. They add value to the offering directly. A typical analysis of primary functions requires you to explore:

On the other hand, secondary activities don’t play a direct role in sales or production but support the primary functions instead. You can expect these activities to improve the efficiency and effectiveness of their primary counterparts. The four main secondary activity heads include:

By considering all these components while conducting a value chain analysis, you can derive a well-rounded operational strategy and better quality control.

Value chain analysis requires disaggregating primary and secondary processes into strategically similar pockets, allowing for simplified value chain management.

There are two main approaches that you can adopt for a value chain analysis:

Let’s explore both approaches one by one. We’ll also see how ClickUp, a complete work and project management solution, can help you conduct a value chain analysis quickly and effectively. 💡

From a cost advantage perspective, value chain analysis aims to help you lower the cost of producing or delivering the product or service that you sell. The result? You get to sell your offering at a lower price than your competitors without compromising on margins. Cost advantage VCA is typically a five-step process:

The first step to doing a cost advantage value chain analysis is to identify the primary and secondary activities in your business operations. The idea is to estimate the range of cost reductions that can be achieved realistically.

The general rule is to be careful while reducing the costs of primary activities because they’re directly linked to your product. There’s no point in introducing modifications that compromise user experience.

A good way to organize the information you need during this step is by using the ClickUp Product Management Suite. It’s perfect for centralizing your value chain analysis for any industry or niche—write process documents, build roadmaps, and visualize the entire product lifecycle.

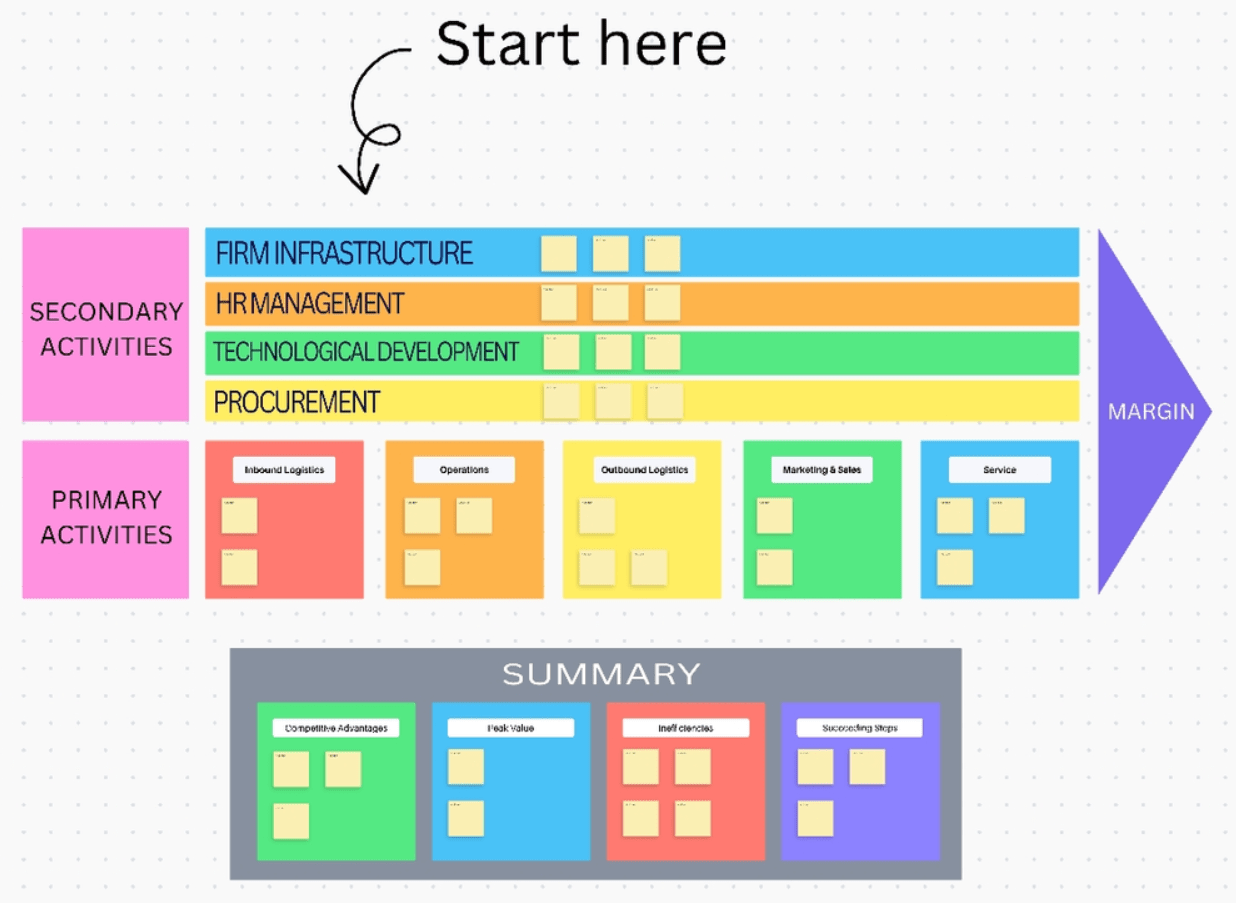

Need a quick start? Get comfortable with the ClickUp Value Chain Whiteboard Template. Its pre-designed visual framework allows you to organize all your primary and secondary activities and establish their relationship with the profit margin. Get your analysis team to link tasks, documents, or even individual products directly into the template and collaborate seamlessly. 😎

If you are managing more than one business, create multiple templates to map out individual value chains in dedicated project Workspaces within ClickUp.

The next step is to figure out the share of each activity in the overall production and delivery cost and see how it compares to the value added by it. In this process, you’ll see that some options, like factory overheads, cost a lot but also offer tremendous value to your core offering.

On the other hand, certain processes are just unnecessary cost centers as they don’t add much value to the chain. Use the information from this exercise to determine the scope for meaningful cost reductions. 💸

Need assistance here? The ClickUp Project Cost Analysis Template can come in handy. Get into the depth of your operational expenses with five different views to analyze your operational costs, including overhead costs, variable costs, material costs, and fixed costs. It also lets you analyze them on parameters like total price, cost, quantity, unit cost, and cost type.

Once you know which activities contribute the most to your overall costs, it’s time to identify individual cost drivers. Cost drivers are unit components of expenses that are shared between various departments. They may fractionally influence the final price of a product.

For instance, the cost of manufacturing a product covers several components, like the cost of raw materials and labor. Cost drivers of labor expenses can include total machine hours, the number of deliveries, and idle time.

The cost drivers will be specific to your industry, but you measure them by:

The goal here is to find specific cost optimization opportunities within a broad function.

Value chain activities are often closely linked to each other—tweaking one aspect can positively or negatively influence the cost, efficiency, and profitability of another. For instance, if you’re a logistics company, then a change in warehousing location can go both ways: say, it increases your transportation cost or makes your delivery cycle faster and more cost-effective.

To sum it up, any cost advantage should not be at the expense of service quality or overall profitability. That’s why it’s crucial that you identify and analyze relationships between interconnected activities in your value chain. ⛓️

A good way to understand these relationships is to visualize them. You can use ClickUp Dependencies to do that easily. Link interconnected tasks in your workflows and use the Relationships option to specify the type of dependency. You can pick:

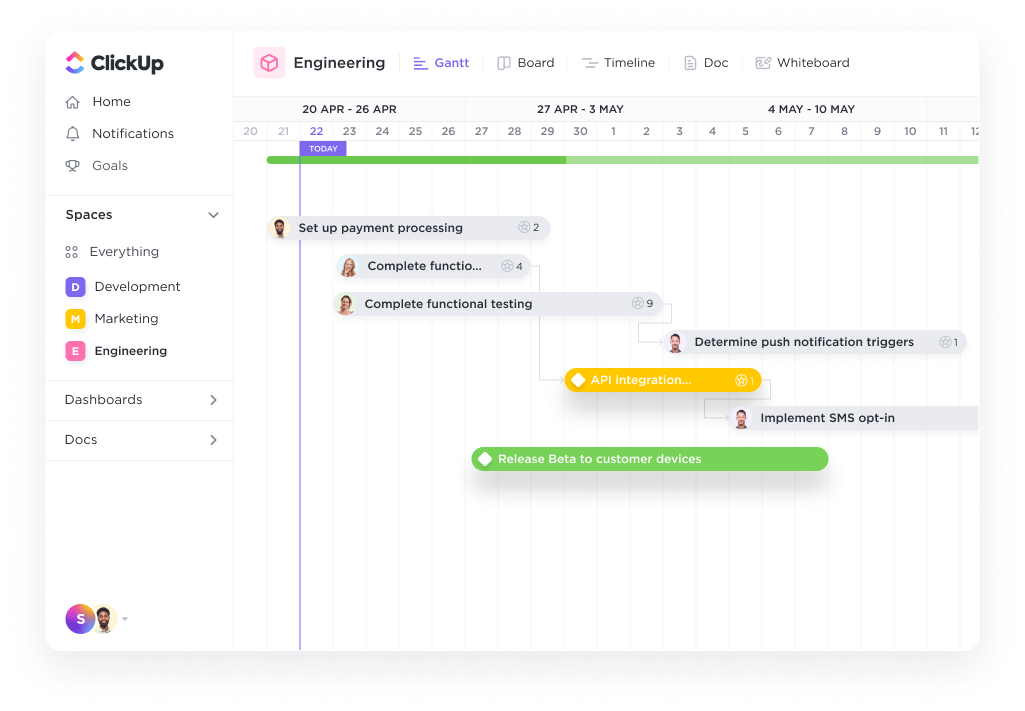

You can also visualize task dependencies using ClickUp’s Gantt View. When in your task list, simply switch to the Gantt view, and you can see how different tasks are dependent on each other. The big picture allows you to make informed decisions about your value chain analysis.

If you want to visualize dependencies or your entire value chain activities, jump on ClickUp Whiteboards. You get an infinite canvas to demonstrate your workflow or product chain using texts, connectors, shapes, sticky notes, and other media components. It supports multiple live collaborators, making it a perfect brainstorming tool for remote teams.

Finally, once you have an idea of your primary activities, secondary activities, and their cost positioning, start devising strategies for cost reduction. 👩🏭

Depending on the type of activities that you’re modifying for cost differentiation, you may need help from the product development or marketing teams. For instance, if the cost advantage is supposed to come from enhancing product management activities, then the product team becomes a close stakeholder throughout the change process.

Many teams end up upgrading their company infrastructure by adding automation tools to their arsenal. Automations helps get rid of many repetitive and redundant processes, helping achieve cost differentiation effortlessly.

Luckily, as a one-stop product management tool, ClickUp offers 100+ built-in Automations to automate repetitive processes that your team may be doing manually. It’s fully no-code—just define a trigger event, an action that’s to be taken when the workflow is triggered, and publish your automation. It’s not only about minimizing labor costs but also about taking care of cumbersome processes that steal a chunk of your time.

Once you’ve finalized a cost optimization plan, use ClickUp Goals to track and manage your costs against the targets that you’ve set. You can connect your goals to actual tasks to help your team find the reasoning behind the changes proposed. Visualize your targets with reports like progress bars and line charts on ClickUp Dashboards.

This type of analysis aims to differentiate your product or service from the competition by adding a unique feature or advantage that provides significant value to the customers. The advantage should improve your offering and be difficult to replicate for your competitors. Let’s see how you can conduct the value chain analysis for arriving at product or service differentiation:

Not all business activities are equally impactful on customer experience and value. Identifying low-value processes is the key to carving out major product differentiation advantages. You can do this by collecting and analyzing customer or user feedback because only they can tell what their pain points are and what would bring them more value.

The ClickUp CRM has a rich set of functionalities to help you out here. From categorizing your customer accounts to streamlining client communication and lead pipeline, it supports you through everything.

For instance, if you want to collect customer feedback in an organized manner, you’ll love ClickUp Forms. Tailor your survey form with questions specific to your value chain and distribute them across channels with a single click. The responses collected are automatically stored in your Workspace. You can go to the Table view to analyze them in one place.

Once you’ve analyzed customer feedback and identified the main contributors or loopholes in your value chain, think of ways to improve. Innovation is the key, and your product development teams may want to devise some new features based on the desired product or service differentiation. 🦄

But not all improvements are sustainable from a financial or operational perspective. Some business process improvements significantly increase your costs, while others are so complicated that they can’t be scaled to your business.

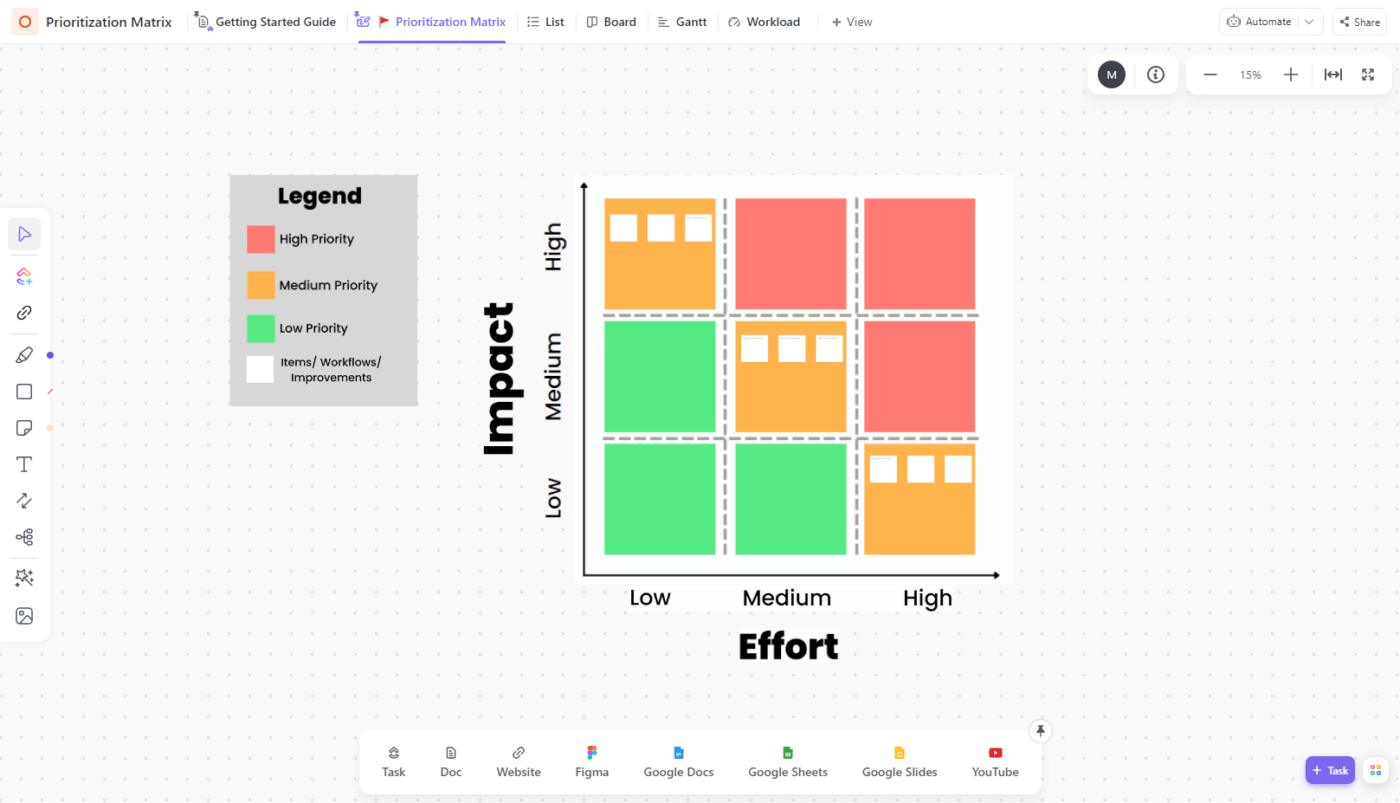

Need help deciding what differentiation to implement? You can use the ClickUp Prioritization Matrix Template to identify the sustainability of each proposed value improvement. Just plot each idea on the X and Y axes of this template in the order of impact and effort. You and your stakeholders will get a visual insight into which value improvements are sustainable and worth implementing.

This last step is often overlooked, but it’s super important. Once you’ve devised your business process improvement techniques to achieve product or service differentiation, also devise some processes that allow you to protect your advantage. It helps you stay relevant and have your differentiation advantage in the market for a long time.🔒

So, file a patent or put up layers of protection around your best practices and trade secrets. Create information silos. Do whatever it takes to protect your differentiation, leaving little room for competitors to replicate your offering and dilute your competitive edge.

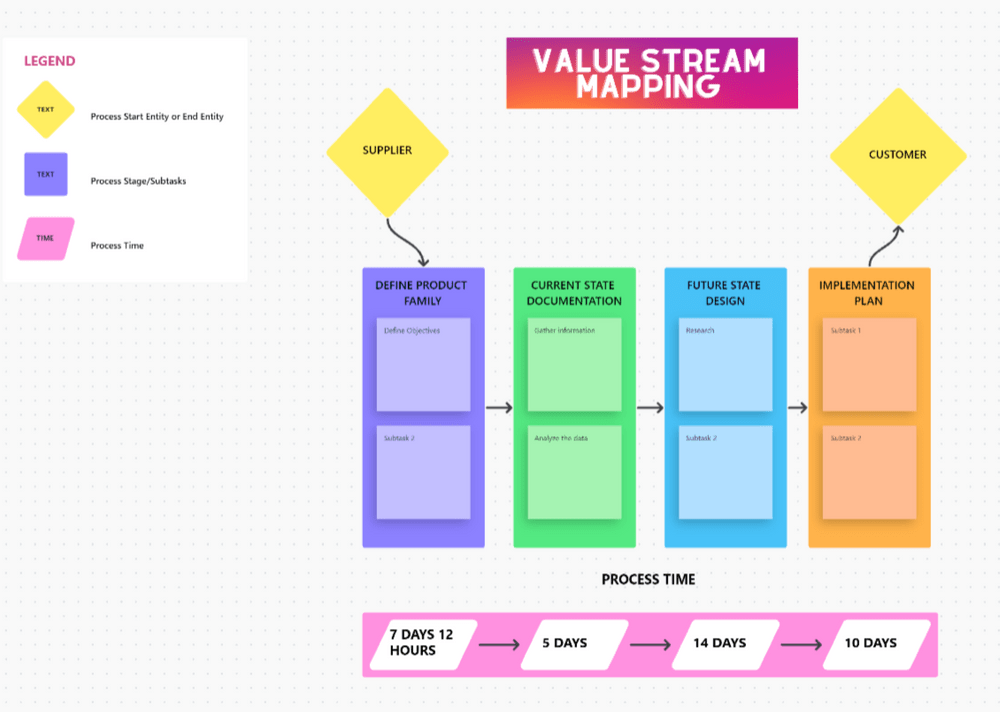

If you still feel stuck, you can use ClickUp’s expert-designed value stream templates with color-coded sections to visualize the relationship between your business activities. The ClickUp Value Stream Mapping Template is excellent for brainstorming product differentiation techniques.

If you want to gain a 360° understanding of your business processes, value chain analysis is the way to go.

ClickUp’s templates, Whiteboards, integrations, and CRM suite can help monitor and optimize your value chain framework consistently. Its workflow automation and process optimization features can help your team members maximize their efficiency further, thus giving you a cost advantage.

So, get ClickUp for free, and start leveraging it to march ahead of your competition steadily and surely. 🫅

© 2026 ClickUp