How To Calculate Lead Time?

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Want to learn how to calculate lead time?

Lead time is the time spent between order placement and fulfillment, and it’s one of the most important metrics in inventory management and supply chain planning.

We know what you’re thinking: this is going to be like high school math all over again!

Absolutely not!

You just need a simple lead time formula.

In this article, you’ll learn about lead time, the lead time formula, and the easiest way to track it.

Both the math-averse and math-fanatics are welcome to join!

No more counting down. Let’s get started!

Lead time is the time taken for one work unit to travel through the production and delivery cycle. For example, cooking and serving time in restaurants, transaction time in banking, or mobile app development and launch time in tech.

Note: Every business has a lead time. However, for the purpose of this article, we’ll interpret lead time with reference to inventory management and supply chain planning, as that’s where it’s most useful.

But why should you bother calculating this metric?

To answer this, we need to dig a little further into the world of

inventory management or inventory control.

For example, let’s say you run a grocery delivery business.

Since you don’t manufacture milk, cheese, or eggs, you’ll need to source them from a supplier. And once you’ve sourced them, you’ll need to store them until you sell them.

Bonus: CRMs for Manufacturing

This store of unsold goods is your inventory.

While managing it, you’ll need to be mindful of two things:

The key? Always maintain just the right inventory level.

And a relatively short lead time is one of the best ways of ensuring this.

Managing timeframes is crucial to businesses. Poorly-managed lead times can mean stock can run out and customers can’t get their orders fulfilled.

When lead times get out of control, a vicious cycle can form with lead times worsening at increased demand. This delay between consumer’s orders and production may result in more delays which can cause lead times to further deteriorate. Bad order management often causes serious and expensive damage to a business as it loses valuable customers and damages its reputation.

That’s why inventory management includes dealing with factors that affect lead time, like:

Because of these factors, lead time determines how much to stock and when to restock.

But just like you can’t make an omelet without breaking eggs, you can’t calculate lead time without its formula.

The most basic lead time formula is:

Lead time (LT) = Order Delivery Date – Order Request Date

But in the context of inventory management, this formula also accounts for a reordering delay.

Lead time (LT) = Supply Delay (SD) + Reordering Delay (RD)

Supply delay is the time a supplier takes to fulfill a customer order after it’s placed.

Reordering delay is the time gap between a fulfilled order and the placement of the next order.

Why account for reordering delay?

Some suppliers may accept orders only a few times a week or month. This means retailers need to anticipate this delay in delivery to maintain a safety stock or a buffer stock.

Your safety stock lets you fulfill your orders while you wait for the supplier to replenish your stock.

For example, let’s say your average daily sales or average daily usage for milk is 20 liters. And supplier A accepts orders for milk only after every 2 days. This means that the reordering delay for your milk supplier is 2 days.

Now, let’s assume that A takes 1 day to deliver milk to your warehouse. This makes their supply delay 1 day.

In this case,

Lead time = Supply delay (1 day) + Reordering delay (2 days) = 3 days

Stocking up for 3 days should be easy enough.

But what if you were selling something that’s high-value and rare, like exotic herbs and designer decor items?

Chances are, such products are relatively slow-moving compared to milk or eggs and have high supply and reordering delays.

This means you’ll need to plan their purchase, stock, and sale months in advance.

But how can you find out how much you need to stock and when should you restock?

The answer lies in safety stock and the reorder point.

Safety stock is the inventory level you need to maintain to cover up for supply delay or reordering delay.

Its formula takes lead time and demand variability (potential fluctuations on demand) into account.

Customer demand for products can fluctuate due to several reasons like holidays, weekends, changes in wholesale prices, offers, etc.

Apart from this, managers also need to stock up for a level of unpredictable demand variability like sudden shortages, weather disturbances, etc.

Because as the demand varies, so does the supply.

The safety stock formula is:

Safety stock = (Maximum daily sales*Maximum lead time) – (Average daily sales*Average lead time)

Your reorder point is the level of inventory that lets you know that you need to reorder.

As for the phrase ‘shop until you drop’ –

That’s a piece of advice only for your customers.

Not you!

As an inventory manager, your decision to restock depends on the reorder point formula. And that is:

Reorder point = (Lead time * Average daily sales) + Safety stock

Each time your stock falls to the reorder point, it’s time to pick up the phone and shop for some stock!

Your reordering quantity will go hand in hand with your safety stock level.

After receipt of order (ARO) is the point that the supplier receives an order. This is the first important point when measuring lead time, as the total time between ARO and delivery of order makes up the lead time.

Manufacturing lead time is the time between when the merchant places an order and the product manufacturer completes it. It includes the time required to acquire, manufacture, or ship goods.

Now that you’re armed with all these formulas let’s get into how you can reduce lead time.

A supply chain is like a rubber band. The longer you stretch it, the weaker it becomes.

And eventually, it could snap!

On the other hand, a relatively short supply chain benefits everyone.

The retailer can sell more goods quickly. The supplier can be reassured of continued business.

And most importantly, the end consumer gets what they need, when they need it.

So how can you reduce the lead time to build such a ‘win-win’ supply chain?

Here are some ideas:

You’d never guess what’s common between inventory management and a healthy diet.

Portion control!

That’s right.

Instead of placing an occasional order for large volumes, place small orders more frequently.

This will become easier if you regularly calculate safety stock levels and update your reorder level accordingly.

According to Lean manufacturing principles, frequently placed small orders have three benefits:

And just like a few small meals spread throughout the day, small and frequent orders keep your stock replenished for longer!

When it comes to inventory management, the Lean manufacturing process is the gift that keeps on giving.

A value stream is a process (with multiple interconnected steps) that an organization needs to take to implement solutions.

A value stream mapping exercise aims to recognize wastage, improves productivity, and makes your value stream more competent and waste-free.

Bonus: Check out the top 10 Value Stream Mapping Templates to Improve Team Processes

Just hand over repetitive tasks to technology and take that much-deserved break.

Bots can manage the safety stock calculation, average demand, and demand variability.

In the meantime, talk to suppliers, keep a keen eye on market trends, or hatch the next big marketing masterplan!

Remember how the supply chain is like a rubber band?

Well, very few rubber bands are elastic enough to go around the globe!

International and cross-country suppliers may tempt you with discounts. But the long lead time (and the hassles it brings with it) aren’t always worth the low prices.

Local suppliers are in a better position to understand your unique needs and respond to them quicker. And if they also offer competitive prices for great products, they’re a keeper.

Ultimately, inventory control is a human affair.

So your relationship with the supplier will be a crucial factor in deciding how long your lead time will be.

In your contract with them, use incentives to reduce lead time.

They can be:

Eventually, this will encourage your supplier to reduce their lead time with each delivery because they feel invested in your business.

But to make all of this happen, you need to start by calculating lead time.

Forget about a pen and paper though.

We have the perfect solution for you!

Between unloading stocks and downloading files, you barely have enough time as an inventory manager. So calculating lead time the good old-fashioned way is out of the question.

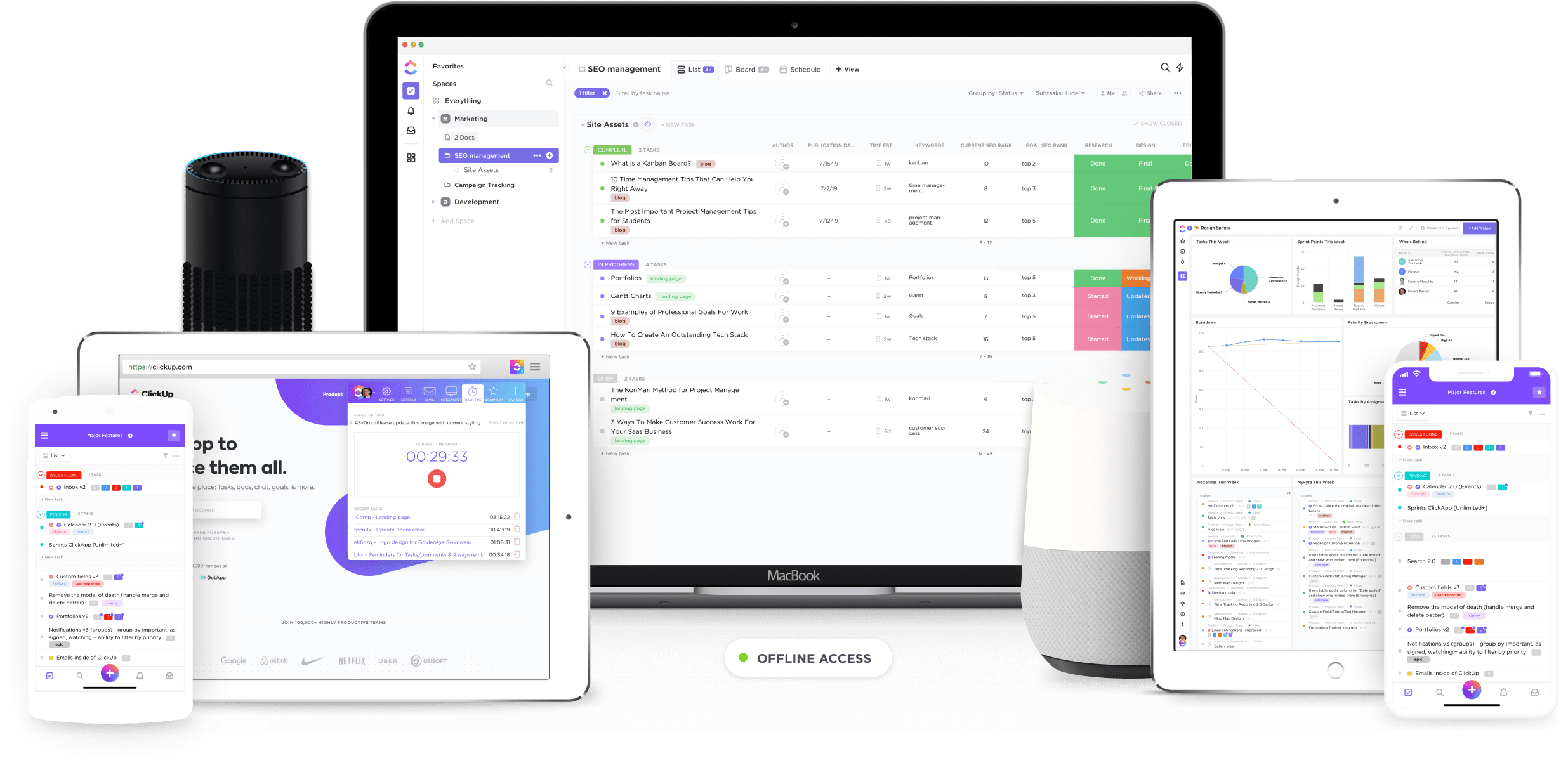

That’s why we suggest using ClickUp.

What’s ClickUp?

ClickUp is the highest-rated project management tool in the world.

It’s the only tool you’ll need to manage all your projects and track your team’s productivity.

Its dynamic set of Agile, Scrum, remote working features are perfect for your exceptional team.

Take a look at how you can use ClickUp to calculate lead time and use the metric to boost your team performance.

You could scan through your project metrics, one by one, with dozens of PowerPoint slides and printouts. Yawn.

Or you can track them all at once, on your ClickUp Dashboard!

Your Dashboard will speak for itself with the help of practical Sprint Widgets like the Lead Time Graph.

Customize lead time graphs with:

But there’s more!

You can get a complete overview by adding more useful Sprint Widgets like Burndown Charts, Burnup Charts, Velocity Charts, and Cumulative Flow Charts to your Dashboard.

ClickUp lets you calculate important project flow metrics like lead time and cycle time. With such crucial data in hand, you can predict all future timelines and set Time Estimates.

Simply add the number of hours each task and subtask will take. Using these numbers, ClickUp calculates the total hours the project is expected to take and updates estimated delivery dates in real-time.

So you calculated lead time and set time estimates based on your historical data. Now how do you ensure that you meet these deadlines?

A loyal, talking clock, perhaps?

We have the next best thing.

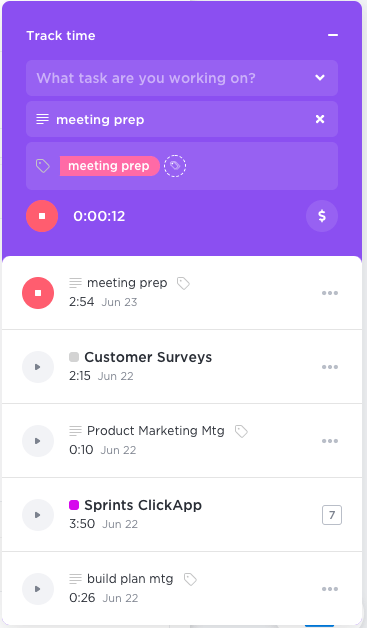

ClickUp’s Native Time Tracking feature.

It may not dole out helpful advice (or timely snark) like Cogsworth from ‘Beauty And The Beast’… But it does help you do your job.

ClickUp’s Global Timer allows you to easily track time whether you’re on a desktop, web, or mobile app. You can even add notes and labels to your time records for additional reference, or mark time as billable!

Prefer using a third-party time tracker like Time Doctor or Toggl instead?

No worries. Just integrate them with ClickUp and get cracking!

But that’s just a tiny list of ways in which ClickUp eases your processes.

Take advantage of other outstanding project management features like:

Want to impress your colleagues with your lead time knowledge?

Or just want to brush up on your facts?

Cover all your bases by reading these frequently asked questions about lead time.

Based on the industry or sector that it refers to, there are three types of lead time:

Anyone who’s job requires forecasting estimated delivery dates and defining a production schedule should have a working knowledge of lead time.

This includes supply chain planning, inventory management, or manufacturing professionals like:

Lead time and cycle time are often used interchangeably, especially in the context of manufacturing. But this can cause confusion.

Lead time begins when a production order is received. It includes the time taken to fully manufacture or process a finished product, as well as the time taken to deliver it. This can run into days or months as well.

Cycle time, however, is the time taken to complete manufacturing a finished product. It’s a measure of the total operation time and does not account for the hours or days spent processing, delivering, or receiving an order.

Read more about how to calculate cycle time and cycle time vs. lead time.

At first glance, the lead time metric simply informs you about how long delivery will take. But if you look closer, you’ll find that it can indicate unnecessary delays, wastage, and other factors that impede your supply chain.

That’s why calculating lead time is the easiest way to ensure that your supply chain remains efficient and effective.

But how can you control the lead time for your lead time calculation?

Simple. By using an online tool that calculates and tracks lead time.

In other words: ClickUp!

The easy-to-use lead time widget needs only a few quick settings to start gathering data instantly. And it’s only one of the hundreds of unique and impressive features that make project management a breeze.

So get ClickUp for free to reduce your lead time and increase your…

© 2025 ClickUp