An average car has about 30,000 parts. Even a seemingly simple fountain pen has about 25 different parts. Some of these might take minutes to manufacture, while others take days.

In manufacturing, organizations use several metrics to accurately schedule the production cycle and get each part just in time. One of the most important metrics is cycle time.

This metric, known to have originated from lean manufacturing, has now become popular in product and service industries. Let’s see why and how you can use them to improve your production efficiency.

What is Cycle Time?

Cycle time refers to the actual duration of a work item’s journey from the start of the production process to completion. It is important to note here that this is a measure of actual time based on past performance, not predictions/forecasts for the future.

Let’s look at a few examples. If you’re manufacturing pens, this is the time from when you put the PPC pellets into the injection mold to when you have completed the assembly of a single pen.

If you’re making bread, it’s when you start kneading the dough and pull the bread out of the oven. If you’re making t-shirts, it’s the time between cutting the material to packaging ready to ship.

If that reminds you of other time-related metrics, here’s everything you need to know about cycle time vs. lead time.

Cycle time and the software development lifecycle

Though originally from manufacturing, cycle time has become a critical metric in calculating software development velocity, engineering productivity, and efficiency.

But first, let’s define it. In software development, this is the time from when a team starts working on a feature until it’s deployed to production. Project teams use cycle time in various ways.

- Delivery projections: Predict how long a task/feature might take to complete

- Sprint planning: Schedule features/tasks in such a way that they work well within the sprint

- Continuous improvement: Incorporate feedback loops into the development process to improve quality

- Reviews: Cycle time helps managers measure individual and team productivity

Cycle time in agile project management

Agile software development is akin to lean manufacturing, in that it focuses on just-in-time scheduling, process optimization, continuous improvement, and eliminating wastage.

Therefore, within software development, cycle time is a key metric in calculating lead time, improving the efficiency and speed of delivery. It is important in supporting the agile development principle of delivering working software frequently.

This is especially applicable in software testing, where tracking cycle time can play a compounding role in your deployment velocity.

The Role and Benefits of Cycle Time

Like lead time, TAKT time, throughput, etc., cycle time is a time/speed-related metric that organizations use for various purposes. Here is how it benefits your organization/project in each case.

Lesser the cycle time, better the efficiency

Reducing cycle time has a direct impact on the efficiency of the process. Any efficiency gain enables the team to address more customer requests or fix issues faster, leading to a more productive development cycle.

For example, a team that refines its code integration and testing phases to reduce cycle time from two weeks to one week can double the number of features it delivers in the same timeframe.

Faster cycles can lead to higher quality

People assume that work done quickly—typically seen as haste or rush—affects the quality of output. In scrum project management, the opposite can be true.

Shorter cycle times encourage more frequent testing and iterations, leading to higher-quality software. Rapid feedback loops reduce the likelihood of significant defects reaching production.

Calculating cycle times creates predictability

When you know how much time a task takes, you can plan better. You can forecast delivery timelines more accurately and manage expectations with stakeholders.

For example, if you know that your average cycle time for delivering a new feature is three weeks, you can schedule releases reliably. This predictability builds trust in all stakeholders.

Cycle time calculations power adaptability

Being agile requires you to be responsive to changes and meet customer demand. Your cycle time is a direct indicator of how soon you can respond. With industry benchmarking, you can reasonably measure your business’ competitive advantage with cycle times.

Cycle time mirrors continuous improvement efforts

Monitoring your cycle time fosters a culture of continuous improvement within the development team, helping them consistently identify inefficiencies and areas for improvement.

For example, a team might discover that code review is a bottleneck and adopt pair programming to address this, thereby improving their overall process and reducing cycle time.

Shorter cycles = happy customers

Every customer is delighted when they can get output faster. So, shorter cycle times directly improve customer satisfaction.

Consider a scenario where a software team reduces the cycle time for new feature requests from one month to two weeks. Customers benefit from faster updates, which can have a direct impact on the bottom line.

All of the above = happy teams

Cycle time is a critical indicator of individual and team performance. Efficient cycle times make team members feel accomplished and valued. Meeting customer demand boosts team morale.

Continuous improvement accelerates their personal learning curves, giving them a sense of pride in their work. Overall, trends of cycle times can often be a measure of a team’s progress.

Now that you know these benefits, how can you reap them? Let’s take a look.

How to Calculate Cycle Time?

Cycle time is simply the time it takes for you to complete a task from the time you’ve begun it. Therefore, the formula for cycle time is pretty straightforward.

Cycle time formula for individual work items

Cycle time = Finish time – start time

The above formula is best applied for individual work items. From kneading dough for bread or coding a single feature. If you started at 1230pm and finished at 230pm, your cycle time for that task is two hours.

Cycle time formula for batches

However, in most cases, the cycle time for a part of the process—like kneading dough or coding—alone might not be most valuable. A project manager is better served knowing the cycle time from development to deployment.

This collection of tasks is called a batch and is measured as batch cycle time.

Batch cycle time = Net cycle time/Number of units produced

Here, net cycle time is the sum of cycle times for all tasks in the batch. It is typically measured in hours, days, or weeks, depending on the scope and scale of the projects. In manufacturing, this is also called net production time.

The number of units produced is the count of all the work items (e.g., features, bug fixes, user stories) that they completed in that timeframe.

If that seems quite simple, think again. Cycle time, especially batch cycle time, is a collection of multiple moving parts, each with its own complexities. A small wrong step can skew calculations, creating various challenges.

Consequences of miscalculating cycle time

Some of the most common consequences of miscalculating cycle time are:

Inaccurate project timelines: Overestimating cycle time may result in inefficient use of resources and delayed delivery, while underestimating leads to aggressive deadlines, stressful situations, team dissatisfaction and decreased quality.

Poor resource allocation: Teams might allocate too many or too few resources based on miscalculated cycle times, causing bottlenecks or leaving resources underutilized.

Customer dissatisfaction: Customers expect timely delivery of products and updates. From the customer’s perspective, miscalculated cycle times can seem shady, creating a loss of trust, negative reviews, and, ultimately, loss of business.

Financial losses: Underestimating cycle time can lead to delays or cost overruns. Overestimating can result in wasted resources, unnecessary expenses, and missed market opportunity.

Stressful experience: All stakeholders, including customers, partners, and employees, can face undue stress resulting from unrealistic expectations based on miscalculated cycle times. The risk of burnout is also high.

This can eventually lead to attrition, causing additional expenses to hire, onboard, and train new talent, to say nothing of the loss in institutional knowledge.

Cycle Time Calculation Examples

To ensure you’re not miscalculating cycle times, you need to understand how to do it right. Here are some actual cycle time calculation examples using the formula above.

Software feature development cycle time

A software developer logs 3 hours to fix a bug. The average time taken for all their bug fixes is their individual bug fixing cycle time.

As a team, you complete and launch eight features in a month with 22 working days. Your cycle time is:

Cycle time = 22 days/8 features = 2.75 days per feature

Manufacturing unit

A car assembly plant produces 300 cars in a month. If the total production time from the start of assembling the first car to the completion of the 300th car is 9,000 hours:

Cycle time = 9000 hours/300 cars = 30 hours per car

E-commerce platform

An e-commerce platform processes and ships 1000 orders in a week, working 24×7. Then, the cycle time is:

Cycle time = 7 days x 24 hours/1000 orders = 0.168 hours per order, i.e., about 10 minutes.

Now that you know how to calculate cycle time, here’s how you can use in your day to day project management.

Using Cycle Time to Reach and Measure Project Goals and Delivery

Measuring, recording, and optimizing cycle times is one of the most transformational aspects of any project management. As we’ve seen above, it can impact various metrics, from team morale to customer bottom line.

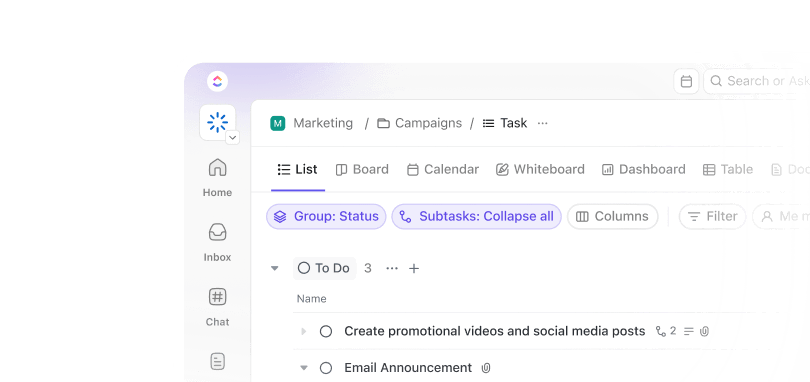

To ensure you track and improve cycle times consistently, begin by using purpose-designed project management software like ClickUp. Let’s see how.

1. Measure cycle time

Before anything else, set up systems to measure cycle times. Typically, this information is available on timesheets, however, most software teams fill timesheets haphazardly in the end.

To track cycle time accurately, try ClickUp’s time tracking features, that allow each team member to start/stop a timer or enter time manually. Teams can track time for each task/sub-task. What’s more? Multiple team members can track time for the same task as well.

2. Analyze cycle times

Once you record the time each task takes, you can start analyzing trends. The ClickUp Dashboard is a great place to curate all the insights you need in one place.

Use these insights from ClickUp’s agile project management software to inform strategic decisions, such as reallocating resources or modifying workflows, to optimize cycle times, and improve project deliverables and performance.

3. Identify productivity killers

The outcome of your cycle time analysis is to identify productivity killers. Some of the most common ones to look for are as follows.

Bottlenecks

The bottleneck is when a particular stage in the process slows down the flow of work, causing delays and increasing cycle times. This can be avoided by:

- Measuring cycle time for every single work item in your batch

- Evaluating items taking undue time

- Implementing targeted improvements to alleviate these blockages, such as reallocating resources or streamlining the workflow

Wait times and delays

Let’s say your individual cycle times add up to 20 hours; however, your batch cycle time for the same process is 80 hours. This means that there is wait time somewhere.

Use ClickUp Gantt charts to see the gaps between the end of one cycle and the start of the next in the same batch. Understand the inefficiencies for better resource scheduling across tasks and projects.

Overprocessing

Overprocessing is when you put more work into a product or service than is required by the client or necessary for the project. This can lead to bad project time management.

The best way to avoid overprocessing is to benchmark cycle times with other projects/industry standards. If you’re taking too long to deliver something, take a look at why.

If you’re unsure where to start, try a few time management templates. Apply them across projects to collect data for benchmarking.

4. Improve processes

Based on accurate calculations and insights, improve your processes to reduce cycle times.

Automate processes that don’t need to be manually completed. ClickUp Automations has 100+ templates across project management needs.

Make hand-offs simpler with ClickUp tasks, sub-tasks, and checklists. Write comprehensive user stories in task descriptions and use the checklists for acceptance criteria.

Streamline product documentation with ClickUp Brain. Use AI to help write documentation or proofread, edit, and summarize your work.

Deliver Projects On Time Every Time With ClickUp

Whether you’re an independent interior designer or a project manager in a large software development organization, cycle time is your primary measure of productivity and efficiency.

As a manufacturer or service provider, it helps you understand how long a task takes. At the bare minimum, you can use cycle times to forecast delivery timelines for your customers. At the most, you can make simple profitability calculations to see if your business can sustain itself at this rate.

Cycle times can be used to optimize complex assembly lines, meet personal development needs, devise the right pricing strategy, or improve budgeting.

Incorporating cycle times into your projects is a powerful strategy to unlock higher productivity and efficiency. It accelerates delivery times and improves the overall quality of the output.

ClickUp makes it extraordinarily simple to incorporate cycle time calculations into your project workflows. See for yourself. Try ClickUp today for free!

FAQs About Cycle Time

1. What is the formula for cycle time?

Cycle time formula for individual work items is as follows:

Cycle time = Finish time – start time

Cycle time formula for batches, i.e., collections of work items that complete a task/delivery is as follows.

Batch cycle time = Net cycle time/Number of units produced

2. How do I calculate my period cycle?

Identify start and end dates: Determine the start date of the project and the expected or actual end date.

Calculate duration: By subtracting the start date from the end date.

If you’re planning and don’t have an end date, you can estimate the duration based on similar past projects.

Period cycle = Project end date – Project start date

3. How do you calculate machine cycle time?

- Identify the start and end points of the operation you’re measuring

- Measure total production time, including actual processing time, loading and unloading time, inspection time, and any idle time between operations

- Count the number of units produced

- Calculate cycle time using the formula: Machine cycle time = Total production time / Total number of units produced

For example, If a machine took 120 minutes to produce 60 units, the machine cycle time would be 120/60 = 2 minutes per unit.

This means that, on average, it takes the machine 2 minutes to complete one cycle of operation, producing one unit.