Operations Management: Examples and Strategies for Business Growth

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

The past is a foreign country; they do things differently there.

It’s easy to get nostalgic about the past in the face of the present moment’s uncertainty. But what if one had to run a business with floppy disks, dial-up internet, pagers, and typewriters?

Sounds quaintly inefficient, right?

Today, modern business operations adopt consistent and competitive work advancements to streamline their business processes. Tesla created Gigafactories to integrate advanced manufacturing technologies. Amazon introduced Kiva robots to automate the picking and packing process–the list goes on.

McKinsey & Company stated that companies that excel in operations management can outperform their peers by 20%.

Scroll down to learn about operations management, its importance, challenges, and some examples.

Operations management is the systematic design, direction, and control of processes that transform inputs into goods and services. It encompasses activities including process design, quality control, inventory management, and supply chain optimization.

You can’t run a marathon without knowing the course, right? You would struggle to keep pace, waste time and effort, and miss checkpoints. That’s what happens when business operations aren’t managed properly. Let’s understand in detail why effective operations management matters so much.

From theory to practice, operations management differs depending on the type of industry and business processes. Let’s examine some real-life operations management examples to better understand it!

Operations management can vary significantly by industry, depending on its unique challenges and requirements. Let’s examine examples of operations management in seven industries!

In manufacturing, operations management involves managing the production process, ensuring efficient machinery, and maintaining product quality.

Dell’s Just in Time delivery model is a great example of operational efficiency. Instead of producing computers in bulk, Dell manufactures products only after a customer orders. This approach minimizes inventory costs, smoothens supply chains, and ensures that each product is customized to the buyer’s specifications.

Improving patient care is the foundation of this industry. The right operational management strategy must support it.

Cleveland Clinic uses a comprehensive BI strategy involving data, analytics, and AI to optimize everything from patient care to resource utilization and operational efficiency.

This means faster treatments, improved patient outcomes, and less time wasted in administrative limbo.

For retail businesses, operations management focuses on managing inventory and optimizing the supply chain.

Retail giants like Walmart rely on an in-house retail link system to provide real-time data to suppliers.

This allows them to manage and replenish their stock, avoid overstocking, and always have just the right amount available to customers.

Change is constant, especially in the hospitality industry! Staying on top of the latest trends is like keeping a buffet stocked with everyone’s favorite dishes and matching everyone’s expectations.

Hospitality leaders need to address changes such as customizing guest preferences through AI, incorporating sustainable practices, and facilitating customer service.

With the agenda of “good food and good service at a fair price,” Marriott International integrates sustainability into its operations, hotel design, and supply chains. It collaborates with hotel owners, franchisees, brands, suppliers, guests, and partners globally and implements biodiversity and natural capital programs.

This helps them serve better and drive improvements in energy and water usage, which helps them limit resource wastage and carbon emissions.

👀 Fun Fact

The National Restaurant Association indicates that one in every ten Americans works in the restaurant and food service industry, making it the second-largest private employer!

Operations management in IT encapsulates system functionality and data management.

A key example is Google, which uses automated infrastructure management systems to maintain and upgrade its global data centers.

Google’s site reliability engineers (SREs) apply DevOps principles to automate repetitive tasks, reduce downtime, and optimize system performance, which is critical to supporting the company’s enormous traffic loads.

In eCommerce, operations management means everything. It helps oversee all aspects of fulfilling online orders, from inventory management and order processing to shipping and customer service.

Amazon is leading by example here. It manages its operations through automated warehousing systems and robotics in its fulfillment centers. Additionally, it uses algorithms to manage inventory levels and reduce delivery times through optimized routing in its distribution networks.

Let’s not forget its superpower, Prime, known for its advanced logistics systems, automated warehouses, and optimized delivery routes. These ensure that orders are processed and delivered within a day in many areas.

Risk management, transaction processing, and optimum customer service are paramount in operations management in financial services.

Finance managers are often burdened with routine operational tasks like accounting, collections, payments, and tax filings. While capable of handling these, they are distracted from their core job—driving business management and growth, which can occur due to insufficient operational management.

We can learn from JP Morgan Chase here. It uses AI tools for operation management, such as data analytics, natural language processing, and machine learning, to detect fraud and ensure compliance.

They also use AI for loan processing and customer support, which enhances accuracy and speed, leading to improved customer satisfaction and lower operational risks.

The right operations management techniques can make or break your efficiency and could help meet customer expectations. Let’s see which ones can transform your routine business processes.

You can’t get a recipe right if you don’t have the right ingredients in the right amount. Operations management is just like that. It requires the art and skill of turning complexity into simplicity, ensuring everything blends well to drive results.

It involves pulling and utilizing resources from teams, equipment, materials, and technology (just like collecting the ingredients). However, merely collecting resources isn’t enough. An operations manager must know how to use them to optimize efficiency, reduce costs, and motivate people to achieve the company’s goals.

Some of the fundamental tools operations managers consider implementing are:

We might have something that helps you harness the power of all the above tools for spot-on operation management. It allows real-time data tracking, ease of integrating processes, and team collaboration.

Meet ClickUp, an all-inclusive project management tool!

ClickUp’s Project Management Software equips your team with a superior way to handle daily tasks. It enables the seamless execution of your operations management strategy.

Here are some of the features that make ClickUp the operations management tool for you:

ClickUp’s documentation feature, ClickUp Docs, allows you to create dynamic procedure documentation with version control. The real-time collaboration features within Docs help you propose changes to a document and invite suggestions, reviews, and feedback from team members.

You can also link documents and tasks seamlessly to keep everything in one place. Add widgets to update workflows, adjust project statuses, assign tasks, and more, all within ClickUp.

ClickUp has a large library of visualization tools to suit your every need. Leverage ClickUp Whiteboards to visualize and optimize business processes. Create workflow flowcharts by adding, deleting, dragging, and dropping shapes, connectors, and sticky notes onto the whiteboard.

Add dependencies, map cross-functional processes, and collaborate on optimization strategies with your team to keep an eagle eye on the state of your ops.

Operations management professionals can also use ClickUp Dashboards, which showcase a real-time view of historical operations data, sniffing out potential bottlenecks and ensuring process improvement and quality control.

💡Pro Tip: To create comprehensive dashboards, set up Goals in ClickUp and link them to the relevant tasks, subtasks, and checklists to monitor progress. Use Cards like progress bars, pie charts, thermometers, and line graphs to display important metrics and KPIs.

ClickUp also helps ensure your processes aren’t strained or risk disruption due to a lack of resources. ClickUp’s Workload View visualizes the tasks assigned to each team member over a selected time frame. This view compares each individual’s workload against their designated capacity, letting you make adjustments that keep the gears turning smoothly.

For advanced planning, ClickUp Goals can be used to manage your process goals efficiently.

Features like task tracking, progress monitoring, and customizable reminders allow you to slice complex and larger operational goals into small, manageable steps. This facilitates setting milestones, ensuring consistent progress, and timely delivery.

Define and organize specific goals into dedicated folders, track progress using customizable metrics like numerical, monetary, or task-based targets, and link your operational tasks and lists directly to your goals, getting real-time updates.

💡Pro Tip: Check out the ClickUp OKR Folder Template, which breaks down objectives and key results (OKRs) into manageable lists, helping you structure and monitor your operations.

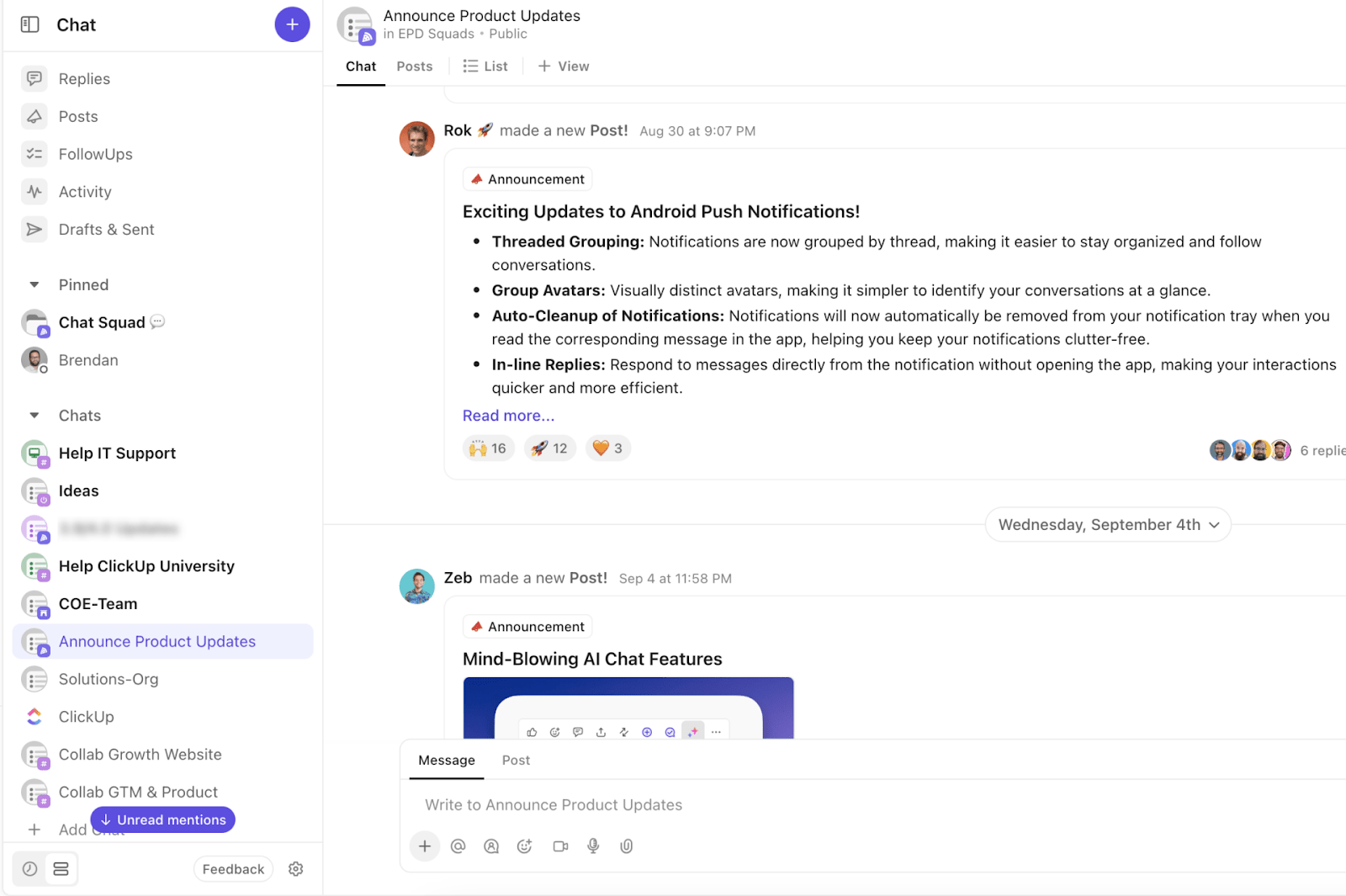

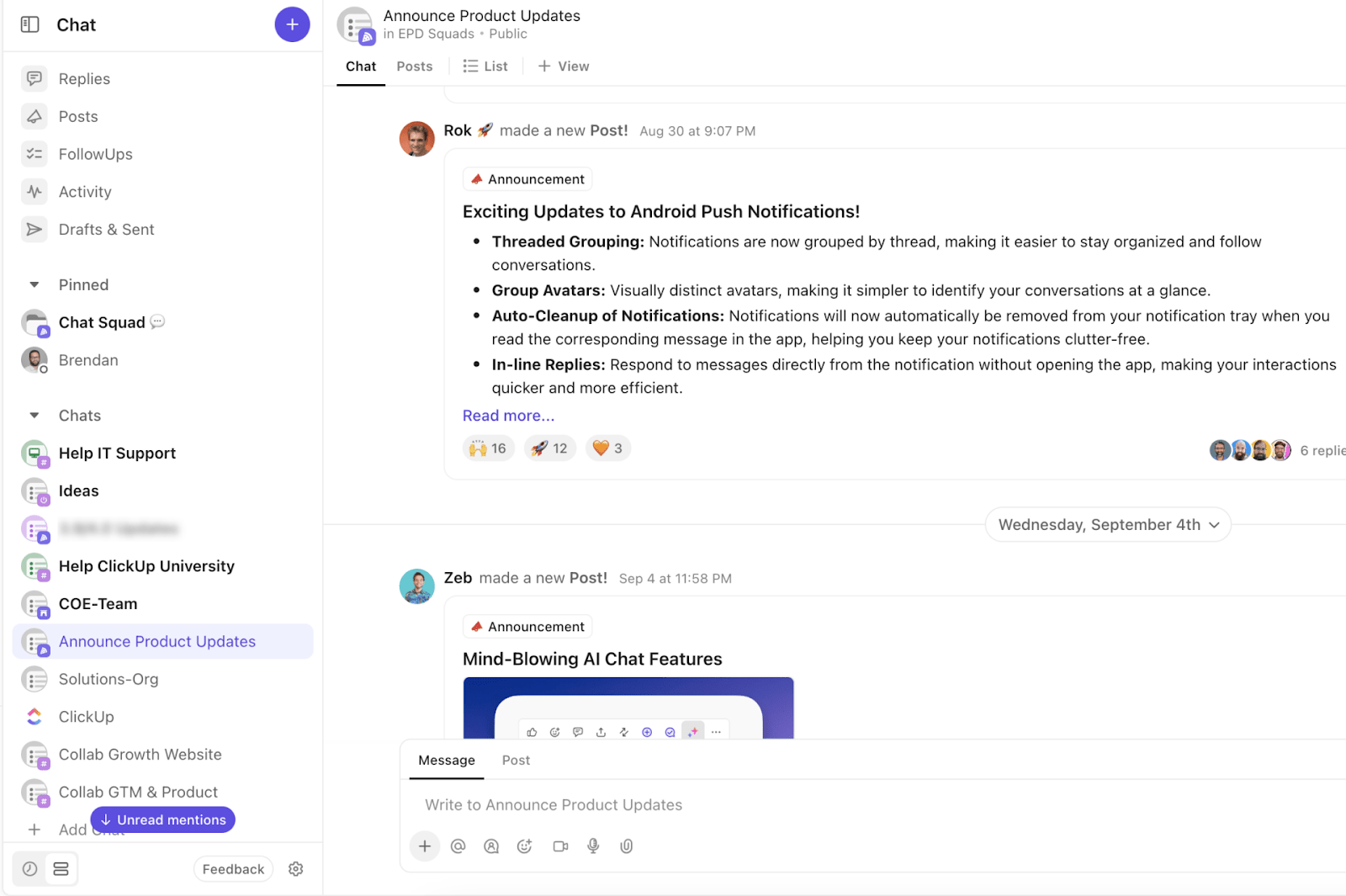

ClickUp offers an all-in-one solution that brings together messaging, tasks, and collaboration in one place—ClickUp Chat. Forget toggling between apps to access features like real-time messaging, task management, video conferencing, and AI-powered assistance. ClickUp Chat offers all of these—within one platform. This truly makes ClickUp ‘the everything app’ for operations management.

ClickUp Chat’s standout features, such as FollowUps for tracking action items, AI-generated task creation, and frictionless integration with other ClickUp tools, let you improve communication, smoothen your workflow, and stay organized.

The best part? Most of your team communications will occur within Chat. From there, you can run your projects and teams and visualize project progress. Communicate and work in tandem without losing context in the process!

Managing processes, operations, and supply chain management takes more than the required work hours of team members dealing with multiple tasks simultaneously. However, everyone is limited by the number of hours they can work each day or week.

So, how do you ensure your team has enough bandwidth and resources to dedicate to a specific project?

ClickUp’s Business Project Management Software offers various operational planning templates to get you started.

Whether you’re launching a new product or optimizing operations, ClickUp’s Operational Plan Template provides tools to develop actionable plans, track KPIs, and collaborate in real time. It strategically enhances business success by aligning teams with common goals.

Additionally, the template features Custom Statuses for task tracking, Custom Fields for operations categorization, and Custom Views for monitoring progress.

For example, a project manager overseeing a new product launch can use it to ensure every team member clearly understands their tasks and responsibilities.

By selecting tasks, attachments, dependencies, and due dates, the operations manager can create a comprehensive plan that tracks key project milestones, assigns resources, and ensures deadlines are met.

Do you have too many details to capture from an important business meeting but are too short on time? ClickUp’s Operations Meeting Minutes Template can simplify note-taking.

Easily document important operation decisions, track action items, and assign responsibilities to team members. The template includes Custom Statuses for operational task tracking, Custom Fields to categorize decisions, and Custom Views like Gantt charts and calendars for better project management.

With built-in features such as screen recording, comment reactions, and automation, this template simplifies capturing progress and updates. It also helps teams stay organized and provides a clear reference point for future discussions, ensuring every decision is tracked, documented, and easily accessible.

Now that you’ve got the tools to streamline your operations, let’s talk about the person behind the scenes who makes it all happen: the operations manager.

Operations managers are like air traffic controllers. They constantly monitor multiple moving parts, ensure nothing crashes, and guide the organization to its destination safely and on time.

It’s time to shine a light on the critical efforts of these heroes!

Operations managers work closely with senior management to analyze market trends, industry benchmarks, and internal capabilities to identify opportunities for improvement and growth.

A significant part of an operations manager’s role involves identifying inefficiencies and implementing strategies to rectify them. This includes redesigning and automating workflows, determining KPIs, automating tasks, and investing in new technologies to enhance productivity and reduce costs.

💡Pro Tip: The free ClickUp Cost Benefit Analysis Template helps operations managers quickly assess the cost-effectiveness of various processes before committing to one. Its classified, color-coded layout makes complex decision-making easier and more efficient.

Operations managers are also responsible for allocating and managing resources, developing staffing plans, managing budgets, and negotiating contracts with suppliers, which ensures optimum resource utilization.

Operations managers prioritize quality assurance by implementing quality control measures, such as inspections, audits, and feedback mechanisms, to identify and address quality issues.

Operations managers must proactively identify and mitigate risks that could disrupt operations or impact the company’s core objectives. This includes developing contingency plans, managing safety protocols, and addressing environmental concerns.

📮 ClickUp Insight: 46% of knowledge workers rely on a mix of chat, notes, project management tools, and team documentation just to keep track of their work. For them, work is scattered across disconnected platforms, making it harder to stay organized.

As the everything app for work, ClickUp unifies it all. With features like ClickUp Email Project Management, ClickUp Notes, ClickUp Chat, and ClickUp Brain, all your work is centralized in one place, searchable, and seamlessly connected. Say goodbye to tool overload—welcome effortless productivity.

This is one of the most important roles of an operations manager, i.e., leading, guiding, and mentoring teams for various operational tasks. They often collaborate with HR to keep track of employee schedules, schedule work effectively, and devise best practices and standard operating procedures (SOPs) to accelerate performance.

Understanding the role is just a small part of operations management; the best practices make operations management truly effective! Read on to understand these practices.

A study indicated that 40% of organizations are ineffective in supporting frontline operations, hindering their ability to respond swiftly to market fluctuations.

Then what does it take to be part of that high-performing 60%? Let’s see:

We live in a world that runs on data, and businesses that can capitalize on and tweak their production lines based on data gain a competitive edge and save a ton of money in the long run. Companies can make smarter decisions faster by using analytics to track performance, identify bottlenecks, and anticipate demand.

UPS, for example, has developed its on-road integrated optimization and navigation system (Orion). UPS has also invested heavily in analytics to improve logistics efficiency and has seen significant cost savings and enhanced customer satisfaction as a result

Small, incremental changes in a manufacturing company—whether reducing unnecessary steps or rethinking supply chain logistics—can lead to significant gains over time.

Toyota revolutionized the auto industry with lean manufacturing, and today, these principles are a cornerstone of its operations management. Another key concept adopted by Toyota is ‘Jidoka,’ which translates to “automation with a human touch.” In Toyota’s system, machines are designed to identify defects or irregularities and automatically stop the production process.

This allows workers to address the issue promptly, ensuring that problems are resolved in real time without compromising quality.

Automation and technology are the two horses that, if tamed properly, can ride us into a golden age of human achievement.

Think of automation as the workhorse—relentlessly handling repetitive, time-consuming tasks like data entry, inventory management, and quality checks. By automating these processes, operations managers can achieve greater consistency, accuracy, and speed, minimizing human error and freeing up resources for strategic initiatives.

Technology is the stallion—dynamic, innovative, and adaptive. From implementing advanced analytics tools for demand forecasting to integrating AI-powered systems for predictive maintenance, technology empowers organizations to stay competitive in rapidly changing markets.

Johnson & Johnson’s Ethicon subsidiary uses OTTAVA robotic surgical systems for various procedures. The systems optimize operating room efficiency, offer flexible clinical options, and deliver reliable Ethicon instrumentation.

Getting the right raw materials to the right place at the right time is vital to operational management. Businesses must regularly evaluate their suppliers, logistics, and inventory management strategies.

Apple’s Supplier Employee Development Program is a great example of process optimization and investing in people who drive a company’s growth.

Your people are your biggest asset. Engaged employees are 17% more productive, and investing in their training directly invests in the company’s success.

When employees understand the processes and the value of efficiency, they are more likely to spot inefficiencies and suggest improvements. Creating a continuous learning culture keeps everyone sharp and ready to adapt to changes.

Honda’s two-way communication approach between associates and supervisors is a benchmark that sets them apart in employee engagement and training. This operational management practice focuses on discussing career paths, performance evaluation differences, and developing a supportive culture.

Operations managers have a lot to deal with—tech advancements, ever-changing consumer preferences, and global supply chain disruptions that seem to pop up when you least expect them.

Let’s understand some hurdles they might face when planning, organizing, and controlling your resources and processes.

Technology offers both opportunities and challenges. While automation and AI can improve efficiency, integrating these technologies requires substantial investment and workforce training.

Cybersecurity is another concern, as increased digitization exposes businesses to potential data breaches, threatening operational continuity. Staying current with rapidly evolving technologies like the Internet of Things (IoT) and artificial intelligence (AI) also creates integration issues with existing systems.

Also Read: Best Operations Management Software Tools

Technical challenges in operations management include system integration and data management. Integrating modern technologies like ERP systems, IoT, and AI with legacy systems often results in inefficiencies due to compatibility issues.

Another key challenge is maintaining automated systems, which, while increasing efficiency, require regular maintenance to prevent costly breakdowns.

ClickUp can be a lifesaver here! ClickUp Automations helps you automate routine operational tasks like sending notifications, assigning responsibilities, and updating project statuses, giving your team more time to focus on strategic planning and problem-solving.

Features like the AI Automation Builder allow users to create tailored automation with dynamic assignees, ensuring flexibility in task management. Project shortcuts, email automation, and robust audit logs also enhance organizational efficiency.

Integrating popular apps extends automation capabilities, enabling teams to focus on what truly matters while ClickUp does the heavy-duty work.

Sustainability is an increasingly pressing concern. Operations managers must adopt environmentally friendly practices and comply with ever-stricter regulations. Implementing green operations, reducing waste, and cutting carbon emissions can increase costs and complexity, particularly in manufacturing.

Communication challenges arise from coordinating across multiple departments and managing global or remote teams. Miscommunication between teams, such as production and procurement, can lead to delays and errors, affecting the entire operation.

ClickUp Notepad is a valuable tool for communicating and collaborating on various business functions, such as collecting important data, brainstorming ideas, taking notes, recording changes, and measuring results. The rich editing feature allows you to proofread and summarize notes and convert inputs into trackable tasks.

Another great way to enhance team management and communication is to use ClickUp Clips, which lets team members create and share short video messages.

These clips help operations managers provide detailed explanations, feedback, and instructional videos where text messages just won’t make an impact.

Operations managers hold the power to transform their teams and drive success by adopting various tools and practices that promote collaboration and clarity. But sometimes, even the finest tools can become obsolete when operational schedules overlap, instructions are unclear, messages get crossed, and clear communication is lacking.

ClickUp offers sure-shot solutions to all your operational problems. We understand the difference between running a business and running it with a vision.

Try ClickUp today and experience seamless collaboration on your operations firsthand!

© 2026 ClickUp