How to Implement Lean Project Management

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

As a project manager, you’re probably already familiar with how challenging some problems can be, such as managing overdue tasks without feeling overwhelmed and putting undue pressure on your team.

When you’re doing a hundred things at once to ensure on-time delivery, you need practical strategies to manage your workload.

Lean project management is all about working smarter rather than harder. It’s focused on being more efficient and reducing wasteful processes. Unlike traditional project management, which has fixed phases, this approach emphasizes flexibility and adaptation, giving you more control over project outcomes.

Besides Agile, Lean is one of the most popular project management methodologies in practice today. How are they different? Is one arguably better than the other?

Let’s quickly explore the differences between Lean and Agile project management before we go deeper into the former and its implementation.

Both Lean and Agile project management methodologies apply mostly to software development, manufacturing, production, and IT.

Lean project management mandates efficiently getting the most out of what you have. It constantly examines the way things are done to find and get rid of unnecessary steps, making sure the final product is of value to the customer.

Agile, however, understands that project plans are not set in stone. Agile project managers know plans can derail, and they are adept at handling changing project demands. They deliver projects in small, iterative chunks, constantly testing and tweaking their approach based on customer feedback to make the project a success.

Lean project management isn’t just about saving money and resources. It uses the perfect amount of tools and manpower to deliver exactly what your client needs right when they need it. It’s all about using the right number of people and tools to get the job done.

By getting rid of wasteful processes [such as waiting periods or unnecessary features], Lean helps you:

Now, let’s unpack the core principles that make Lean project management so effective.

No matter where you use Lean, the core principle stays the same: deliver maximum value by eliminating wasteful processes.

But what is waste?

Lean uses three key Japanese terms, Muda, Mura, and Muri, developed by the Toyota Production System [TPS], to identify waste. Let’s break them down.

Suppose your team has seven programmers working on features but only three testers to review their work [Mura]. This creates a bottleneck where features pile up waiting to be tested [Muri], overloading your testers [Muri]. Rushed testing due to this overload can lead to bugs slipping through [Muda], ultimately delivering faulty software to the customer [more Muda]. By tackling all three Ms, you can simplify your workflow and achieve peak efficiency.

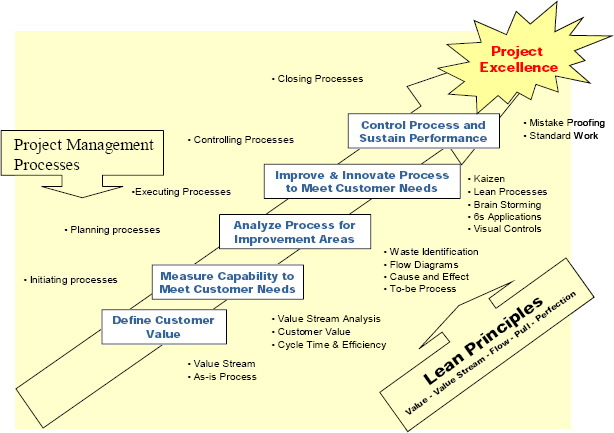

The Project Management Institute [PMI] is the world’s leading professional association for project management. Founded in 1969, it serves over 3 million professionals in nearly every country.

PMI recognizes that Lean is an effective tool for increasing project efficiency and delivering value. Here’s how PMI promotes a lean culture:

PMI considers Lean project management tools to be a key element in boosting project performance and providing maximum customer value. Their training and certification programs give project professionals the tools they need to use Lean project management principles and achieve successful project results.

You already know that the Lean methodology wasn’t formulated as a theory in a lab. It was a practical solution to the real-world needs and problems faced by the Toyota Production System [TPS].

After World War II, Japan’s resources were limited. Toyota had to be efficient with limited materials and workforce. They began to rethink traditional manufacturing processes.

Taiichi Ohno, an industrial engineer at Toyota, developed the core principles of Lean. His focus was mainly on delivering value to the customer and knocking out anything that didn’t contribute, that is, waste.

But not all waste is created equal. There are different ways to categorize Muda in lean project management.

Another core principle that supplements this approach is Kaizen, the Japanese philosophy of continuous improvement. It advocates for constantly analyzing processes, identifying areas for waste reduction, and always trying to be more efficient.

In 1990, James Womack’s ‘The Machine That Changed the World’ popularized the term and helped spread Toyota’s Lean and Kaizen principles beyond the automotive manufacturing industry.

Lean project management isn’t a quick fix; it’s a journey that unfolds in five stages, which are also known as the five core principles of the Lean methodology.

Before you build anything, understand what ‘value’ means to your customer.

Suppose you’re a software development team building a new fitness app. Is ‘value’ a fancy calorie tracker or a simple, user-friendly app that helps people stay motivated? Talk to potential users, gather feedback, and define what features truly matter to their fitness goals.

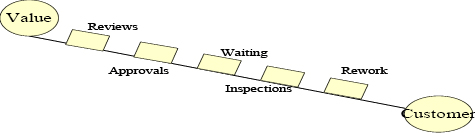

Value Stream Mapping: Analyze every step involved in delivering that value. Identify and get rid of any waste [Muda].

Let’s say your app development project process involves multiple rounds of design revisions and lengthy code reviews. This can lead to bottlenecks and delays. Map the entire process, identify steps that don’t directly contribute to a better app [like too many design reworks], and simplify the workflow.

Think of your project as an assembly line. Arrange the value-adding activities in a smooth, continuous flow.

For instance, break down your app development into smaller, manageable tasks. Use Kanban boards to visualize the workflow, prioritize tasks, and identify any roadblocks that might slow down progress.

Respond to actual customer demand, not trends or predictions. Produce only what’s needed when it’s needed.

For example, take things one step at a time. Instead of trying to do everything at once, release a minimum viable product [MVP] first and gather feedback. Use the feedback to figure out which feature of the app you need to work on next. This way, you’ll make sure you’re building features that people actually want and avoid wasting time on [potentially unnecessary] bells and whistles.

Continuous improvement is the heart of lean, and efficiency is its brain. Always look for ways to simplify project processes.

For instance, hold regular team discussions to determine what’s working well in the app and what needs improvement. Encourage team members to suggest new ideas to improve the app, no matter how small. Keep tweaking your workflow to improve speed, efficiency, and accuracy for the future.

While Lean, Agile, and Scaled Agile focus on improvement, they differ in their targets. Lean tackles waste across any process; Agile thrives on adapting to changing project needs; and Scaled Agile coordinates Agile practices for large projects. Lean Six Sigma blends Lean’s waste-minimization focus with Six Sigma’s statistical analysis to optimize existing processes.

Let’s take a closer look at these differences.

| Feature | Lean | Agile | Scaled Agile | Lean Six Sigma |

| Focus | Eliminating waste, maximizing value delivery | Adaptability, responding to change | Aligning large teams and projects | Reducing defects, improving process efficiency |

| Project phases | Not strictly defined, continuous improvement | Iterative sprints with flexible planning | Frameworks for scaling agile across large enterprises | A data-driven approach to process improvement |

| Project management | Simplified workflows, minimizing waste | Collaborative, customer-centric approach | Frameworks for coordinating large teams | Data-driven, statistically-focused |

| Change management | Encourages continuous improvement | Embraces change and iteration | Frameworks for managing complex change across large teams | Data-driven approach to process improvement |

| Suitable for | Well-defined projects with clear value proposition | Projects with changing requirements or uncertain outcomes | Large, complex projects with multiple teams | Projects with defects or aiming for high process efficiency |

| Examples | Manufacturing, software development | Software development, marketing campaigns | Enterprise software development, large-scale product launches | Manufacturing, customer service processes |

Let’s break each of these models down and learn how to apply them.

Lean focuses on avoiding waste [Muda] and maximizing value delivery to the customer.

Agile is about adaptability and responding to changing customer needs through short, flexible development cycles [sprints].

Making sure big teams and projects in a company work together while sticking to Agile principles

A data-driven approach that combines Lean principles of waste reduction with Six Sigma’s focus on defect reduction and process improvement. It uses the DMAIC [Define-Measure-Analyze-Improve-Control] cycle for continuous improvement.

You need a project management model that meets your needs. Here’s how you can define your needs:

Sometimes, a hybrid approach combining elements from different project management processes can be the most effective strategy for your project management plan.

Simply choosing any project management method won’t guarantee success—be it Agile or Lean. To effectively manage projects using these approaches, you need a project management software that offers specific functionalities:

Project management methodologies aren’t one-size-fits-all. Teams might use Agile, Scrum, Kanban, Lean, Six Sigma, or even a hybrid approach, depending on the project.

Let’s explore some Lean tools and methodologies:

How are these methodologies specifically useful for software development? You can apply the Lean approach to software development in various ways:

Lean supports continuous improvement efforts by increasing efficiency and productivity, reducing waste and costs, improving customer satisfaction, and engaging employees productively.

In 2009, researchers studied a small software development team at BBC Worldwide in London to see how well Lean methods worked. They examined the team’s work, task boards, and meetings, interviewed the team members, and crunched numbers.

After a year of implementing Lean, things were much better: Software releases were 37% faster and more consistent [47% improvement], and customers found 24% fewer bugs.

Faster releases, focusing on what customers valued most, also meant less risk from technology changes or market shifts.

Although this study was done years ago, it shows that Lean is a project management model worth trying out, especially given the tremendous time and cost savings it can unlock.

How do you get started with Lean? There are several platforms or combinations of tools that you can use.

But which one’s the best?

While there’s no single answer because each team has a unique set of workflows and requirements, adaptability is key. Luckily, you’ve got ClickUp, a project management platform that can help you switch methodologies based on project and team needs. This lets your team focus on what matters: delivering successful projects.

Here’s how ClickUp can simplify Lean project management for you:

ClickUp equips you with powerful tools to seamlessly integrate Lean and Agile principles into your project management workflow.

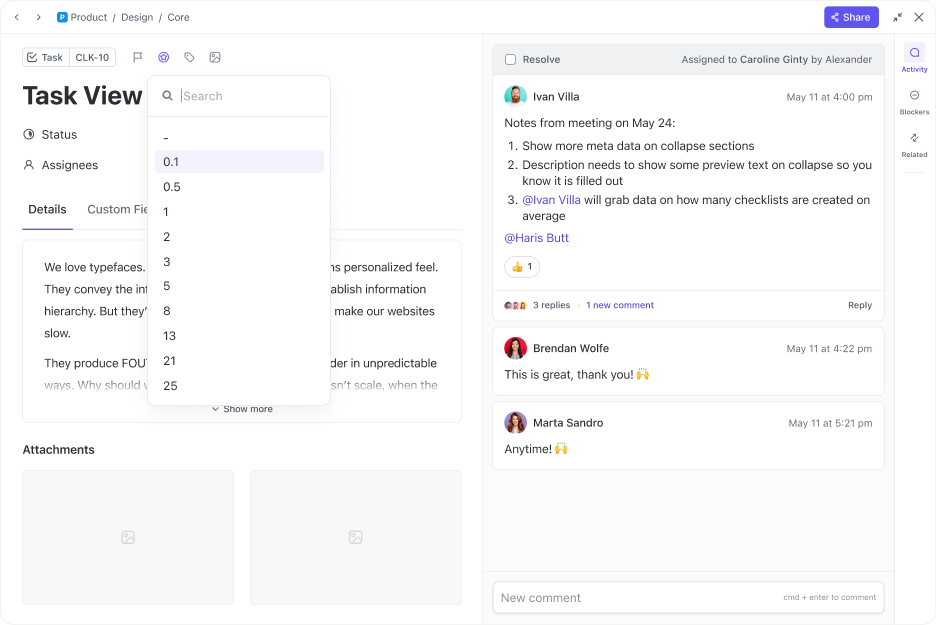

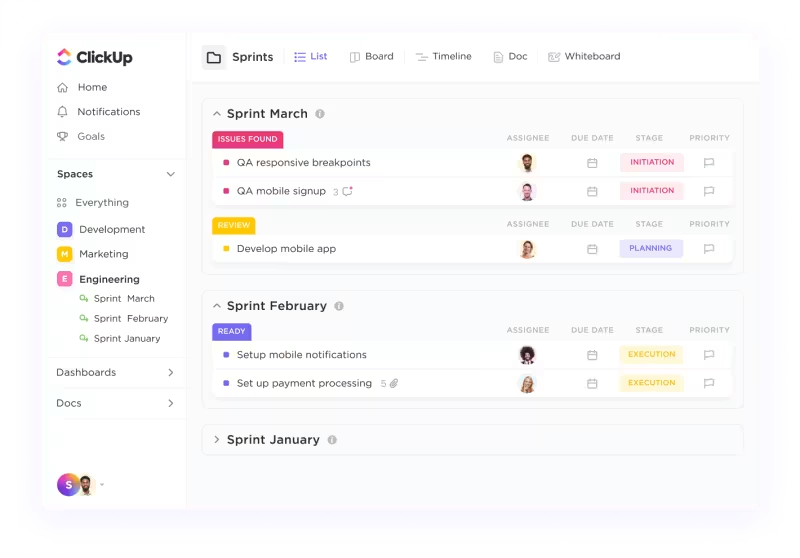

Create visual ClickUp Kanban Boards with the boards representing project stages [like ‘To Do,’ ‘In Progress,’ ‘In Review,’ ‘Done’]. Break down large tasks into smaller, more manageable subtasks within each section. This keeps your workflow organized and ensures everyone on the team understands their roles and responsibilities.

Drag and drop tasks between Boards to visualize workflow progress and prioritize tasks. Use color coding to highlight urgent tasks or tasks requiring specific skill sets.

Set WIP limits for each stage to prevent bottlenecks and ensure smooth flow. WIP limits the number of tasks that can be done at a particular stage at any given time. This helps prevent teams from taking on too much work at once, ensuring tasks get done through the workflow without getting stuck.

Use ClickUp Tasks and ClickUp Custom Fields to merge PDCA into your Lean project management workflow. Here’s how:

Value Stream Mapping [VSM] is a useful tool for identifying waste and optimizing processes. However, creating a clear and actionable VSM can be a challenge.

Brainstorm and visually map out the entire project value stream, identifying all steps involved in delivering value to the customer.

ClickUp’s Mind Maps are perfect for capturing all the ideas and steps involved in your value stream. Start by creating a central node representing the final value delivered to the customer.

Then, branch out to map out all the upstream processes, sub-processes, and activities that contribute to delivering that value.

Use sub-nodes to represent decisions, approvals, handoffs, or any other steps that contribute to the overall flow of work. Color coding can help differentiate between different types of activities or departments involved.

Create a dedicated ClickUp Whiteboard to collaboratively map out the current state and desired future state of your value stream. We have a great template for this, so you don’t have to start from scratch.

ClickUp’s Automated Value Stream Map Whiteboard Template is your one-stop shop for simplifying your value stream analysis:

Combine ClickUp Automations with ClickUp Dashboards to automate tasks and generate in-depth reports of any task, milestone, or goal to achieve, ultimately optimizing your workflow.

ClickUp’s Automations lets you set up custom rules to automate repetitive tasks across your projects. Here are some examples:

ClickUp Dashboards act as your customizable command centers to provide a real-time view of your project management. With drag-and-drop functionality, you can build dashboards specific to your needs, displaying key metrics and insights to help you identify areas for improvement.

You can create dashboards for the following purposes:

ClickUp’s many project management solutions let you establish flexible methods for managing software development at your organization.

Let’s first look into ClickUp Agile Project Management Software, especially pre-made for Agile teams that want to use Agile-first tools alongside others.

Here’s how you can put ClickUp to use for agile methodologies:

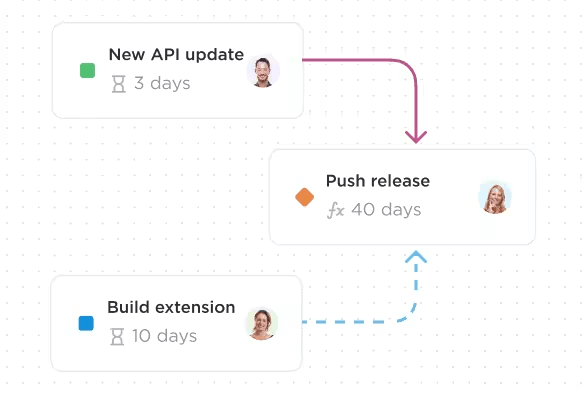

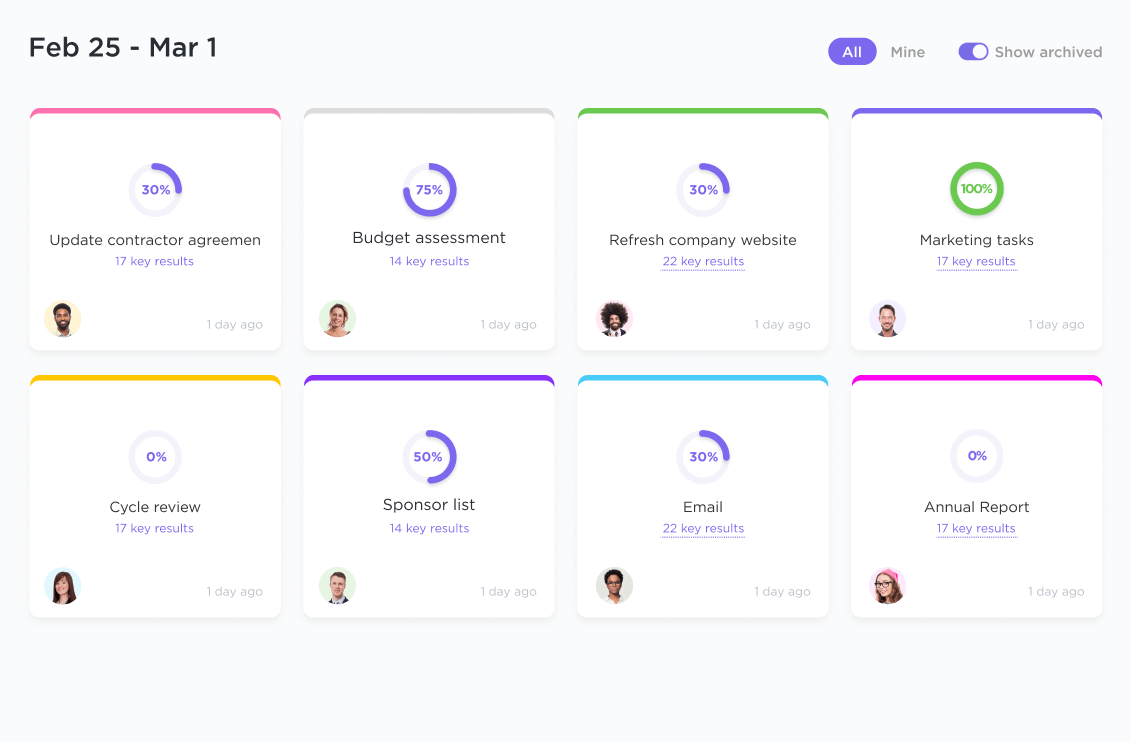

Automatic reporting lets software teams keep stakeholders up to date without any manual intervention. Monitor your progress using numeric, financial, binary [true/false], and task-based targets. Combine tasks from various teams to create goals, such as sprint targets or weekly sales objectives

For instance, the ClickUp Agile Project Management Template is designed to help you implement Agile practices effectively.

Use this template to:

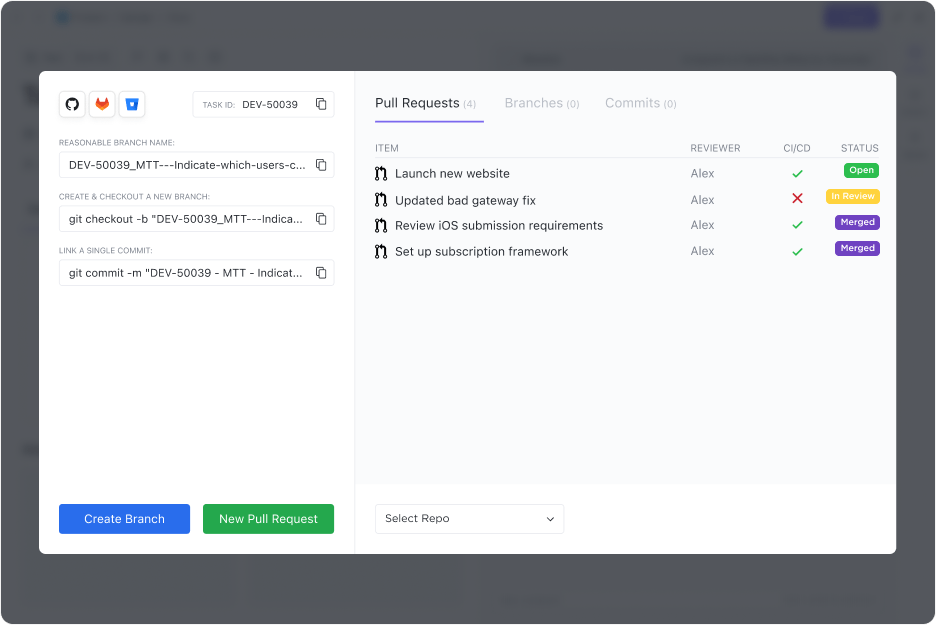

ClickUp Integrations connects all your external tools in one place to create the perfect agile project management hub.

For instance, the ClickUp-GitHub integration helps you:

You can also set up ClickUp Sprints in Board View and apply the scrum methodology for whichever project requires it.

Here’s a breakdown of how to effectively implement ClickUp Sprints within your Scrum workflow in ClickUp:

The ClickUp Lean Business Plan Template simplifies incorporating this methodology within your organization.

This comprehensive template equips you with the tools to transform your business ideas into a reality—efficiently and affordably:

Let’s examine how ClickUp helped Lids, a sports apparel company serving North America, Europe, and Australia.

Lids, a retailer with over 1200 stores, faced challenges managing rapid expansion due to disorganized workflows. They relied on various scattered tools like spreadsheets and email, leading to communication gaps and inefficiencies.

They onboarded ClickUp to centralize communication and tasks. Now, different departments collaborate seamlessly within ClickUp. This reduced email traffic and shortened meetings by 66%, freeing up valuable time.

ClickUp also improved Lids’ inventory management. Previously, they manually tracked inventory costs, making budgeting difficult. ClickUp allows them to track unit costs and build more accurate budgets for new stores. Overall, ClickUp has increased productivity and saved Lids over 100 hours across teams.

With ClickUp, our teams are more collaborative, efficient and we’re all more on-top of our work. It has made the way we work so much better.

As a lean project manager, you must prioritize delivering maximum value to the customer while eliminating waste throughout the project.

Lean project teams are structured specifically to achieve maximum efficiency and value delivery. Here’s a breakdown of the key roles and how they contribute to the overall success:

By pairing the right tool with the Lean philosophy, teams can boost project results and overall business performance.

Companies such as Amazon, Nike, and Caterpillar Inc. have successfully integrated Lean principles into their project management practices, and you can too!

However, implementing Lean requires a change in mindset and company culture, which can be challenging. When dealing with large, complex projects, Lean’s focus on simplicity may be less applicable. But with the right tool, making this transition becomes easier.

What should you not compromise with? A US survey found that 36% of project management software users considered functionality the most important factor in choosing their software.

ClickUp’s flexibility provides the muscle you need for all the heavy lifting involved in complex projects. Prioritize tasks based on what matters most, visualize workflows for maximum efficiency, collaborate seamlessly via built-in communication tools, and track progress with laser focus. The road to project success is clear with ClickUp—are you ready to take the wheel?

Sign up for ClickUp today!

The five rules of Lean management are:

Yes, Lean is one of the core pillars of SAFe [scaled agile framework] alongside agile and systems thinking. SAFe integrates these principles to help large organizations scale Agile practices.

The ‘Lean 5’ likely refers to the 5S methodology, a core foundation of lean practices. It focuses on creating a clean, organized, and efficient work environment through five steps: Sort, Set in Order, Shine, Standardize, and Sustain.

© 2026 ClickUp