As a project manager, you’re no stranger to creating and optimizing processes. While optimization is a must, there are different ways to improve your project management practices.

Process improvement methodologies help you identify problems in your business processes and fix them. With the right framework, you’ll speed up work, cut costs, and enhance work quality. ⭐

In this guide, we’ll explore business process improvement methodologies, discuss the most important approaches, and provide a few templates to speed up process improvement.

What Are Process Improvement Methodologies?

Process improvement methodologies are structured approaches or strategies used by organizations to analyze, enhance, and optimize their business processes. These methodologies aim to make operations more efficient, reduce waste, improve quality, and increase customer satisfaction.

Instead of trying to figure things out through trial and error, the methodology gives you a proven framework for analyzing, reviewing, and improving processes within your business. 🛠️

How to implement process improvement methodologies—a quick guide

Most process improvement methodologies follow these steps:

- Identification: First, identify which processes you want to optimize so you only spend time and resources on the processes that matter most to you

- Analysis: Do a deep dive into your existing processes to see what is and isn’t working. Lean on data and metrics so you make decisions with less bias

- Strategy and implementation: Create a strategy to address inefficiencies based on what you’ve learned

- Review and iteration: Your first strategy might not be a winning one, so iterate on the process until you get the results you need. You may need to collect feedback and monitor key performance indicators (KPIs) to see what is and isn’t working

All methodologies are different, but they all act as a blueprint to refine and manage your internal workflows and optimize existing processes.

The most commonly used methodologies

There are a bajillion process improvement techniques out there. You’re free to choose the option that speaks to you, but let’s take a look at some of the most commonly used methodologies.

- Lean: Originally derived from Toyota’s Lean manufacturing team, this methodology focuses on eliminating waste in all its forms. This makes Lean methodology popular with manufacturing, construction, and any other industry that relies heavily on materials, parts, and labor

- Six Sigma: This methodology focuses on reducing variability in manufacturing processes. There are two schools of thought within the Six Sigma methodology. Choose between Define, Measure, Analyze, Improve, Control (DMAIC) and Define, Measure, Analyze, Design, Verify (DMADV) to improve processes

🧠 Fun Fact: Six Sigma aims to reduce defects to near perfection: 3.4 defects per million opportunities (DPMO)

- Kaizen: A Japanese term that means “change for the better,” Kaizen focuses on continuous process improvement in just about everything, so it’s a helpful methodology that works for any organization

- Total Quality Management (TQM): TQM focuses on improving product quality and services for customer satisfaction. If you rely heavily on end-consumers, TQM might be a good fit

- PDCA Cycle: Plan, Do, Check, Act is also known as the Deming cycle. It’s a continuous loop that creates a constant stream of improvement initiatives. It’s a great way to create a culture of constant improvement

- BPM: Business Process Management maps out your current processes with flowcharts and other process modeling tools. Then it redesigns, executes, monitors, and refines your processes over time

Remember, these are just the most popular methodologies. Below, we share other process improvement methodologies in detail to give you a better idea of your options and why they might work for you.

⭐ Featured Template

Improving processes requires constant oversight and team effort. ClickUp’s free Process Improvement Work Breakdown Structure Template simplifies it by providing you and your team a dedicated space to plan improvements, assign tasks, and track progress to keep things on course.

The Best Process Improvement Methodologies to Implement for Your Business

Let’s break down some of the most useful process improvement methodologies to improve your team’s output and say bye-bye to bottlenecks. ⏱️

Before we do so, here’s a quick comparison table to give you an overview:

| Methodology | Focus | Scope | Suitability | Tools/Techniques |

|---|---|---|---|---|

| Agile | Iterative improvement through flexibility and feedback | Cross-functional, project-based | Teams needing adaptability, collaboration, and continuous iteration | Sprints, Kanban Boards, Retrospectives, Burndown Charts |

| Kanban | Visualizing workflow and reducing inefficiencies | Team or project-level | Teams managing tasks through fixed phases or wanting visibility | Kanban Boards, Custom Task Statuses, WIP Limits, Cumulative Flow Diagrams |

| Root Cause Analysis | Identifying and eliminating underlying problems | Problem-specific | Complex or recurring issues where symptoms aren’t the real problem | 5 Whys, Fishbone Diagram (Ishikawa), Fault Tree Analysis, Whiteboards |

| Just-In-Time (JIT) | Minimizing inventory waste and improving cash flow | Operational, especially production | Businesses with predictable demand and efficient supply chains | Custom Fields, Demand Forecasting Dashboards, Automations, Gantt Charts |

| SIPOC Analysis | High-level process mapping to clarify roles and steps | Cross-functional processes | Early project stages, stakeholder alignment, or complex processes | SIPOC Diagrams, Process Mapping Tools |

| Theory of Constraints | Identifying and resolving process bottlenecks | System-wide | Businesses needing throughput improvement by addressing limiting factors | Bottleneck Analysis, Drum-Buffer-Rope, Task Priorities, Dashboards |

1. Agile

Agile is a project management strategy that prioritizes flexibility, feedback, and collaboration. It’s typically a tool for product development, but you can also use it for process improvement.

With Agile methodology, you create a plan, design it, develop it, test it, deploy it, and review it. Once you review the process improvement plan results, you start the process over again. Agile is never really “over,” which makes it a good fit for any team that likes to iterate and work together closely.

👀 Did You Know? Organizations that adopted Agile software development said it offered a 41% improvement in the predictability of software deployment and its success rate!

Common use cases:

- Software development projects where requirements change over time

- Projects with iterative feedback and changes, like customer experience projects

Best for:

- Teams that need flexibility with scope

- Complex projects that don’t have clear requirements at the start

- Teams that value collaboration

Implementation tips:

- Start with a clear, measurable goal for each sprint. Define what success looks like—whether it’s reducing turnaround time, improving customer satisfaction, or increasing team throughput. Agile thrives on clarity and accountability

- Create a lightweight but visible workflow. Use a shared task board (like ClickUp’s Kanban Boards) to map out each step of your process. Visibility keeps everyone aligned and helps spot bottlenecks early

- Include retrospectives in every sprint cycle. After each sprint, gather the team to discuss what worked, what didn’t, and what to improve. This consistent feedback loop is the engine of Agile-driven improvement

- Empower cross-functional collaboration. Agile isn’t just for developers—real improvement happens when everyone shares ownership. So, encourage team members from different roles to participate in problem-solving

- Iterate in small, testable changes—not sweeping overhauls. Agile is about incremental progress. Pilot your changes within a sprint, gather real data, and refine based on what actually works, not assumptions

Tools and templates to try:

ClickUp for Agile teams offers a suite of features that facilitate iterative development, collaboration, and continuous improvement.

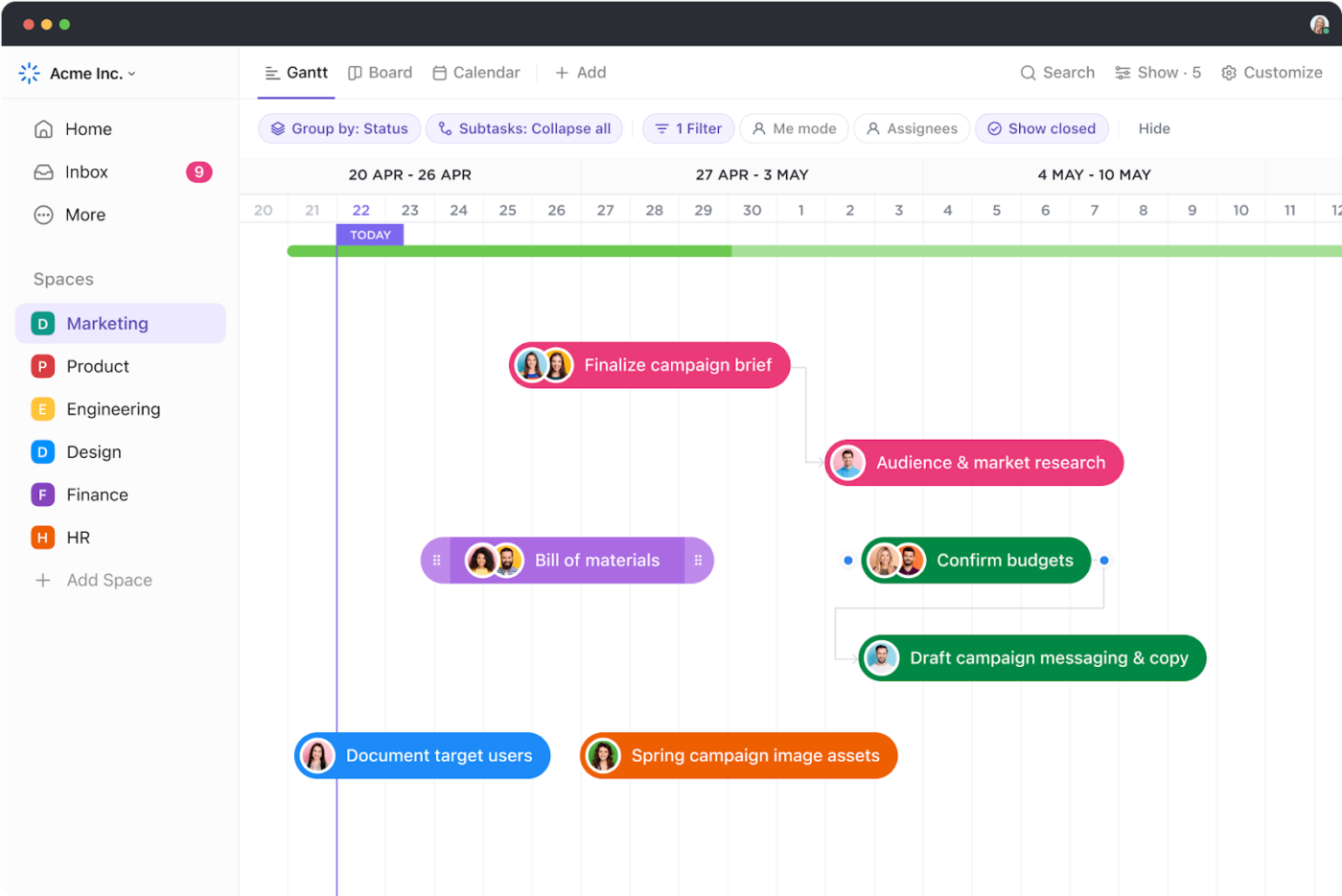

Use ClickUp Sprints to plan, execute, and review sprints efficiently. Estimate sprint points, set sprint durations, and create and assign ClickUp Tasks at the click of a button. Tracking progress is also simple through built-in burndown charts and velocity reports.

ClickUp’s collaboration tools, including task comments, @mentions, and real-time editing inside shared ClickUp Docs, enable team members to communicate effectively, share updates, and resolve issues promptly without switching across multiple tools.

Learn how to apply Agile to non-software teams in our video 👇🏽

Bonus: Adaptive Project Management!

2. Kanban

Kanban is a visual workflow management improvement tool. This tool makes it easy to see each project’s status, assignees, and progress.

For process improvement, Kanban acts as a whiteboard tool that allows you to map out your current processes and identify friction points.

Since it’s a visualization tool and not necessarily a methodology on its own, it’s best to combine Kanban boards with other process improvement methods. Even so, it’s a helpful tool for visualizing complex processes and simplifying them until you’re happy with the result. ✨

Common use cases:

- Content planning and execution

- Workflow visualization

Best for:

- Projects with fixed steps or phases

- Identifying workflow inefficiencies

Implementation tips:

- Visualize every step of your workflow. Use a Kanban board to lay out each stage of your process (e.g., To Do → In Progress → Review → Done). Clear visualization makes inefficiencies, delays, and blockers instantly noticeable

- Limit work in progress (WIP) to reduce context switching. Set strict WIP limits for each column to prevent task overload. This helps your team stay focused, finish what they start, and maintain a steady flow of work

- Measure and optimize cycle time. Track how long tasks take from start to finish. Shorter, more predictable cycle times are a key sign of a healthy, improving process

- Make process policies explicit. Clearly define rules for how work moves through each stage—e.g., what “Done” actually means or when something can enter “Review.” This builds team alignment and improves handoffs

- Continuously improve using flow metrics. Use Kanban analytics (like cumulative flow diagrams and lead time charts) to identify bottlenecks and experiment with process tweaks—then observe the results and iterate

Tools and templates to try:

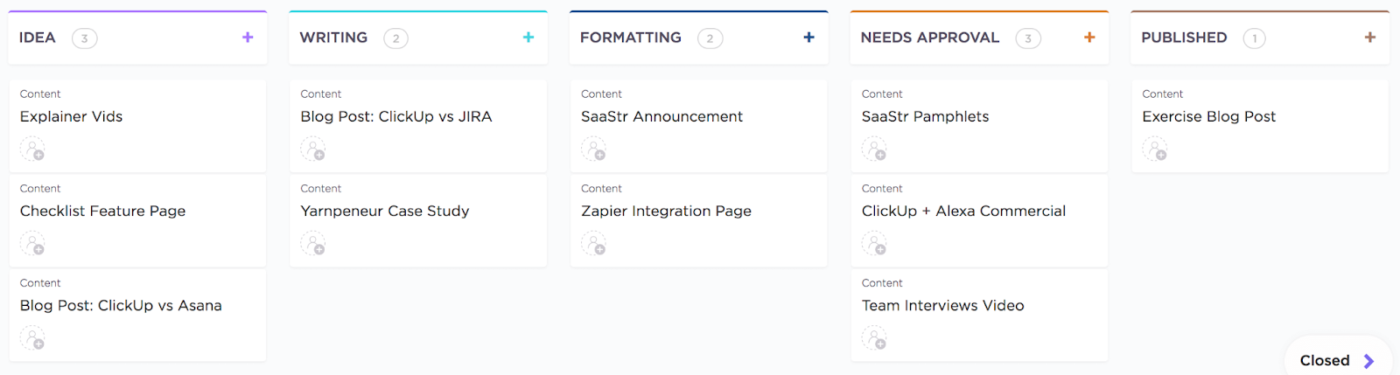

ClickUp’s Board View enables drag-and-drop functionality, allowing users to move tasks across different status columns effortlessly, reflecting real-time progress. Teams can define Custom Task Statuses in ClickUp to match their specific processes for a tailored Kanban experience.

📌 For example, a content marketing team using ClickUp might set up Custom Task Statuses like Idea, Researching, Writing, Editing, Ready for Review, Scheduled, and Published. This workflow helps them track each piece of content from the initial concept all the way through to publication.

In contrast, a software team’s custom statuses could include Backlog, Ready for Development, In Progress, Code Review, QA Testing, and Done. This setup aligns with the iterative nature of software development, emphasizing stages like peer review and quality assurance testing before marking a task complete.

3. Root cause analysis

Root cause analysis (RCA) is a problem-solving strategy project managers use to deal with the actual problem instead of its symptoms.

📌 For example, if you have an issue with customer support response times, your knee-jerk reaction might be to put pressure on your customer service team. But with RCA and a little digging, you might realize your tech setup is actually causing the delays, not your team. 👀

By taking the time to identify the true cause of an issue, you’ll work more efficiently and prevent problems from recurring.

Common use cases:

- Addressing system and safety failures

- Quality improvement projects

Best for:

- Complicated situations that need more than a simple fix

- Proactively preventing issues

Implementation tips:

- Start with the problem, not the symptom. When something goes wrong, it’s tempting to jump to quick fixes—but RCA demands that you slow down and define the exact problem clearly before you dig deeper

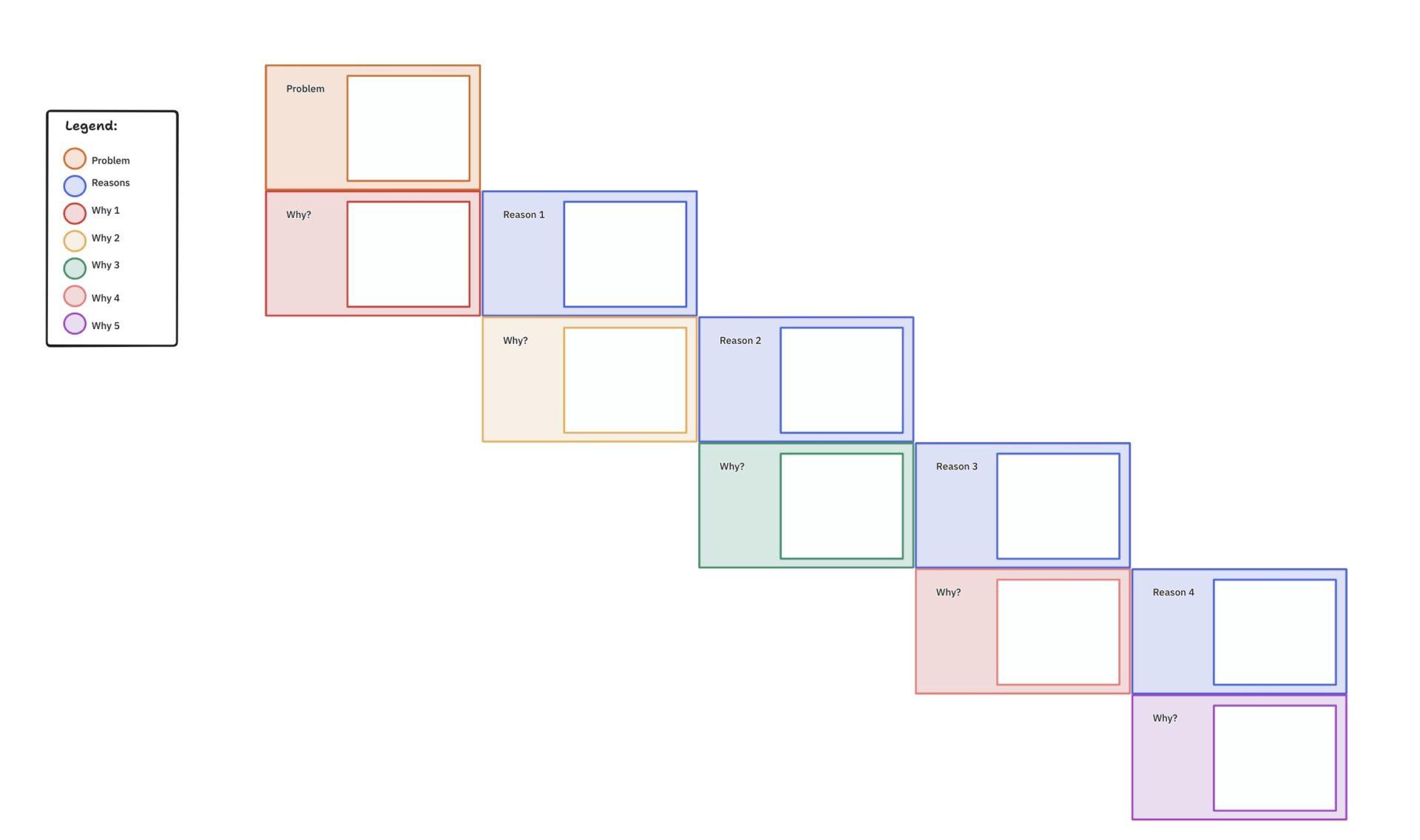

- Ask “Why?”, but don’t stop at one. Use the “5 Whys” technique to peel back the layers of an issue. Repeating the question helps uncover deeper systemic issues rather than surface-level causes

- Think visually: Have you mapped the cause and effect? Tools like fishbone (Ishikawa) diagrams or fault trees can help your team visualize contributing factors and spot connections that aren’t immediately obvious

- Who should be in the room? Involve people closest to the process, not just leadership. The frontline team often knows the reality behind the breakdowns—and the insights you’ll need to prevent them

- Don’t stop at identification—build in prevention. Once you’ve found the root cause, design solutions that eliminate or mitigate it long-term. This might include training, automation, policy changes, or clearer documentation

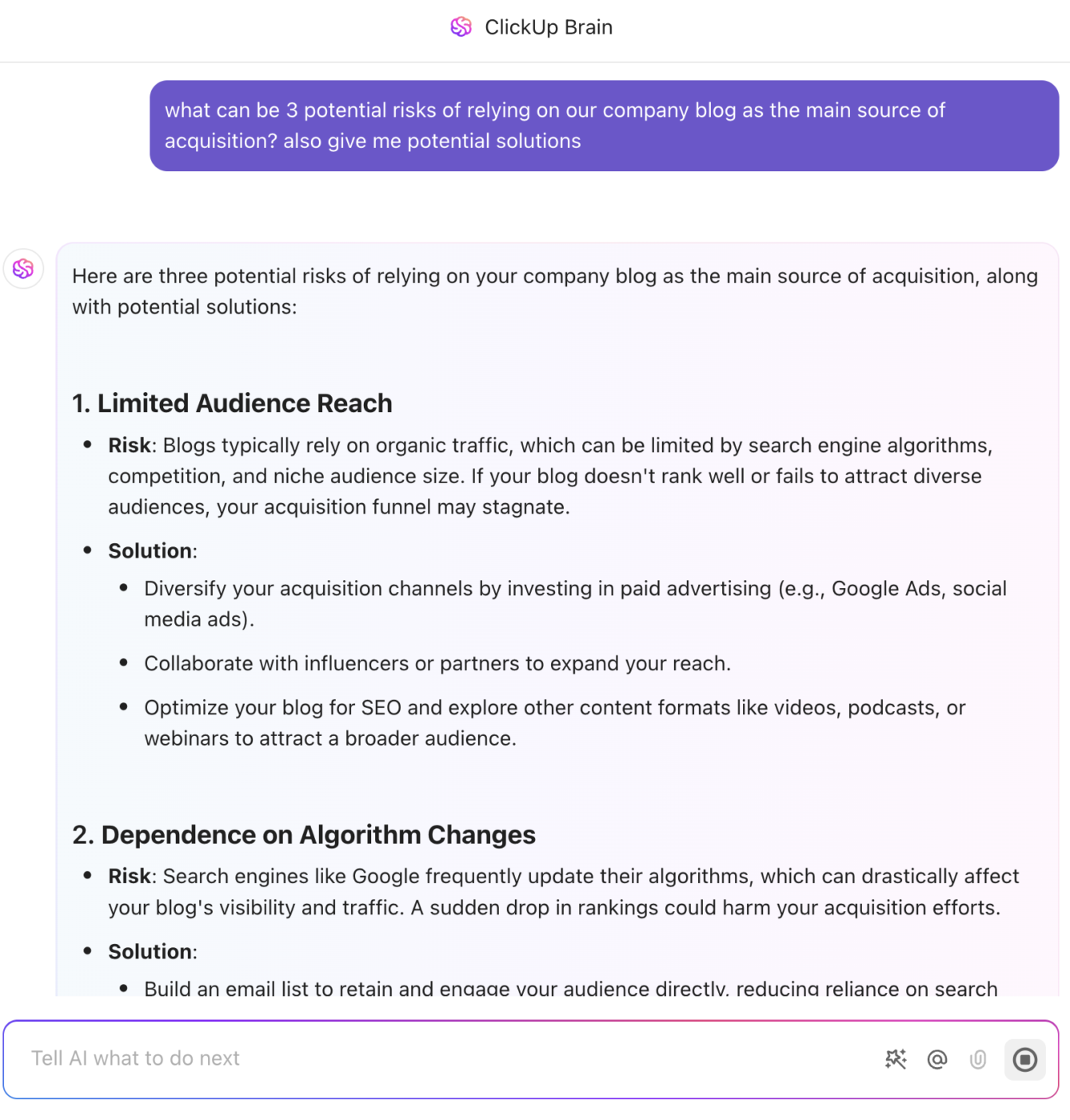

💡 Pro Tip: ClickUp Brain, ClickUp’s native AI assistant, can be of great help in RCA by summarizing complex issue threads, identifying recurring problems through natural language search, and auto-generating RCA documentation. It also suggests preventive actions to ensure long-term resolution and risk management.

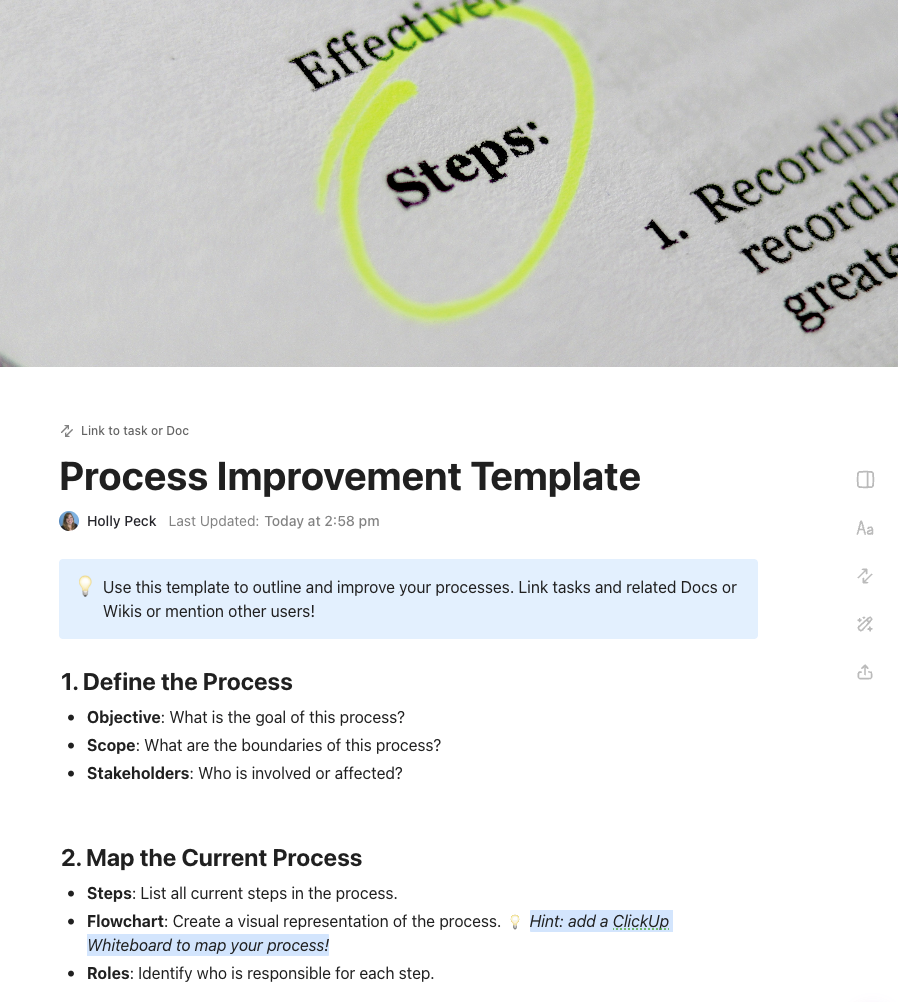

Tools and templates to try:

Whiteboards in ClickUp provide the perfect canvas for brainstorming potential causes leading to a problem. Use them to create visual representations by mapping out categories such as methods, materials, and personnel, to systematically explore contributing factors.

You can also use ClickUp’s Ishikawa (Fishbone) Diagram Template for this.

In addition, ClickUp’s 5 Whys Template guides teams through iterative questioning to uncover the root cause of issues.

It provides a straightforward format for documenting each “Why” and the corresponding answers.

4. Just-In-Time (JIT)

JIT is a production strategy in which items are created only as needed.

🧠 Fun Fact: The JIT manufacturing approach originated from Toyota, but it can be used by any business that relies on physical inventory or materials.

If you have a lot of inventory in stock and it’s tying up your budget, switching to JIT will minimize waste and improve your cash flow. 💸

Common use cases:

- Streamlining manufacturing processes to reduce inventory costs

- Minimizing material waste

Best for:

- Businesses with a reliable supply chain and quick production capabilities

- Organizations that need to reduce the costs of inventory and boost cash flow

Implementation tips:

- Reduce inventory—but tighten coordination. JIT works best when you minimize excess inventory, but that requires rock-solid communication with suppliers and internal teams to avoid stockouts

- Is your team ready to respond quickly? Train your staff for flexibility so they can adapt to changing demand, fix issues fast, and keep production flowing smoothly without delays

- Streamline the entire workflow—not just one part. JIT requires consistency across the process. Bottlenecks in one area (e.g., shipping delays) can break the entire system if not addressed holistically

- Use demand forecasting tools you trust. Accurate, real-time data is the backbone of JIT. Invest in tools or dashboards that help you predict and respond to customer demand with precision (like ClickUp Dashboards!)

Tools and templates to try:

ClickUp makes it easy to enable smooth, demand-driven workflows with minimal waste.

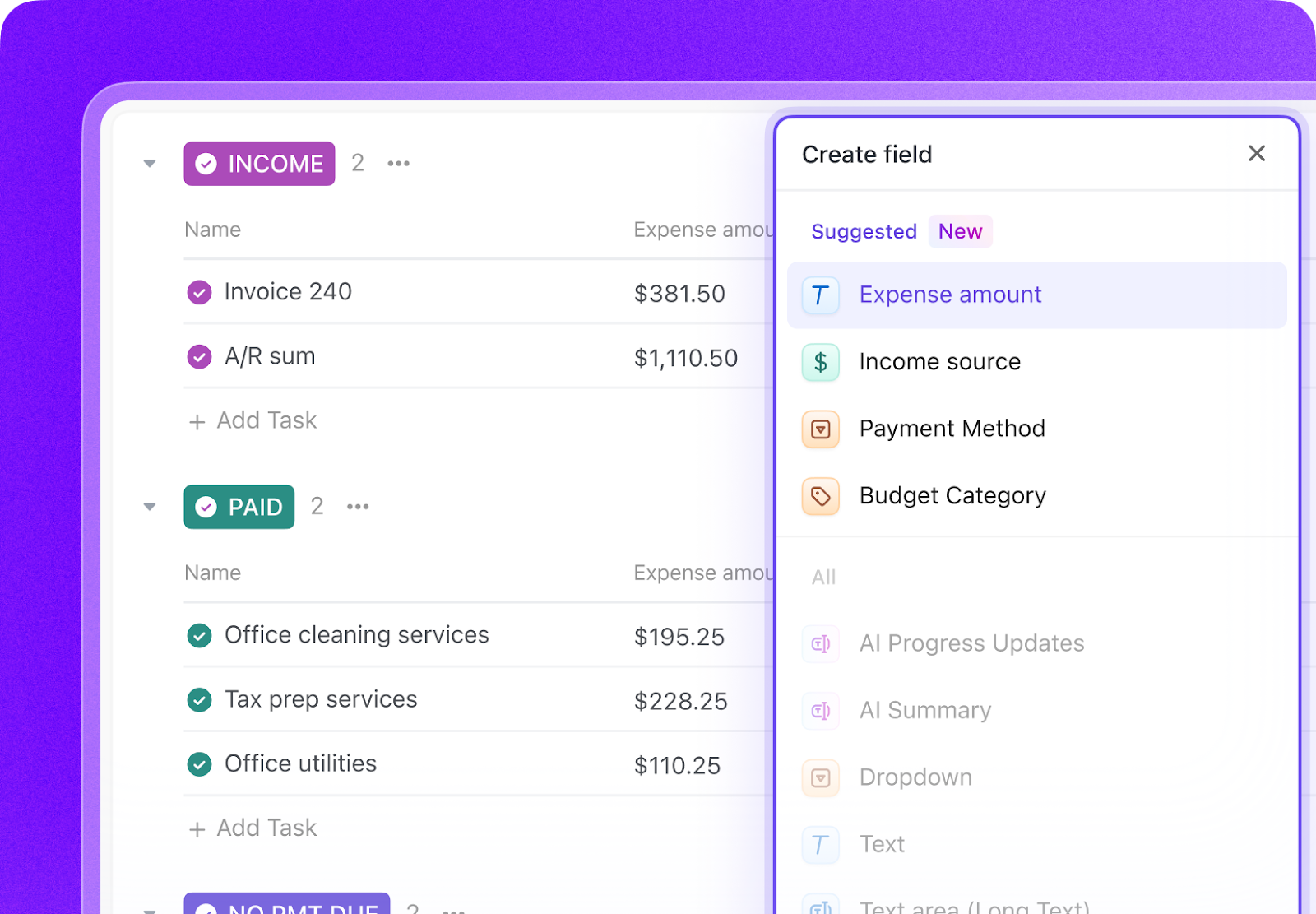

Teams can create Custom Fields in ClickUp to monitor inventory levels, reorder points, or task batch sizes, ensuring that work or materials flow only as needed.

ClickUp’s Gantt Charts visualize schedules and delivery deadlines in real time, helping align production with actual demand and avoid unnecessary buildup.

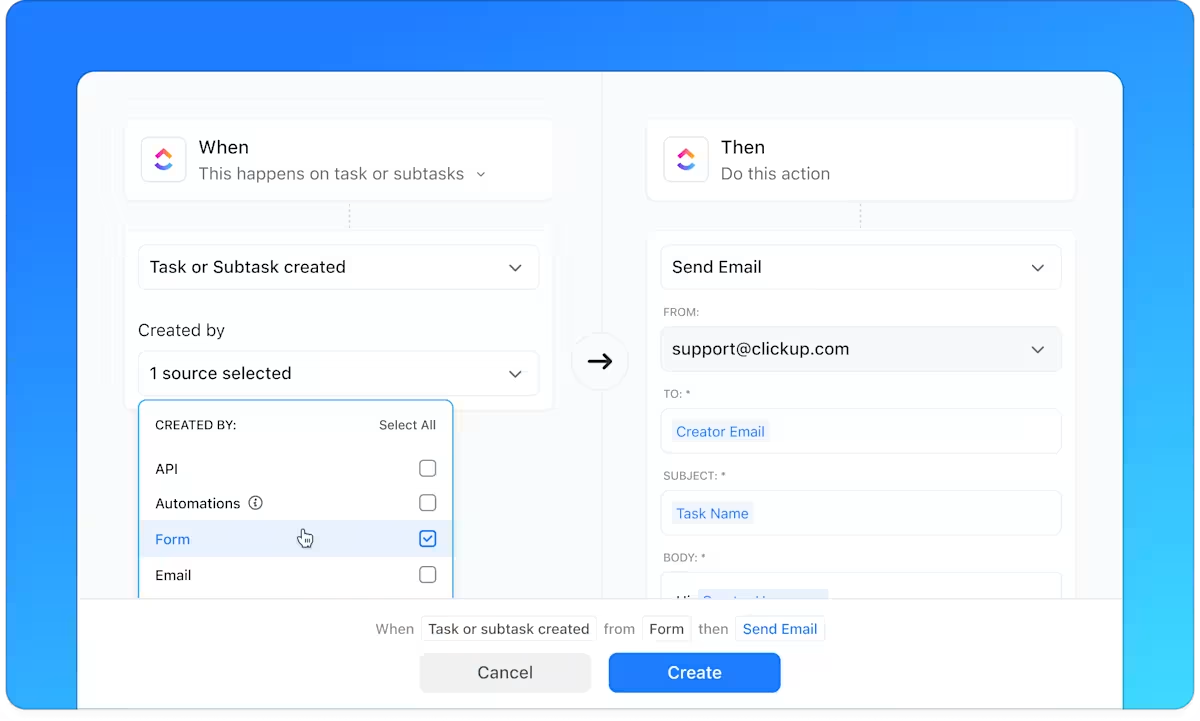

With ClickUp Automations, you can even automate task creation or notifications when stock or task capacity hits a threshold, so your team responds immediately without delays or overproduction.

5. SIPOC Analysis

Suppliers, Inputs, Process, Outputs, and Customers (SIPOC) is a process improvement methodology that visualizes processes at a high level.

It doesn’t get into the nitty-gritty details, but if you need to compare several processes simultaneously, SIPOC is the best tool for the job. SIPOC is also ideal if you want to quickly get everyone on board with your project.

Common use cases:

- Gaining a high-level view at the start of projects

- Clarifying components of a process

- Sharing a project’s scope with other stakeholders

Best for:

- Businesses in the early stages of process mapping

- Teams that need clarity on roles, responsibilities, and deliverables

- Complex processes that transcend departments or teams

Implementation tips:

- Start with the “P” and work backward. Define your Process first, then identify the Inputs, Suppliers, Outputs, and Customers. This keeps your analysis grounded in what actually happens day to day

- Are you seeing the full ecosystem? Use SIPOC to highlight how changes in inputs or supplier performance ripple down to impact customer outcomes. It’s a powerful way to spot where misalignments begin

- Get cross-functional input early. Pull in voices from every part of the SIPOC spectrum—especially customers and frontline teams. They often see what leadership overlooks

- Use your SIPOC diagram as a launchpad. Don’t just create it and forget it. Use the completed diagram to drive root cause analysis, gap identification, and smarter process redesigns

Tools and templates to try:

ClickUp’s ready-to-use SIPOC Template is designed to map Suppliers, Inputs, Process, Outputs, and Customers clearly and collaboratively. The process improvement template offers predefined columns for each SIPOC element, allowing users to systematically document and visualize their processes.

📌 For example, a product launch team can use this template to identify suppliers (designers, marketing), inputs (design files, campaign briefs), process steps (content creation, approvals, distribution), outputs (launch assets), and customers (sales teams, end-users).

With features like Custom Statuses, Custom Fields, and multiple views (such as SIPOC Board, Suppliers, Inputs, Processes, Outputs), teams can gain a comprehensive understanding of their workflows and identify areas for improvement.

6. Theory of Constraints

Theory of Constraints is a process improvement methodology that actively looks for roadblocks (constraints) and eliminates them to streamline workflows. You can’t eliminate every constraint, but even then, improving or removing a few bottlenecks can dramatically improve your processes. 🎯

Common use cases:

- Manufacturing lines that want to increase output

- Addressing supply chain management slowdowns

- Fixing issues with cash flow or wait times

Best for:

- Businesses that are trying to overcome bottlenecks or slow performance

- Organizations that need to significantly increase their output

Implementation tips:

- Don’t fix what isn’t broken. TOC starts by identifying the one constraint (or weakest link) limiting your system’s performance. Focus your efforts there before touching anything else

- What’s slowing you down right now? Constraints shift over time. Today it might be staffing, tomorrow it could be equipment. TOC is a continuous cycle—keep reassessing where the real limit is

- Exploit the constraint first, then elevate. Before investing in new tools or people, ask: Are we fully using what we already have? Often, small tweaks to scheduling, workflow, or prioritization can significantly boost throughput

- Don’t forget the “drum-buffer-rope” system. Use this TOC concept to synchronize work: the drum sets the pace (the constraint), the buffer protects it from disruptions, and the rope controls upstream flow to prevent overproduction

- Improve the constraint, then watch the constraint move. Once you’ve addressed one limiting factor, another will emerge. That’s a sign TOC is working—keep repeating the process to unlock more capacity

Tools and templates to try:

Easily visualize workflows and spot bottlenecks in ClickUp by tracking task progress across 15+ ClickUp Views. Gantt and Timeline views highlight scheduling conflicts, while the Workload View can pinpoint overloaded resources that might be constraints.

Use Task Priority Flags in ClickUp to monitor and focus efforts on tasks that may be critical bottlenecks. Automate notifications and task assignments when bottleneck tasks reach critical points, ensuring timely attention and resolution.

📮ClickUp Insight: Think your to-do list is working? Think again. Our survey shows that 76% of professionals use their own prioritization system for task management. However, recent research confirms that 65% of workers tend to focus on easy wins over high-value tasks without effective prioritization.

ClickUp’s Task Priorities transform how you visualize and tackle complex projects, highlighting critical tasks easily. With ClickUp’s AI-powered workflows and custom priority flags, you’ll always know what to tackle first.

Building custom Dashboards in ClickUp will help you monitor key metrics related to constraints, such as cycle time, task queue length, or resource availability, giving real-time insights into system performance.

3 Must-Try Process Improvement Methodology Templates

Methodologies are helpful, but even with a methodology in hand, you have to create all of the process documentation yourself. That’s a lot of work, isn’t it?

Fortunately, there’s no need to do process improvement solo. As we saw, ClickUp’s free templates are here to back you up, whether you need to understand your team’s scope of work or create SOPs for new processes. 🌻

Let’s look at some of the best ones now:

ClickUp Process Improvement Work Breakdown Structure Template

Instead of tracking everything via email, chats, or sticky notes, use the ClickUp Process Improvement Work Breakdown Structure Template.

It takes your big, audacious improvement goals and breaks them into smaller, digestible tasks. This template identifies bottlenecks in the process improvement process, assigns tasks, and tracks progress in one place.

ClickUp Process Improvement Project Charter Template

The ClickUp Process Improvement Project Charter Template is a must-have process document for kicking off your first process improvement project. Use this template to:

- Document your end goals, scope, and deliverables

- Identify your current state

- Define milestones and timelines

- Assign responsibilities and tasks

If you’re trying to plan a big meeting about process improvement, this charter template will get everyone on the same page, faster.

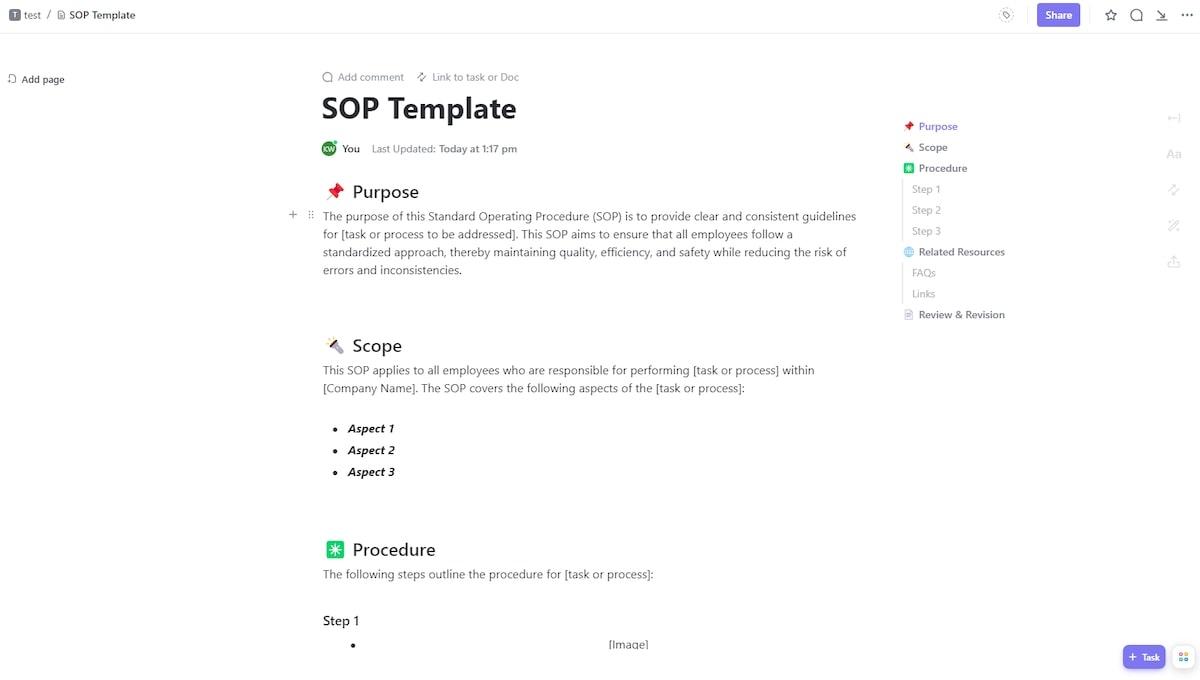

ClickUp Continual Improvement SOP Template

At this point, you have goals and a plan, but sometimes implementation is where projects grind to a halt. Don’t let procedural hiccups get you down. Use the ClickUp Continual Improvement SOP Template.

Standard operating procedures (SOPs) go into excruciating detail about how exactly your team will do continual process improvement. This ClickUp template also tracks progress and measures the impact of your changes, so you can tell pretty quickly if something works or needs retooling.

The Benefits of Implementing Process Improvement Methodologies

Everybody likes improvement, but is it really worth your time to use a process improvement methodology? Some teams can get by without one, but that isn’t a good way to see real, lasting change. Implementing process improvement methodologies comes with many benefits.

- Eliminate inefficiencies: Process improvement methodologies identify activities that don’t add value. They apply a critical lens to your processes to pinpoint redundancies and minimize waste, whether that’s in terms of time, resources, or materials 🛠️

- Reduce time-to-delivery: With improvement methodologies, you streamline workflows for even the most complicated processes. The benefit is that you work in a more straightforward way, which reduces confusion and shortens turnaround times 🙌

- Improve quality control: Process improvement methodologies give you clear metrics and benchmarks to understand how you’re doing. If you struggle with generating quality work at scale, business process improvement enables data-driven decision-making. Plus, templates and standardized processes reduce deviations and errors, ultimately improving the quality of your team’s work 🤩

⚡️ Template Archive: Check out these quality control templates!

- Boost customer satisfaction: Improving your processes, whether internal or customer-facing, has a direct impact on the customer experience. If you optimize the right things, this can boost loyalty and encourage repeat business 😄

- Encourage continuous learning and improvement: It won’t be overnight, but something amazing happens when you start improving processes: it creates a culture of problem-solving. A continual improvement process spurs more creative ideas and better working methods, which benefits your team and customers. It’s a true win-win 💡

- Increase profitability: Eliminating inefficiencies and optimizing workflows comes with a happy side effect: lower costs. Happier customers tend to spend more, so lower costs and higher earnings will boost your profitability 💰

Improve Processes and Streamline Productivity with ClickUp

No process is perfect, but there’s always room for improvement. Even if your processes are near perfect, things will continue to change. Follow the best process improvement methodologies to stay on the cutting edge of your industry while working in the most efficient way possible.

The good news is that you don’t have to do this alone. ClickUp combines the power of Tasks, Automations, Templates, Whiteboards, and more to streamline your work processes.

Experience the time-saving benefits of a truly all-in-one work platform. Sign up for ClickUp now—it’s free forever.