10 Kaizen Examples for Continuous Improvement

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Post World War II, Japan needed a miraculous overhaul to recover from the devastation caused to the public’s morale, infrastructure, and industries. The Kaizen philosophy came in as their savior; it went beyond fixing what was broken and pushed them toward striving to be better.

This philosophy became the cornerstone of Japan’s economic miracle, an iterative process propelling the nation from devastation to a global economic powerhouse.

Kai means ‘making a change,’ and zen means a way or a path.’ Today, this philosophy translates to ‘continuous improvement’.

This philosophy was turned into a strategy in lean manufacturing, wherein employees at all levels actively collaborate to make ongoing, small-scale process improvements in manufacturing, unleashing the company’s collective potential for constant betterment.

In this blog post, we’ll cover how Kaizen as a philosophy has evolved, review Kaizen examples, and explore tools for implementing this philosophy.

Kaizen methodology emerged in post-WWII Japan as a way of rebuilding the nation’s economy and, with it, its spirit.

American statistician W. Edward Deming arrived in Japan in the early 1950s to share statistical control processes to aid recovery. However, at Toyota, he found workers already using a scientific approach. Deming adapted his concepts into the Plan-Do-Check-Act [PDCA] cycle, which was followed by the workers during that time and has evolved ever since

Taiichi Ohno, a Toyota manager and Deming’s contemporary, incorporated Deming’s ideas, his own experience on the shop floor studying time and motion, and even elements of Henry Ford’s mass production [highly respected in Japan] into the manufacturing process.

Ohno’s guiding principle was ‘some days little up, some days big up’—the core of Kaizen’s incremental improvement philosophy. This fusion of various influences led to the creation of the Toyota Production System [TPS], which remains the gold standard for Kaizen and continuous improvement.

Since then, the spread of Japanese business philosophies has significantly impacted global business practices.

Did you know that Agile and Kaizen are closely related? Both emphasize the power of small, incremental changes for continuous improvement. Check out how you can extend these philosophies to various types of teams and industries through this short video:

To understand the true meaning of Kaizen, let’s go through its core principles:

Kaizen is, therefore, part action plan and part philosophy.

As an action plan, it includes organized improvement events where cross-functional teams, especially plant floor employees, tackle specific areas. And as a philosophy, it creates a culture where all employees actively suggest and implement improvements, becoming involved in every aspect of a lean company.

Management commitment is when the higher level executives directly participate in an organization’s critical program or aspect.

In Kaizen, managers are responsible for implementation and are the main motivators during the process. They should empower and encourage all company members to participate in every supply chain process and commit to full performance in their roles.

Traditionally, factory work followed rigid hierarchies and strict product management rules with limited employee input. Kaizen flips this script!

Kaizen hinges on empowering employees at all levels. By encouraging suggestions and active participation with continuous improvement tools, employees feel valued and invested in the company’s success.

As a result, a sense of ownership is created, fueling creative problem-solving. Empowered workers are more likely to identify inefficiencies and propose solutions, leading to a more agile and adaptable organization that continuously strives for improvement.

Kaizen thrives on a constant loop of problem-solving and improvement. It all starts with recognizing an issue or an opportunity for a better way of doing things.

This acknowledgment triggers action:

Root cause analysis [RCA] is a systematic method for identifying and fixing the underlying causes of a product or process’s defects, errors, or failures.

When implemented in RCA, Kaizen can help organizations identify the root causes of problems and continuously improve their processes to prevent them from reoccurring.

RCA is an important tool in continuous improvement methodologies such as Lean Manufacturing and Six Sigma. It involves investigating negative effect patterns, finding hidden system flaws, and discovering specific actions contributing to the problem.

One well-known RCA technique is the 5 Whys technique, which involves repeatedly asking ‘Why?’ in different ways at least five times to uncover the layers of symptoms.

Example: Late product shipments using Root Cause Analysis with Kaizen

Problem: A company is experiencing frequent delays in shipping finished products to customers.

Root Cause Analysis [RCA] with Kaizen:

The company assembles a cross-functional team with representatives from production, logistics, and sales. The team:

5 Whys Analysis: The team gathers around a visual representation of the process [e.g., flowchart] and asks “Why” questions about the delays:

Based on the analysis, the root cause could be the lack of preventative maintenance causing machine breakdowns and production delays.

Kaizen improvement suggestions:

Lean manufacturing has been heavily influenced by the Toyota Production System, which prioritizes eliminating waste, or ‘Muda’ in Japanese, within the production process.

Here’s how the Kaizen method tackles each type of Muda:

When put into practice, Kaizen reduces costs, improves accuracy, and establishes efficiency in every step of lean manufacturing.

Kaizen offers a toolbox of techniques for tackling waste, simplifying processes, and achieving lasting improvements across an organization’s various aspects.

The following techniques will help you understand how to merge Kaizen within your workflows to create an action plan for continuous improvement.

Kaizen principles emphasize continuous improvement, and value stream mapping is a powerful tool for enhancing process quality.

A Kaizen Value Stream Mapping [VSM] workshop is a multi-day event [2–5 days] where cross-functional teams collaborate to identify and eliminate waste. While doing a series of activities, the team creates maps depicting the current, ideal, and future state of their chosen product or service.

These activities include:

Process improvement isn’t just for factory floors. While it often tackles manufacturing productivity, its power extends across your organization.

Here’s where you can identify bottlenecks, simplify workflows, and unlock hidden potential:

Change management is important for the successful implementation of Kaizen. It’s the process of planning, implementing, and evaluating organizational changes. It involves communicating, engaging, and supporting stakeholders, especially employees who may be resistant to change.

True success with continuous improvement goes beyond a program. It’s about a cultural transformation where every employee takes ownership of improving things. Embedding continuous improvement into your company’s DNA drives lasting results, not a superficial implementation.

The Kaizen mindset can be cumbersome to implement and track, especially when you’re just starting to establish the process in your manufacturing business.

A lean project management platform like ClickUp can act as your guide. As the everything app for work, ClickIp provides visual tools to track each step of the process and helps you strengthen the ethos of transparency, open communication, enhanced productivity, and accurate work management.

Let’s look at various ClickUp tools and their role in implementing Kaizen in your business:

Mastering operational excellence is not easy as it requires a deep conceptual understanding of Kaizen and applying it to real-world business scenarios. Here are the key steps for implementing Kaizen:

Brainstorm as a team to pinpoint processes or departments that could most benefit from Kaizen. To start with, you’ll need to address bottlenecks and delays by getting your team’s and consumers’ opinions.

Use ClickUp Forms to get feedback from customers and employees. Create intuitive forms with conditional logic that evolve as people answer. Share them in real time with ClickUp Chat, which lets you @mention people in comments, assign tasks, attach docs, and so much more.

Let’s say your feedback survey reveals that 70% of your customers feel your mobile app search is buggy, and only 10% feel that the home screen loads slowly. You could prioritize fixing the search over the load speed, recruit a team of engineers to solve it, and assign each relevant engineer specific Tasks in ClickUp, like writing new code, running tests, staging it, and finally making it live.

With powerful ClickUp Automations, you can fully control and turn form responses into tasks that plug directly into your workflows.

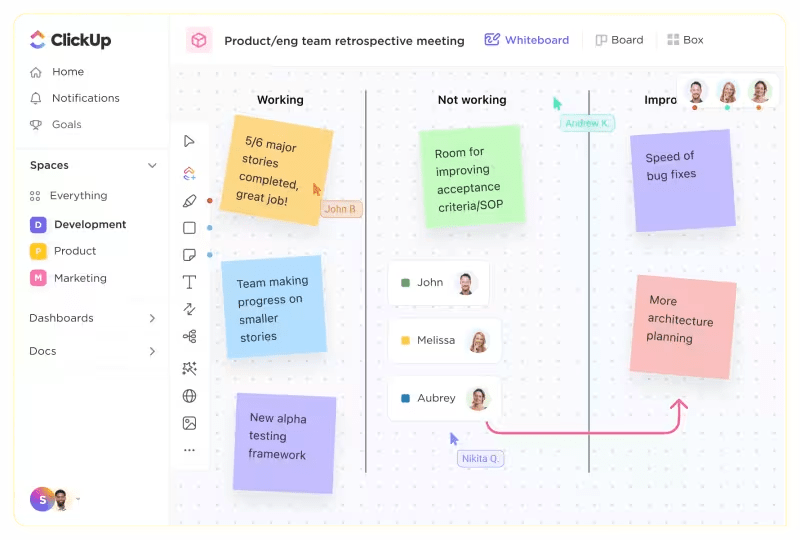

After selecting your target process, establish specific, measurable, achievable, relevant, and time-bound [SMART] goals for your Kaizen initiative. Use ClickUp Whiteboards to visually capture goals and ensure clarity for the team. Your goals should be clear, concise, and directly tied to the improvements you aim to achieve.

This visual tool allows you to break down overarching goals into smaller, actionable steps, making the path to improvement more manageable and trackable. Use digital post-its to write down idea topics, map them further into sub-topics, and assign team members tasks to find solutions.

📮 ClickUp Insight: Low-performing teams are 4 times more likely to juggle 15+ tools, while high-performing teams maintain efficiency by limiting their toolkit to 9 or fewer platforms. But how about using one platform?

As the everything app for work, ClickUp brings your tasks, projects, docs, wikis, chat, and calls under a single platform, complete with AI-powered workflows. Ready to work smarter? ClickUp works for every team, makes work visible, and allows you to focus on what matters while AI handles the rest.

Assemble a Kaizen team that represents the diverse perspectives of everyone involved in the target process.

Whiteboards are instrumental in collaboration. Team members from different departments can access the board simultaneously, add their insights, and brainstorm improvement ideas in real time.

A centralized platform such as ClickUp ensures everyone is on the same page and that valuable contributions from all areas of expertise are considered. Involve a leader who can provide the resources, make decisions, and cultivate the advocacy necessary for the Kaizen initiative to thrive.

Having a leader on board rings true to Kaizen’s philosophy as they actively participate in discussions and brainstorming sessions, sending a strong message of commitment from leadership.

Physically observe the current process in action. Capture key observations, bottlenecks, and pain points through photos, notes, and annotations by directly embedding them on the whiteboard.

This is known as taking a Gemba Walk, which means going to places where work is taking place to observe and identify areas of improvement.

Using ClickUp Table View, create a digitally accessible spreadsheet to record data you’ve gathered about the current process, such as cycle times, error rates, and customer feedback. You can directly link this to relevant SMART goals on your whiteboard.

Use the visual steam mapping method on your whiteboard software to map out each process step, highlighting the flow of action, information transfer, and potential waste [Muda].

Use shapes and sticky note features to represent different process stages and visually identify inefficiencies.

For specific bottlenecks, use the 5 Whys technique directly on the whiteboard. Ask ‘Why?’ five times to delve deeper and identify the root cause of problems. You can comment on the whiteboard or ask for clarification by communicating openly on ClickUp Chat.

Explore different approaches through collaborative drawing tools, allowing team members to sketch out potential solutions and workflows.

Try ClickUp Mind Maps, idea trees, and other visual formats to generate creative solutions for eliminating waste and simplifying the process.

Benchmarking research can also be visually incorporated. Compile findings from competitor analyses and industry best practices, allowing the team to compare their current process against external benchmarks. Visualize competitor workflows and best practices side-by-side with their process map. The team can identify areas for improvement and draw inspiration for more innovative solutions.

Collaborate on a clear action plan outlining specific improvement steps, timelines, and responsible individuals. You can make an action plan on the whiteboard or use a pre-built one that’s ready-to-use and fully customizable, like the ClickUp Action Plan Template.

This whiteboard template goes beyond basic action plans, providing features tailored explicitly for the Kaizen methodology:

Once a successful improvement is verified, document the revised process and establish it as the new standard on your whiteboard.

Use ClickUp Dashboards to track product management KPIs and metrics and observe the effectiveness of implemented changes. You can also track deadlines, manage tasks, observe workload, and see who’s working on what in real time.

Encourage ongoing feedback from team members using comments and discussions on the whiteboard. Keep the Kaizen process visible and adaptable to bring alive a culture of continuous improvement.

A Kaizen event is an intensive workshop focused on rapidly improving a specific process within your organization.

Here are some tips for preparing for a Kaizen event:

Get set to host your Kaizen event and see continuous workflow improvements.

Leadership is crucial to the success of Kaizen implementation not only in manufacturing but also in establishing lean principles in software development.

Senior leaders are responsible for setting the stage for Kaizen, providing support and resources, and creating an environment for positive change.

They often use the Hoshin Kanri approach [a top-down strategy that involves management setting goals and employees implementing them] to align goals and improvement efforts.

Kaizen leaders should also have empathy, digital soft skills, data analytics, a growth mindset, and creativity.

Leaders can demonstrate their commitment to Kaizen by:

As we’ve covered, implementing Kaizen in your manufacturing process isn’t easy.

However, by equipping you with a step-by-step guide, Kaizen event prepping tips, and defining the role of leadership, we hope we’ve driven the process home.

Here are some key success factors for Kaizen implementation:

Kaizen offers a powerful framework for optimizing processes, increasing efficiency, and achieving long-term success.

Here’s a breakdown of the key benefits and impactful outcomes organizations can expect when using Kaizen:

Kaizen is more than an arsenal of philosophical strategies and processes; it also includes tools to equip your organization to achieve lasting results.

We’ve already covered some of these above, such as Value Stream Mapping [VSM], 5 Whys Analysis, and Gemba Walks.

Here are two more that can help you build robust operational workflows in your organization:

ClickUp also offers a range of built-in digital tools to streamline your Kaizen implementation.

Kaizen is a broad philosophy and an even more comprehensive process with a number of implications.

This blog post is just the tip of the iceberg. To know more about this, here are some helpful books and study materials on the topic:

This journey of continuous improvement doesn’t have to be complex. Incorporating Kaizen principles and using the right tools can empower your teams to make significant strides.

ClickUp, with its suite of collaborative features and visual tools, such as ClickUp Whiteboards, ClickUp Dashboards, ClickUp Forms, and several customizable templates, can be your central hub for taking on Kaizen initiatives and excelling at them.

Sign up for ClickUp today and start optimizing your business processes!

© 2026 ClickUp