Best Factory AI Alternatives for Smarter Operations

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

According to McKinsey’s latest ‘State of AI’ survey, 88% of companies now use AI in at least one business function.

Factory AI is one of the popular names in this space. However, on manufacturing floors, adoption isn’t as straightforward as it seems. Customising it to fit legacy machinery or mixed equipment setups can demand more engineering effort than expected. And unique production workflows often require workarounds.

In this blog, we’ll explore the best Factory AI alternatives that offer better workflow orchestration, machine data integration, and predictive analysis. 💁

Let’s see how these workflow automation tools stack up against each other:

| Tool | Best For | Best Features | Pricing* |

| ClickUp | All-in-one project management & workflow optimization for teams of all sizes | ClickUp Docs for relational SOPs & process documentation, ClickUp Brain for AI-driven insights, Automations & Dashboards for real-time operations | Free Forever; Customizations available for enterprises |

| MaintainX | Mobile-first maintenance execution for mid-sized manufacturing teams | AI voice memos, smart procedure guidance, IoT integrations, photo/video work orders | Free; Paid plans from $25/user/month |

| Limble CMMS | Simple, effective maintenance management for large teams | Automatic workflow generation, AI-driven PM Builder, predictive analytics | Custom pricing |

| Fracttal One | Cloud-based + IoT-driven maintenance for enterprises | Prebuilt AI apps, scenario planning, and Energy Management tools | Custom pricing |

| Tulip Interface | No-code shop-floor workflows for large manufacturing teams | Drag-and-drop app builder, live IoT data, AI-powered operator guidance | From $100/month per interface |

| C3 AI Manufacturing | Enterprise-scale industrial AI for large cross-functional teams | 3D process simulations, AR workflows, and MES execution | Custom pricing |

| Siemens MindSphere | IoT machine analytics & asset monitoring for enterprises | Native PLC integrations, AI-driven OEE monitoring, cloud-to-edge management | Custom pricing |

| Dassault DELMIA | Full digital manufacturing & digital twin solutions for multinational enterprises | AI Reliability Scores, Smart Alerts, and inspection collaboration tools | Custom pricing |

| KONUX | Predictive rail asset monitoring for the railway industry | Machine health monitoring & optimisation | Custom pricing |

| Augury | Machine health monitoring & optimization for large manufacturing teams | Edge-native sensor fusion, AI diagnostics, remote monitoring | Custom pricing |

When you pick an AI tool, you must think of all the production lines, sensitive data, and operational efficiency that’s on the line.

Here’s a simple checklist of aspects to assess to ensure you’re picking the right Factory AI alternative for your operations strategy:

📮 ClickUp Insight: 34% of workers say the biggest barrier to automation is uncertainty about which tools to use. While many want to work smarter, they’re overwhelmed by the choices and lack the confidence to take the first step. 😓

ClickUp removes this confusion by offering intuitive, user-friendly AI Agents that can automate your work within a single platform—no need to juggle multiple tools. With features like ClickUp Brain, our AI assistant, and custom AI agents, teams can automate processes, plan, prioritise, and execute tasks without advanced technical expertise or tool overload

💫 Real Results: Lulu Press saves 1 hour per day per employee using ClickUp Automations, leading to a 12% increase in overall work efficiency.

Let’s explore some of the best Factory AI alternatives that go far beyond basic CMMS or monitoring to make an operations manager’s life easy. 👇

Our editorial team follows a transparent, research-backed, and vendor-neutral process, so you can trust that our recommendations are based on real product value.

Here’s a detailed rundown of how we review software at ClickUp.

Work sprawl is real. App switching and fragmented workflows contribute to a hidden ‘tax’ on mental energy and time. In fact, employees spend 61% of their working hours just sharing, searching, or updating information, rather than doing meaningful work. On top of that, 75% of workers use disconnected AI tools, creating what’s called an ‘AI sprawl.’

The solution is a converged AI workspace like ClickUp. It’s the everything app for work that combines project management, documents, and team communication, all in one platform—accelerated by next-generation AI automation and search.

Let’s look at how it helps workflow optimization:

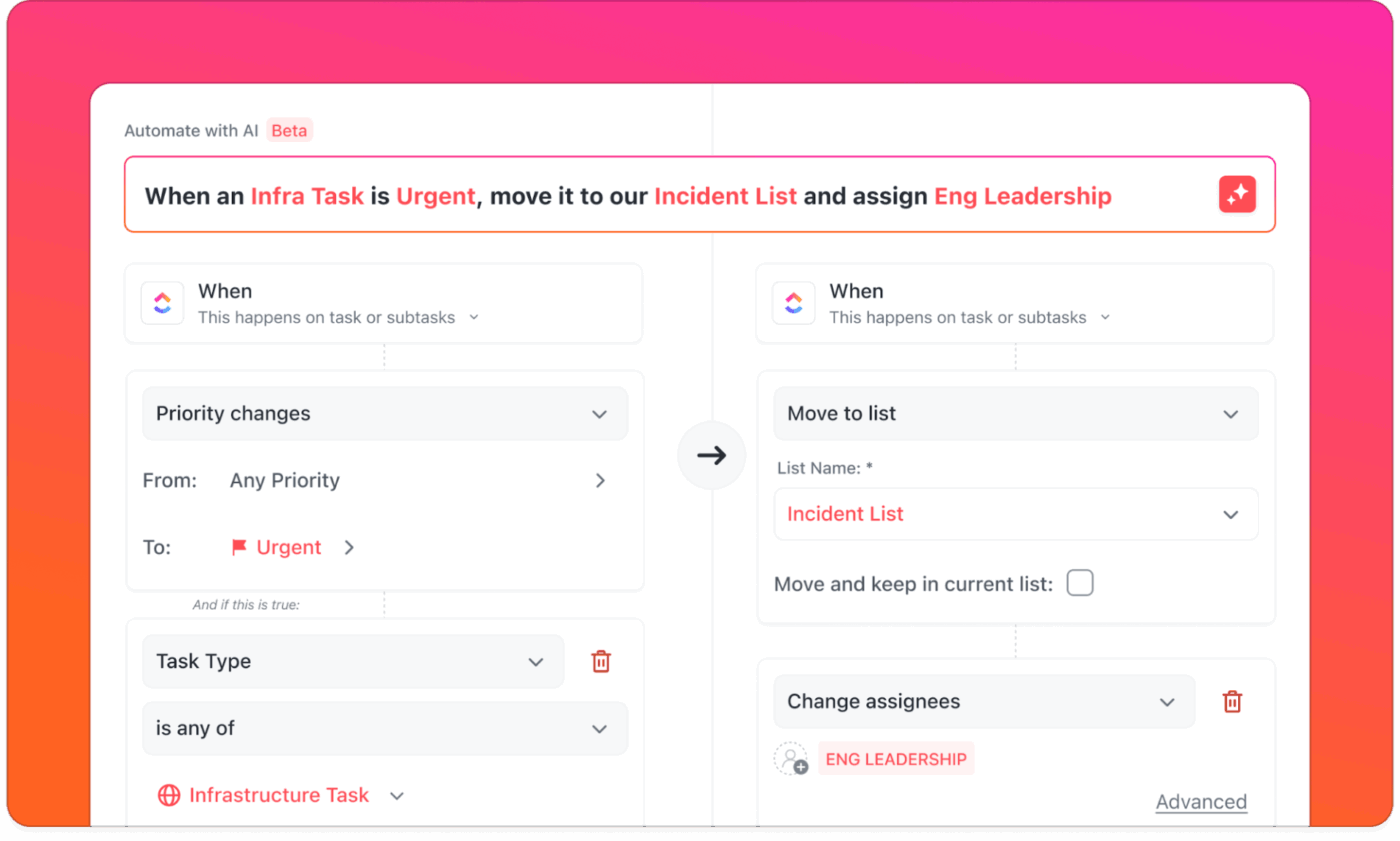

ClickUp Docs is a centralized knowledge base for engineering procedures, maintenance checklists, and SOP templates. Unlike static files, Docs in ClickUp are relational. This means you can link them directly to ClickUp Tasks, pin them to dashboards, and control their versions as workflows evolve.

The flexible, rich formatting lets you add collapsible headers, tables, subpages, callouts, flowcharts, and embedded videos for operator training. Engineers can embed equipment diagrams or CAD snapshots, while quality teams can integrate inspection forms or NCR workflows directly into the doc itself.

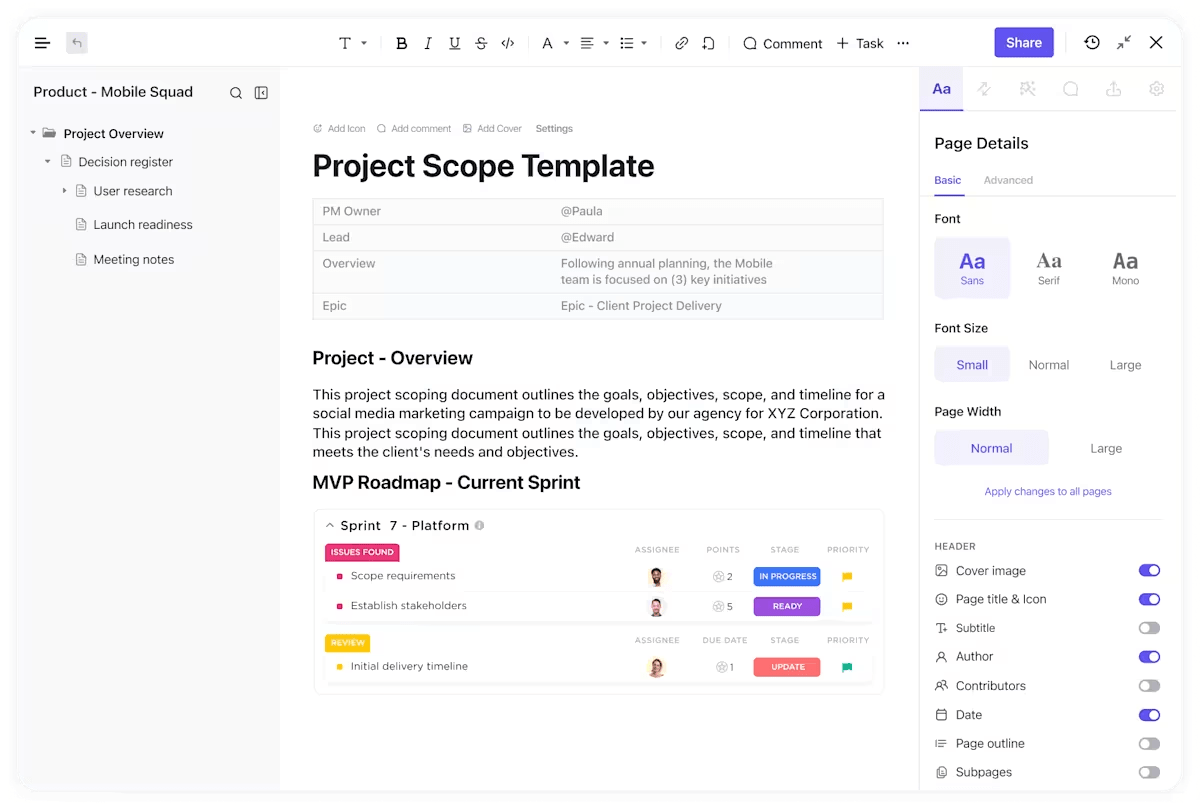

ClickUp Brain, the platform’s AI-powered assistant, is built for operational context. Since it lives in your workspace, it can read SOP docs, analyze task history, track workflows across shifts, pull trends from dashboards, and translate them into actionable suggestions.

Its AI Project Manager functions like a virtual production coordinator. It automatically tracks progress, flags delays, generates task lists, and can even draft stand-up reports based on real activity.

For instance, a maintenance supervisor could say: Identify which PM tasks were delayed this week and generate a catch-up plan for the night shift. Brain analyzes overdue tasks, groups them by asset criticality, and builds a prioritized task list in just seconds.

Here are some example prompts to help you use AI for operations management:

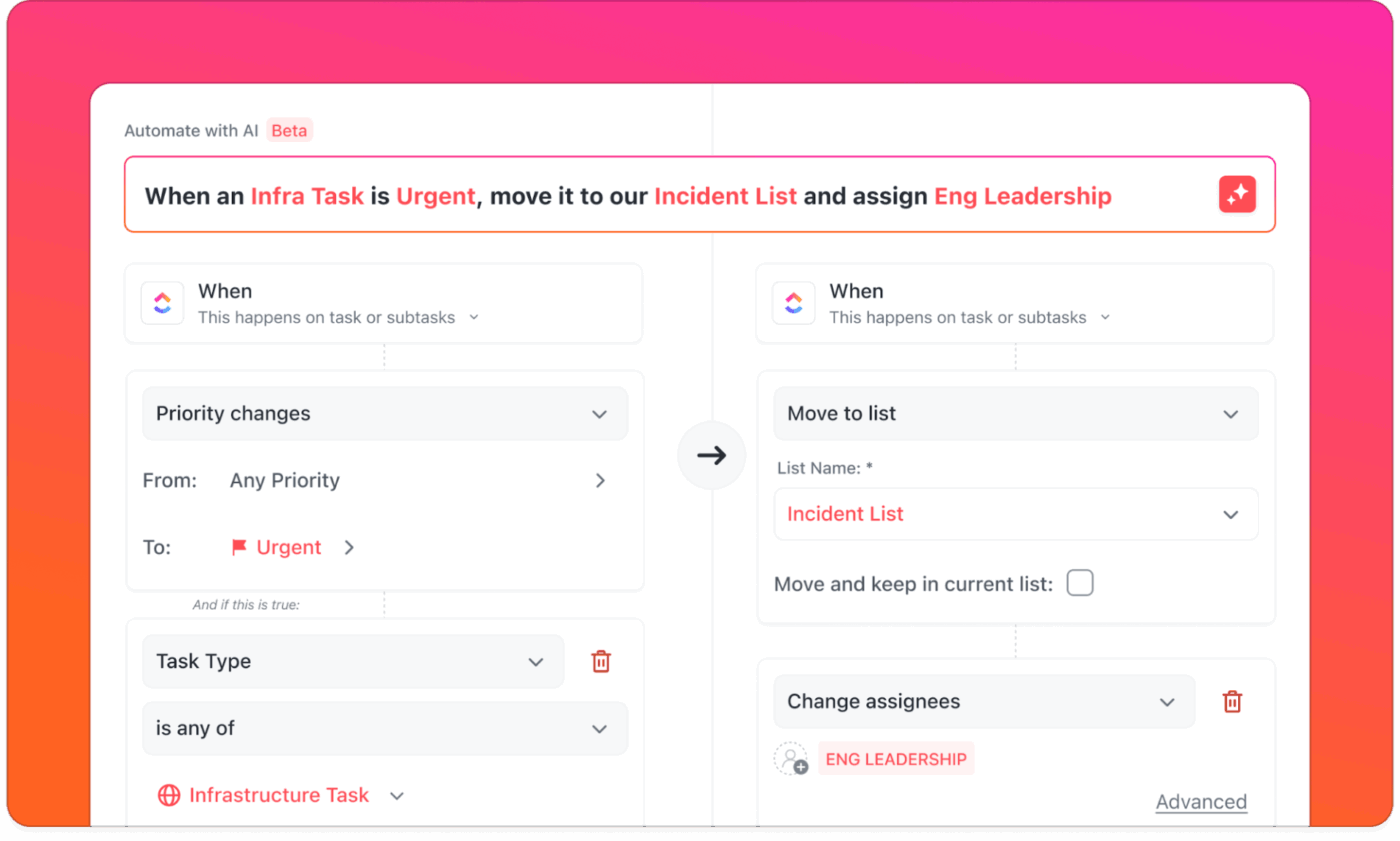

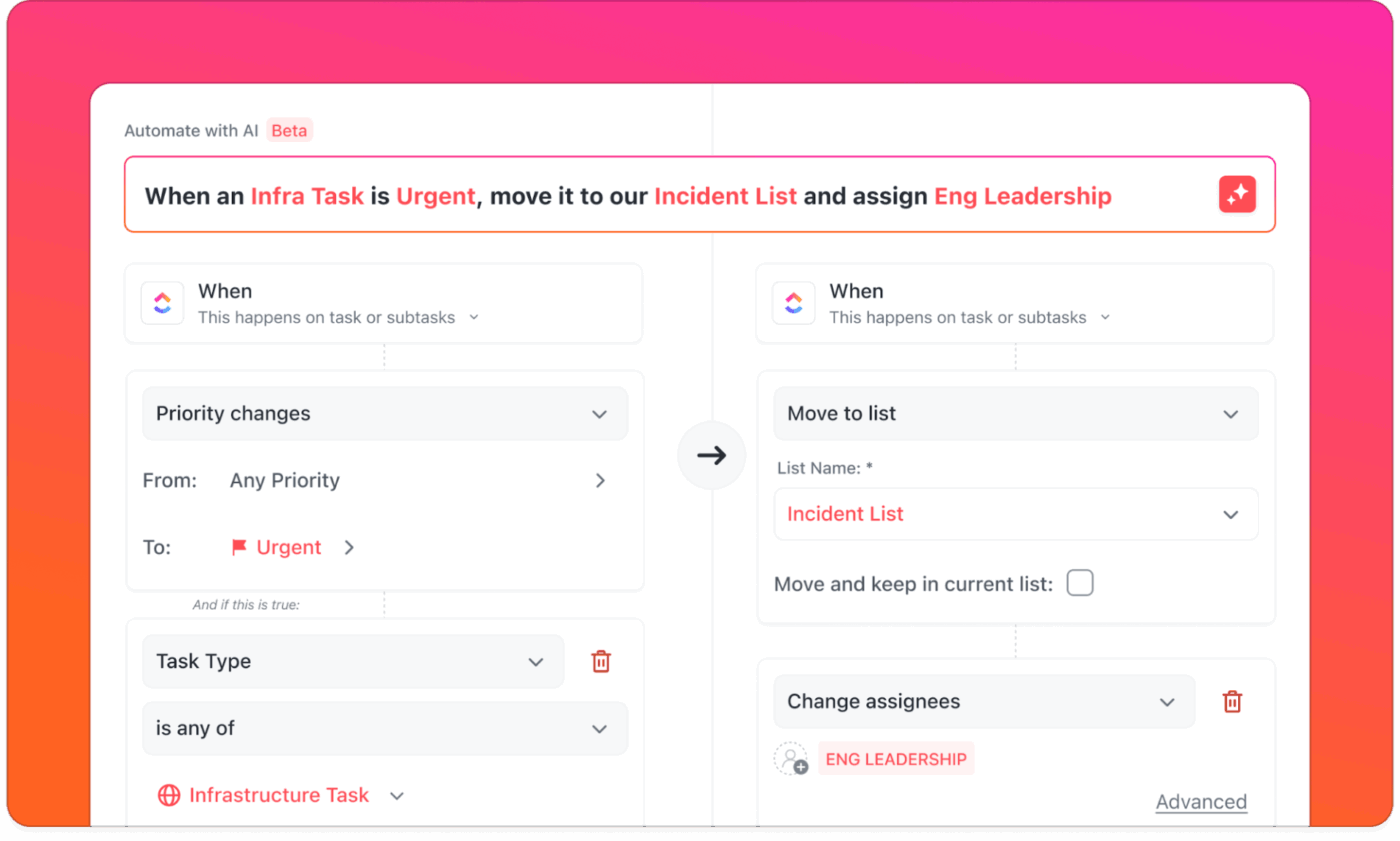

ClickUp Automations reduces manual orchestration that slows down operational work. Routine handoffs, such as assigning technicians, routing approvals, and updating statuses, all occur automatically based on predefined rules or AI logic.

For instance, if a machine failure is logged via a ClickUp Form, Automations can assign the task to the right technician, generate a subtask checklist, notify the maintenance lead, and open a post-mortem doc for later analysis.

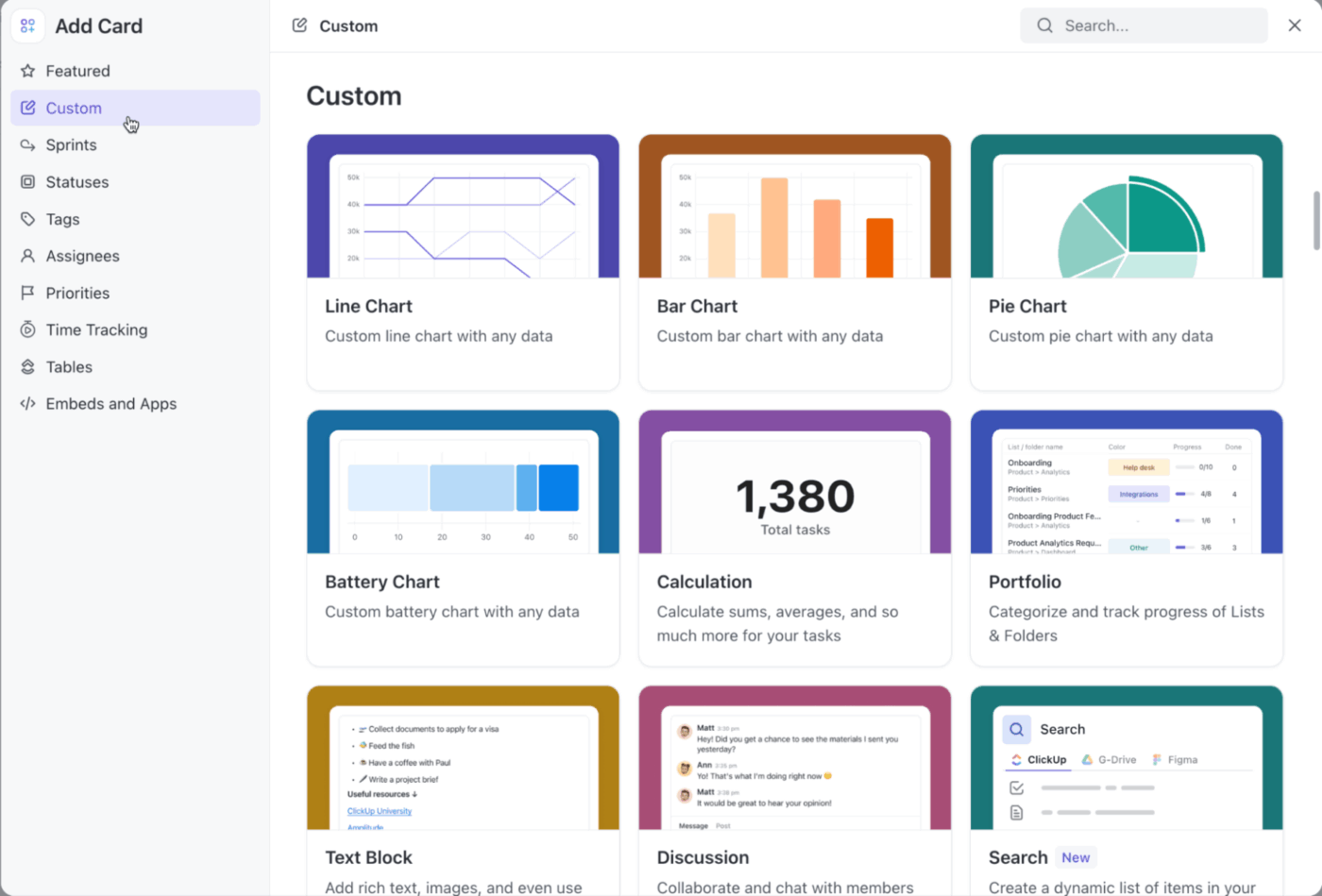

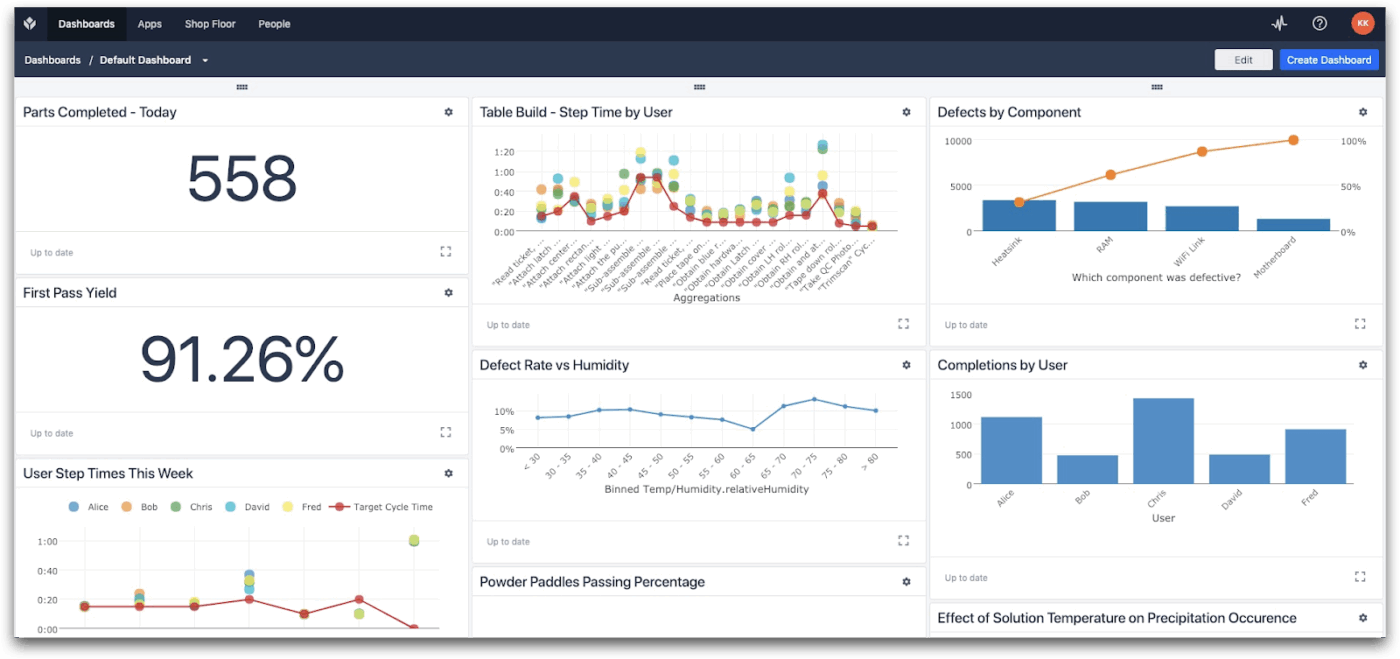

ClickUp Dashboards function as live operational control towers. Instead of pulling reports from individual systems, teams can view OEE trends, maintenance backlog, unplanned downtime frequency, ticket SLA adherence, inspection results, and resource utilization.

For instance, a production lead might maintain an operations dashboard tracking metrics with:

This review really says it all:

ClickUp brings everything we need into one place: task management, documentation, chat, and project planning. It replaced tools like Asana, Slack, and Notion for us, which simplified our workflow a lot.

Each team uses it a bit differently, but we can still stay connected across the company. We especially like the custom views (List, Calendar, Gantt) and the ability to automate recurring actions. The new AI assistant helps us create tasks faster and summarizes project details well.

🚀 ClickUp Advantage: ClickUp Brain MAX’s Talk to Text is an excellent tool for operations managers on the floor. Speak directly into ClickUp and log observations, report issues, or generate action items instantly.

For instance, if you walk past a machine showing signs of early wear, just talk into your phone: ‘Flag maintenance for Press Machine A. Vibration levels increasing, check bearings in the next shift.’ ClickUp Brain turns this immediately into a ClickUp Task, assigns it to the right team, and tracks it all.

Here’s why you should turn to it:

Unlike Factory AI, which often functions as a separate analytics layer, MaintainX embeds AI directly into daily maintenance and work execution. The frontline tool reduces downtime and improves procedures as work happens, including procedure creation, project reporting, anomaly detection, and labour planning.

Features like AI voice memos, contextual technician assistance, and smart procedure guidance ensure that insights flow to the people on the floor. Plus, you don’t have to manually prep data. The tool structures, cleans, and contextualises data when it’s captured (from handwritten notes, images, and even free text).

It also scales well with an enterprise-ready design. You get native integrations for IoT sensors, role-based permissions, a central data model, and multi-site performance insights.

Here’s what a G2 user had to say:

I would say that MaintainX is extremely user-friendly, regardless of your previous experience with other CMMS systems. One of the biggest advantages is having it available across all devices – phone, tablet, or laptop. The ability to access it online through a web page adds great flexibility, allowing you to retrieve information without any obstacles. Another major benefit is real-time tracking. Seeing live data with timestamps and updates provides full visibility into work orders and assets, which is a game-changer for managing operations.

🧠 Fun Fact: The first known ‘assembly line’ dates back to ancient Venice. Shipbuilders organised materials and labour in sequential steps to speed up production.

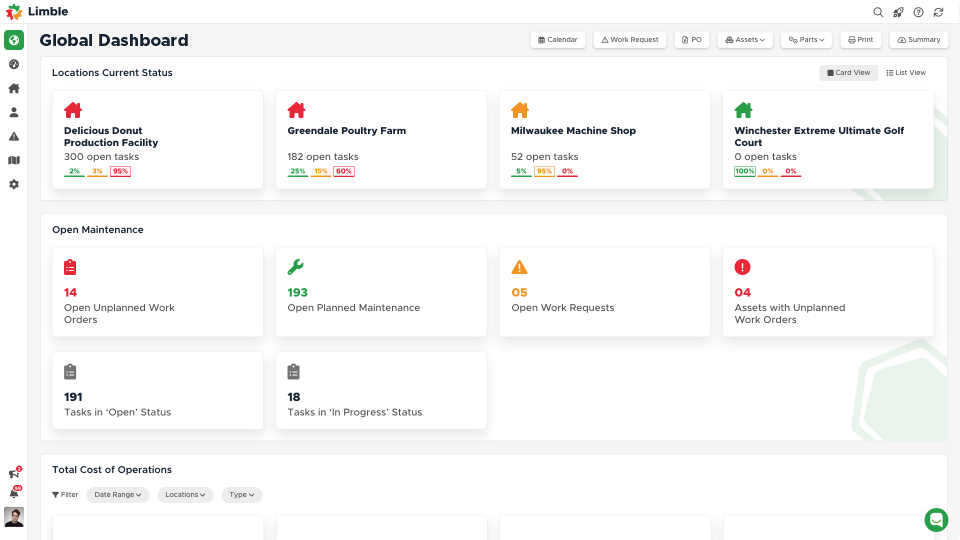

Limble focuses on making maintenance execution easier to roll out and scale. While Factory AI requires heavy setup, this platform shortens this initial stage by generating preventive routines and workflows automatically using asset metadata.

Additionally, its AI assists in planning and execution. The PM Builder helps create standardized routines instantly, while predictive analytics and IoT integrations flag early warning signals.

Limble also automates routing, escalation, and reporting based on asset criticality or sensor triggers. This way, your maintenance teams get clear visibility into resource management, costs, and downtime impact.

Straight from a real-life user:

Limble is a great CMMS tool that allows for quick set up, is simple to use, and has a great support structure for implementation. We have even had requests from other departments to use the system to track other resources!

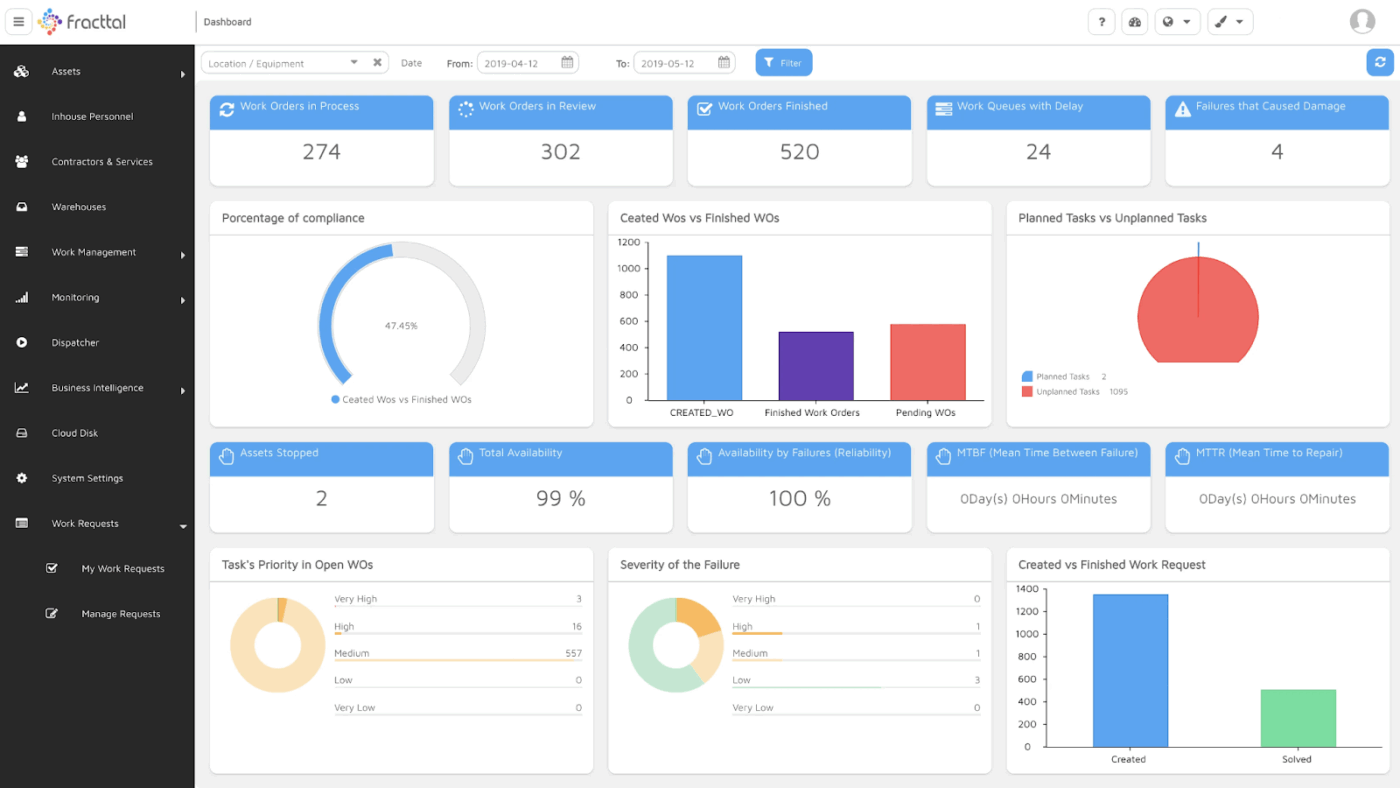

Fracttal One takes an IoT-first approach, positioning itself as a fully mobile, intelligent maintenance platform. Where Factory AI often struggles to integrate with real-time sensor data, this platform builds its workflows around it.

Signals about temperature, vibration, speed, and pressure from connected equipment feed directly into its predictive engine. This automatically triggers alerts, creates tasks, and escalates issues before failures disrupt operations.

The platform’s strength is its automation and traceability. With asset hierarchy, compliance structures, inventories, and work orders, Fracttal turns condition data into decisions. Its AI dashboard generator gives leaders visibility into KPIs and trends across plants, fleets, and facilities.

From a Capterra review:

Very great maintenance app, great for managing my business…The price, it´s often very hard to chose if pay the membership or continue with the older method

🧠 Fun Fact: Some factories in the early 1900s hired ‘human alarm clocks’ called knocker-uppers to wake up workers, particularly during the Industrial Revolution. They would go door-to-door, using long poles, batons, or even pea shooters to tap on windows and make sure people got up on time for their shifts.

Tulip takes a different path altogether: instead of traditional CMMS or analytics tools, it allows frontline teams to build their own apps without coding. Where Factory AI sits mostly in dashboards or reports, this tool embeds AI inside the workflows operators use on the floor.

You get assembly steps, troubleshooting guides, label checks, inspection routines, and quality capture. Everything is built around rapid iteration, letting process engineers modify apps as conditions change.

AI becomes part of the work itself. Operators can query SOPs, ask questions in natural language, or record defect notes by voice. OCR tools scan labels in real time, while AI-guided workflows help catch mistakes and prompt corrective actions on the spot.

From a reviewer’s perspective:

The more you like the platform, the more you want to do with it and the expectations grow continuously. After our first global deployments, we have reached the point where we need more controls and features around full EBR-like use cases for lifescience. Tulip is working on these enhancements in their product roadmap.

C3 AI Manufacturing operates at the enterprise layer to provide AI applications that optimize planning, supply chain, quality, and production performance.

While Factory AI gives you analytics on factory workflows, this strategic planning software brings together ERP, MES, historian, sensor, and external data.

Its prebuilt apps accelerate adoption; this means you don’t need to start from zero or assemble tools. Instead, you can deploy proven solutions that improve throughput, scheduling, and service levels.

C3 AI’s model-driven architecture and broad suite of enterprise AI apps are a bonus. Teams can adapt or build new apps quickly, simulating “what-if” scenarios across the supply chain, production, and maintenance departments.

🔍 Did You Know? The Luddite movement began around 1811 in England, led by skilled textile workers who were worried about how factory owners were using them. Instead of hiring trained artisans, many factories began using cheaper labour with new machinery, leading to wage cuts, job losses, and poor working conditions. The workers—calling themselves Luddites after the folk figure “Ned Ludd”—protested by targeting the factories that misused machines, not technology itself.

Insights Hub (formerly MindSphere) edges close to the IoT and automation layer. It connects assets, machines, and lines to a cloud-to-edge environment for AI-driven monitoring and optimization.

Unlike Factory AI, which often requires separate data pipes or middleware, MindSphere integrates natively with Siemens hardware, PLCs, and automation systems.

The platform’s AI models process sensor and time-series data to detect inefficiencies, predict failures, and optimize energy consumption or OEE. It also enables new digital service models: performance-as-a-service, continuous monitoring, and asset benchmarking, all powered by real-time analytics.

A G2 review says:

Insights Hub provides a centralized and easy to navigate platform that helps to consolidate data from various sources in one place…some features require additional configuration before they become fully useful, which can be time consuming. At times, the system can feel slow when handling large volumes of data or complex dashboards…

DELMIA offers full digital twin capabilities that link process design, virtual commissioning, MES execution, and supply chain planning.

Where Factory AI analyzes existing operations, DELMIA simulates them before they exist. This is how the platform optimizes workflows, automation logic, and resource management before you make any physical changes.

Built on the 3DEXPERIENCE platform, it pushes toward software-defined production, replacing vendor-specific PLC programming with model-based automation. Its AI tools enhance MES, scheduling, routing, and scenario planning. Computer vision models detect defects and feed insights into continuous improvement loops.

AR overlays, virtual simulations, and interactive 3D environments allow teams to test process changes digitally.

A quick snippet from a real user:

The 3dexperience Delmia platform provides seamless link tracking and ability to visualise all the CAD and Processes and establish synergy with collaboration among different teams and projects.

🔍 Did You Know? The concept of predictive maintenance existed long before AI. Mechanics used to place screwdrivers on machines and “listen” to the vibrations to detect issues.

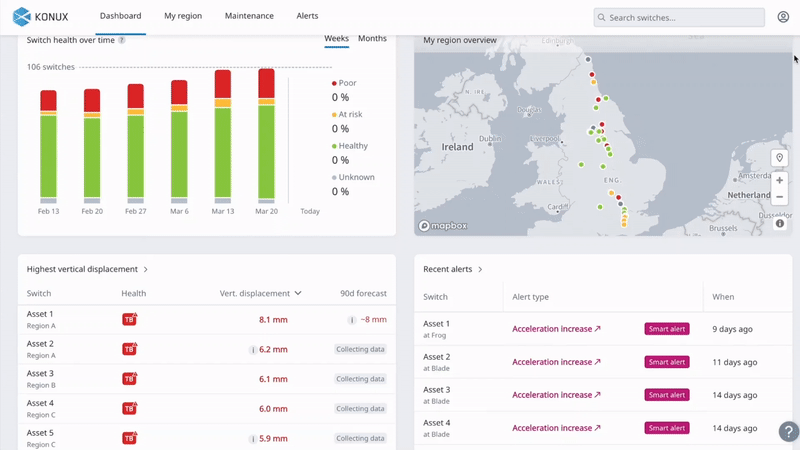

Konus is an example of the rise of ultra-vertical AI. It’s built specifically for rail infrastructure, with its flagship Switch solution focused on the most failure-prone asset in rail.

Rather than broad analytics like Factory AI, this platform combines rail domain expertise, sensor technology, and AI models to detect degradation early and prescribe when to intervene.

Its engine guides maintenance timing and prioritization based on traffic load, historical failure data, and risk thresholds. This Factory AI alternative helps rail operators extend asset lifetimes, optimize resource allocation, and reduce service-impacting delays.

🧠 Fun Fact: In 1961, General Motors introduced the first industrial robot, named Unimate, to work on a production line. It weighed two tons and had just one programmed movement.

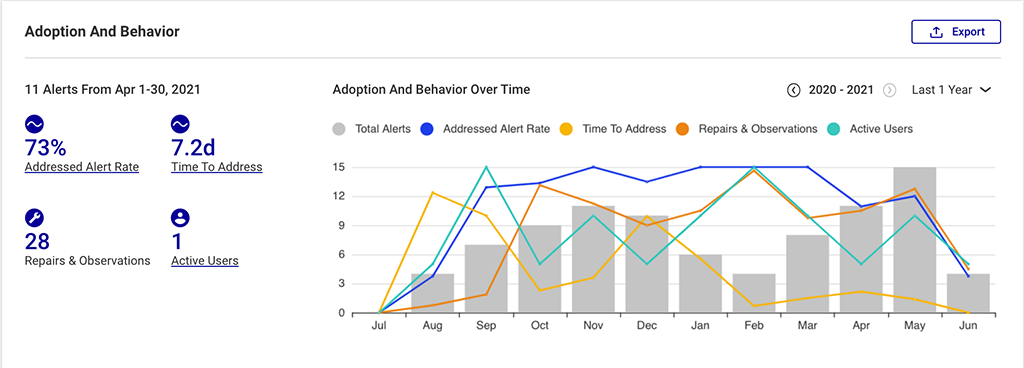

Augury is a part of the ‘machine health’ category. It uses vibration, magnetic, and temperature sensors with AI models trained to diagnose faults and recommend actions across rotating equipment and critical assets.

In contrast to Factory AI, which enhances workflow visibility, this platform embeds intelligence directly at the machine level. It utilizes edge-native sensors that analyze data on-device, even in harsh environments.

Augury’s AI automatically establishes baselines within days of installation and detects fault signatures with root causes. Sensor fusion enables advanced capabilities like phase analysis, while prescriptive guidance and expert support help teams act on insights quickly.

Here’s a firsthand perspective:

The support staff from Augury is phenomenal, including the Vibes Analysts, CSM’s, and RSM’s. They truly make the Augury experience better all around. Additionally, the value generated from the product is invaluable.

🔍 Did You Know? Early factory and computing control panels were so massive that they were sometimes called ‘wall computers.’ Operators didn’t click buttons; they walked across the room to toggle switches, spin dials, and read blinking lights and analog meters.

The most effective Factory AI alternatives understand your workflows, adapt to changing conditions, and help teams act with clarity.

ClickUp, the everything app for work, simplifies workflow orchestration with its AI Agents, context-aware automations, real-time dashboards, and deep integrations across ERP, MES, and SCM tools. It connects planning with execution, documentation with decision-making, and data with action

So, don’t wait around anymore. Sign up to ClickUp for free today! ✅

Factory AI is built to apply artificial intelligence to real manufacturing challenges, such as quality inspection, production efficiency, and machine data analysis. It helps factories optimize processes using data from sensors, machinery, and workflows. In many cases, it acts as an assistant for operators and engineers by spotting inefficiencies, recommending improvements, and supporting predictive maintenance to prevent downtime.

While Factory AI is powerful, teams often discover limitations when adapting it to their existing factory setup. Legacy machinery, specialised workflows, and mixed coding experience across teams can require heavy customization.

While the ideal automation tool depends on your specific operational goals, ClickUp is one of the strongest options if you need flexibility and context-aware automation. Its no-code AI Agents react to real production data while seamless ERP, MES, and SCM integrations connect all your tools. The AI Project Manager also tracks progress on its own.

Absolutely. ClickUp can structure factory operations, shift planning, maintenance schedules, SOPs, audits, and more. Teams can build smart workflows using automation, store procedure docs with version control, and even run AI process optimization using ClickUp Brain. With a custom plan, manufacturing teams can create factory-specific dashboards, link work orders to machines, and manage compliance.

AI-powered dashboards turn raw machine and workflow data into actionable insights. Instead of guessing where delays or losses are happening, teams can see patterns in real time and optimize processes with confidence. They can track predictive maintenance alerts, spot bottlenecks, and even forecast production risks before they affect output.

© 2026 ClickUp