How to Streamline Production Using Contract Manufacturing

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Some of the largest, most powerful, and most iconic manufacturing businesses worldwide don’t manage all their manufacturing in-house.

An average car has thousands of parts. An average car manufacturer has about 18,000 suppliers across the full value chain, finds McKinsey. For aerospace, this number is 12,000, and for technology, it’s 7000.

For a variety of reasons, manufacturers turn to smaller or specialized suppliers to produce the parts they need—a process popularly known as industrial contract manufacturing.

In this blog post, we explore what it is and how you can streamline it in your organization.

Contract manufacturing is the process of outsourcing the production of goods to a third-party manufacturer.

In this arrangement, you typically focus on research, customer insight, design, and marketing, while the actual manufacturing of the product is outsourced to a vendor. If you’ve seen “Designed in California. Assembled in China.” on any of your tech products, this is what it means.

The primary role of a contract manufacturer is to produce goods in line with the contract’s specifications. This can be the entire product or just a part of it. However, in practice, contract manufacturing services include more.

Specialized services: Contract manufacturers support the entire manufacturing process with specialized services, such as sourcing raw materials, training assembly line employees, packaging, etc.

Quality standards: They ensure compliance with SLA, industry standards, and regulatory requirements.

Scalability: Contract manufacturers often have additional capacity for production available on hand, offering the ability to scale up without significant time or equipment investment.

Distribution: Some contract manufacturers also handle the distribution of products directly from their warehouses. For instance, if you’re a US-based company selling globally, you may arrange to have your overseas manufacturer ship directly to other markets.

Does this mean that contract manufacturers always do all the manufacturing? No, they don’t. There are various types of contract manufacturing, and we explore them below.

There are various types of contracts within the manufacturing industry, and they define how the relationship works.

On the one end, a pencil manufacturer might get the wooden parts alone produced by an external supplier and handle the graphite lead and assembly in-house. On the other, your laptop might come completely manufactured and assembled by a vendor. And there’s a lot in the middle.

As the name suggests, end-to-end manufacturing involves the contract manufacturer handling the entire production process, from sourcing raw materials to delivering the finished products.

Typically, the contracting company creates the product design and gives clear specifications. And the contract manufacturer manages everything else, including material sourcing, production, quality control, packaging, and logistics.

The pharmaceutical industry prefers this model owing to compliance and quality demands.

For example, a pharmaceutical company may outsource the production of a new drug to a contract manufacturer that oversees the entire process from synthesis to packaging.

Private labeling is when one brand slaps its name on products created by another. It’s not as shady as it sounds, though. Typically, a private label manufacturer would be a small business with specialized expertise in creating specific products.

A larger manufacturer would choose from a catalog of the private label manufacturer’s existing products and pay good money to see the final product under their own brand name.

This type of contract manufacturing is common in fast moving customer goods (FMCG) as well as food and beverage products.

For example, many supermarket chains brand and sell private-label products manufactured by third-party vendors under their own name.

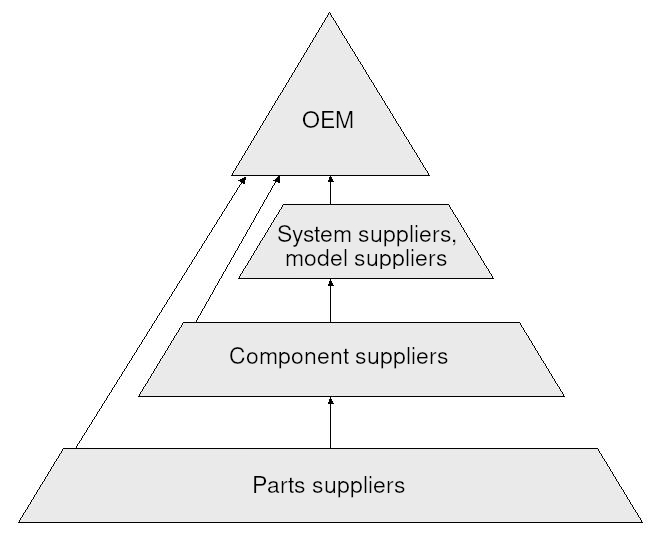

Here, a vendor manufactures specific parts or components used in a larger product. This is common in the electronics, automotive, and aerospace industries, where complex products comprise numerous components sourced from different suppliers.

In component manufacturing, the contracting company typically has suppliers for various parts, often multiple ones for each component. In some cases, they curate all these components and assemble them on their own. In several cases, that part of the process is also handed off to another contractor in a process known as outsourced assembly. ..

Outsourced assembly occurs when the contract manufacturer assembles components into a finished product on your behalf. You may supply the parts or rely on the manufacturer to source them.

This is common in industries like electronics and consumer goods.

For example, tech companies often outsource the assembly of smartphones or other gadgets to contract manufacturers with the necessary equipment and expertise.

Subcontracting is when a manufacturer outsources part of the production process to another manufacturer. This is often seen in large-scale industries like construction and aerospace, where multiple subcontractors are responsible for different components of a larger project.

For example, an aerospace company might subcontract the production of engine components to a specialized manufacturer while focusing on the overall aircraft assembly.

Every industry employs external contractors for various parts of its process. This is especially so in manufacturing because of the innumerable parts, even in the simplest product.

Take, for example, a cupcake. To make cupcakes and sell them in a supermarket, you need to:

Let’s take just one step back from this. We assume here that your butter and milk will be bought off the shelf. If your operation is large enough, you might have customized flour, sugar, or butter produced by a contract manufacturer to specification.

This way, with contract manufacturing, you can outsource a procurement, processing, or a part of the production itself. Here’s how some of the world’s largest companies do it.

Starbucks’ coffee beans: Starbucks purchases 3% of the world’s coffee supply from contract manufacturers in over 30 countries in Latin America, Africa, and the Asia/Pacific regions, many of whom grow it to their specifications. They then put these coffee beans through a range of roasting, packaging, storing, and transportation—all through suppliers—before they reach a store near you.

Magna Steyr and car manufacturing: Austrian company Magna Steyr is the world’s largest contract manufacturing company in the automobile industry. In addition to manufacturing successful models for BMW, Toyota, Jaguar, Volkswagen, and more, Magna also helps brands develop/engineer new vehicles.

Seed Beauty and Kylie Cosmetics: Forbes reports that Kylie cosmetics outsources its manufacturing and packaging “to Seed Beauty, a private-label producer in nearby Oxnard, California.” In this industry, it’s fairly common. Estee Lauder, the company that owns cosmetics brands like Clinique, Mac, Bobbi Brown, Tom Ford Beauty, etc. also outsources regularly.

Original equipment manufacturer (OEMs): When one product uses another company’s product (not just a component, but an assembly in itself), it’s called an OEM. For example, the speaker in a laptop may be made by an OEM.

The above examples are just a cross-section of the most popular contract manufacturing examples in the world. Nearly every manufacturer, across industries, business sizes, production processes, etc. uses contractors. Why? Because the benefits far outweigh the risks.

As the manufacturer of a product, you want complete visibility and control. Without that, you might face cost, quality, and sustainability risks. Yet, even the world’s most valuable companies use contract manufacturing, often overseas. Here’s why.

Contract manufacturing is cheaper because you don’t need to build and maintain production facilities, purchase equipment, and incur labor costs. Contract manufacturers already have these resources, allowing you to produce goods at a lower cost.

Contract manufacturers specialize narrowly. Many of them niche down to as much as just almond cake or iPhone screens. Even those who do more than one product keep it within their area of expertise.

This means they have access to the latest technologies and production techniques, which might be prohibitive for you to adapt to.

Contract manufacturing offers you the flexibility to scale production based on demand. You can increase or decrease production volumes without investing in additional infrastructure.

This is particularly useful for industries with fluctuating demand, like Christmas trees or firecrackers. A contract manufacturer will be able to reorganize their assembly line to scale up and down through the year.

While the risks mentioned above still exist at some level, contract manufacturing has matured enough to mitigate them effectively. By clearly stating specifications and signing water-tight contracts, you can mitigate risks associated with output, quality control, equipment failure, regulatory compliance, etc.

This way, the contract manufacturer assumes responsibility for ensuring that products meet the required standards and regulations. Additionally, you are less exposed to potential disruptions in production, as the contract manufacturer is equipped to manage these risks through their expertise and infrastructure.

Outsourcing production allows you to focus on core competencies like research, design, product development, marketing, etc. Contract manufacturing frees up valuable resources and enables you to operate more strategically in competitive markets.

If that sounds like a good business proposition to you, here’s how you can implement contract manufacturing effectively.

Whether you’re making cupcakes or sports cars, manufacturing is a collection of several moving parts.

This means that you need these parts to be of great quality and work well with the other parts of the system.

For instance, it isn’t enough if you have the world’s best brake pedal. It also needs to fit in your car and work with the electricals of your car.

To ensure that and streamline your production using contract manufacturing, you need the right processes and tools. Let’s look at how you can create that with the help of a comprehensive project management tool like ClickUp.

Modern manufacturing is very demanding. To do that effectively, you need the right supplier. So, prioritize supplier shortlisting. Use a contract management software if you’re processing too many requirements at a time.

Request for proposal (RFP): When you’ve decided what you need manufactured, create a detailed RFP. Clearly outline your expectations from the supplier.

ClickUp Docs is a great way to do this. Use ClickUp Docs to write your requirements, highlight elements, add images/processes, and share your RFP securely with anyone.

Evaluation: Once you have proposals from various vendors, evaluate them based on their expertise, industry experience, and ability to meet production demands. At this stage, shortlist 3-5 vendors to consider.

Estimation: Consolidate the quotes you’ve received from various vendors for comparison. To streamline this, you might use contractor estimate templates so every proposal is on the same scale.

Negotiation: Bring your preferred supplier to the table and discuss their ability to deliver, track record, references, commitments, pricing, etc.

When working with contract manufacturers, your success is defined by clear, open, and effective communication. This could be:

While some of these might need in-person or online meetings, most others can be managed using a robust collaboration tool. ClickUp’s latest feature launch, ClickUp Chat, is designed to be exactly that.

Integrating project management with communication, ClickUp Chat allows you to share messages, link tasks/docs, publish longer posts, organize chats info folders, and so on.

That’s not all. You can convert any chat message into a task and get to work in a jiffy! You can ask ClickUp Brain to summarize messages and give you a report. And make one-click calls with integrations right within ClickUp!

To streamline your contract manufacturing arrangements, you need rock-solid quality control measures. Here are a few ways you can do it.

Set expectations: Clearly define what you mean by quality in your contract itself. Keep it granular and thorough. Where possible, create a prototype of the product and demonstrate it to the contractor.

If you’re unsure, check out some contract templates for inspiration on how to set expectations.

Collaborate: Don’t sign and forget. Work with your contract manufacturer at every step of the way to ensure that they are set up for success.

Monitor and track: Even when you feel like everything is going as planned, closely monitor your contract manufacturing processes. Track what stage each process is in, when the delivery is expected, what checks need to be done, who is responsible for output, etc.

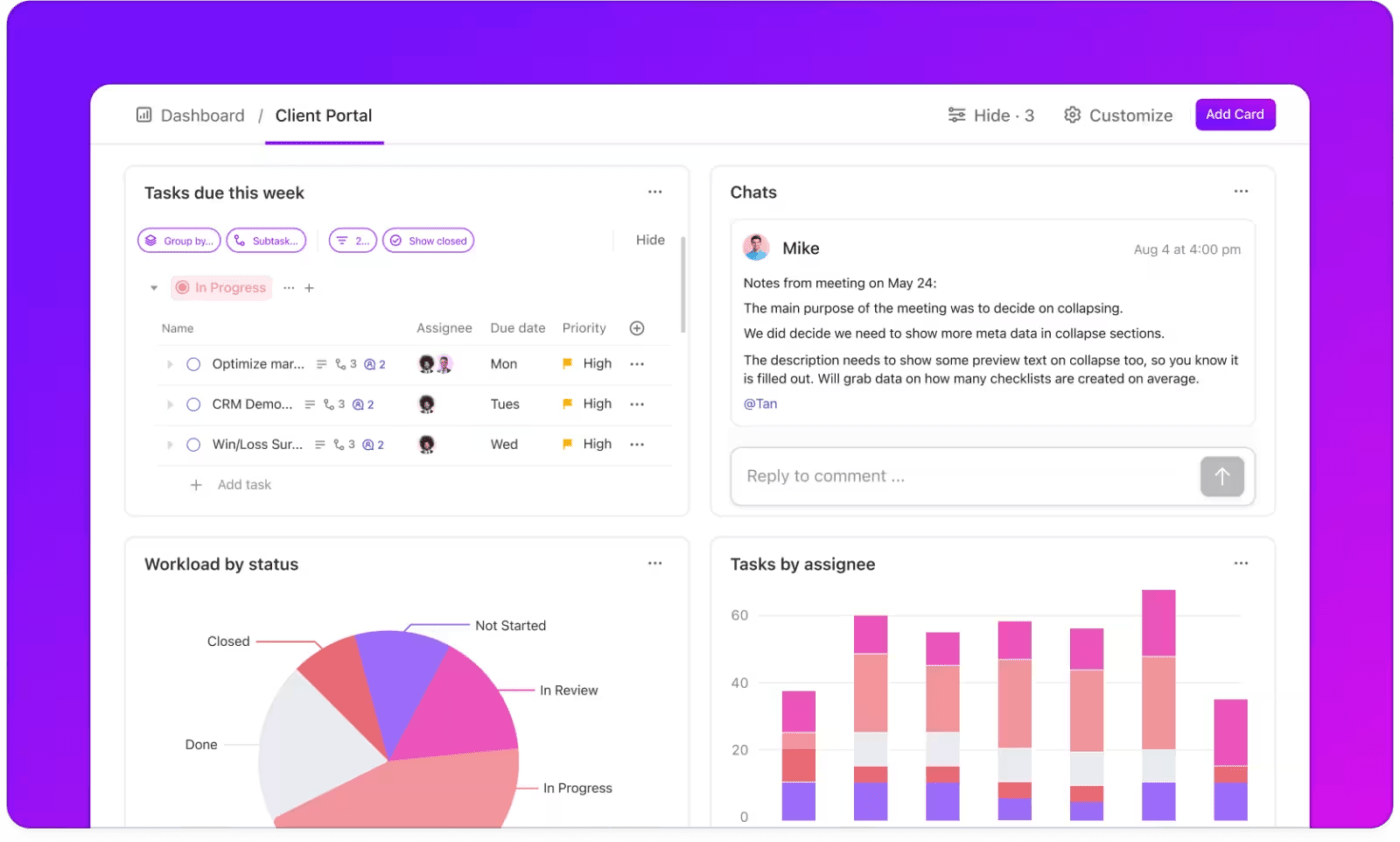

To make this efficient and repeatable, use a framework. The ClickUp Production Tracking Template is a good starting point. This intermediate level template helps you go from pre-production to delivery productively.

If you’re paying the contractor on a time and material (T&M) basis, like in the construction industry, set up a construction time tracking software to streamline the reporting process.

Inspect: Drop by once in a while to inspect how everything is going. Not just the final output, also look at the raw materials and monitor labor processes. Carry something like ClickUp’s Quality Control Checklist Template to guide your inspection.

Audit: Conduct regular audits. Go through every step of the process in great detail. Ask for financial records and look through them as well.

Don’t feel the pressure to do everything by yourself manually. Integrate and automate what you can.

Integrate: Does your contract manufacturer use a different ERP? Integrate it with ClickUp. You can also build your own custom integrations for your unique workflows or tools with ClickUp’s public API.

Manage: Consolidate your contracts and set up alerts/notifications for those that need your attention. Try ClickUp’s Contract Management Template to create a robust repository of all your contracts—stored, managed, and tracked from one place.

Report: Build KPI-driven real-time reporting with ClickUp Dashboards. Customize the widgets to reflect what you need. Then, automatically send notifications to all relevant stakeholders with a link to the dashboard they need.

Automate: For repetitive tasks and trigger-based activities, try ClickUp Automations. For example, if you need to inform the quality inspector when a stage of production is complete, set up an automation that assigns the task to the right user when the status changes. Choose from 100+ pre-designed automation workflows to eliminate busy work.

With the foundation of those strategies, you’re all set to get your contract manufacturing started. Still not confident? We’ve got your back.

The above strategies offer a strong foundation. Despite its strength, it’s just a start. At each stage of your contract manufacturing, several things can go wrong. Here are some of the best practices organizations follow to avoid pitfalls later.

Most contract manufacturers have bottlenecks in their process. For instance, one might have the capability to bake 100 cupcakes a minute, but if they can only pack 3 a minute, your total output is only three—a bottleneck.

While evaluating suppliers, inspect the entire process and understand potential bottlenecks. Discuss their plans to eliminate them.

In contract manufacturing, you would be sharing your proprietary knowledge in the form of requirements and specifications. To begin with, share only what’s needed by the contract manufacturer.

However, if you’re choosing one supplier for end-to-end output, the manufacturer would know your ingredients, recipe, and distribution strategy. To avoid misuse of this knowledge, draft airtight procurement contracts with severe penalties for non-compliance.

Remember how manufacturing hubs all over the world were forced to shut down operations nearly overnight? Global supply chains were devastated as a result. One of the key reasons for this is that organizations did not have backup manufacturers anywhere else.

To avoid risks of large-scale disruption in your supply chain management, it is prudent to have a diverse set of contract manufacturers, even if it’s a bit more of a logistical overhead.

Every contract comes with a use-by date, at which point you will need to renew the contract. This is a great opportunity for you to review performance, renegotiate terms, resolve disputes etc. So, think ahead about contract renewals.

Set up your contractor management software to notify you when it’s time for renewal. If you’re using ClickUp for contractor management, you can set an automation to alert you 30/60/90 days before contract expiry. When it’s time, use contract renewal templates to track the expiring contract. Take the time to evaluate and renew the relationship proactively.

The average life span of a tech tool is barely three years. Technological improvements are rapid and exponential today. To meet the needs of such a market, you need to improve your production processes as well.

Whether you’re building a paper plane with one raw material or an actual airplane with a million parts, industrial contract manufacturers can make your process efficient, cost-effective, and sustainable.

Despite its advantages, contract manufacturing can also be risky. What if the contractor doesn’t understand your requirements? What if they don’t meet the deadline? What if their output doesn’t integrate with the rest of the product?

Preventing such risks requires a robust project management and automation tool. That’s where ClickUp comes in.

ClickUp is an all-in-one solution for streamlining contract manufacturing with features for production planning, monitoring, supplier management, and more. Take ClickUp for a spin.

© 2025 ClickUp