How AI for Predictive Maintenance Works in 2026

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Most predictive maintenance programs fail not because the AI predictions are wrong, but because the alert gets buried in an inbox while a technician checks three different systems to figure out what part to order.

When implemented correctly, an AI-powered maintenance program can cut downtime by 90%. This guide walks you through how AI for predictive maintenance works, from sensor data to machine learning models, and shows you how to close the operational gap between prediction and action.

Clear documentation is often what separates a reactive maintenance strategy from a proactive one.

ClickUp’s SOP Template makes it easy to create, manage, and organize standard operating procedures for all your maintenance processes in one secure place. With this template, you can:

AI for predictive maintenance is the use of machine learning algorithms to analyze data from equipment sensors and forecast failures before they happen. This data can include vibration, temperature, pressure, and even acoustic signals.

Instead of reacting to breakdowns or performing maintenance on a rigid schedule, AI models learn the normal operating behavior of each machine. This allows the system to detect subtle anomalies and degradation patterns that signal a developing problem.

The goal isn’t just to predict a failure, but to predict it with enough lead time to schedule repairs, order necessary parts, and perform the work during a planned downtime window. A successful program combines three key components: a data collection infrastructure, the analytical models that interpret the data, and a workflow system to turn those insights into action.

📚 Also Read: Master Your Maintenance Schedules with ClickUp

You might be servicing equipment based on the manufacturer’s recommended schedule, but that’s a preventive approach, not a predictive one. This can lead to servicing machines that don’t need it or, worse, having a critical asset fail between scheduled check-ups. This inherent waste and risk is a major frustration for operations teams.

Predictive maintenance, on the other hand, monitors the actual condition of your assets in real time. Preventive maintenance is like going to the doctor for a check-up every six months, while predictive maintenance is like wearing a smartwatch that alerts you the moment your heart rate is abnormal. You only act when the data tells you to.

| Approach | Trigger for Maintenance | Pros | Cons |

|---|---|---|---|

| Preventive | Calendar or usage-based schedule | Better than waiting for failure | Can lead to unnecessary servicing and waste |

| Predictive | Real-time condition data | Optimizes resources and minimizes waste | Requires investment in sensors and analytics |

Most organizations find a balance, using a hybrid model. They apply predictive maintenance to their most critical assets and stick with preventive schedules for lower-priority equipment.

Implementing AI for predictive maintenance creates a positive feedback loop. When you reduce downtime, you also cut costs, freeing up your budget to make further improvements to your operations.

When a critical machine goes down without warning, it doesn’t just stop one process; it can halt an entire production line. This single point of failure leads to a cascade of problems, including production delays, missed deadlines, and frustrated customers. You’re left scrambling to find technicians, source parts, and manage the fallout.

Did You Know: Unplanned downtime can cost manufacturers up to $852 million every week, deeply impacting profitability.

AI for predictive maintenance transforms this chaos into a well-planned, orderly process. Instead of a sudden emergency, you get an alert days or even weeks in advance, giving you the time to schedule the repair during a planned shutdown.

This shift from emergency response to planned intervention means your team can prepare everything they need ahead of time, ensuring operations run smoothly and predictably.

Your maintenance budget can often feel like a black hole, drained by overtime pay for emergency repairs and rush-order fees for parts. You’re forced to stockpile expensive spare components “just in case,” tying up capital that could be used elsewhere. Meanwhile, you’re still throwing away parts like filters and belts that have plenty of life left, simply because the calendar says it’s time.

This approach is incredibly inefficient and harms your operational efficiency. With predictive maintenance, you can address these issues directly:

You’ve invested heavily in your machinery, and you expect it to last. But when a small, undetected issue like a misaligned bearing goes unaddressed, it creates a ripple effect of wear and tear that prematurely ages the entire asset. This leads to unexpected capital expenditures that can throw your entire budget off track.

Catching these small problems early prevents the secondary damage from ever occurring. By addressing issues before they cascade, you protect the whole system and maximize the return on your investment. This capital preservation allows you to get more years out of your existing assets and delay expensive replacements.

A failing machine isn’t just a productivity problem; it’s a safety hazard. Overheating motors can cause fires, failing pressure vessels can rupture, and worn components can create dangerous conditions for your operators. The constant worry about a potential safety incident adds a layer of stress that no team needs.

Predictive maintenance helps you catch these dangerous conditions before they escalate. Moreover, for compliance purposes, these systems create an automatic and indisputable audit trail. Every alert, work order, and repair is documented, simplifying regulatory reporting and demonstrating due diligence without the manual effort of chasing down logs.

See the different ways in which AI can help improve your day-to-day workflows:

Predictive maintenance technology isn’t a single piece of software but a tech stack where several systems work together. Each layer has a specific job, and a weakness in one can limit the effectiveness of the entire program.

The “brain” of the operation is the machine learning (ML) model that analyzes your data. There are a few common types:

The right model depends on the data you have available. It’s also crucial to remember that these models need to be trained for specific assets, as “normal” can vary greatly from one machine to another.

The data for these models comes from Internet of Things (IoT) sensors installed on your equipment. These sensors are the system’s eyes and ears, providing a continuous stream of information about asset health. Common types include:

Proper sensor placement is key to catching the right failure modes. In some cases, edge computing devices are used to process data locally before sending it to a central system, which is useful for time-sensitive alerts.

A single sensor can generate millions of data points a year. When you multiply that across an entire facility, you’re dealing with a massive volume of information. Big data platforms are designed to aggregate, store, and process this information at scale.

Pattern recognition algorithms then sift through this data to find correlations that a human analyst would never spot. For example, a slight increase in temperature combined with a specific vibration frequency might signal a failure mode that neither indicator would reveal on its own.

This video will show you how AI Agents can help with data analysis:

Having the right technology is only half the battle. The real value comes from an end-to-end workflow that turns raw sensor data into completed maintenance work. This is where many teams struggle, as insights get lost in the shuffle between different tools.

The process starts with sensors attached to your equipment, which capture condition data either continuously or at set intervals. This data is sent through gateways to a central system, which can be on-premises or in the cloud. However, data quality can be a challenge, as sensors can fail, connections can drop, and readings can be noisy.

To make sense of the sensor readings, you also need contextual information. Data on operating parameters, environmental conditions, and production schedules helps the system understand what it’s seeing. For example, a temperature spike during a heavy production run means something very different than one that occurs while the machine is idle.

Did You Know: The number of IoT devices across all industry verticals is forecast to grow to more than 8 billion by 2033.

Once collected, the raw data needs to be prepared for the machine learning models. This involves cleaning the data to remove outliers, normalizing it to account for different operating conditions, and transforming it into features that the models can understand.

This analysis happens at multiple levels, from real-time processing for immediate alerts to batch processing for long-term trend analysis.

With clean data, the models get to work. They compare the current operating conditions against the patterns they’ve learned to estimate an asset’s remaining useful life (RUL) or the probability of failure within a specific time window.

These predictions aren’t a simple “yes” or “no” but are presented with confidence levels, which helps you prioritize your response.

An alert from your analytics tool is useless if it just sits in an email inbox. The prediction only creates value when it triggers a timely action. This is where many predictive maintenance programs fall apart due to context sprawl.

An alert fires, but then a planner has to manually create a work order in a separate system, check a spreadsheet for parts, and use a chat app to find a technician. The value of the prediction is lost in the delay. This operational gap is the most common point of failure.

📮ClickUp Insight: 92% of knowledge workers risk losing important decisions scattered across chat, email, and spreadsheets. Without a unified system for capturing and tracking decisions, critical business insights get lost in the digital noise.

With ClickUp’s Task Management capabilities, you never have to worry about this. Create tasks from chat, task comments, docs, and emails with a single click!

While the core technology is the same, the way it’s applied varies by industry, depending on the types of assets and the consequences of failure.

In manufacturing, every minute of downtime has a direct and calculable impact on revenue. Predictive maintenance is commonly used to monitor critical assets like CNC machines, conveyors, pumps, and compressors. The main challenge is monitoring a diverse range of equipment, each with its own unique failure modes.

📌 For example, Tetra Pak enables asset health monitoring for equipment across customer locations with a mix of real-time data and operational know-how. Using secure, custom-built sensors, the platform captures vital performance signals and enriches them with expert manufacturer oversight.

The result is a user-friendly interface that provides an immediate snapshot of asset health, ensuring that technicians only receive alerts that are truly actionable.

For logistics companies, the focus is on mobile assets like engines, transmissions, and refrigeration units on trucks. The challenges here differ from those on a factory floor: vehicles are geographically dispersed, connectivity can be inconsistent, and maintenance must be performed at various service locations.

Predictive maintenance helps route vehicles for service before a failure leaves them stranded on the side of the road.

In the energy sector, reliability is paramount. A failure can affect not just the company but entire communities. Predictive maintenance is used to monitor turbines, generators, transformers, and other grid equipment.

The challenge often involves monitoring assets in remote locations with limited connectivity while adhering to strict regulatory requirements.

📚 Also Read: Top AI Prompts for Predictive Maintenance

Implementing predictive maintenance isn’t a simple plug-and-play solution. There are a number of roadblocks to deal with:

📮ClickUp Insight: While 35% of our survey respondents use AI for basic tasks, advanced capabilities like automation (12%) and optimization (10%) still feel out of reach for many.

Most teams feel stuck at the “AI starter level” because their apps only handle surface-level tasks. One tool generates copy, another suggests task assignments, a third summarizes notes—but none of them share context or work together.

When AI operates in isolated pockets like this, it produces outputs, but not outcomes. That’s why unified workflows matter.

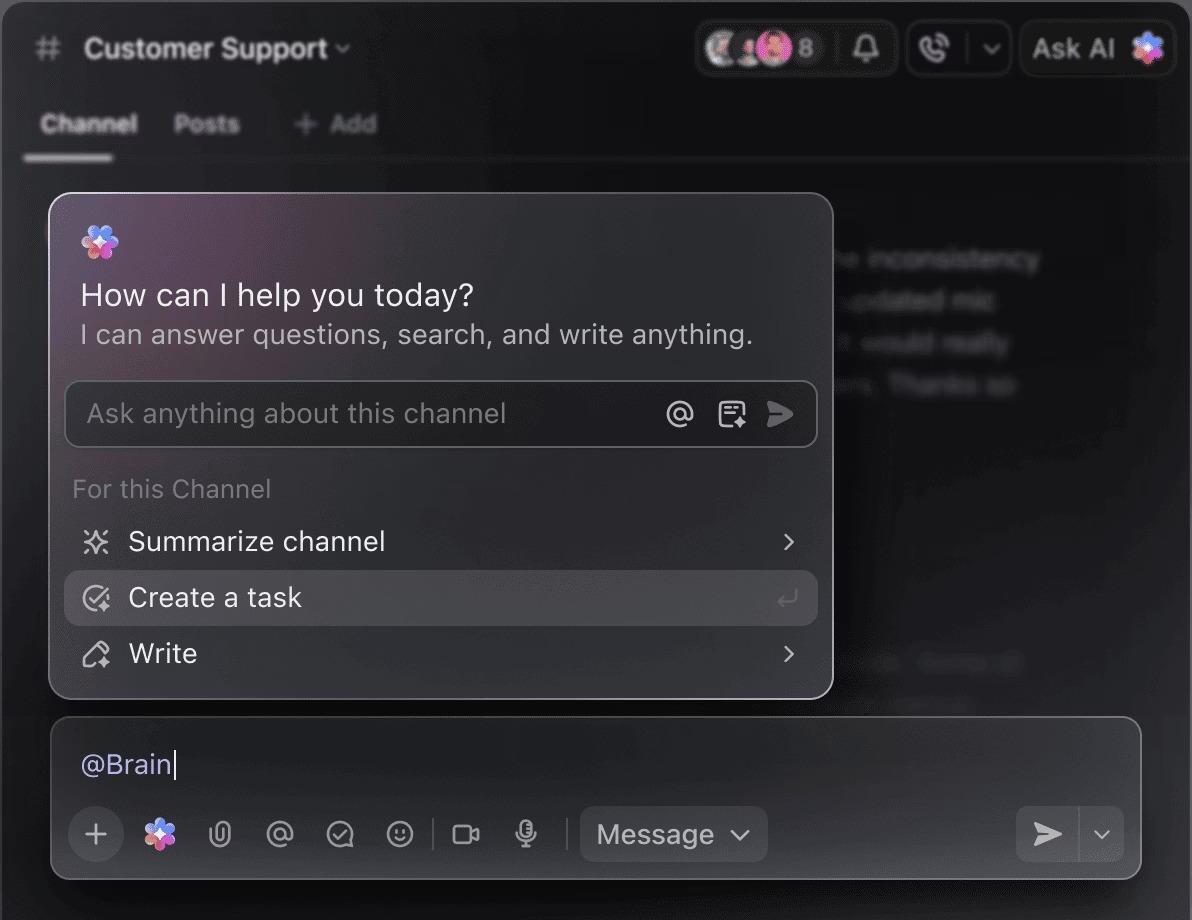

ClickUp Brain changes that by tapping into your tasks, content, and process context—helping you execute advanced automation and agentic workflows effortlessly, via smart, built-in intelligence. It’s AI that understands your work, not just your prompts.

Your expensive predictive analytics tool fires an alert, but it lands in a void. It’s just another notification in another siloed app. This is the pain of context sprawl, and it’s where most maintenance workflows break down.

A planner sees the alert, opens a separate CMMS to create a work order, checks a spreadsheet for parts, and then uses a chat app to find a technician. By the time work begins, the value of the early prediction is gone.

Eliminate this fragmentation with ClickUp’s converged AI workspace. Our unified platform brings together all work apps, data, and workflows with contextual AI embedded as the intelligence layer that connects your predictions to your actions.

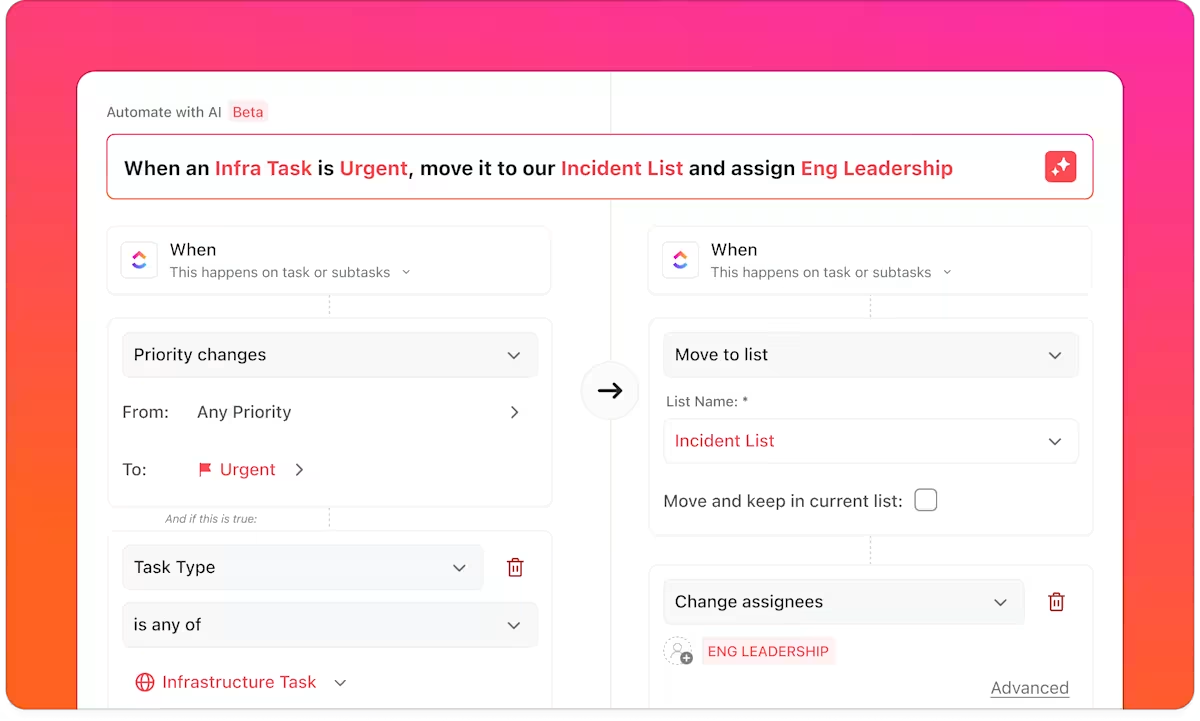

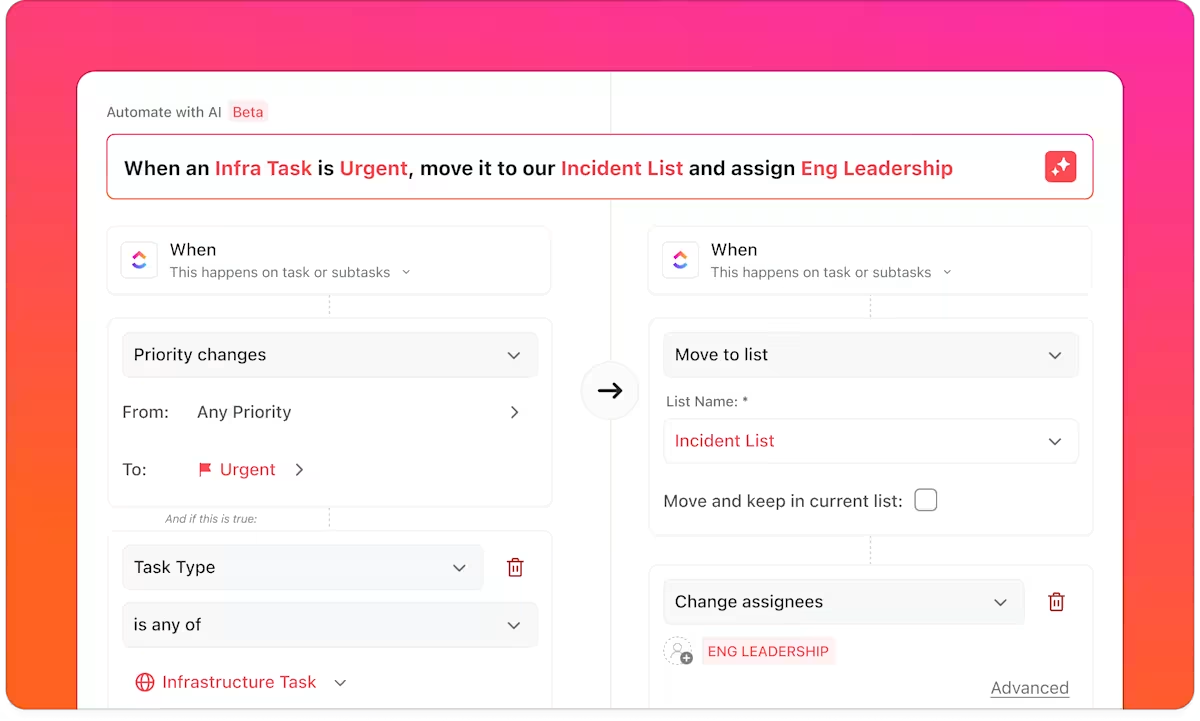

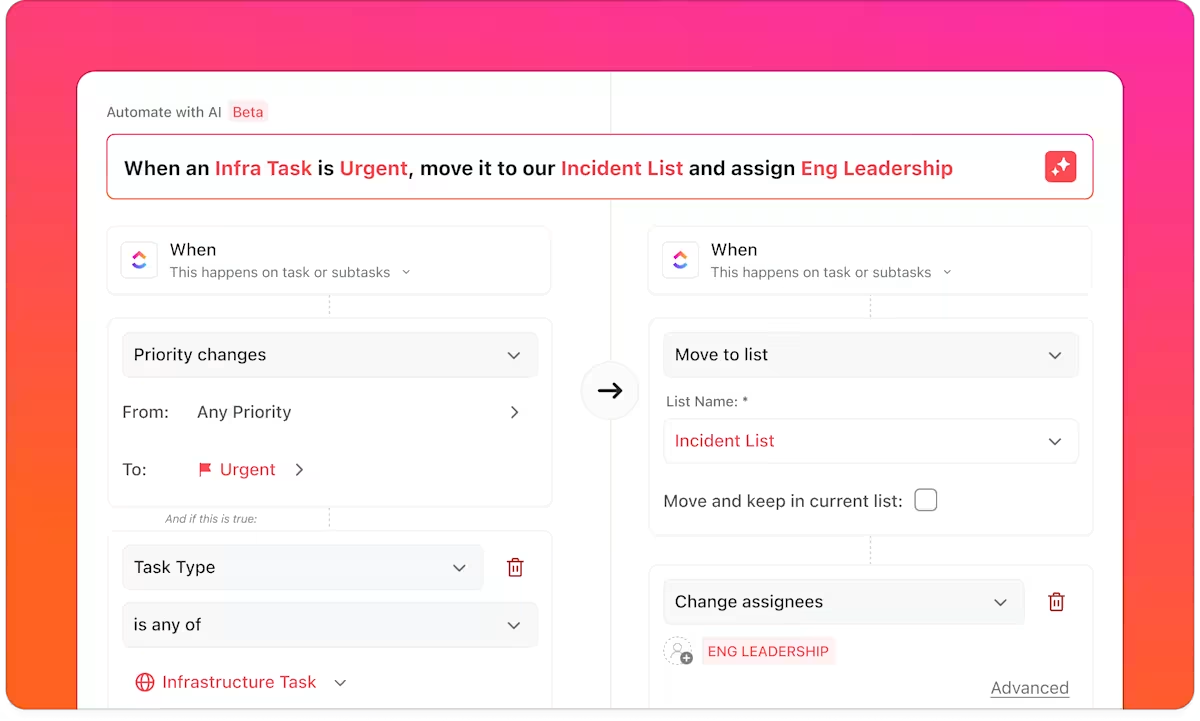

Stop wasting time on manual data entry and coordination chaos. Instantly turn an alert from your analytics platform into a detailed task using webhooks with ClickUp Automations.

When an external system detects a predicted failure, ClickUp Automations can instantly create a task with all relevant details attached—asset ID, failure type, urgency level, sensor readings, and recommended action.

Instead of relying on manual handoffs, work order management becomes automatic:

ClickUp Tasks serve as dynamic work orders enriched with Custom Fields such as:

This structured approach gives maintenance managers complete team visibility across all assets—without jumping between a CMMS, spreadsheets, and chat apps.

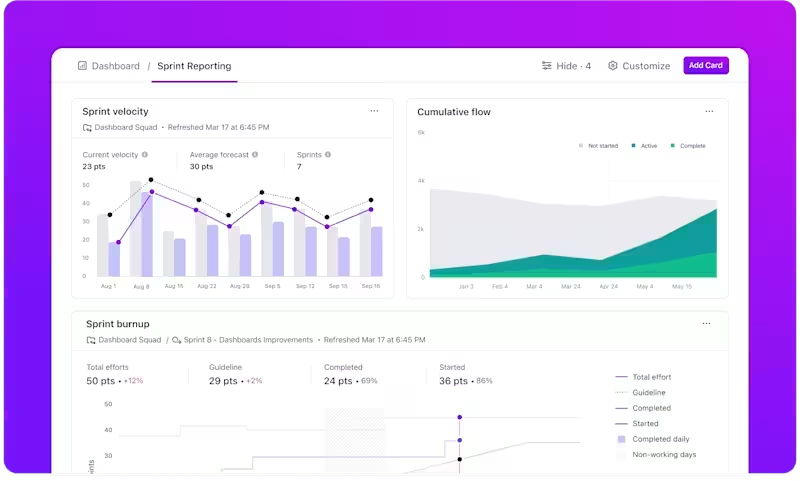

Maintenance coordination depends on clarity. ClickUp Dashboards provide a centralized view of information such as:

Instead of stitching together reports from multiple systems, teams get real-time operational visibility in one place.

You can also set up your own Super Agent in ClickUp to automatically create and share status updates on various maintenance activities. Learn more here 👇

Predictions are only as useful as the context behind them. ClickUp Brain enhances documentation management and maintenance coordination by:

For teams scaling predictive maintenance programs, this helps connect analytics with institutional knowledge—closing the loop between prediction and performance.

💡 Pro Tip: Keep all your standard operating procedures and equipment manuals in searchable ClickUp Docs, linked directly to your asset tasks. Ensure all conversations stay in context with the work being done by using threaded ClickUp Comments and @mentions in ClickUp Chat to discuss specific repairs.

AI for predictive maintenance is about shifting your team from reactive firefighting to proactive, planned work. But the technology alone won’t get you there. The real value is unlocked when your predictions are seamlessly translated into timely, coordinated action.

A successful program requires reliable data, accurate models, and, most importantly, an operational workflow that closes the gap between insight and execution. As the technology becomes more accessible, the organizations that master this workflow will be the ones who truly pull ahead.

ClickUp integrates with the specialized tools already used for monitoring and predictive maintenance. It becomes the unified workspace where insights turn into scheduled, tracked, and completed work.

Ready to unify your maintenance workflows and turn predictions into action? Get started for free with ClickUp today.

Traditional maintenance tracking is for recording work that has already been completed. Predictive maintenance software analyzes real-time data to forecast when work will be needed in the future.

Many platforms now offer pre-built models for common equipment types, which reduces the need for custom development. You can start with a vendor-supported solution for your most critical assets and build internal expertise over time.

Reactive maintenance has the lowest upfront cost but the highest long-term cost due to emergency repairs and downtime. Preventive maintenance is a middle ground, while predictive maintenance optimizes for both reliability and cost-efficiency.

The return on investment varies based on your asset criticality and current practices, though 95% achieve positive ROI with proper implementation.

These are typically driven by reduced downtime, lower maintenance costs, and extended equipment life.

© 2026 ClickUp