Top AI Prompts for Predictive Maintenance

Harness AI Prompts to Revolutionize Predictive Maintenance

Maintaining equipment reliability goes beyond routine checks—it demands foresight and precision.

Predictive maintenance teams juggle sensor data, failure histories, and maintenance schedules, all while aiming to minimize downtime and costs. AI prompts are now pivotal in managing this complexity.

With AI prompts, teams can:

- Quickly identify patterns indicating potential equipment issues

- Generate detailed maintenance plans from raw sensor inputs

- Summarize technical manuals and failure reports efficiently

- Transform scattered observations into clear action items and alerts

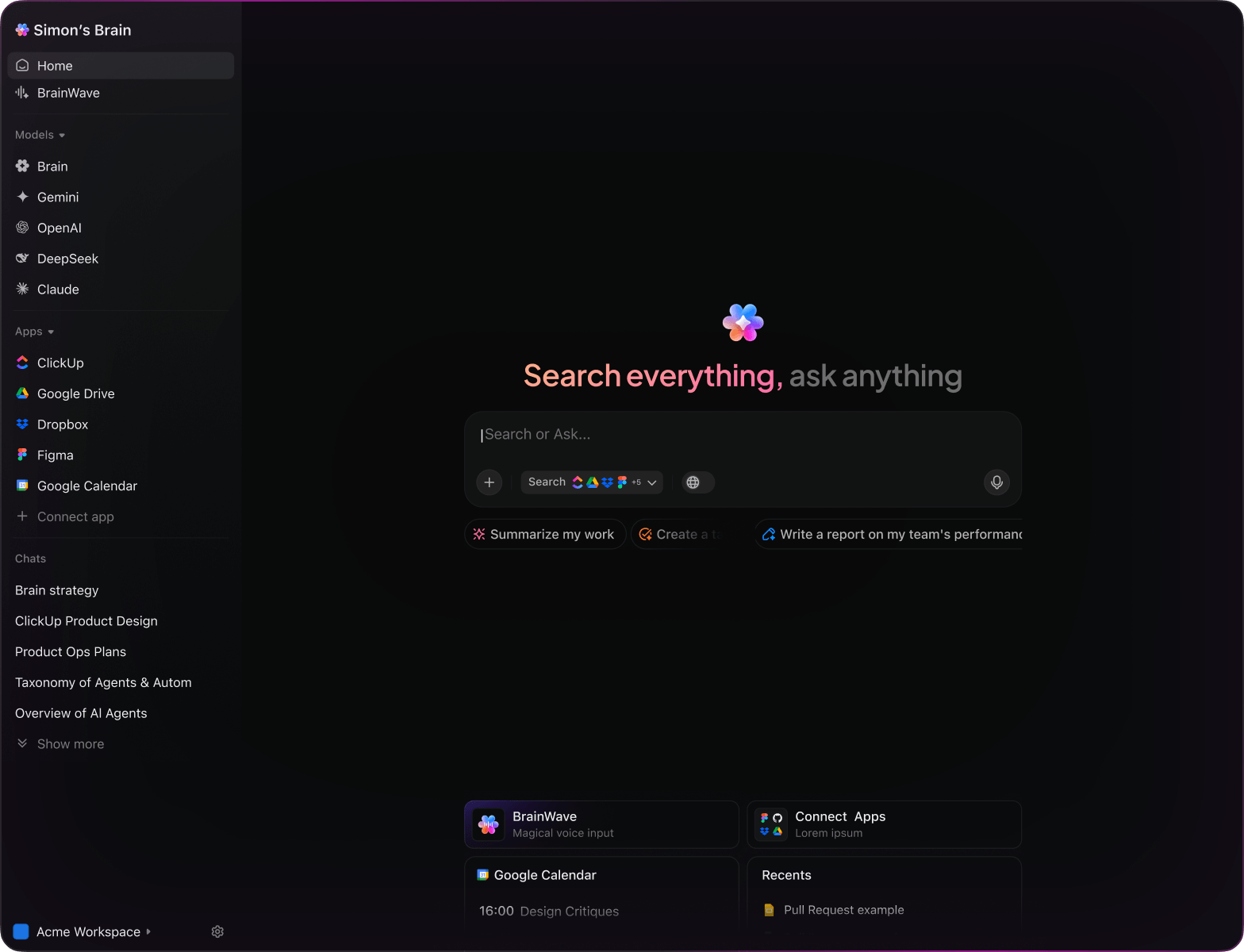

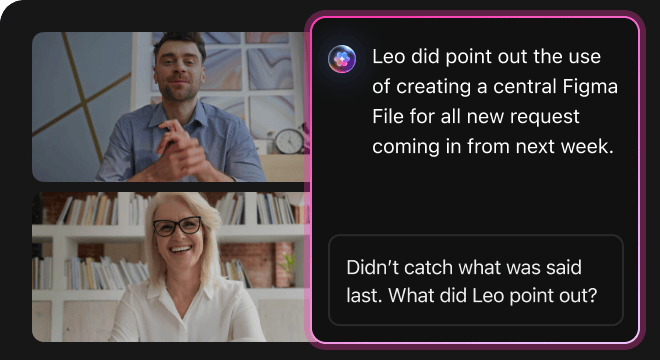

Integrated into daily tools like dashboards, notes, and task trackers, AI in ClickUp Brain acts as a proactive partner, converting data insights into prioritized maintenance workflows.

Discover Why ClickUp Brain Stands Apart

Standard AI Platforms

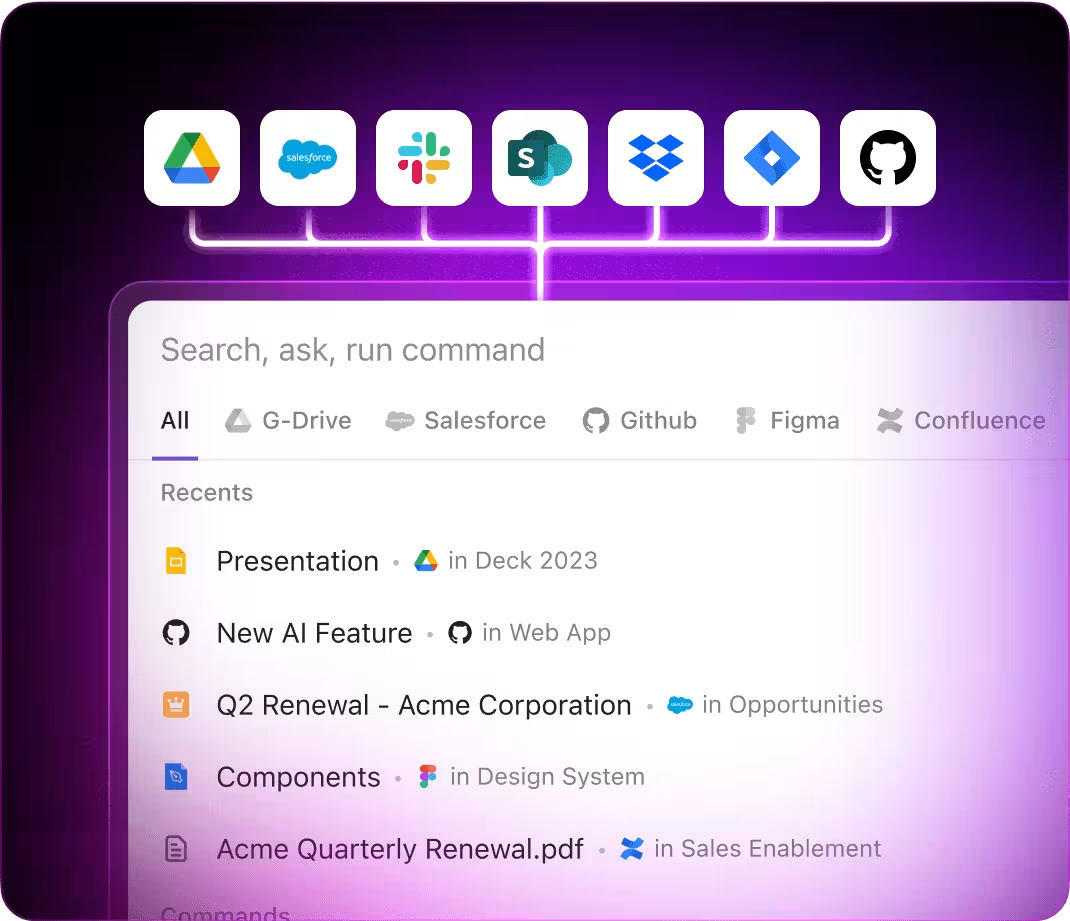

- Constantly toggling between apps to collect information

- Reiterating objectives with every new query

- Receiving generic, irrelevant feedback

- Hunting through multiple platforms to locate a single document

- Interacting with AI that only processes input without insight

- Manually switching among different AI models

- Merely an add-on in your browser

ClickUp Brain

- Deeply integrated with your maintenance schedules, reports, and team communications

- Retains your project history and objectives

- Provides detailed, context-aware guidance

- Consolidated search spanning all your resources

- Supports voice commands through Talk to Text

- Automatically selects the optimal AI model: GPT, Claude, Gemini

- Dedicated desktop application for Mac & Windows designed for efficiency

15 Essential AI Prompts for Predictive Maintenance

Identify 5 common exterior equipment failure patterns from the ‘Maintenance Logs Q1 2024’ document.

ClickUp Brain Behavior: Analyzes maintenance records and highlights recurring external fault trends for proactive attention.

What sensor technologies are currently favored in predictive maintenance for manufacturing lines under $50K budget?

ClickUp Brain Behavior: Aggregates insights from internal reports; Brain Max can supplement with relevant industry data if accessible.

Draft a maintenance task brief for vibration analysis based on ‘Vibration Monitoring Protocol’ and past inspection notes.

ClickUp Brain Behavior: Extracts key points from linked documents to assemble a clear, actionable task outline.

Summarize wear benchmarks between Conveyor Model A and Model B using our ‘Wear Analysis Q2’ document.

ClickUp Brain Behavior: Pulls tabular and descriptive data from internal files to deliver a concise comparative summary.

List top materials prone to thermal degradation in high-load machinery, referencing R&D and supplier specification documents.

ClickUp Brain Behavior: Reviews internal documentation to identify frequently noted materials and their thermal performance characteristics.

From the ‘Hydraulic Pump Validation’ document, generate a DVP&R-style checklist for component testing.

ClickUp Brain Behavior: Extracts test parameters and formats them into a structured checklist within a task or document.

Summarize 3 emerging control system trends in predictive maintenance from post-2023 research and technology review documents.

ClickUp Brain Behavior: Detects patterns and recurring themes from linked research files and notes.

From the ‘Technician Survey Q1’ document, summarize key preferences for maintenance interface usability.

ClickUp Brain Behavior: Analyzes survey data to highlight common user interface preferences and pain points.

Write clear and engaging copy for the maintenance alert screen using the style guide in ‘CommunicationTone.pdf’.

ClickUp Brain Behavior: References tone and style documents to propose effective alert messaging variations.

Summarize key updates in OSHA 2025 safety regulations and their implications for equipment maintenance protocols.

ClickUp Brain Behavior: Reviews linked compliance documents and summarizes critical changes affecting maintenance procedures.

Generate placement and dimension guidelines for safety indicators, referencing region-specific compliance documents in our workspace.

ClickUp Brain Behavior: Extracts measurement standards and positioning rules from internal files to create a compliance checklist.

Create a safety inspection checklist using OSHA 2025 PDFs and our equipment maintenance folder.

ClickUp Brain Behavior: Identifies key safety requirements from PDFs and organizes tasks by inspection area or priority.

Compare sustainability features like recycled components across major equipment brands using our competitive analysis documents.

ClickUp Brain Behavior: Summarizes documented comparisons into an easy-to-read format (summary/table).

What maintenance strategies are gaining traction in Industry 4.0 environments since 2023?

ClickUp Brain Behavior: Synthesizes trends from internal research notes, strategy summaries, and uploaded reports.

Summarize key equipment usability issues from the Southeast Asia maintenance feedback folder (components, interfaces, procedures).

ClickUp Brain Behavior: Extracts and prioritizes technician-reported problems across surveys, feedback notes, and tagged tickets.

Predictive Maintenance Prompts Powered by ClickUp Brain

Prompts for ChatGPT

Prompts for Gemini

Prompts for Perplexity

Prompts for ClickUp Brain

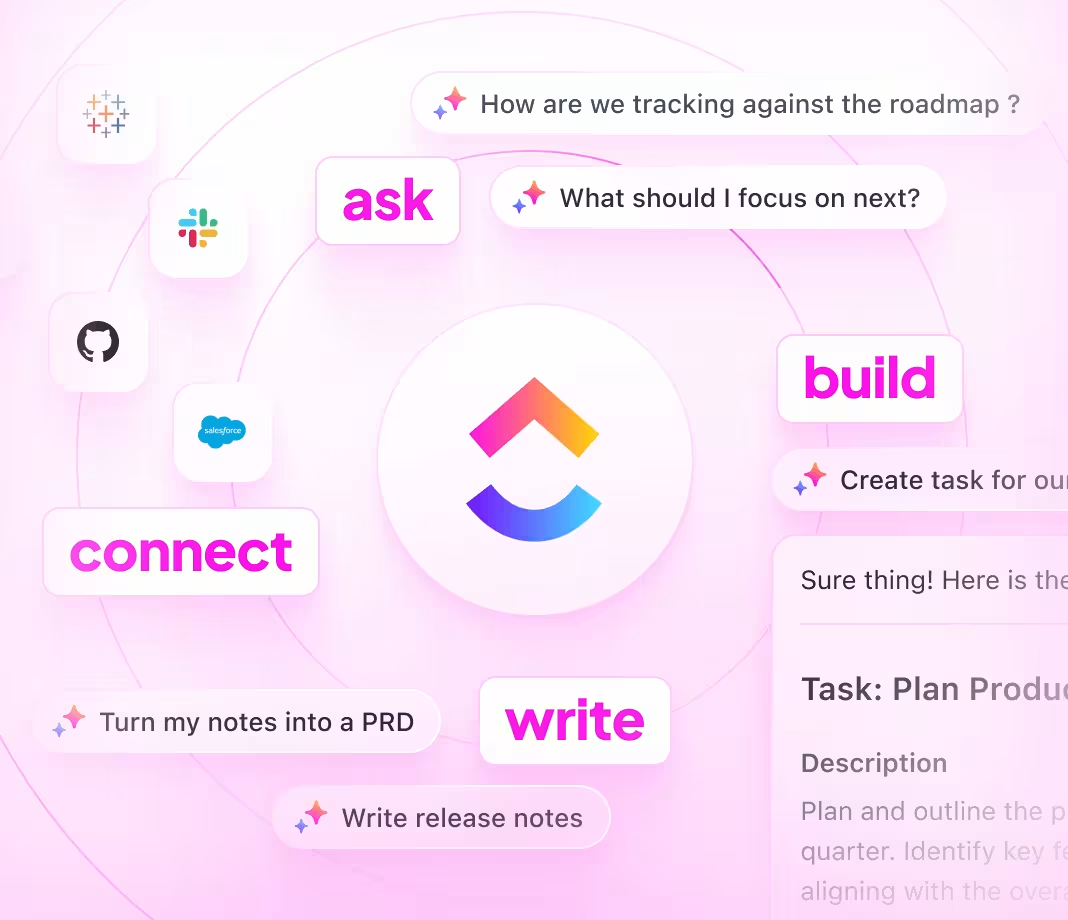

Transform Initial Thoughts Into Actionable Plans

- Convert scattered observations into detailed maintenance strategies swiftly.

- Generate innovative solutions by analyzing historical equipment data.

- Build standardized templates that accelerate routine upkeep tasks.

Brain Max Boost: Quickly access previous maintenance records, sensor feedback, and repair logs to guide your upcoming interventions.

Accelerate Maintenance Planning and Execution

- Break down intricate maintenance plans into straightforward tasks.

- Transform inspection logs into actionable work orders effortlessly.

- Automatically compile maintenance summaries and performance reports without lifting a finger.

Brain Max Boost: Retrieve historical equipment data, failure trends, or maintenance records instantly across all assets.

How AI Prompts Elevate Every Phase of Predictive Maintenance

Quickly Identify Maintenance Needs

Maintenance teams spot potential issues early, prioritize repairs effectively, and prevent unexpected breakdowns.