Continuous Improvement Examples to Elevate Your Processes

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

A smartphone today packs unimaginable storage capacity that would have taken up many rooms full of computers just 20 years ago—a transformation that did not happen overnight.

It happened due to an iterative process, which focuses on small changes that you can continue making to evolve your product or processes. This helps create outstanding technological advancements that make the world look on in awe.

Any organization must today follow the iterative process of continuous improvement. History offers many examples of companies that once dominated their markets but failed to adapt when competition advanced and were either rendered obsolete or died out. Organizations today need to evolve with market changes or risk obsolescence.

The lesson here is to incorporate continuous improvement to eliminate inefficiencies from your processes.

In this blog, we’ll explore the world of continuous improvement processes, its core principles, and the benefits they can bring to your business goals.

Imagine a never-ending loop of progress, where every step forward informs the next, and every project completed becomes a stepping stone to even greater achievements. That’s the essence of continuous improvement, an iterative process that slowly refines existing processes, workflows, and practices.

The continuous improvement process is a company-wide philosophy that encourages everyone to be on the lookout for ways to improve quality, efficiency, and overall performance.

The roots of process improvement can be traced back to Japan, which pioneered the concept of Kaizen. It is a Japanese term for continuous improvement efforts, which served as the basis for Japanese philosophy and business culture.

There are nine basic principles of continuous process improvement:

Now that we have understood how the overall process improvement process works, here is a look at some of the frameworks for process improvements:

The Lean methodology focuses on minimizing waste and maximizing value in every step of the production process. This approach was pioneered by Japanese carmaker Toyota as the Toyota Production System and gradually developed into today’s Lean.

In this methodology, the typical process is as follows:

In software development, Lean principles can be applied to simplify workflows, eliminate unnecessary features, and optimize resource allocation.

Similar to the Lean methodology, this data-driven approach emphasizes defect prevention and process improvement through statistical analysis. Six Sigma can be used in any business or industry to identify and create avenues for process improvements.

The Six Sigma approach follows this basic framework:

Bonus: Learn about adaptive project management!

PDCA is another popular approach to process improvement. Also called the Deming cycle, it follows the following framework:

The Plan-Do-Check-Act cycle promotes a culture of experimentation and iteration, allowing you to refine your approach and achieve operational excellence continuously.

Traditional improvement methods often focus on one-time fixes or major overhauls. Continuous improvement, in contrast, is a never-ending process of small, incremental changes. Some of the differences between these two theories include:

| Feature | Continuous Improvement | Traditional Improvement Methods |

| Focus | Ongoing process of small, incremental improvements | One-time fixes or major overhauls |

| Goal | Continuously improve efficiency, quality, and performance | Address specific problems or inefficiencies |

| Culture | Collaborative, data-driven, learning-oriented | May be a siloed, top-down approach |

| Pace of change | Slow and steady, iterative | Can be rapid but less sustainable |

| Data usage | Highly data-driven, with ongoing measurement and analysis | May rely less on data and metrics |

| Employee involvement | Empowers employees to identify and implement improvements | Limited employee involvement |

| Flexibility | Adapts easily to changing circumstances | May be less flexible and adaptable |

| Risk | Lower risk due to small, incremental changes | Higher risk due to larger-scale changes |

| Examples | Lean manufacturing, Agile development, Kanban, PDCA cycle | Reorganizing a department, implementing a new software program (without ongoing improvement) |

Now that we have understood process improvement concepts and methodologies, let us look at some process improvement examples that can be implemented in business processes:

As mentioned earlier, Lean principles are potent tools for continuous improvement in software development. They focus on delivering maximum value to the customer while enabling waste reduction. They emphasize a collaborative and iterative approach, breaking down projects into smaller, manageable chunks and prioritizing features that deliver the most value to the end user.

A great example of Lean software development is the MoSCoW approach, which breaks down critical functions into:

This approach helps prioritize activities based on the above categories—enabling a smooth, continuous improvement workflow.

Another cornerstone of continuous improvement in software development and operations management is the Agile methodology. Agile is a flexible and iterative approach that prioritizes collaboration, rapid feedback, and continuous adaptation.

It breaks down projects into manageable ‘sprints’ with clearly defined goals. Teams work collaboratively in short cycles, constantly refining the product based on user feedback and ongoing testing. This allows for faster course correction and ensures the final product remains relevant and user-centric.

Scrum, a popular Agile framework, provides a specific structure for iterative development and continuous improvement. It takes a time-boxed approach, with projects divided into short sprints (typically 1-4 weeks) where focused work occurs.

Each sprint has a defined goal, and the team works collaboratively to achieve it. Scrum emphasizes roles like the Product Owner (who prioritizes features), the Development Team (who builds the product), and the Scrum Master (who facilitates the process).

Kanban development offers another Agile framework that thrives on continuous improvement principles. It utilizes a visual workflow management system, typically a Kanban board with columns representing different stages of development (e.g., To Do, In Progress, Done). Tasks are represented by cards that move across the board as work progresses. Kanban focuses on limiting work in progress (WIP) to avoid bottlenecks and ensure a smooth workflow.

Iterative and incremental development involves breaking down projects into smaller, manageable pieces.

Each iteration focuses on delivering a functional increment of the product, gathering user feedback, and incorporating that feedback into subsequent iterations. This allows for continuous refinement and ensures the final product aligns with user needs.

Iterative and incremental development are most popular in product development. The first iteration is the minimum viable product (MVP), which includes the core functionalities. This is released, and then incremental updates are added to this product after gathering user feedback and prioritizing development efforts.

While development methodologies like Agile and Scrum provide a framework for continuous improvement, it’s crucial to have mechanisms in place to ensure quality throughout the process. This is where quality assurance (QA) and usability testing come into play:

QA and usability testing provide valuable data and insights that fuel continuous improvement. By identifying bugs, performance issues, and usability problems early and often, teams can continuously iterate and refine the software, leading to a higher-quality and more user-friendly product.

Since process improvement focuses on continuous change, it can face several roadblocks. Some of the most common challenges include:

Many organizations have existing processes that were created after several rounds of trial and error. These processes use existing frameworks and technology to get the job done, making them not so easy to replace. For example, many traditional banks using legacy mainframe infrastructure tend to resist digitizing banking processes since it could create many disruptions. Existing teams have to be upskilled and trained to work with these new technologies, and these changes can bring significant disruption to the overall banking process.

Solution: To go beyond this resistance, organizations must create a continuous improvement culture while clearly communicating the ‘why’ behind any improvement processes. Introduce subtle changes and build incrementally to ensure that this resistance can be overcome.

Bottlenecks in production

In most organizations, production processes are interdependent. So, if one task is delayed or stuck, it will hinder overall progress in every task that depends on the successful completion of the former. This is a bottleneck and causes significant challenges in the continuous improvement cycle.

Solution: To address this, organizations can use automation software or process mapping tools to track and automate simple tasks and identify task dependencies, thereby improving efficiency.

You can use the ClickUp Gantt chart view to understand the relationship between each activity and map dependencies. It helps you visualize task dependencies, clearly showing how tasks rely on each other’s completion. This helps identify potential bottlenecks and plan accordingly.

Imagine navigating a complex improvement project without a clear view of progress, resource allocation, or other critical data. This is the reality when visibility is limited. Lack of visibility can lead to:

Solution: To ensure that you have detailed insights into your processes, implement data collection and reporting systems to gain clear visibility into project progress, resource utilization, and other key metrics.

Another issue that can cripple processes is the insufficient clarity on individual roles, team goals, and priorities. This can lead to several issues:

Solution: To avoid this issue, organizations must clearly define roles, responsibilities, and organizational goals to ensure everyone is on the same page.

By communicating the goals and creating avenues for open communication, you can generate relevant feedback and address any lingering confusion that could dismantle the entire project.

A smooth-running improvement process relies on having the necessary resources readily available. Inefficient inventory management can lead to several issues:

Solution: Use tools to track, manage, and optimize inventory levels.

With ClickUp, you can customize and track inventory levels, creating custom fields for quantity, reorder points, and other relevant information. The tool also includes ready-to-use templates, such as the Inventory Management Template, to help you stock, reorder, track order statuses, manage vendors and costs, and more. The advanced template helps you to:

Organizations can leverage iterative improvement cycles and on-ground training to obtain the required resources for improvement processes. This enables the organization to scale or adapt to the evolving needs of a continuous improvement mindset.

Continuous improvement isn’t just about methodologies and tools. It takes a combined effort to foster a culture that embraces ongoing learning and implementing automated workflows. Here’s how to create an environment where continuous improvement thrives:

Using these strategies, you can empower your team to implement continuous improvement methodologies in your business process. ClickUp, an all-in-one project and process management software, equips you with a powerful arsenal of features designed to make continuous improvement an intuitive and collaborative endeavor.

This unique platform allows you to get all your data in one place, enabling you to gather the required information, prepare plans, and adapt or refine your approach. This gives you the flexibility and agility you need to learn, iterate, and continuously achieve lasting success.

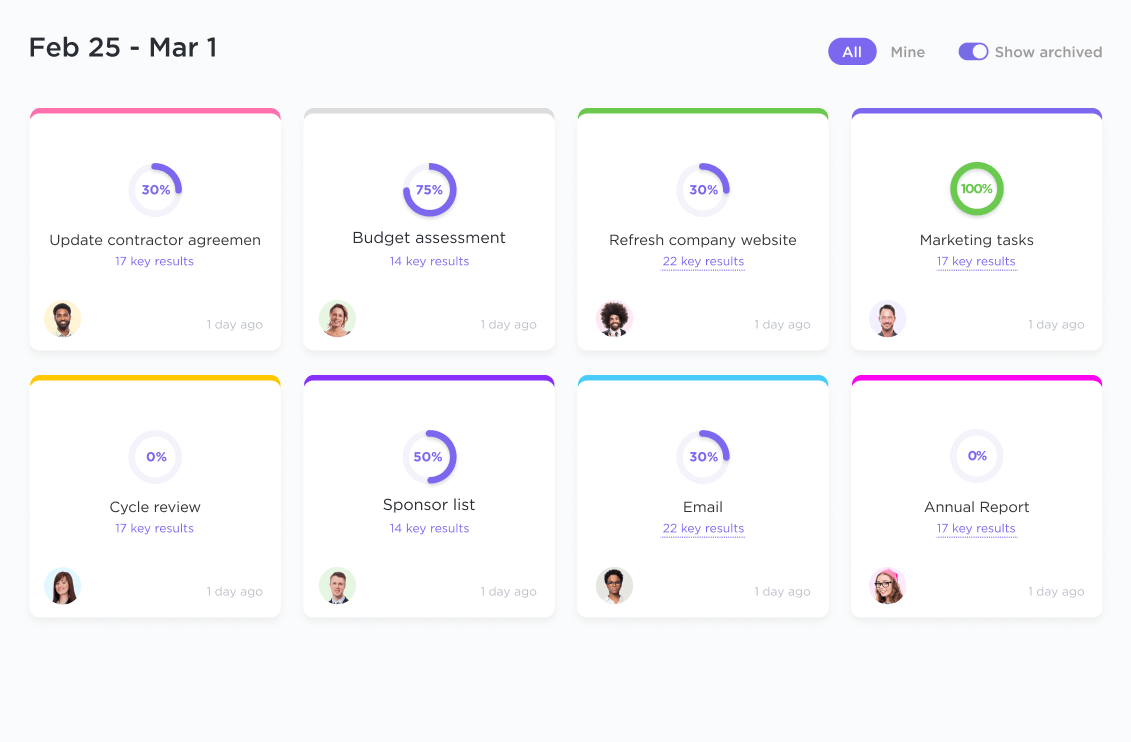

ClickUp helps you visualize your improvement journey, allowing you to:

Continuous improvement is a consistent quest for excellence. By embracing this method and implementing the strategies outlined above, you can empower your team to achieve remarkable results.

By combining ClickUp’s features with these strategies, you can transform your approach to continuous improvement. Ready to take the first step towards continuous improvement?

Sign up for your free ClickUp account today and implement continuous improvement effectively within your team!

Continuous improvement is a company culture that focuses on constantly refining processes, workflows, and practices to achieve better results and build innovative solutions. It involves strategies and methodologies that encourage all employees to identify inefficiencies and seek ways to improve efficiency, quality, and overall performance.

There are numerous examples of continuous improvement across various departments. Here are a few examples specific to software development:

To improve continuous improvement processes within your organization, you can do the following:

© 2026 ClickUp