How to Automate Inventory Management with AI for Better Accuracy

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Inventory management is basically dealing with that same old issue over and over!

Your bestsellers are out of stock while slow-moving items pile up in storage. Manual counts take forever and still miss discrepancies.

Artificial intelligence handles the repetitive parts while catching patterns humans miss. It tracks stock in real time, predicts future demand shifts, and flags anomalies that signal problems.

In this blog post, we’ll walk through how to automate inventory management with AI, plus how ClickUp streamlines the entire process. 🤩

Old-school inventory methods had their moment, but they can’t keep up anymore. Here’s why they fall short. 👇

Easily track stock levels, restocks, and order history with the ClickUp Inventory Management Template. With AI built in, you can instantly generate low-stock alerts, summarize updates across tasks, and get quick answers on what’s moving fast (or not at all).

Here’s how using AI for inventory management sharpens forecasting, speeds up decisions, and helps you stay lean without losing control. 📄

🔍 Did You Know? About 8.3% of products in retail stores are out of stock at any given time. That means a shopper trying to buy 10 things has less than a 50-50 chance of finding them all in one trip.

When you combine inventory processes with ClickUp’s intelligence, your inventory practically manages itself.

Let’s walk through how this works in practice with inventory management software features. 👀

Remember when forecasting meant looking at last year’s numbers and hoping for the best? Those days are over.

Modern AI digs into your sales history, seasonal patterns, and market trends to tell you exactly what customers will want three months from now.

Think about a sporting goods retailer. AI can spot that hiking boots always spike in March (spring planning season), dip in June (too hot), then surge again in September (fall adventures). It notices that rain jackets sell differently in Seattle versus Phoenix. These insights turn guesswork into strategy.

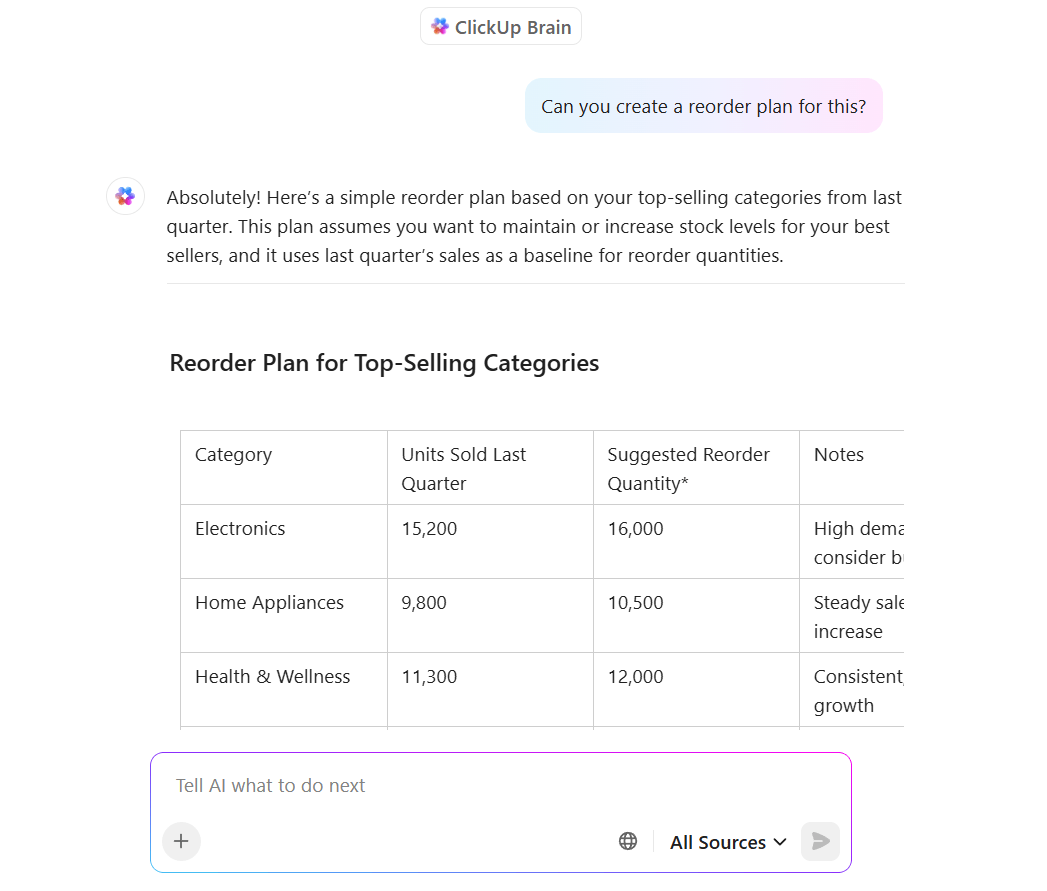

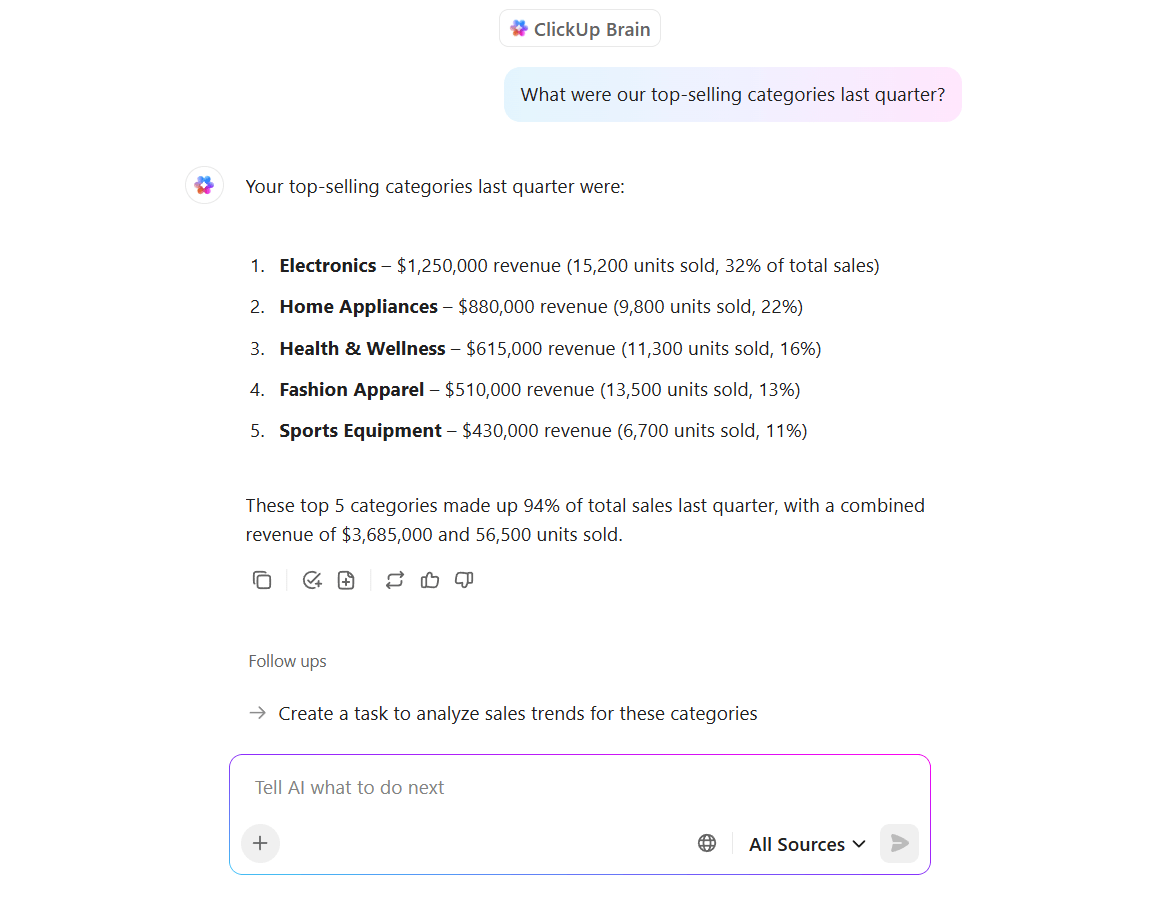

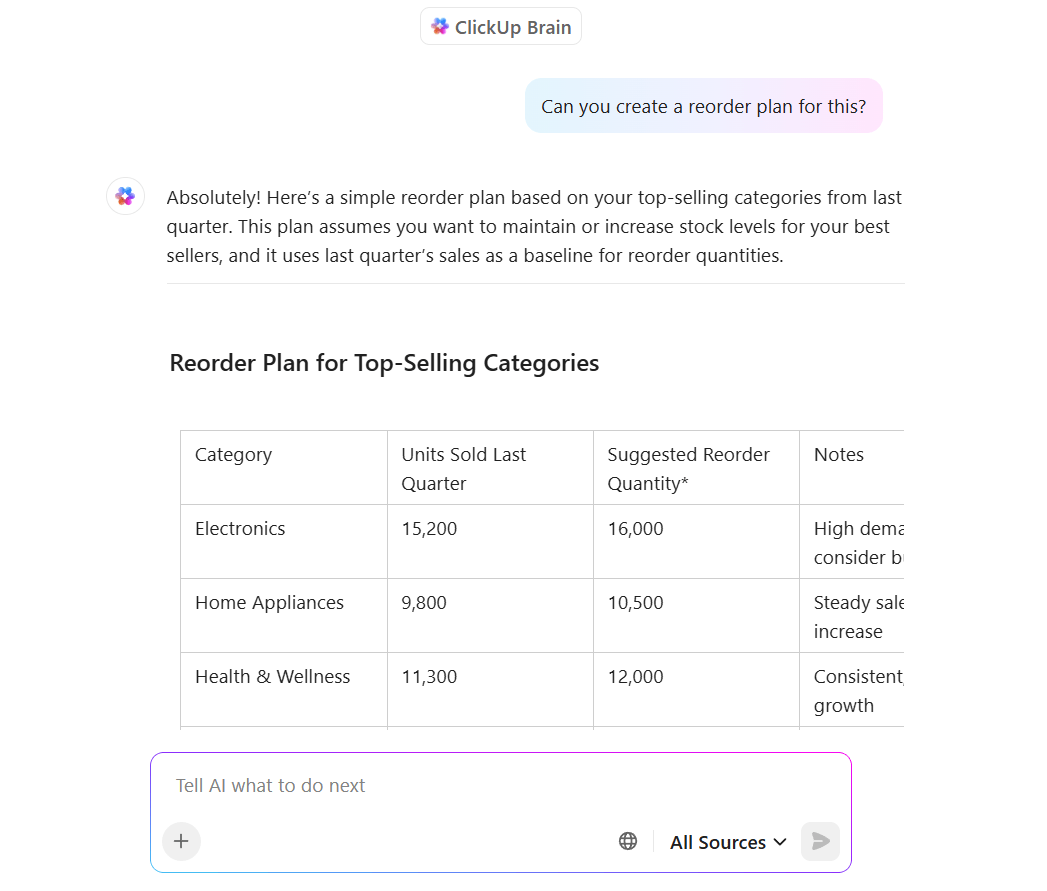

ClickUp Brain becomes your forecasting partner here.

You can ask questions like ‘What were our top-selling categories last quarter?’ or ‘Which products usually spike during the back-to-school season?’ It pulls the data, spots the trends, and presents insights in plain English.

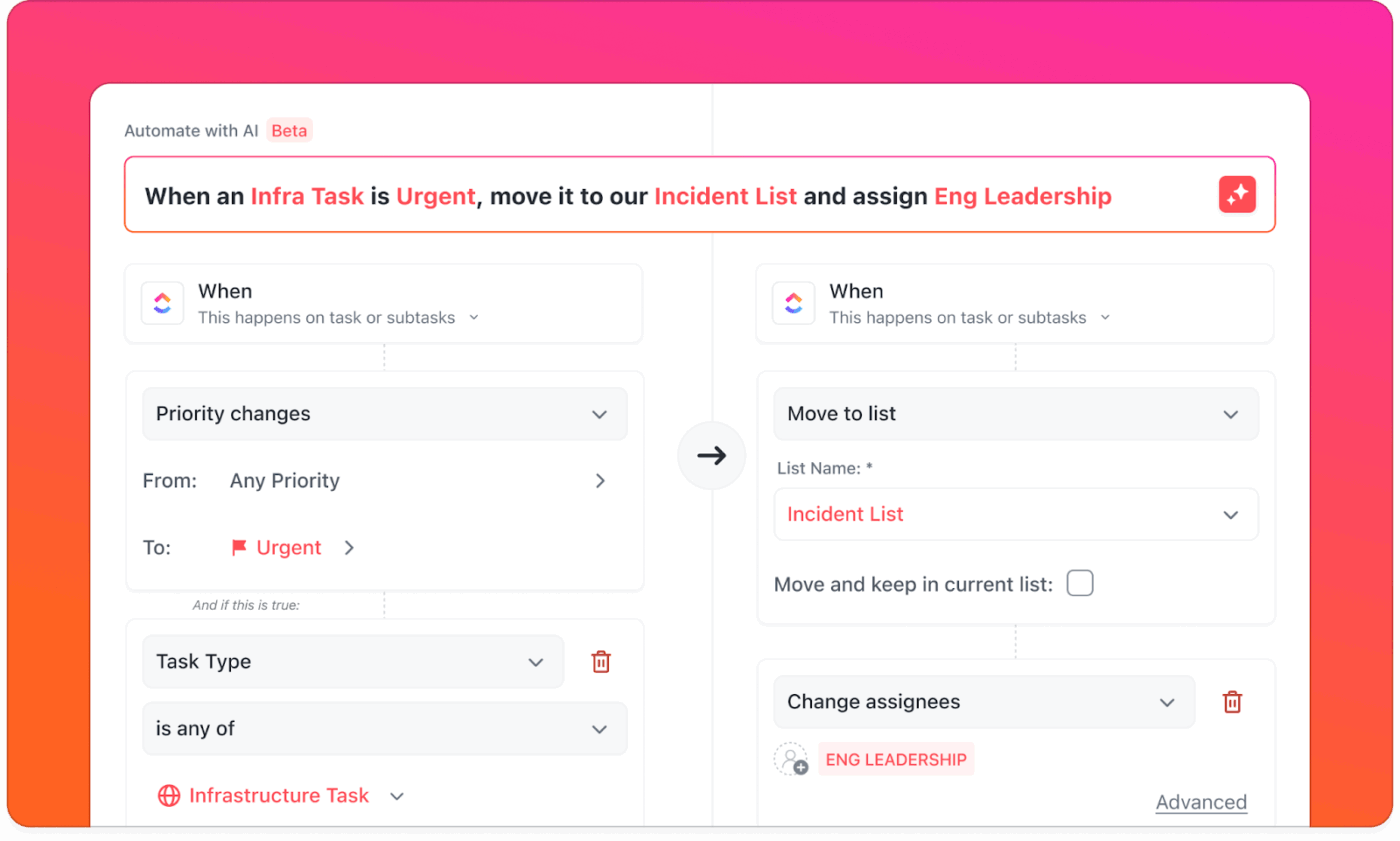

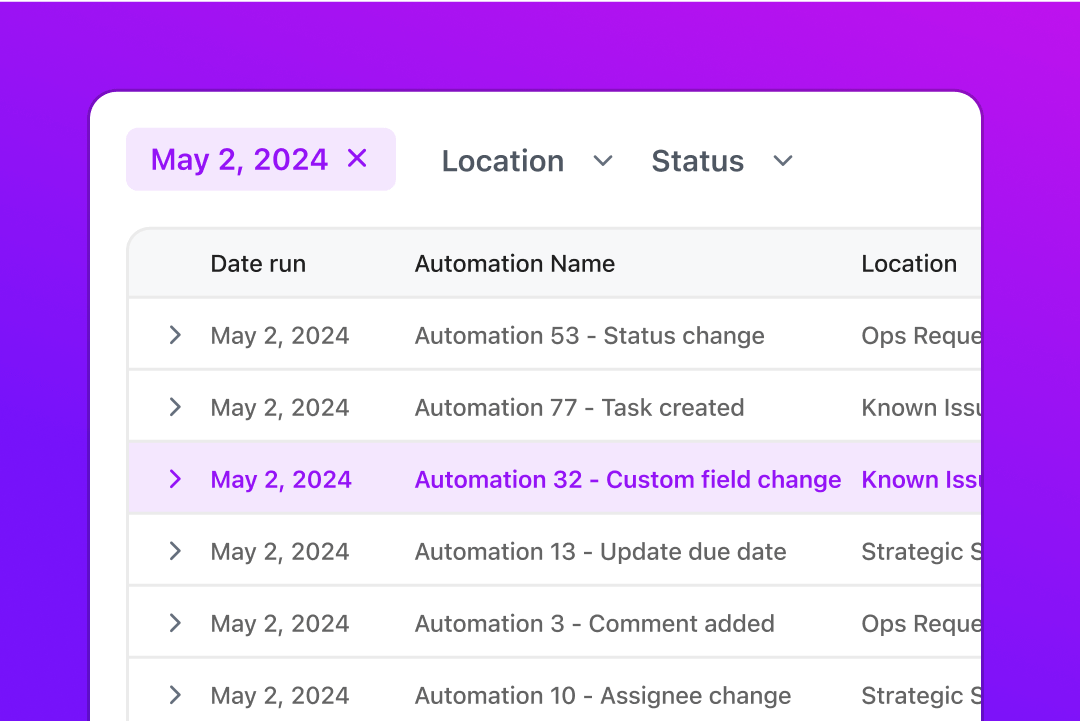

Once you know what’s coming, ClickUp Automation turns that knowledge into action.

Set up rules that create procurement tasks when demand forecasts hit specific thresholds.

Suppose your AI predicts a 40% jump in camping gear sales for May. Boom—procurement tasks automatically appear in March, giving your team two months to secure inventory.

📮 ClickUp Insight: 34% of workers say the biggest barrier to automation is uncertainty about which tools to use. While many want to work smarter, they’re overwhelmed by the choices and lack the confidence to take the first step. 😓

ClickUp removes this confusion by offering intuitive, user-friendly AI Agents that can automate your work within a single platform—no need to juggle multiple tools. With features like ClickUp Brain, our AI assistant, and custom AI agents, teams can automate processes, plan, prioritize, and execute tasks without advanced technical expertise or tool overload.

💫 Real Results: Lulu Press saves 1 hour per day per employee using ClickUp Automations, leading to a 12% increase in overall work efficiency.

AI eliminates stock surprises by tracking inventory levels, sales velocity, and supplier lead times simultaneously. It knows when to reorder before you do.

Here’s a scenario: Your AI notices that wireless headphones are selling 15% faster than usual, and you’ve got a 3-week lead time from your supplier. The math is simple—reorder now, or face empty shelves in two weeks.

ClickUp Automation becomes your early warning system.

When headphone inventory drops below 25 units, it instantly creates a ‘Reorder Now’ task, assigns it to your purchasing manager, and tags it with the warehouse location.

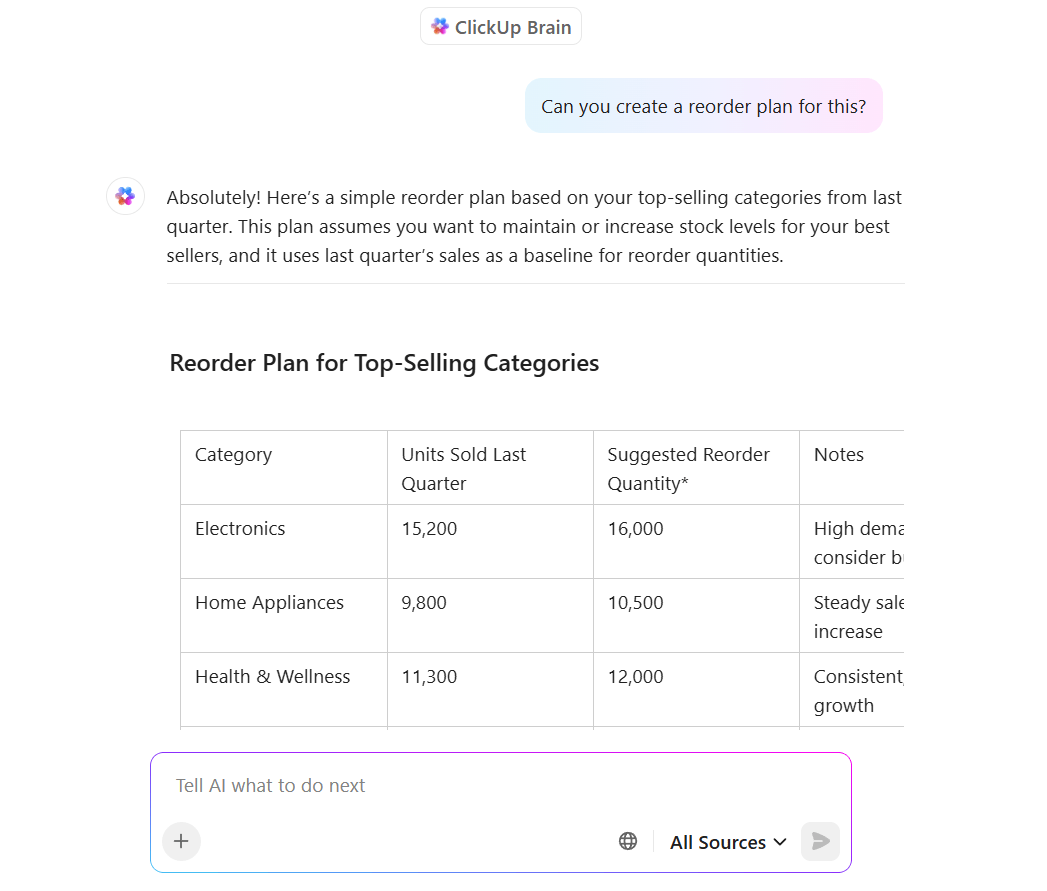

Want to get strategic about reordering?

Ask ClickUp Brain for recommendations based on your actual sales patterns.

For example, ‘Which sizes should we prioritize for our next shoe order?’ The AI assistant might suggest loading up on size 9s (fastest movers) while scaling back on size 13s (slow sellers).

For the full picture, build a ClickUp Dashboard that shows stock levels, reorder points, and incoming shipments all in one view. Your team can spot problems at a glance and make decisions based on real-time inventory metrics within the supply chain dashboard.

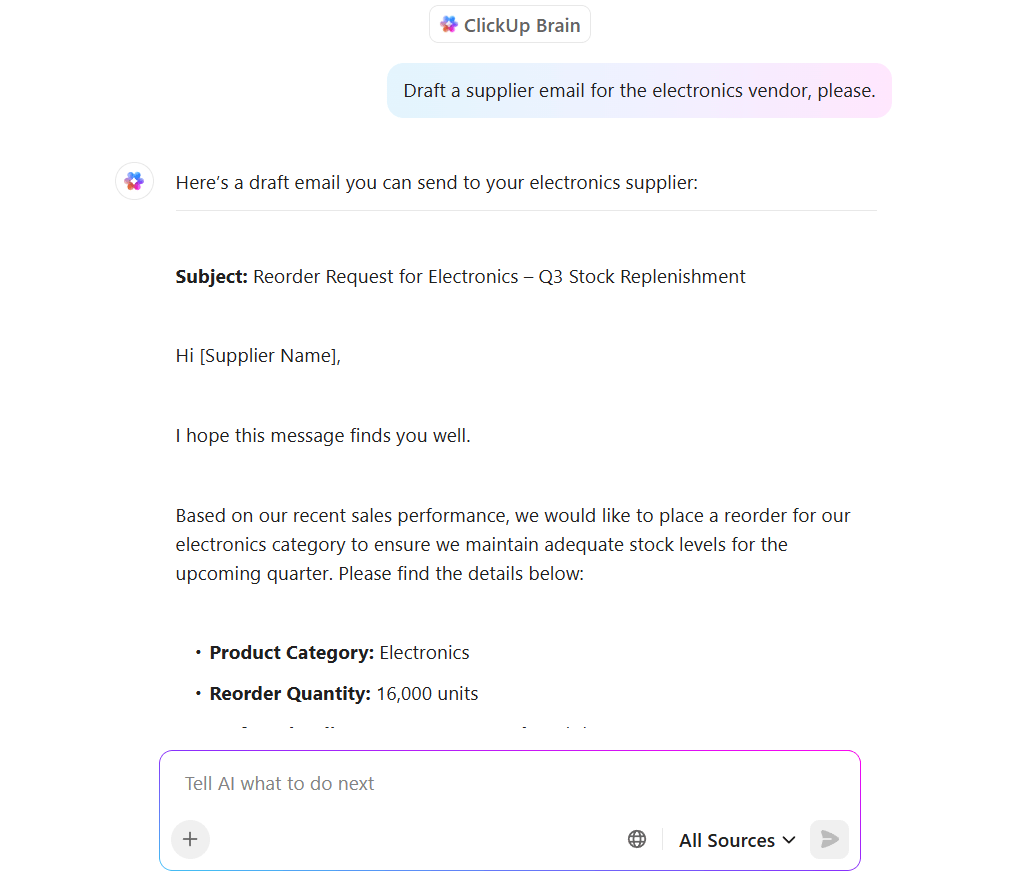

Getting approval for a reorder is one thing. Actually creating and sending purchase orders? That’s where things usually get messy.

AI streamlines this entire process by learning from your purchasing patterns and automating the paperwork. It knows which suppliers you use for specific products, typical order quantities, and standard terms.

In ClickUp, this translates to seamless workflows.

When a manager approves a reorder request, The AI Agents in ClickUp can step in for you immediately. It creates a purchase order task, assigns it to the right person, and drops it into your ‘Pending POs’ list.

Then, when you need to draft a supplier email, ClickUp Brain can pull up your last three orders with that vendor, copy the relevant details, and write a professional message in seconds.

It knows your usual quantities, preferred delivery dates, and standard terms. Writing POs becomes a 30-second task rather than a 30-minute ordeal.

🧠 Fun Fact: Sometimes the system says something’s in stock, but it’s not actually on the shelf. This is known as phantom inventory, which occurs due to theft, misplacement, or tracking errors.

Picture two stores in your chain: downtown is overflowing with winter coats in February, while the mountain location is completely sold out. Automated inventory management systems spot these imbalances automatically and recommend transfers to optimize sales across all locations.

The intelligence comes from analyzing sales patterns, seasonal demands, and local trends simultaneously. Maybe the downtown store ordered too many large coats, but the mountain store can’t keep larges in stock.

AI inventory management software connects those dots.

ClickUp Automation acts on these insights immediately.

When Store A hits 150% of target inventory and Store B drops below 40%, transfer tasks appear automatically for your logistics team. The system calculates optimal quantities and even suggests which items to prioritize based on demand velocity.

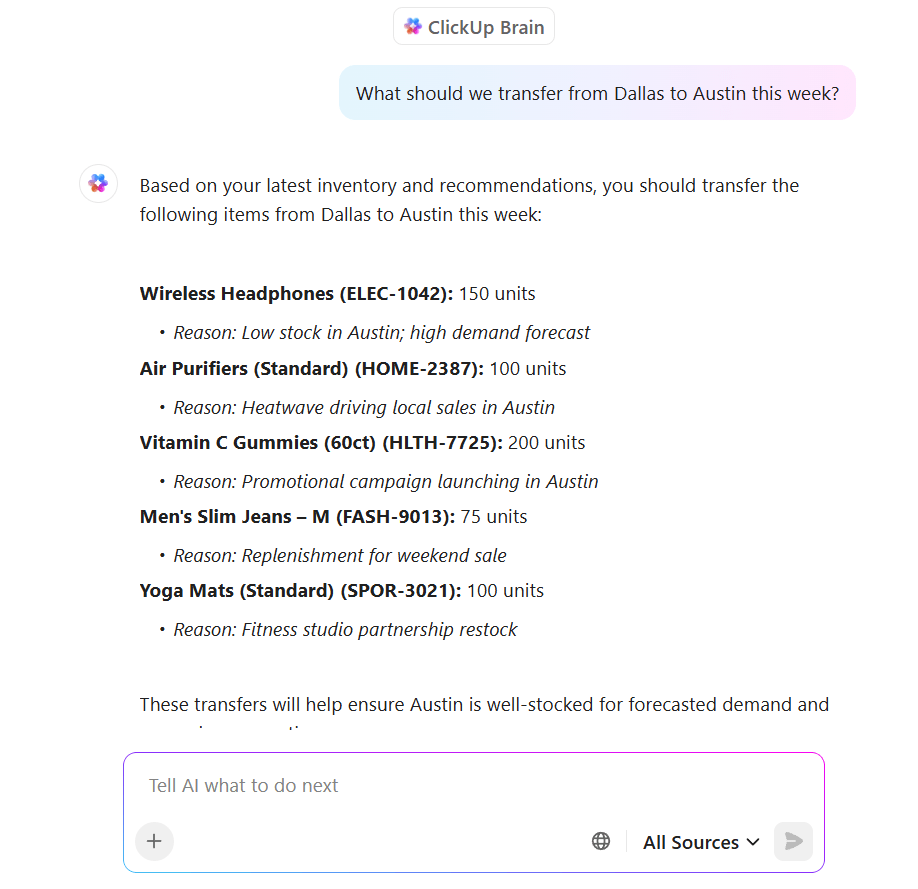

For complex transfer decisions, ClickUp Brain provides detailed recommendations.

Ask questions like ‘What should we transfer from Dallas to Austin this week?’ It considers sales trends, upcoming promotions, historical data, and seasonal factors to suggest specific products and quantities.

Plus, it might recommend moving summer dresses north to south in August, or shifting hiking gear from urban to suburban stores before spring.

💡 Pro Tip: Set alerts for ‘almost wrong’ data, not just errors. AI can catch things that aren’t technically errors but still risky, like a price that’s off by $10 or a stock count that looks fine but hasn’t changed in weeks. These signals are often missed until they become expensive.

Every growing business faces the same problem: product catalogs that balloon over time.

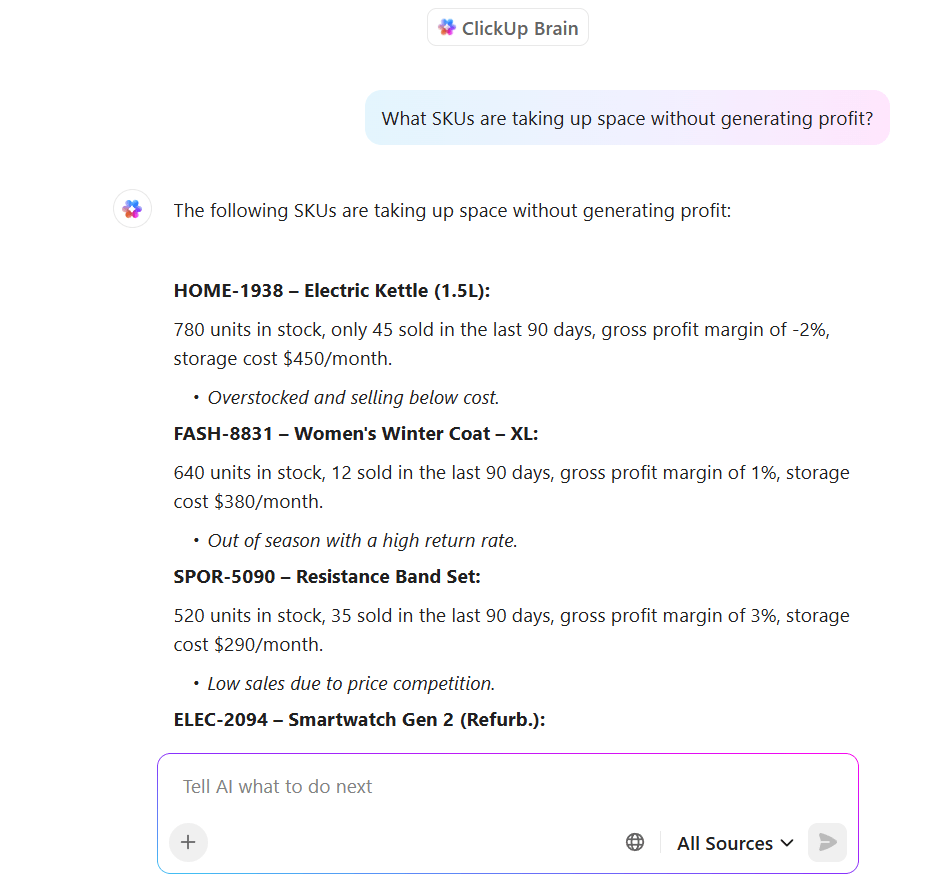

Intelligent SKU analysis looks at sales velocity, profit margins, storage costs, and seasonal patterns to classify your entire catalog. Fast movers get priority treatment. Dead stock gets flagged for clearance. Seasonal items get properly categorized for timing decisions.

ClickUp Brain makes this analysis conversational. Ask questions like ‘Which products haven’t sold in six months?’ or ‘What SKUs are taking up space without generating profit?’

AI delivers answers instantly, along with recommendations for action.

🛠️ Toolkit: Want to skip the setup work? The ClickUp Inventory Management Template comes pre-built with lists, views, and workflows designed for SKU optimization. You get automated categorization, performance tracking, and cleanup workflows right out of the box.

Following up with suppliers often turns into a game of memory—what was said, who was tagged, and what got done. Automated inventory management software helps cut through that mess and keeps your supply-side updates right where your inventory work happens.

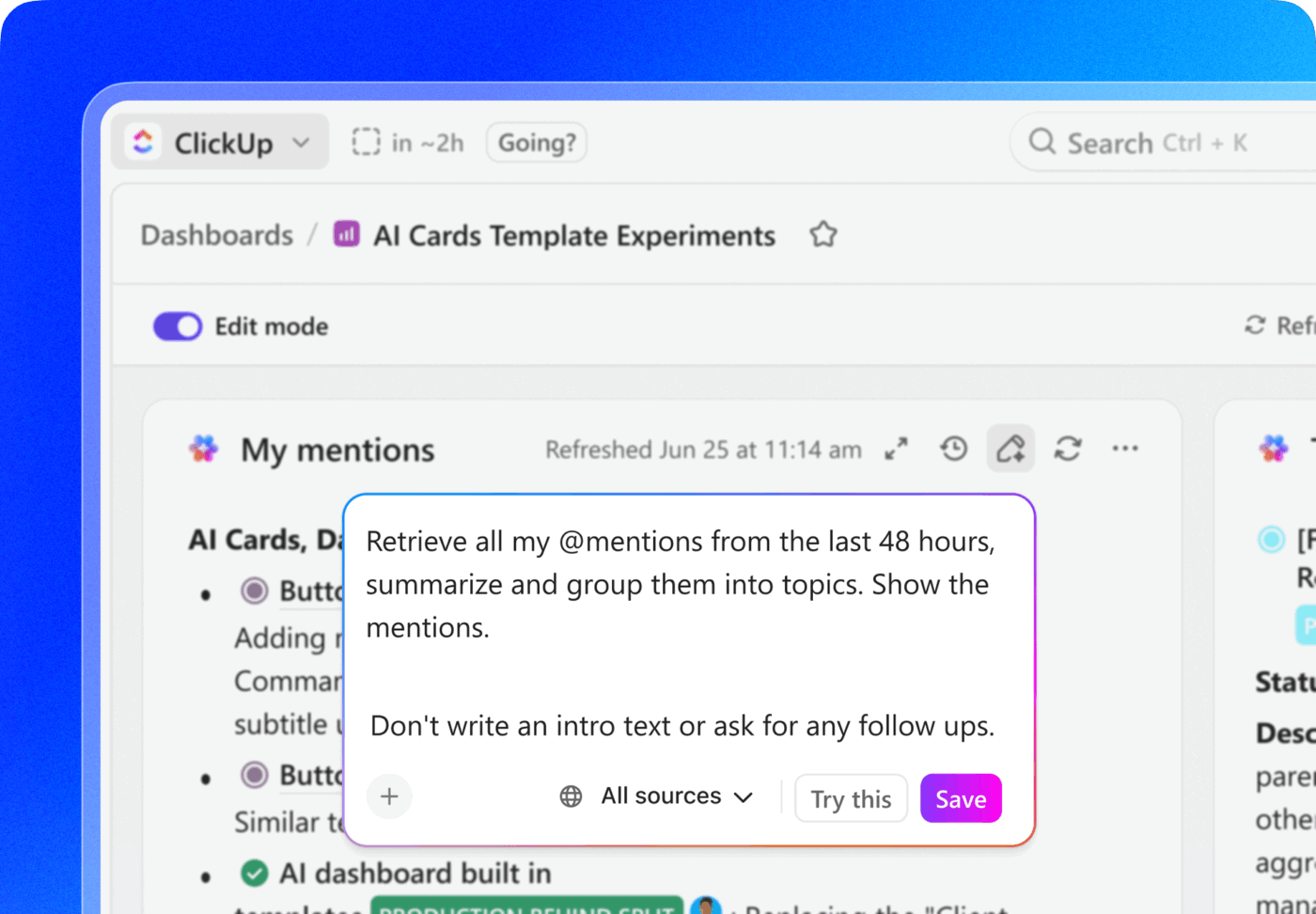

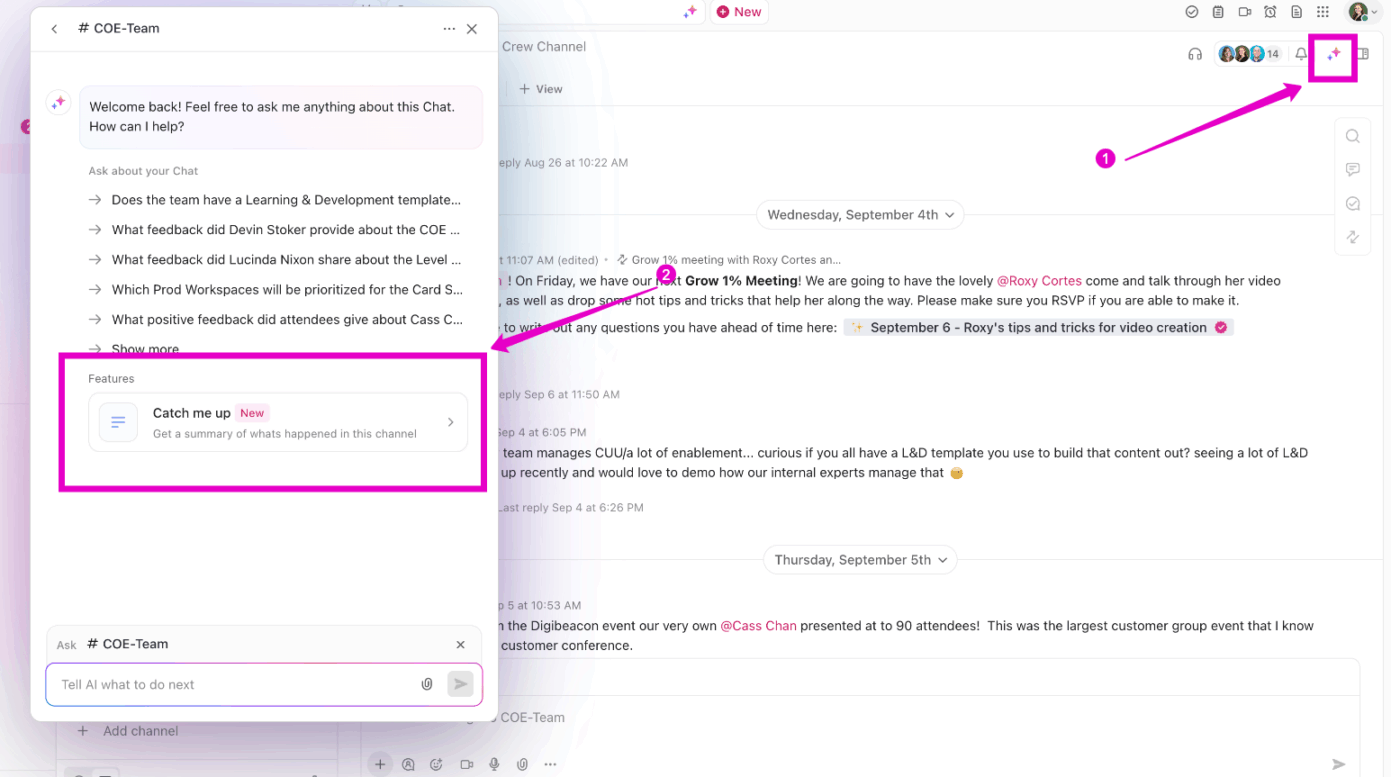

In ClickUp Chat, each Space, Folder, and List comes with its own channel. That means your supplier conversations, restock updates, and PO approvals all stay exactly where the tasks and timelines live.

If you’ve been away or missed a thread, ClickUp AI CatchUp summarizes everything for you. You’ll get a quick overview of what’s been discussed, any open issues, and updates you need to act on.

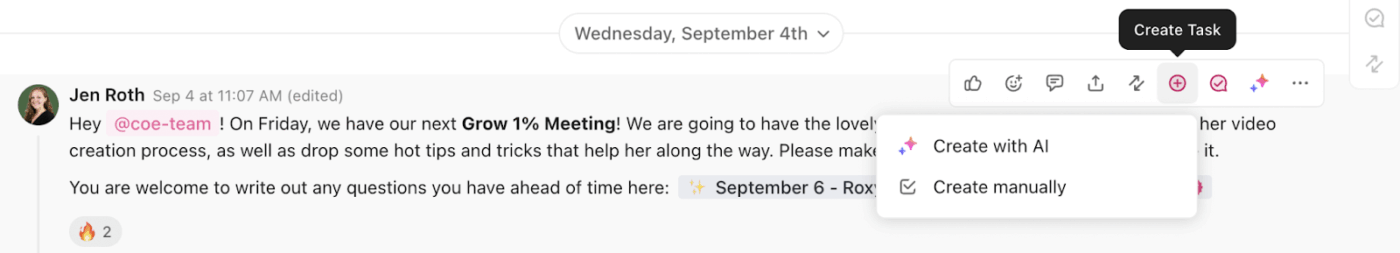

When issues come up and someone forgets to turn a message into a task (which happens more often than we admit), AI Task Creation picks it up. Just click once, and AI creates a task using the full conversation as context—description, assignee, and all.

You don’t even have to leave the thread.

To stay proactive, let ClickUp Agents can step in for you here too. For example, you can assign an agent to monitor the inventory channel for mentions of shipment delays and auto-create follow-ups if no action happens in 24 hours.

Or configure one to post a weekly summary of supplier activity, open POs, and flagged concerns—no chasing, no micromanaging.

📖 Also Read: How to Create an Inventory Management System

Wondering how all this plays out in your world? Here’s a quick look at how different industries are using AI to support inventory optimization and stay ahead. 📈

Shipt is a same-day delivery service that powers everything from groceries to household essentials for millions of shoppers across the U.S. Behind the scenes, their Data Platform team handles a nonstop stream of requests — everything from dashboards to data pulls to pipeline fixes.

Before ClickUp, all of that work was scattered across forms, Slack threads, and random spreadsheets, making it nearly impossible to track or prioritize.

But the team needed a reliable platform to pull all intake into one place, and automations took over the tedious stuff—tagging, routing, assigning, and keeping every request moving. Suddenly, they weren’t chasing down context or digging for missing details. Work flowed, communication tightened, and a huge chunk of manual coordination simply disappeared.

The ability to monitor our operations so closely and with such clarity has transformed how we manage our strategy—we can better support our requests with data and ensure decisions we make are prioritized properly.

⭐️ Industry Callout: UBTECH just dropped a major flex in humanoid robotics with its new Walker S1—a robot designed not for show, but for real industrial work. Built with partners like BYD, Audi, Geely, Foxconn, and SF Express, the Walker S1 is already proving itself: UBTECH released footage of it carrying a 16.3-kg (36-lb) load while casually strolling on a treadmill, barely breaking stride. With 360° vision, tactile-sensor hands, and AI that lets it handle complex, multi-step tasks, this isn’t a demo robot—it’s factory-ready. In fact, the Walker line is already deployed in places like Zeekr’s 5G Smart Factory and FAW-Volkswagen’s Qingdao plant, taking on demanding manufacturing jobs with the balance and coordination of a seasoned worker.

📣 The ClickUp Advantage: If you’re a one-person team running inventory operations on your own, you need that one AI super app that can help you with it all, and we’ve got just the thing!

With deep integration across your spreadsheets, order forms, emails, and calendar, ClickUp Brain MAX brings all your inventory data into one unified dashboard. You can use talk-to-text to quickly log new stock, update quantities, or set low-inventory alerts hands-free. Leveraging multiple leading AI models, Brain MAX can analyze sales trends, forecast demand, and even suggest optimal reorder times—helping you avoid stockouts or overstocking.

It automates routine tracking, organizes supplier communications, and keeps your inventory workflow organized, so you can focus on growing your business instead of getting bogged down in manual busywork.

🔍 Did You Know? When a small change in customer demand hits the supply chain, it often triggers way bigger changes upstream. Manufacturers overreact, distributors overorder, and the whole system piles on inventory. This is the bullwhip effect, and it usually stems from poor communication and guesswork.

🔍 Did You Know? Instead of closing up shop once a year for a big inventory count, teams can do smaller, regular checks through cycle counting. This method helps spot issues early, keeps inventory data accurate, and doesn’t interrupt day-to-day operations.

When every inventory process depends on someone remembering to update a spreadsheet, reply to a message, or fix a mistake before it snowballs, burnout creeps in fast.

But AI shifts that burden.

When you run these processes inside ClickUp, things start to click. You turn conversations into tasks, sync updates in real time, and let AI take the grunt work off your plate.

All of that adds up to fewer delays, cleaner stock data, and a whole lot less operational stress. 😓

Sign up for ClickUp today! ✅

Yes, AI can manage inventory by automating processes such as demand forecasting, real-time tracking, and stock replenishment. AI systems analyze historical sales data and external factors to optimize stock levels, reduce errors, and improve overall efficiency.

Inventory management can be fully automated using AI technologies. Automation covers tasks like monitoring inventory levels, predicting demand, and triggering reorders when stock runs low. This reduces manual effort, minimizes the risk of overstocking or stockouts, and ensures smoother operations.

To create an AI-driven inventory management system, start by collecting and integrating relevant data such as sales history and supplier information. Implement machine learning models to analyze this data and predict demand. Set up automated workflows for tasks like reordering and use tools such as Amazon Rekognition Custom Labels for image-based inventory tracking. Regularly monitor and update your AI models to adapt to changing business needs.

Amazon uses AI extensively in its inventory management. The company employs warehouse automation with robots for sorting and moving packages, uses AI-powered forecasting to predict demand and optimize stock levels, and leverages technologies like smart eyeglasses for delivery drivers to enhance delivery speed and accuracy. These innovations help Amazon streamline its inventory and delivery processes, setting industry standards for efficiency.

How does Amazon use AI in inventory management?

Amazon uses AI extensively in its inventory management. The company employs warehouse automation with robots for sorting and moving packages, uses AI-powered forecasting to predict demand and optimize stock levels, and leverages technologies like smart eyeglasses for delivery drivers to enhance delivery speed and accuracy. These innovations help Amazon streamline its inventory and delivery processes, setting industry standards for efficiency.

© 2026 ClickUp