9 Essential Steps to a Successful Procurement Strategy

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Dale Carnegie said, “An hour of planning can save you 10 hours of doing.”

Plan your procurement strategy well, and you win better deals with suppliers.

With a well-planned procurement strategy in place, you can monitor purchasing decisions by different departments, track supplier performance, and identify scope for streamlining processes or improving cost optimization .

In this article, we’ll show you how to build a solid procurement strategy.

Get ready to gain control of your spending, mitigate risks, and improve operational efficiency for business growth.

Let’s get right into it. 👇

A procurement strategy is an organization’s plan for obtaining items at the best possible price while maintaining delivery and quality standards. It involves finding the right suppliers, negotiating the best price, making purchases, and securing deliveries.

A strong procurement policy and strategy guides your procurement team toward achieving long-term business goals. Therefore, it should be flexible, adaptable, and constantly evolve alongside your company’s needs.

Procurement strategies are not just about slashing costs or getting the cheapest deals—although that’s important. It’s more about acquiring quality goods and services at the right price and time to keep your business operations running smoothly.

The best procurement strategies go beyond basic purchasing. They align with your company’s bigger goals, from prioritizing social responsibility to fostering innovation through supplier partnerships.

Taking a comprehensive strategic approach to procurement helps your team make a solid plan, turning the whole process into a valuable asset that gives you a competitive advantage.

An effective procurement strategy tackles four agendas:

There’s no one-size-fits-all. So here are six types of key procurement strategies that can help you achieve your goals:

The context says it all: getting the most value for your money. This cost-reduction strategy goes beyond the initial purchase price. It uses techniques like competitive bidding and value analysis to help you negotiate the best deals and consider the total cost of ownership (TCO)—including maintenance, repairs, and disposal costs.

Example: Consider a company that produces packaged snacks in a crowded and competitive market. In such circumstances, where most manufacturers compete on price and distribution, keeping cost prices low is a significant concern. This company could decide to reduce its input pricing by achieving cost reductions across raw materials and packaging. They could float an RFQ for packaging material, invite companies to bid for the contract, and opt for a new supplier who can give them significantly lower costs for the same material.

Best suited for:

Supply chain disruptions often lead to production delays and lost revenue. A strong procurement risk management strategy helps you anticipate and mitigate potential supply chain disruption problems.

The strategy involves partnering with multiple reliable and efficient vendors to ensure you’re not reliant on a single source for critical items. Ultimately, securely procuring business essential supplies during unexpected events, like natural disasters or supplier insolvency.

Example: A global automotive manufacturer uses a risk management strategy to sort semiconductor crises. They’d partner with multiple reliable chip suppliers in different geographical locations, ensuring smooth production even in case of disruption at a particular supplier or region.

Best suited for:

Supplier management and optimization strategy focuses on building better business-supplier relationships. The strategy mainly involves setting supplier performance standards, conducting audits, and providing training and support.

While specifics might differ from business to business, fostering strong supplier relationships is crucial to production-heavy firms. Imagine collaborating with your suppliers on innovation, jointly planning for future needs, and having reliable partners that deliver consistently.

Let’s see how to implement this strategy with an example. 👇

Example: Suppose a clothing company implements a supplier management strategy with a fabric manufacturer. After establishing quality standards for the manufacturer, the company conducts regular audits to ensure consistent quality.

Additionally, they conduct brainstorming sessions with the manufacturer, discussing new fabrics, technologies, and designs trending in the market. The strong relationship fosters trust and ensures high-quality fabric.

Best suited for:

Being environmentally responsible extends to your own procurement policies and practices. Green purchasing does precisely this.

This procurement strategy involves procuring products or services with minimal environmental impact. The procurement strategy framework focuses on suppliers committed to sustainability, prioritizing products from recycled material, low-emission, or energy-efficient products.

Example: A grocery store chain adopts a green purchasing strategy. They prioritize sourcing fruits and vegetables from local farms that utilize sustainable practices like organic farming and water conservation.

They might also choose cleaning products with eco-friendly certifications and packaging made from recycled materials.

Best suited for:

Companies with a serious commitment to reducing their carbon footprint

Global sourcing involves extending your supplier base beyond local markets. It leverages the competitive landscape of a globalized economy, potentially leading to significant cost savings.

Also, looking beyond your borders creates new possibilities, like exploring untapped markets and finding better prices or higher quality goods.

Global sourcing strategies are mainly used by companies that need raw materials that are not readily available or cost a fortune in their local market.

Example: A furniture company may find it hard to source hardwood lumber due to flora differences across regions locally. However, they might learn that the same wood may be readily available in some other regions, say Southeast Asia.

So, to counter the supply deficit, the company implements a global sourcing strategy for procuring hardwood lumber. This ensures consistent supply, reduces costs, and allows the company to sell imported wood at better rates.

However, it requires careful planning and management. Cultural differences, complex logistics, and quality control procedures must be addressed to ensure a smooth and successful experience.

Best suited for:

Total Quality Management (TQM) is a procurement strategy that emphasizes proactive quality control measures throughout the supply chain—setting quality standards, conducting inspections, and implementing quality control measures.

The strategy aims to minimize defects and ensure that products meet quality standards. Both buyers and suppliers continuously work to improve processes, identify opportunities for cost reduction, and enhance overall quality.

Example: Petroleum-producing companies generally use TQM in their procurement process. Since the stakes are high in petroleum production, TQM helps them address quality-related issues in procuring technical materials for oilfield facility maintenance and project construction.

Best suited for:

Use our proven nine-step process to build a robust procurement strategy that delivers:

Before charting a new strategy, it’s essential to understand your current procurement spend. To do so, conduct a thorough audit of your spending habits. Gather data on your existing procurement policies and activities, including:

Analyze this data to identify areas of high spending, potential cost-saving opportunities, and any instances of maverick spending (unauthorized purchases).

Diving deep into the nuances helps pinpoint your efforts and tailor your strategy accordingly.

What outcomes do you desire from your procurement strategy?

Having clear goals provides a roadmap for your strategy execution and allows you to measure its various success metrics.

Here are some common procurement goals:

Clearly defining your business requirements and goals ensures your strategy is well-targeted and delivers business-centric results.

Changes in the external environment can significantly impact your procurement strategy. Consider factors like:

Staying informed about market conditions allows you to adapt your business strategy due to changes and make well-rounded decisions.

For instance, if you anticipate rising material costs, you may want to explore alternative suppliers or negotiate longer-term contracts with existing ones.

Based on your strategic procurement priorities, goals, and market analysis, define how you’ll source the goods and services you need. Here are some common sourcing strategies you can look forward to:

The best sourcing strategy depends on your type of purchase. For example, competitive bidding is ideal for standard office supplies, while single sourcing is preferred for acquiring complex machinery with few qualified vendors.

Technology can significantly streamline your procurement process, improve accuracy, and save your team’s time. Here’s how:

Integrating such tools into your processes improves efficiency, reduces errors, and allows your procurement teams to focus on strategic tasks like supplier relationship management and market research.

A well-defined procurement vendor management team structure starts with outlining clear roles and responsibilities for each team member. This could include:

Clearly defined roles and responsibilities prevent confusion, ensure accountability, and contribute to the smooth execution of your procurement strategy.

Key Performance Indicators (KPIs) are quantifiable measures that allow you to track progress and identify grey areas in your procurement process.

Consider these potential KPIs to measure your procurement efforts:

By tracking these metrics, you demonstrate the procurement strategy value to stakeholders and identify areas with optimization needs.

👀Note: Regularly review and refine your KPIs to ensure relevancy and alignment with your evolving goals.

A winning procurement strategy is a living document. It needs to iterate and adapt to changing circumstances. Therefore, developing a culture of continuous improvement within your procurement team.

Use this checklist to ensure your procurement strategy is flexible and adjustable to changes:

By fostering a culture of continuous improvement, you build a procurement strategy that delivers long-term value for your business.

Regularly communicate the procurement strategies and its goals to all relevant stakeholders, including:

This communication should address how the strategy aligns with overall business objectives and how it benefits stakeholders.

Keeping everyone in the loop and informed of strategic objectives fosters collaboration, ensures buy-in, and helps achieve the desired outcomes.

And Voila!

These steps will help you develop and implement a comprehensive procurement strategy that optimizes spending. Use them to mitigate risks and see the steady flow of the goods and services your business needs to thrive in a competitive marketplace.

Also Read: The best vendor management software for your business

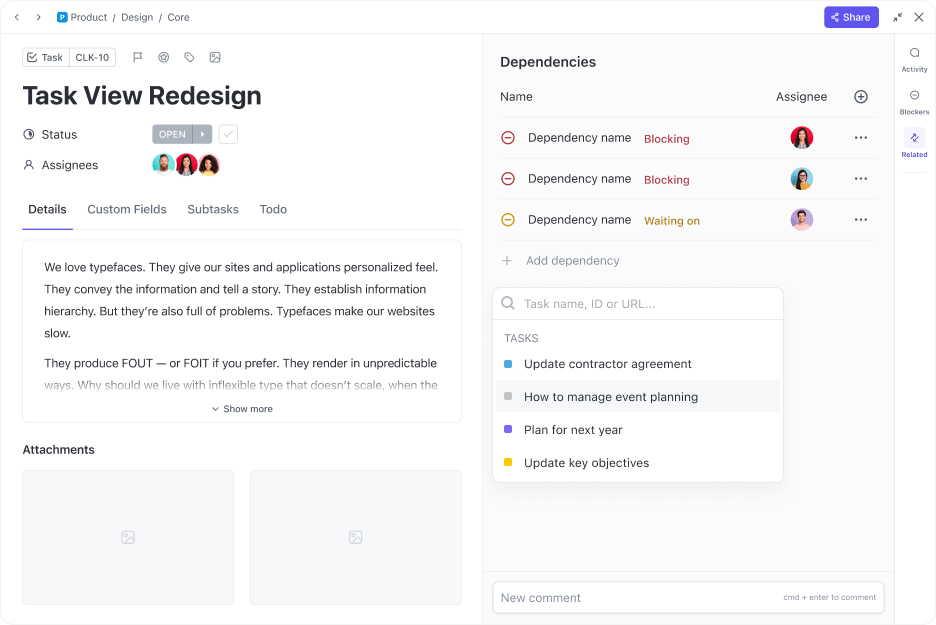

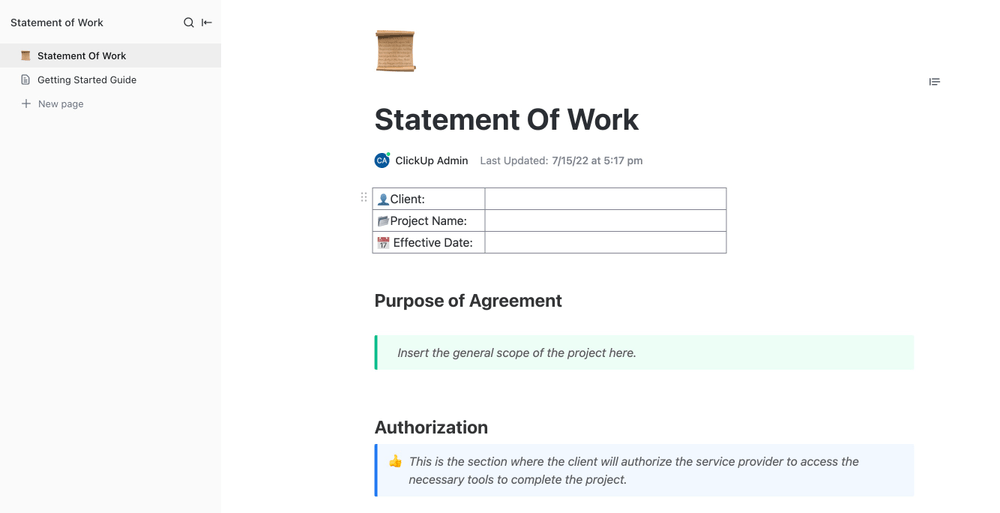

A procurement strategy is essential, but managing it efficiently can be challenging. ClickUp is a powerful project management tool offering a comprehensive toolkit to streamline your procurement performance.

Let’s see how. 👇

ClickUp’s Procurement Template helps you standardize the supplier selection process, stay organized, communicate effectively with vendors, and reduce errors by eliminating manual data entry. Easily customize the template to fit your specific procurement activities, automating administrative tasks like sending requests for quotations, managing approvals, and tracking deliveries.

Take a look at some real-life examples of successful procurement strategies with sources you can explore further:

Walmart is known for its aggressive cost-cutting measures, and procurement plays a big role. They leverage their massive buying power to negotiate lower prices with suppliers worldwide.

A key sourcing cost efficiency strategy is establishing long-term contracts with key suppliers and encouraging them to reduce costs continuously.

This strategy has been instrumental in Walmart’s consistently low prices for consumers. It’s estimated that they save billions of dollars annually through this approach.

The Air Force streamlined its procurement process by collaborating with other military branches. This involved standardizing procurement procedures and leveraging combined buying power to negotiate better supplier deals.

Collaboration has led to significant cost savings for the Air Force and improved efficiency in the procurement process.

Building a procurement strategy is no easy feat. But with ClickUp as your partner, you can simplify the purchasing process further, optimize spending, and achieve your goals.

ClickUp empowers you at every stage—from automating repetitive tasks to fostering collaboration and insightful data analysis.

Optimize your procurement processes and secure greater value for your business. Start your free ClickUp trial today and see the difference!

© 2026 ClickUp