In the 1900s, canaries were used as sentinels in coal mines. When carbon monoxide—undetectable to human beings—reached dangerously high levels, the birds stopped singing. This served as a timely warning, giving the miners enough time to escape.

Control charts are like canaries. When everything is under control, the control chart, which is a graph plotting quantitative measures against time, will present a non-threatening picture. Unexpected variations or extraordinary deviations that threaten your project will set alarm bells ringing.

First developed in 1924 by Walter A. Shewhart, control charts were used to differentiate between random variation—which is normal—and disruptive variation in the manufacturing process for telecommunications equipment at Bell Labs. Today, these charts are used in quality control, healthcare, R&D, and service industries.

Project Management Professionals (PMPs) use them for quality management and process control. They help monitor performance, identify special-cause variations, and ensure project managers can take corrective action to keep variation within predefined limits. In the long term, they serve as a tool to drive continuous improvement and data-driven decision-making.

This article explains the use of control charts in project management with examples describing real-world scenarios. Let’s see how they can help you build proactive rather than reactive project management strategies and stay one step ahead.

Understanding Control Charts

A control chart, also called a statistical process control (SPC) chart or Shewhart chart, is a powerful graphical tool designed to monitor and maintain control over process quality and project execution. It ensures that operations proceed under stable, consistent conditions, helping to maximize efficiency and maintain the overall flow of your business.

Example 1: Let’s say the school bus is meant to arrive at your doorstep at 7:00 AM every morning. Some days it’s a bit late, others it’s a little early. Either way, it reaches school before the morning bell rings, so you aren’t too worried.

Now, what happens if one day, the bus arrives 20 minutes early? Or 20 minutes late? That’s a large variation from the usual routine and one that will severely disrupt your own morning schedule.

So, the basic idea behind control charts is that every process involves variations, but only some of these variations result in catastrophic failure. By visually tracking all process variations, a control chart can help identify variations and address issues in projects early. This proactive approach supports a smoother, more reliable business operation.

Every control chart contains five elements.

- Data points: These are the individual measurements or values, each representing a snapshot of your process at a specific time. In the control chart above, the school bus arrival times are your data points

- Time axis (x-axis): The horizontal axis typically represents time, showing when each data point was collected. This helps you see how your process changes over time

- Measurement axis (y-axis): The vertical axis represents the variable you’re tracking, such as the number of defects, flight departure delays, deviations in weight or volume, or any other metric relevant to your process

- Center line (central line): This horizontal line represents the average of all your individual data points. It’s your baseline for understanding normal process behavior

- Upper control limit and lower control limit: The upper control limit (UCL) is a line set above the mean, and the lower control limit (LCL) is a line below the mean. Both control limits are usually set at three standard deviations. Together, the UCL and LCL form a band around the mean line. Your process is under control as long as your data points stay within this band. When points fall outside the band created by the control limits, it signals a potential issue

How do you create a control chart?

Creating a control chart is simple. Here’s what you do:

- Gather your data: First, collect the data you want to monitor. This could be anything from daily sales figures to the time taken to complete tasks

- Plot the data: On a graph, plot your data points along a timeline. The x-axis usually represents time, while the y-axis represents the variable you’re measuring. Plotting data points against time gives you a time series plot—the first stage of a control chart

- Calculate the mean: Find the average of your data points and draw a horizontal line across your chart at this value. This line represents your process’s central tendency

- Set control limits: Calculate the upper and lower control limits to help you determine when a process goes off track. Draw lines at these values above and below the mean line

- Interpret the chart: Observe how your control chart behaves with reference to your established control limits as you add data. Your process is stable if your data points stay within these limits. If they go beyond the limits, take action to correct the process before it spirals out of control

Key control chart metrics and data

Once you’ve created a project control chart, you’re halfway there. It’s now time to analyze the results. Use these metrics to assess your performance:

- Range (R): The range is the difference between your sample’s highest and lowest data points. You can use it to get a quick sense of the variability within each data subgroup

- Deviation (x − xˉ): Deviation refers to the difference between a single data point and the average value (mean). It tells you how far that particular point is from the mean

- Standard deviation (σ): This measures the spread of all the data points around the mean. It calculates the average amount that each data point deviates from the mean, giving a sense of the overall variability in the data

- Variance (σ2): Variance measures how much your data points differ from the average (mean). It’s calculated by squaring the differences between each point and the average and averaging those squared differences. In simpler terms, variance shows you how much variation there is in your process

You can also use the Rule of Seven in PMP, a simple yet powerful measure for identifying patterns of out-of-control processes.

The Rule of Seven states that if seven consecutive data points fall on one side of the center line—either all above or all below—then the process may be experiencing an issue that requires investigation.

The Rule of Seven is significant because:

- This pattern often indicates a subtle shift even within the control limits that could eventually lead to a more significant problem

- It helps determine whether external factors are influencing your process or if there’s a consistent shift in the way the process is behaving

Now, let’s explore the control charts you can use to manage your projects’ scope, cost, timeline, quality, resources, and risk.

Types of Control Charts with Examples

There are many types of control charts, each catering to a unique type of control requirement.

1. Variable charts

Are you looking to use precise measurements to control specific aspects of your process, such as weight, temperature, or time? A variable control chart is exactly the statistical tool you need.

This type of chart helps you monitor processes where you measure something that can take any value within a range, like a product’s weight or the time it takes to complete a task.

Example 2: Your manufacturing plant produces custom sheet metal parts for industrial clients with exact specifications, particularly in terms of thickness. To ensure quality, you use a variable control chart to monitor the thickness of the parts.

Every hour, you measure a sample of parts and plot the average thickness on the chart. If the measurements stay within the specified range, your process is in control, ensuring consistent quality. But if the chart shows a drift, it signals a need to adjust your machinery to avoid producing defective parts.

2. Attribute charts

Are you dealing with pass/fail results or counting defects in your process? That’s where an attribute control chart comes in. Unlike variable charts that measure specific values, attribute charts focus on present or absent qualities, like whether a product meets standards or how many defects appear in a batch.

Example 3: Your company produces electronic components for businesses. You inspect each batch for defects, like faulty wiring or missing parts. Using an attribute control chart, you can track how many control chart components pass inspection versus how many are defective.

If the number of defects stays within an acceptable range, your process is under control. But if defects rise, the chart will highlight this, prompting you to investigate and fix the issue before it impacts your deliveries.

3. Additional charts

Specific control charts, like Cumulative Sum (CUSUM) and Exponentially Weighted Moving Average (EWMA) charts, are perfect for detecting small shifts and trends.

Example 4: Your company produces vaccines for pharmaceutical companies. Even minor variations in the concentration of ingredients can lead to product failures or regulatory issues.

Using a CUSUM chart, you can continuously monitor the cumulative sum of deviations from a target concentration level. This chart allows you to detect even the smallest shifts in the vaccine components over time. If the chart shows a drift from the target, you can take immediate action to correct the issue before it affects an entire batch.

Example 5: You want to predict stock price volatility as part of financial risk management. By collecting the daily returns of 100 companies listed on the stock exchange over a period of 5 years, you can use the data to build an EWMA model and display the results using an EWMA chart.

Your EWMA chart can provide insights into the trend of stock prices and point you toward likely periods of volatility based on historical volatility.

Using the correct chart can help you track and analyze process performance, identify areas of improvement, and make data-backed decisions in your project management.

Using Control Charts in Project Management

Control charts allow you to automatically monitor every process, ensuring immediate attention to any alarming changes beyond control points. This approach frees you from the need to micromanage.

Here’s how to effectively use control charts in project management processes:

- Define key metrics and identify which aspects of your project you need to monitor

- Gather data consistently to feed into your control chart, as it helps in accurately assessing performance trends and making timely adjustments

- Look for patterns or shifts in your control chart to identify potential issues early and take corrective actions before problems escalate

Let’s guide you through using control charts in project management with practical examples:

- Tracking project timelines: Suppose you’re managing a software development project. You can use control charts to monitor how long each development phase takes compared to the planned timeline. If you notice that the actual durations consistently exceed the control limits, it signals that adjustments are needed in your planning or resources

- Budget monitoring: In a construction project, a control chart works to help track budget expenditures against the planned budget. If the spending starts to exceed the control limits, it may indicate overspending or hidden costs, prompting a review of your budget management strategies

Note that every control chart has a specific function: monitoring process stability and variation for a single process. If you want to examine a process’s performance using historical data and identify bottlenecks, a Cumulative Flow Diagram that visualizes your project’s workflow in terms of accumulating tasks over time would be more useful.

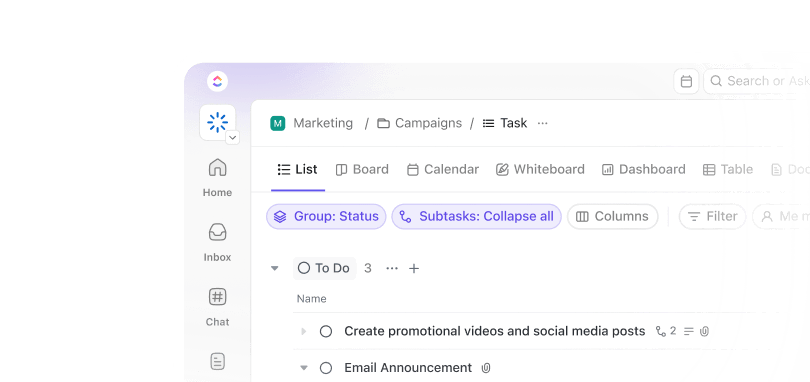

Creating control charts with ClickUp

While control charts are invaluable for project management, creating them can often be tedious. That’s where project control software such as ClickUp comes in. You can also use robust AI tools for data visualization to create and visualize control charts.

ClickUp Whiteboards

ClickUp Whiteboards is a data visualization tool that allows you to design and customize any control chart from scratch. You can draw and arrange graphs and charts to match your specific project metrics and needs.

Not just this, you can also use Whiteboards to brainstorm and collaborate with your team on control chart design and visualize different data points, discuss potential issues, and adjust your charts in real time.

Plus, you can integrate data from various sources into your Whiteboards, creating comprehensive control charts that accurately reflect your project’s performance.

ClickUp Dashboards

If you find it challenging to manage and navigate different metrics and control charts simultaneously, ClickUp Dashboards is just the right tool for you. It provides a comprehensive view of aggregate data from multiple sources and unifies it for swifter project coordination.

You can customize your Dashboards to display control charts in a way that suits your preferences. Choose from various chart types and layout options to highlight the most critical information.

Additionally, it reflects real-time data. This means you have a bird’s-eye view of up-to-date control charts that reflect the latest project data, helping you monitor trends and variations as they happen.

ClickUp Gantt Chart View

ClickUp’s Gantt Chart View helps you track project timelines and milestones. Incorporating control charts with Gantt charts assists with project monitoring of how task durations and completion rates compare to planned schedules.

The central role of Gantt charts is to show task dependencies and how delays in one task might impact others. You can also use them to compare this with control chart data to see any discrepancies between planned and actual performance.

Using ClickUp for control chart creation can help you:

- Get a comprehensive view of your project’s performance by combining Whiteboards, Dashboards, and Gantt charts

- Spot trends, deviations, and potential issues before they obstruct the whole project

- Streamline your workflow, making it easier to create, track, and analyze control charts

The Advantages and Disadvantages of Control Charts in Project Management

Using project management charts to control different processes has advantages and disadvantages.

Some advantages you can benefit from include:

- Performance monitoring: Every control chart provides a clear visual, helping you understand how a project is performing over time and identify trends and deviations

- Quality control: They help ensure that the quality of your deliverables meets the required standards by highlighting any variations that could impact the final output

- Process improvement: By analyzing the data from control charts, you can identify areas where processes can be optimized. This continuous feedback loop fosters ongoing improvements

- Data-driven decisions: Control charts provide objective, data-based insights, reducing reliance on guesswork. This helps in making informed decisions that are backed by actual performance data

With these advantages, there are also certain limitations you must consider before creating a control chart, such as:

| Limitation | Description | Mitigation |

| Complexity | Control charts can be difficult to create and interpret, especially for teams tracking multiple processes. | Provide training and use software tools like ClickUp to simplify the process and make it more accessible to your team. |

| Over-reliance on data | Focusing solely on data might lead to ignoring human and qualitative aspects of project management. | Balance control charts with qualitative insights from team members and stakeholders for a well-rounded approach. |

| Misinterpretation of data | Inaccurate interpretations can lead to misguided decisions. | Regularly review control charts with a team of experts or use software that offers clear and straightforward analysis. |

You can combine tools and techniques such as Gantt charts and dashboards for a comprehensive project view. Further, stay updated with changes in the control charts to allow for timely interventions.

Optimize Project Performance with Control Charts in ClickUp

Control charts help you keep your projects and individual tasks in control. Today, they rank among the most basic quality tools used by any project management professional. You can easily analyze when a particular aspect of project management is out of control and immediately take action to ensure the project deadlines remain unaffected. You can use different control charts for varied purposes and even combine them where necessary.

Leveraging project management platforms like ClickUp makes creating and integrating control charts effortless. With features such as Dashboards, Whiteboards, and Gantt charts, you can maintain a comprehensive and real-time visual representation of all project processes.

This integration empowers you to make proactive decisions swiftly, ensuring your projects progress smoothly and meet their intended goals on time.

Sign up for ClickUp today and optimize project performance in no time.