Procurement KPIs: A Guide to Tracking Procurement KPI Metrics

Sorry, there were no results found for “”

Sorry, there were no results found for “”

Sorry, there were no results found for “”

A sound procurement strategy stands for more than just cost savings.

Procurement managers constantly look for tools and metrics to optimize their strategy and measure supplier performance. Are you stuck in a similar loop? We’ve got you covered with this guide to tracking procurement KPI metrics.

As per the Market Research Report, the Procurement as a Service (PaaS) market will boom at a CAGR of 6.4% between the years 2020 and 2027. As procurement activities become increasingly complex, data becomes an important efficiency driver.

For this reason, companies actively track purchasing metrics (also known as procurement KPIs).

We’ve listed some of the top KPIs procurement leaders use to measure the effectiveness of the procurement department. Break the loop and improve your procurement performance with this guide.

The procurement process covers everything your procurement department does to obtain and source goods and services.

Procurement Key Performance Indicators (KPIs) are measurement metrics that help understand your procurement management efficacy. These KPIs analyze how the company regulates time, cost, and quality.

When it comes to setting these procurement KPIs, you’ve got to consider a few things like:

Your choice of procurement KPIs could vary depending on where you stand on these five parameters.

Remember, there’s no perfect set of procurement metrics. It’s not a one-size-fits-all solution; it needs a personalized approach.

The three main factors that make procurement metrics important are:

Also read: 20 Marketing KPIs you need to track

Measuring procurement efficiency has many benefits for your business:

Identify opportunities for savings: By tracking metrics like spend under management, procurement ROI, and cost per invoice, procurement teams can find ways to save costs and improve the organization’s overall profitability.

Manage supplier risk: Supplier risk is a real concern for procurement leaders everywhere. Risks from suppliers could be financial, legal, operational, or even reputational. Metrics like supplier defect rate, PO accuracy, and vendor availability rate can help you avoid any downsides of working with a sub-par supplier.

Streamline procurement activities: Procurement could become decentralized in large organizations with multiple business units. In such cases, tracking procurement metrics like price competitiveness, purchase order cycle rate, and compliance rates can help you ensure that procurement activities across the organization follow specific processes and best practices.

Align with organizational goals: Leaders should also track procurement KPIs to ensure the team’s efforts align with the organization’s overall strategic direction. For instance, if the organization’s goal includes having the highest quality of products, procurement teams’ KPIs should reflect the stress on quality, even if that means lower cost savings.

While the ideal procurement strategy is subjective, we have outlined some essential KPIs every procurement team can benefit from.

Measure how many suppliers you have and which ones you depend on the most using this metric. Companies sometimes have multiple sales points for different products or even multiple suppliers for a single product.

While having limited suppliers proves beneficial in the form of discounts and better quote management, they might heighten dependency. On the other hand, having multiple suppliers might reduce your dependency but increase costs.

Increasing suppliers, especially for critical products, can help reduce risk and meet new market demands.

Think of this KPI as your supplier rating scale. Supplier quality rating helps you identify risks or problems, and improve supplier quality over time. It looks at delivery speed, supplier responsiveness, cost, and the quality of the service. Apart from quantitative measures, organizations could also use qualitative measures like supplier audits and management assessments.

Setting clear supplier quality goals and monitoring the supplier data can help procurement teams improve supplier quality and procurement efficiency over time.

Compliance rate is a vital procurement metric aligned with supplier performance. It helps you know whether suppliers adhere to compliance requirements and align with business needs.

Compliance rate KPI is crucial to manage because a drop here automatically leads to increased indirect procurement. Contractual and legal compliance is also critical for legal security. To compute this metric, identify the proportion of disputed invoices among the total invoices and track gaps between the price quoted and the price paid.

To begin with, a compliance KPI of 50% is a reasonable target for a mid-sized firm.

Even with the most detailed planning, there are bound to be occasional emergencies when you need supplies urgently. This KPI indicates how reliable a particular vendor is, so you can feel confident about turning to them in emergencies. Supplier availability KPI is calculated as a ratio of how many times the supplier delivered urgently to the total number of times an urgent requirement was placed.

A 90% and above supplier availability indicates a reliable supplier and an efficiently running supply chain.

Supplier defect rate is a measure to evaluate an individual supplier’s quality. This metric becomes a crucial factor for the purchasing department in evaluating the overall quality of the product.

Calculate supplier defect rate by dividing the total number of substandard products by the total units inspected, often expressed as the defect rate per million units. This measure actively assesses product quality and keeps suppliers accountable. To gain deeper insights, break down the supplier defect rate by defect type, enhancing your understanding of individual vendor quality.

Naturally, supplier defect rates are critical metrics in industries such as aerospace or automobiles, where defects can lead to loss of lives.. Depend on this key metric to rank your sellers and ensure the highest quality in your product delivery.

The purchase order cycle time is a KPI you just cannot ignore. It determines which supplier is ideal when you are in a rush.

This metric covers the purchasing journey from order placement and approval to delivery, invoice, and payment. The purchase order cycle time results vary from hours to days altogether.

Categorize your suppliers depending on their order cycle and place orders with them accordingly.

Allocate urgent orders to suppliers, guaranteeing a shorter purchase order cycle and comfortable orders to those with a relatively larger cycle. Tracking this metric keeps your procurement process robust and accurate.

Lead time refers to the time a particular vendor takes to fulfill an order. You measure this by checking the time elapsed between the moment an order being placed with the company and the time when the product is delivered.

The math behind it is pretty simple: just subtract the time it takes to accept a Purchase Order from the total delivery time, and there you have it! That’s your supplier lead time in a nutshell.

Supplier lead time = Delivery time – Order time (PO acceptance)

Achieving shorter lead times without compromising quality can help keep customers happy.

This metric records the number of timely purchases within stipulated budgets. A data-driven report on this KPI provides insight to the purchasing team about whether the organization’s resources are optimally utilized. It is an operational KPI that reflects directly on the efficiency of the procurement department.

If most of your purchases match the targeted cost and time, your purchasing efficiency game is on point. Conversely, frequently overshooting budgeted time and costs would raise alarm bells among procurement teams.

Carefully tracking this metric, and optimizing as needed, will help you meet the purchase budget and time target.

Besides analyzing supplier cost and quality, procurement leaders must also track various cost-related metrics such as the internal cost of the purchase order. This is the total cost of purchasing an order, from purchase and creation to invoice closure.

The factors comprising the cost of purchase vary from business to business. While some businesses might account for both direct and indirect costs, others might consider only the direct costs.

If you’d like one general formula for this KPI, it can be calculated as the sum of purchase, ordering, and holding costs.

Accounting for this KPI helps enhance the efficiency of the procuring-to-pay lifecycle and ensures that the cost and errors are minimized.

Spend under management refers to the percentage of procurement spend regulated by the management. A rise in a company’s spend under management improves the ability to optimize costs and forecast expenses. This metric is particularly influential in tapping unrealized cost savings.

Continually evaluate spend, and keep an eye on vendor contracts to identify scope of improvement. Consolidated purchasing and volume discounts eventually add to the organization’s bottom line.

A critical procurement metric, this tracks the profitability of investments–the ultimate goal of all businesses. It gives you an insight into the profitability and cost-effectiveness of the procurement strategy. Calculate procurement ROI by dividing annual cost savings by annual procurement costs.

Remember that despite being a leading factor to consider, procurement ROI alone will not give you a correct picture. For best results, combine this metric with others, such as procurement cost avoidance, to get a complete picture.

Set your purchasing ROI target as 10x the internal investments to launch a good procurement strategy.

Want to track how often your company requires emergency purchases? This is the metric you need.

A few emergency requests are inevitable for all businesses. However, placing emergency requests time and again reflects poorly on your operations. Emergency purchases impact your business by inflating your overall procurement costs.

A low emergency purchase ratio helps businesses save costs, streamline procurement plans, enable uninterrupted services, and minimize supply risks. This metric reflects on the procurement performance and is a basis for managing future operations.

Effective management eliminates procurement process inefficiencies and prevents product shortages. Calculate the emergency purchase ratio by dividing the number of emergency purchases by the total number of purchases over a fixed period.

The vendor rejection rate and cost metric measures internal quality management. It reflects the frequency and cost impact of vendor product rejection due to poor quality or other issues. An increase in either of these two factors calls for action from the buyer.

Identifying deviations and implementing recovery solutions helps to avoid bottlenecks and maintain a healthy buyer-vendor relationship.

Check out these vendor management tools!

Tangible cost savings continue to be a primary objective of procurement teams. Procurement cost reduction is an effective metric to study the efficiency of the procurement function. It measures the percentage of cost savings on every order made via price negotiations.

The total cost savings made throughout the year through price negotiation and discounts highlight the efficiency of cost management.

An effective way of measuring cost reduction is by comparing the old and the new prices for the same product or service. This calculation helps you optimize supplier lifecycle management and train staff on cost-saving measures. Eventually, it assists you in building cost management strategies.

Regularly tracking procurement KPIs is essential for improving your procurement processes. While we’ve mentioned the commonly chosen procurement KPIs, your business size, category, and functioning will determine the metrics most relevant to you.

Tracking the procurement functioning helps to save costs, optimize business functioning, identify bottlenecks, and strategize to overcome them. Pick a combination of these metrics and combine them with others to strengthen your business and enhance overall performance.

In addition to identifying the right procurement KPIs to track, organizations also need to choose a dedicated procurement management software to manage procurement effectively.

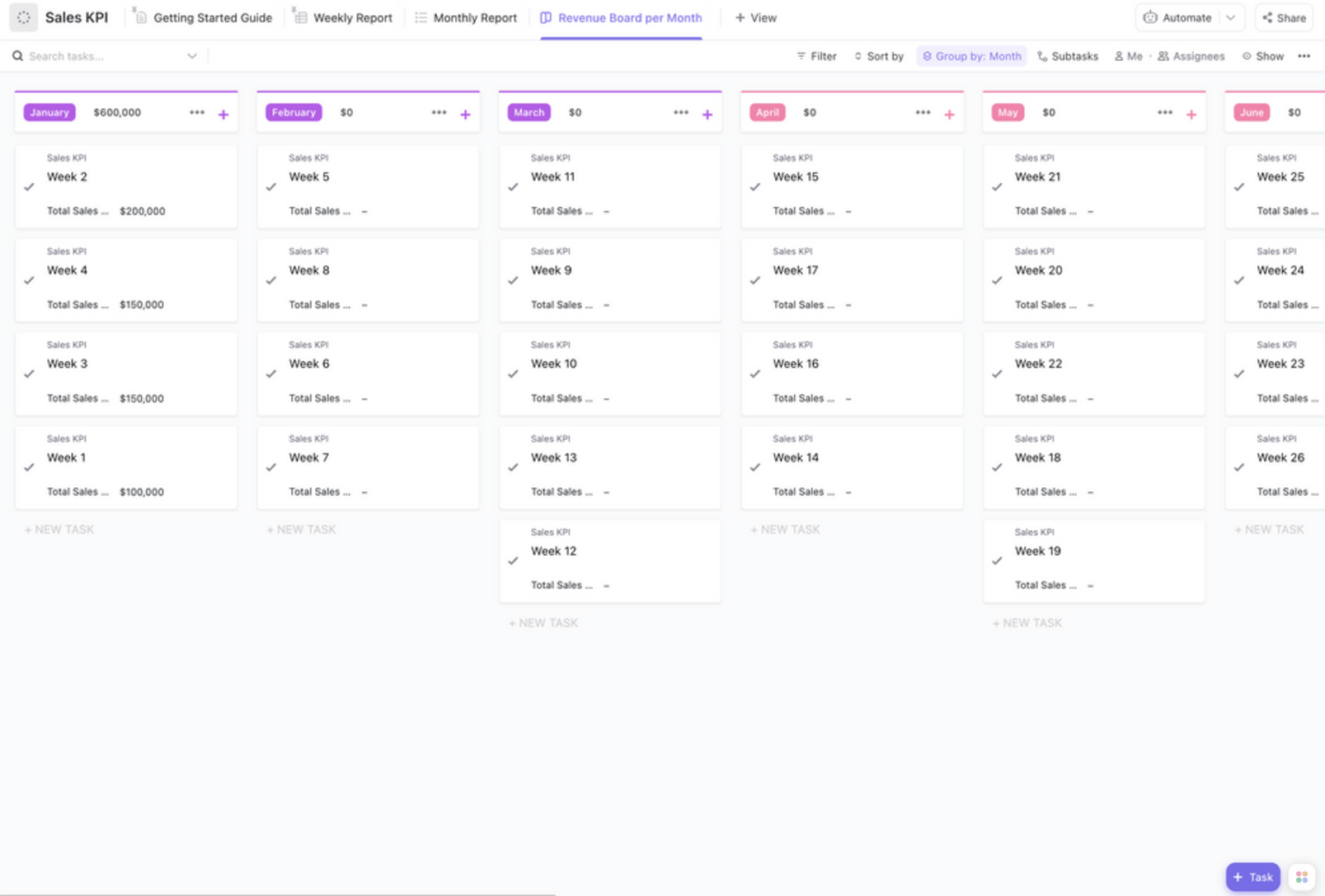

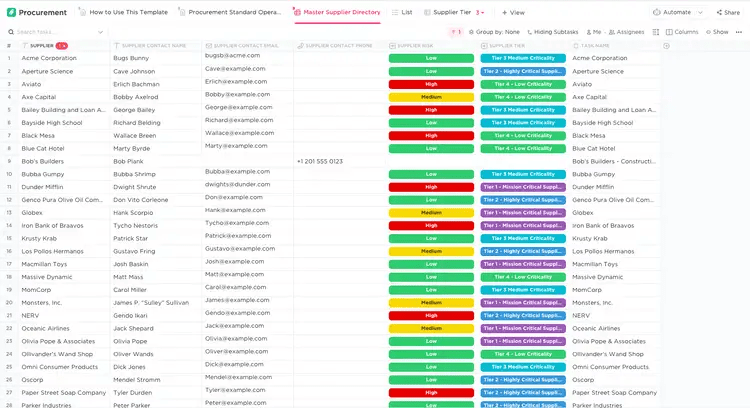

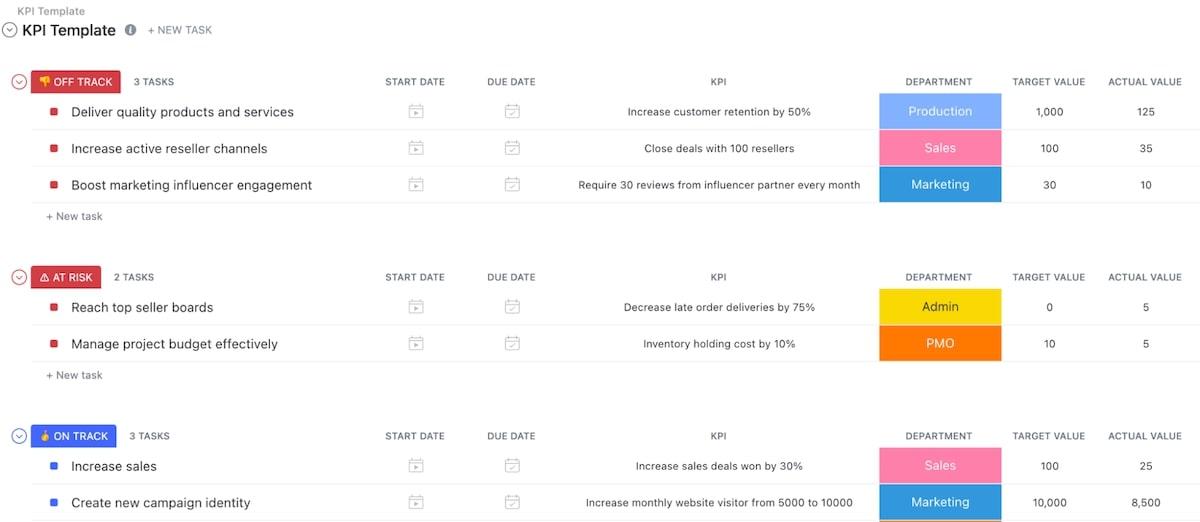

Our team at ClickUp had all your procurement KPIs in mind when designing the ClickUp Procurement KPI tracking template. It is fully equipped to make tracking KPI metrics easy. Its robust features like Goals, Whiteboards, Docs, customizable fields, and dashboards enable you to track KPIs effectively in one place.

With ClickUp Goals you can organize, track, and share procurement KPIs with ease. For each KPI, determine the target within the goal and specify achievement within the timeframe. Now customize your metrics to track your objectives:

With ClickUp you can also represent the task completion and progress visually via progress bars, graphs, and charts.

Additionally, use ClickUp Dashboards to combine different targets in a single overview. ClickUp features of the dashboard empower you to:

These views offer output analysis at a glance to help you identify and bridge the gaps. The ClickUp Procurement Template categorizes KPIs into five categories: Completed, Off track, On track, Not started, and At risk to track progress.

Not only this, but the ClickUp reporting feature equips you with valuable insights to make data-driven decisions.

Manage and analyze your procurement metrics with ClickUp to achieve peak efficiency. Computing data, analyzing it, and using the results to enhance procurement management becomes a cakewalk with ClickUp.

Opt for ClickUp right away to make measuring procurement KPI metrics a breeze!

© 2026 ClickUp