Top AI Prompts for Six Sigma with ClickUp Brain

Revolutionizing Six Sigma Analysis with AI Prompts in ClickUp Brain

Mastering process improvement demands precision and clarity at every step.

From defining problems to analyzing data, implementing controls, and monitoring results, Six Sigma projects juggle numerous variables—and countless reports, charts, and action items. AI prompts are now integral to this complex workflow.

Teams leverage AI to:

- Quickly identify key process metrics and anomalies

- Generate detailed analysis reports and improvement plans

- Interpret statistical data and quality standards efficiently

- Transform meeting notes into prioritized action lists and project milestones

Embedded within familiar tools like documents, dashboards, and project boards, AI in ClickUp Brain goes beyond simple assistance. It actively organizes insights and drives your Six Sigma initiatives forward with clarity and speed.

Discover How ClickUp Brain Elevates Six Sigma Analysis

Conventional AI Assistants

- Constantly toggling between apps to collect data

- Reiterating your objectives with every inquiry

- Receiving generic, irrelevant suggestions

- Hunting through multiple platforms for a single report

- Interacting with AI that lacks initiative

- Manually selecting different AI engines

- Merely a browser add-on without deep integration

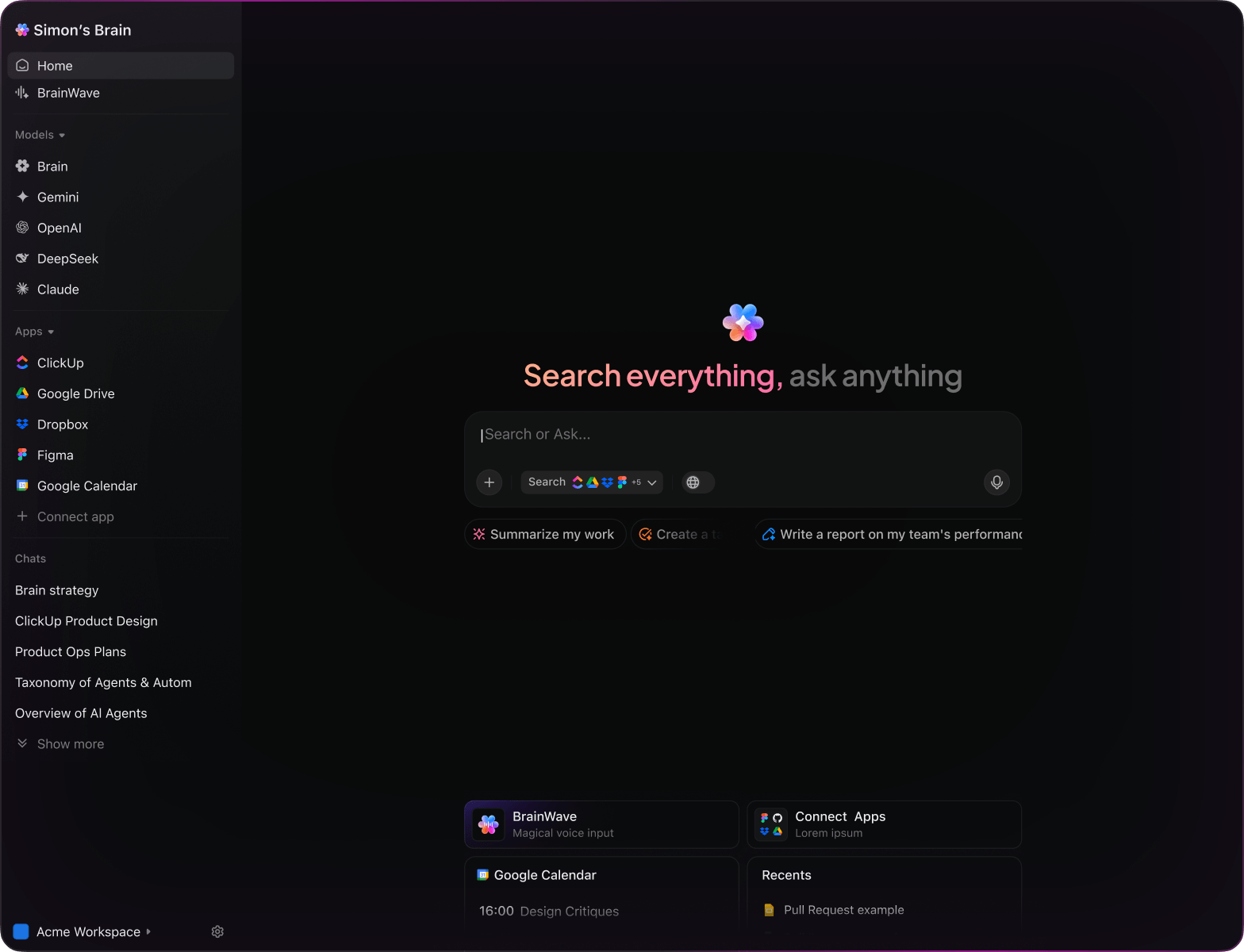

ClickUp Brain

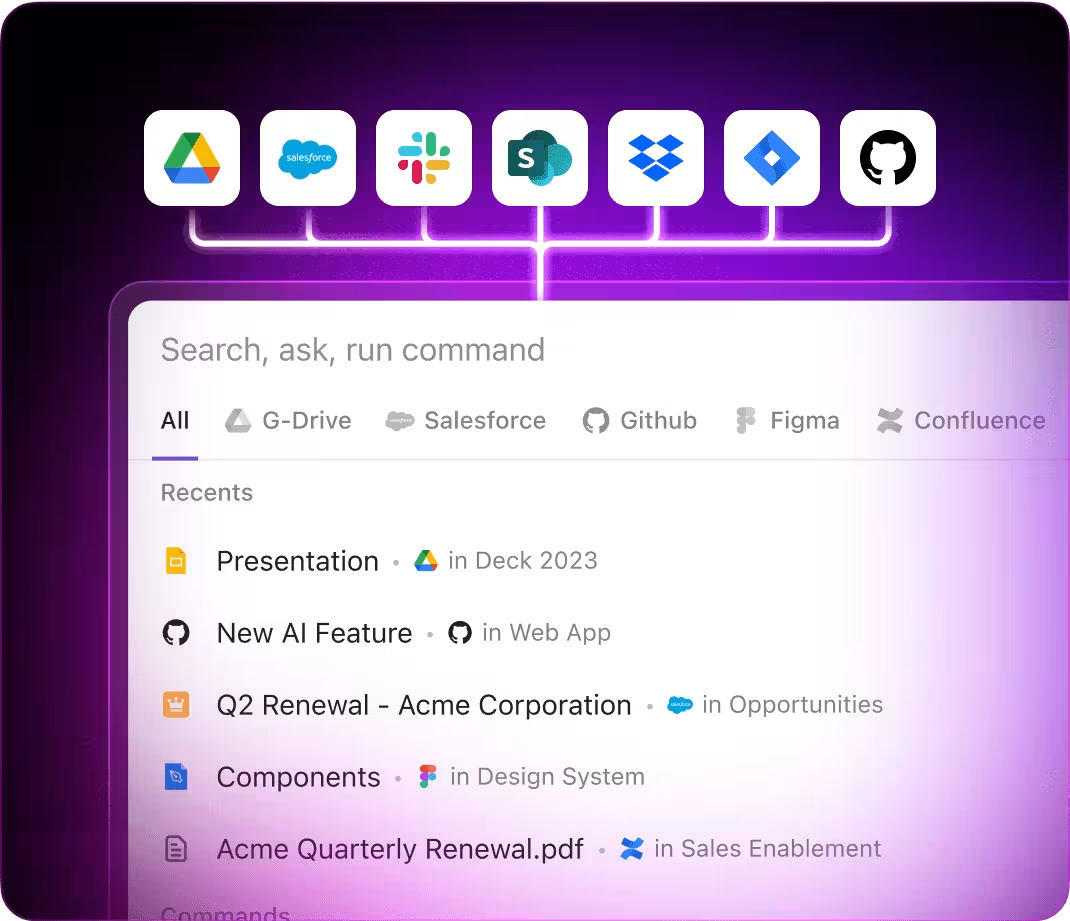

- Instantly accesses your Six Sigma projects, documents, and team inputs

- Retains your analysis history and improvement targets

- Provides detailed, context-aware guidance

- Searches across all your resources in one place

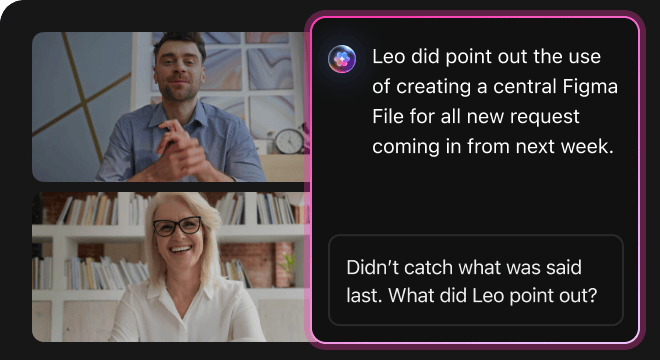

- Supports voice commands with Talk to Text

- Automatically chooses the optimal AI model: GPT, Claude, Gemini

- Dedicated desktop app for Mac & Windows designed for efficiency

15 Targeted AI Prompts for Six Sigma Analysis

List 5 critical variables affecting defect rates in the ‘Q3 Manufacturing Data’ report.

ClickUp Brain Behavior: Analyzes linked documents to extract and prioritize variables impacting quality outcomes.

What defect reduction strategies are most effective in electronics assembly under $50K budgets?

ClickUp Brain Behavior: Aggregates insights from internal case studies; Brain Max can supplement with relevant external research.

Create a Six Sigma project charter for reducing cycle time, referencing ‘Process Mapping v2’ and prior DMAIC notes.

ClickUp Brain Behavior: Pulls key data and objectives from linked files to generate a structured project charter.

Summarize Cp and Cpk benchmarks between Plant A and Plant B using the ‘Capability Analysis Q1’ report.

ClickUp Brain Behavior: Extracts statistical data and provides a concise comparative summary.

Identify top root causes of variation in injection molding from R&D reports and supplier quality documents.

ClickUp Brain Behavior: Scans documents to list frequent causes and associated impact notes.

From the ‘Control Plan Template’ doc, create a checklist for monitoring key quality characteristics.

ClickUp Brain Behavior: Converts documented criteria into a clear, actionable checklist within tasks or docs.

Extract 3 main customer feedback themes from post-2023 survey and complaint logs related to product defects.

ClickUp Brain Behavior: Identifies recurring patterns and sentiments from linked customer data.

From the ‘Supplier Feedback Q2’ doc, summarize key preferences and concerns about delivery timelines.

ClickUp Brain Behavior: Reviews survey data to highlight common feedback points and improvement areas.

Draft concise step-by-step instructions for the assembly line’s inspection phase, referencing ‘Standard Work’ guidelines.

ClickUp Brain Behavior: Uses tone and style from linked documents to produce user-friendly procedural text.

Outline recent changes in ISO 9001 standards and their implications for our quality management system.

ClickUp Brain Behavior: Reviews compliance documents and summarizes key updates affecting processes.

Create guidelines for conducting Gage R&R studies based on internal quality manuals and industry standards.

ClickUp Brain Behavior: Extracts best practices and formats them into a practical checklist.

Using FMEA documents and past incident reports, compile a checklist of high-risk failure modes for the new product.

ClickUp Brain Behavior: Identifies critical failure points and organizes them into actionable tasks.

Evaluate waste reduction efforts across three manufacturing sites using internal sustainability reports.

ClickUp Brain Behavior: Summarizes comparative data into an easy-to-read format with key metrics.

What process improvement trends have emerged in the semiconductor industry since 2022?

ClickUp Brain Behavior: Synthesizes insights from research notes, industry reports, and uploaded studies.

Summarize main usability challenges reported in the ‘Operator Feedback’ folder, focusing on equipment interface and controls.

ClickUp Brain Behavior: Extracts and ranks user-reported issues from surveys, feedback forms, and support tickets.

LLMs vs. Workflow Intelligence: How ClickUp Brain Enhances Six Sigma Analysis

Prompts for ChatGPT

Prompts for Gemini

Prompts for Perplexity

Prompts for ClickUp Brain

Transform Raw Data Into Clear Six Sigma Insights

- Convert scattered data points into detailed Six Sigma reports swiftly.

- Generate innovative solutions by analyzing historical project outcomes.

- Build standardized templates that accelerate process improvements.

Brain Max Boost: Quickly access previous analyses, feedback, and process documents to guide your next quality enhancement.

Accelerate Six Sigma Analysis Workflows

- Break down intricate process data into straightforward improvement actions.

- Transform measurement findings into assignable project tasks.

- Automatically produce detailed analysis summaries without extra effort.

Brain Max Boost: Instantly retrieve historical process metrics, defect rates, or control chart insights across all initiatives.

Harness AI Prompts to Enhance Every Phase of Six Sigma Analysis

Quickly Develop Effective Improvement Ideas

Teams explore process enhancements rapidly, make informed choices, and prevent analysis delays.