AI in Supply Chain Management

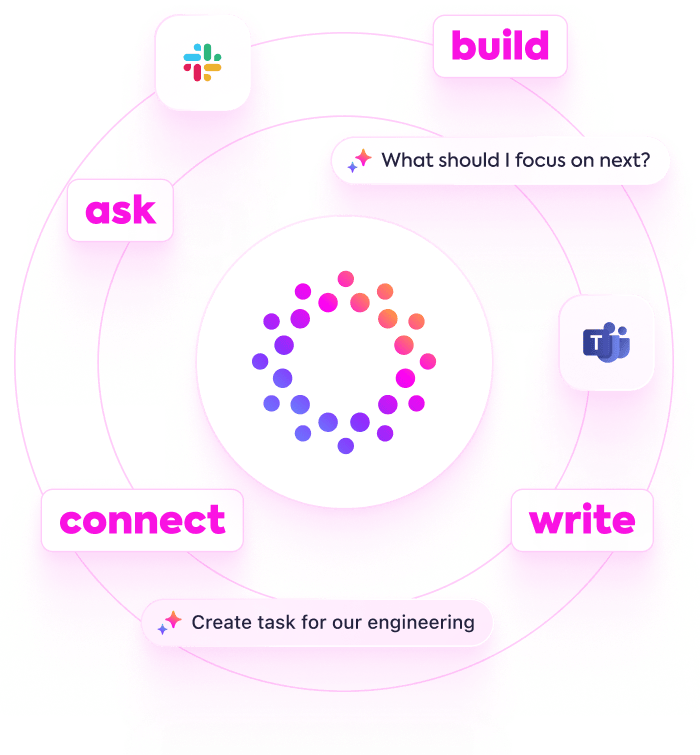

Top AI Prompts for Supply Chain Excellence

Optimize your supply chain operations, reduce delays, and enhance decision-making with ClickUp AI tailored for supply chain teams.

Trusted by the world’s leading businesses

AI in Supply Chain Operations

Revolutionizing Supply Chain Management with AI Prompts

Managing supply chains today means juggling countless variables—from procurement and inventory to logistics and delivery schedules.

Every step involves complex coordination, data analysis, and rapid decision-making. AI prompts are stepping in to simplify these challenges.

Supply chain teams leverage AI to:

- Quickly identify demand patterns and supplier risks

- Generate procurement plans and shipment schedules with ease

- Digest lengthy compliance and customs documents

- Transform scattered data into clear action plans, checklists, or project tasks

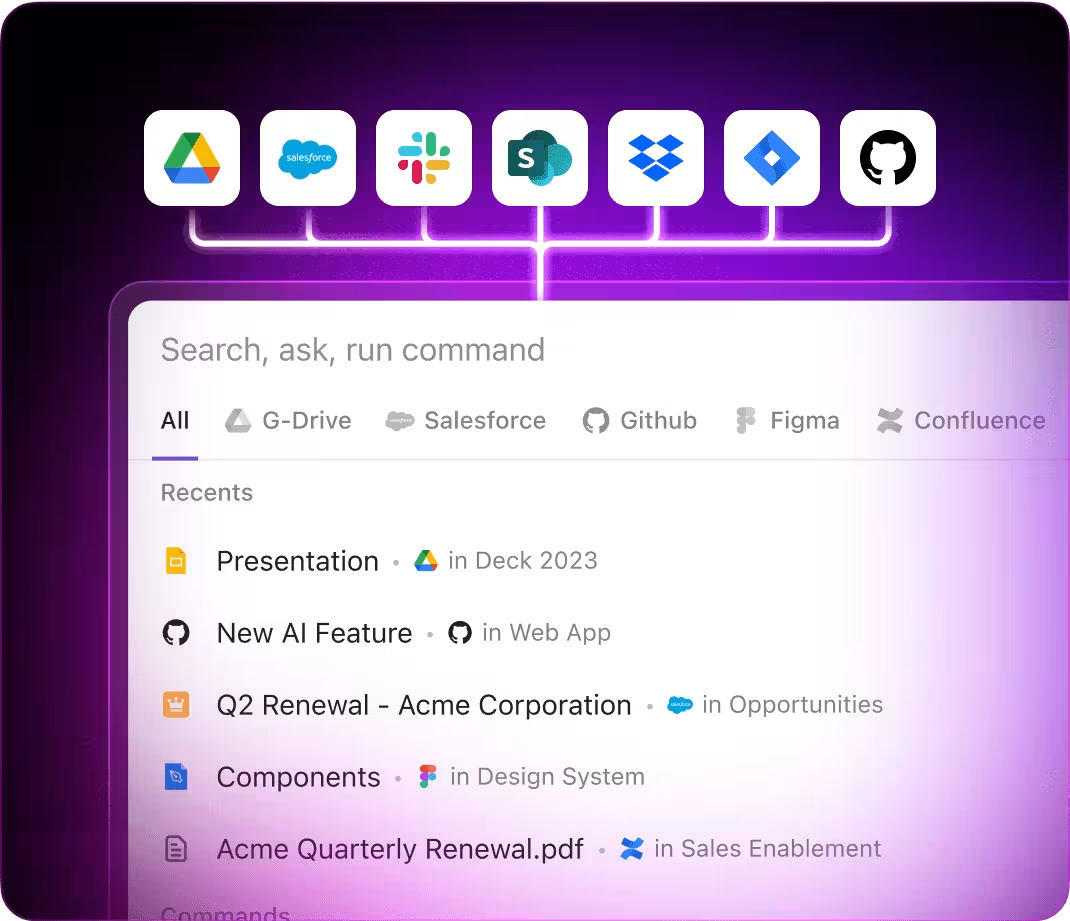

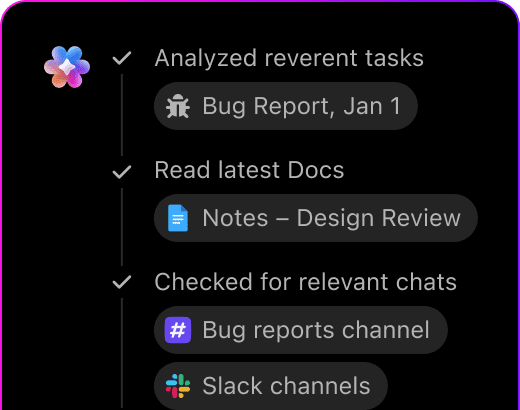

Integrated into familiar tools like docs, dashboards, and project trackers, AI in solutions such as ClickUp Brain acts as a proactive partner—turning raw data into structured, manageable workflows.

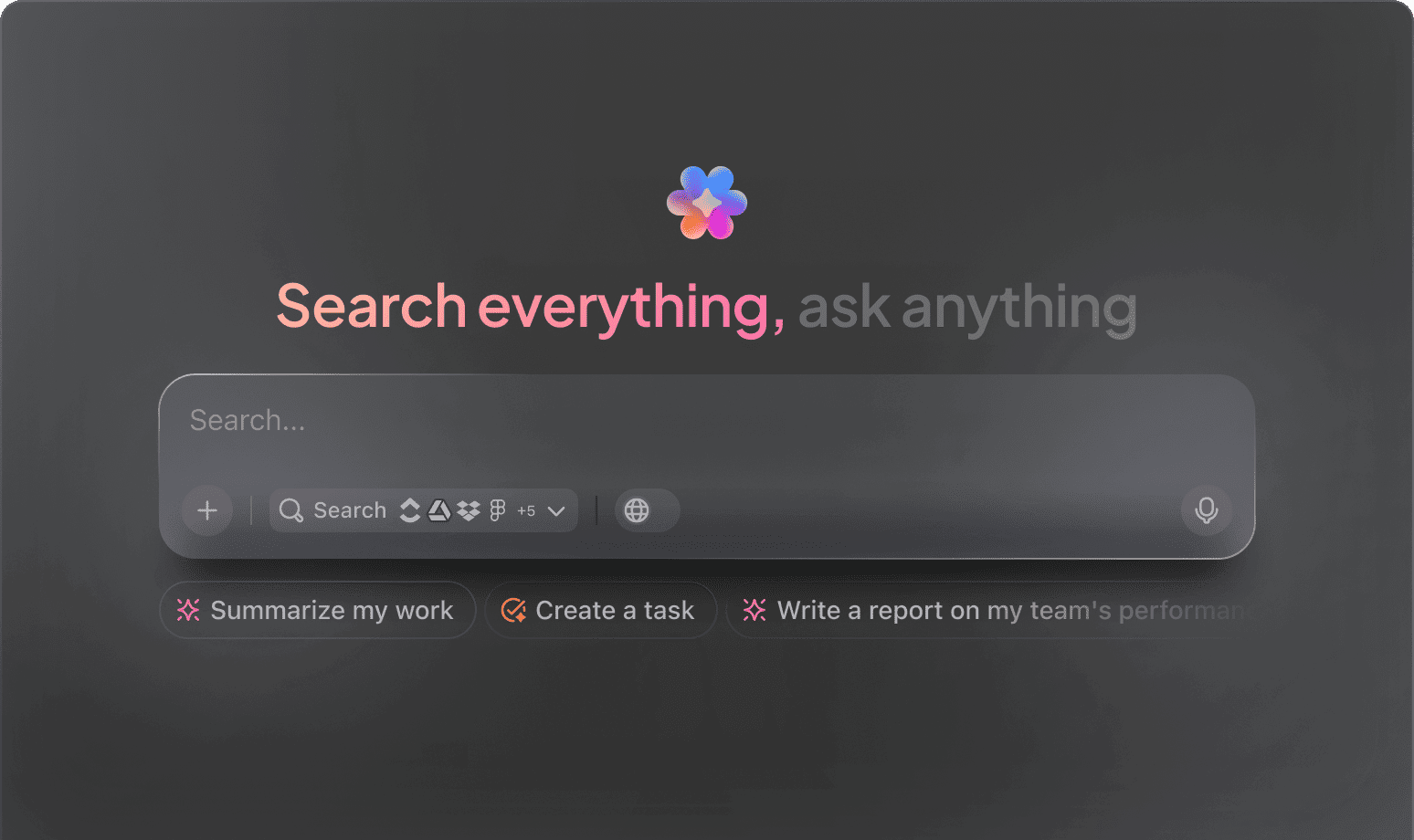

ClickUp Brain vs Conventional Solutions

Why ClickUp Brain Stands Out

Designed to understand your supply chain context instantly, ClickUp Brain lets you focus on results, not explanations.

Conventional AI Platforms

- Constantly toggling between apps to collect data

- Repeating your objectives with every query

- Receiving generic, irrelevant feedback

- Hunting through numerous systems for a single document

- Interacting with AI that lacks understanding

- Manually switching among different AI engines

- Merely a browser add-on with limited integration

ClickUp Brain

- Deeply integrated with your supply chain tasks, documents, and communications

- Keeps track of your project history and targets

- Delivers insightful, context-aware guidance

- Provides a consolidated search across all your resources

- Supports hands-free input with Talk to Text

- Automatically selects the optimal AI model: GPT, Claude, Gemini

- Available as a native app on Mac & Windows, optimized for performance

AI Prompts for Supply Chain Management

15 Essential AI Prompts for Supply Chain Management (Optimized with ClickUp Brain)

Enhance supply chain operations—forecasting, optimization, and risk management simplified.

List 5 innovative sourcing strategies for sustainable materials, inspired by the ‘Q2 Supplier Insights’ report.

Use Case: Accelerates supplier selection by leveraging past sustainability research.

ClickUp Brain Behaviour: Analyzes linked documents to extract key sourcing approaches and sustainability themes.

What logistics trends are shaping last-mile delivery for budgets under $100K in North America?

Use Case: Guides cost-effective delivery planning with up-to-date market insights.

ClickUp Brain Behaviour: Aggregates findings from internal studies; Brain Max enhances with relevant external data if available.

Create a supplier evaluation checklist emphasizing quality and compliance, referencing ‘Supplier Audit #12’ notes.

Use Case: Aligns procurement and quality teams on assessment criteria.

ClickUp Brain Behaviour: Extracts critical points from linked audit documents to generate a structured checklist.

Summarize inventory turnover benchmarks comparing Chicago and Dallas warehouses using the ‘Inventory Q1’ report.

Use Case: Enables data-driven inventory management decisions.

ClickUp Brain Behaviour: Pulls tabular and narrative data from internal reports to produce a concise comparison.

List leading risk mitigation tactics in global supply chains, based on risk assessment and compliance documents.

Use Case: Supports proactive risk management strategy development.

ClickUp Brain Behaviour: Scans internal files to identify frequent risk control measures and their effectiveness notes.

From the ‘QC Procedures’ document, generate a detailed testing plan for inbound shipment quality control.

Use Case: Simplifies quality assurance planning with standardized formats.

ClickUp Brain Behaviour: Extracts testing criteria and formats them into actionable checklists within tasks or docs.

Summarize 3 emerging automation technologies in warehouse operations from recent research and pilot reports.

Use Case: Keeps operations teams informed on innovative efficiency solutions.

ClickUp Brain Behaviour: Identifies patterns and key findings from linked research and trial documentation.

From the ‘Customer Feedback Q1’ document, summarize primary pain points in order fulfillment.

Use Case: Helps teams prioritize improvements based on real user feedback.

ClickUp Brain Behaviour: Analyzes survey responses to highlight recurring issues and themes.

Write clear and concise communication templates for supplier updates using tone guidelines from ‘CommStyle.pdf’.

Use Case: Accelerates consistent messaging with brand-aligned language.

ClickUp Brain Behaviour: References tone/style guides to suggest varied, professional copy options.

Summarize upcoming international trade regulation changes and their effects on import procedures.

Use Case: Keeps compliance teams prepared for regulatory shifts.

ClickUp Brain Behaviour: Synthesizes linked compliance documents; Brain Max can incorporate public updates if added.

Generate packaging compliance guidelines for hazardous materials shipments, based on regional regulations.

Use Case: Ensures adherence to safety standards across markets.

ClickUp Brain Behaviour: Extracts rules and specifications from internal regulatory documents to create checklists.

Create a supplier performance dashboard outline using KPIs from ‘Supplier Metrics 2024’ and related documents.

Use Case: Facilitates monitoring and continuous improvement of supplier relationships.

ClickUp Brain Behaviour: Identifies key metrics and organizes them into a structured reporting format.

Compare sustainability initiatives among leading logistics partners using competitive analysis reports.

Use Case: Guides selection of environmentally responsible partners.

ClickUp Brain Behaviour: Summarizes documented comparisons into clear, actionable insights.

Identify emerging supply chain resilience strategies following 2023 disruptions, based on internal research and whitepapers.

Use Case: Provides strategic direction for risk mitigation and recovery planning.

ClickUp Brain Behaviour: Synthesizes trends and recommendations from linked documents and reports.

Summarize main operational challenges reported by Southeast Asia distribution centers using feedback and incident logs.

Use Case: Drives targeted improvements in regional logistics operations.

ClickUp Brain Behaviour: Extracts and prioritizes recurring issues from surveys, feedback notes, and incident reports.

Innovate Supply Chain Efficiency with ClickUp Brain

Cut down delays, unify your logistics team, and produce smarter strategies through AI-enhanced processes.

AI Applications

Leading 3 Applications of AI Prompts in Supply Chain Management

Enhance efficiency, reduce errors, and discover innovative strategies with AI-powered support

From Initial Plans to Detailed Supply Chain Strategies

Initial supply chain plans often start as disorganized spreadsheets and fragmented comments. ClickUp Brain reshapes these into clear, collaborative strategy documents—right inside ClickUp Docs.

Leverage ClickUp Brain to:

- Convert preliminary logistics notes into actionable workflow templates

- Develop innovative solutions informed by previous supply chain data (through context-sensitive AI assistance)

- With Brain Max, instantly access historical shipment records, vendor feedback, and operational documents to enhance your next plan.

From Planning to Execution

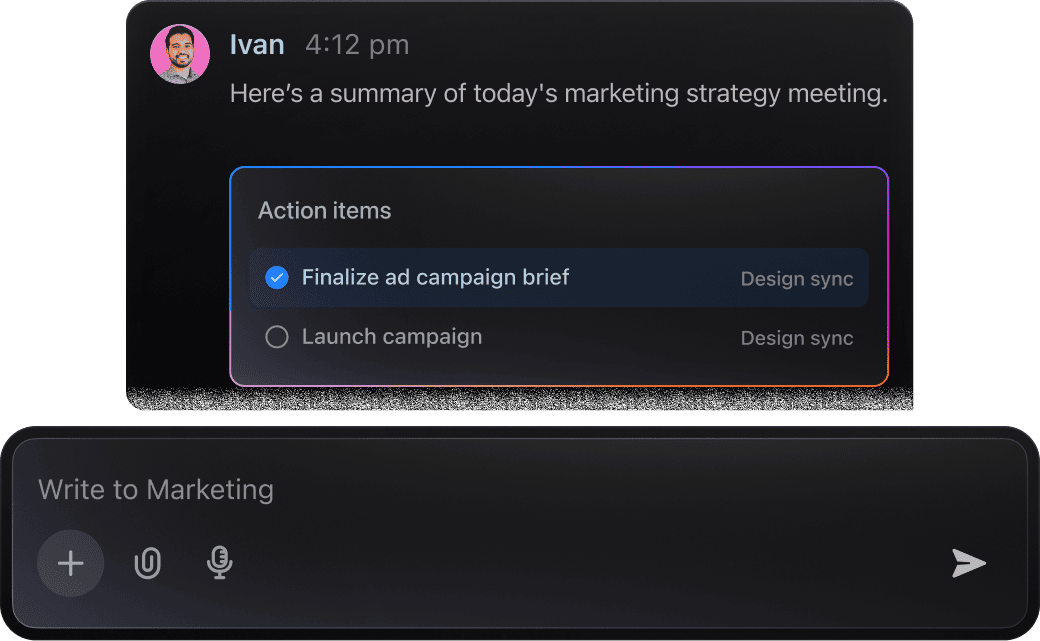

Supply chain teams handle complex logistics and detailed documentation daily. ClickUp Brain simplifies your workflow by pinpointing key tasks, identifying risks, and creating clear next steps from your operational notes.

Leverage ClickUp Brain to:

- Condense lengthy supply chain meetings and reports into actionable summaries

- Convert inventory and shipment annotations into precise follow-up tasks

- Automatically generate incident logs or transfer briefs without extra work

- With Brain Max, instantly retrieve past supplier decisions, shipment comparisons, or route discussions across your workspace—eliminating tedious manual searches.

Supply Chain Management with ClickUp Brain

Managing supply chain operations involves coordinating data from shipments, inventory, and vendor communications. ClickUp Brain simplifies this complexity by extracting key insights and crafting clear, consistent communication for your team.

Leverage ClickUp Brain to:

- Analyze shipment logs and highlight critical delays

- Create precise status updates tailored for different stakeholders

- Convert supplier feedback into actionable tasks or process improvements

- Brain Max enhances this by providing quick access to past logistics reports or similar supply chain scenarios, supporting decision-making throughout extended project timelines.

AI Advantages

Why AI Prompts Are Revolutionizing Supply Chain Operations

Harness AI-driven prompts to enhance every stage of your supply chain process:

- Accelerate planning: Transform raw data into actionable forecasts and schedules swiftly

- Reduce errors: Detect discrepancies early by analyzing shipment histories and vendor feedback

- Align your team: AI-crafted summaries and reports ensure everyone stays informed and coordinated

- Make informed choices: Use prompts to gather market trends and regulatory updates

- Innovate logistics: Generate fresh strategies that push beyond traditional supply chain limits.

All these capabilities integrate directly within ClickUp, turning your AI prompt results into documents, tasks, and dashboards that drive tangible progress.

Prompt Guidance

Crafting Effective Prompts for Supply Chain Solutions

Clear questions unlock precise answers.

Specify the exact supply chain challenge

Broad prompts yield vague responses. Always detail factors like product type (e.g., “perishable goods” or “electronics”), operational goals (e.g., “reduce lead time” or “optimize inventory”), or region (e.g., “North American distribution centers”).

Example: “Recommend inventory strategies for a fast-moving consumer goods company facing seasonal demand spikes.”

Ask for side-by-side evaluations

AI excels at dissecting differences between strategies. Use prompts like “compare X and Y” to assess supplier options, logistics methods, or cost models.

Example: “Compare just-in-time versus just-in-case inventory approaches for automotive parts suppliers.”

Frame prompts as actionable objectives

Treat your prompt as a clear assignment for AI. Instead of vague requests like “Suggest improvements,” focus on outcomes:

Example: “Design a risk mitigation plan for supply chain disruptions caused by port delays.”

Request structured responses

Need a risk assessment checklist, process flow diagram, or KPI dashboard layout? Be explicit. AI delivers better when the output style is clear.

Example: “Provide a bullet-point list of five cost-saving measures for warehouse operations with brief explanations.”

Optimize Supply Chain Operations with ClickUp Brain

ClickUp Brain goes beyond basic task tracking—it's your strategic partner throughout every phase of supply chain management.