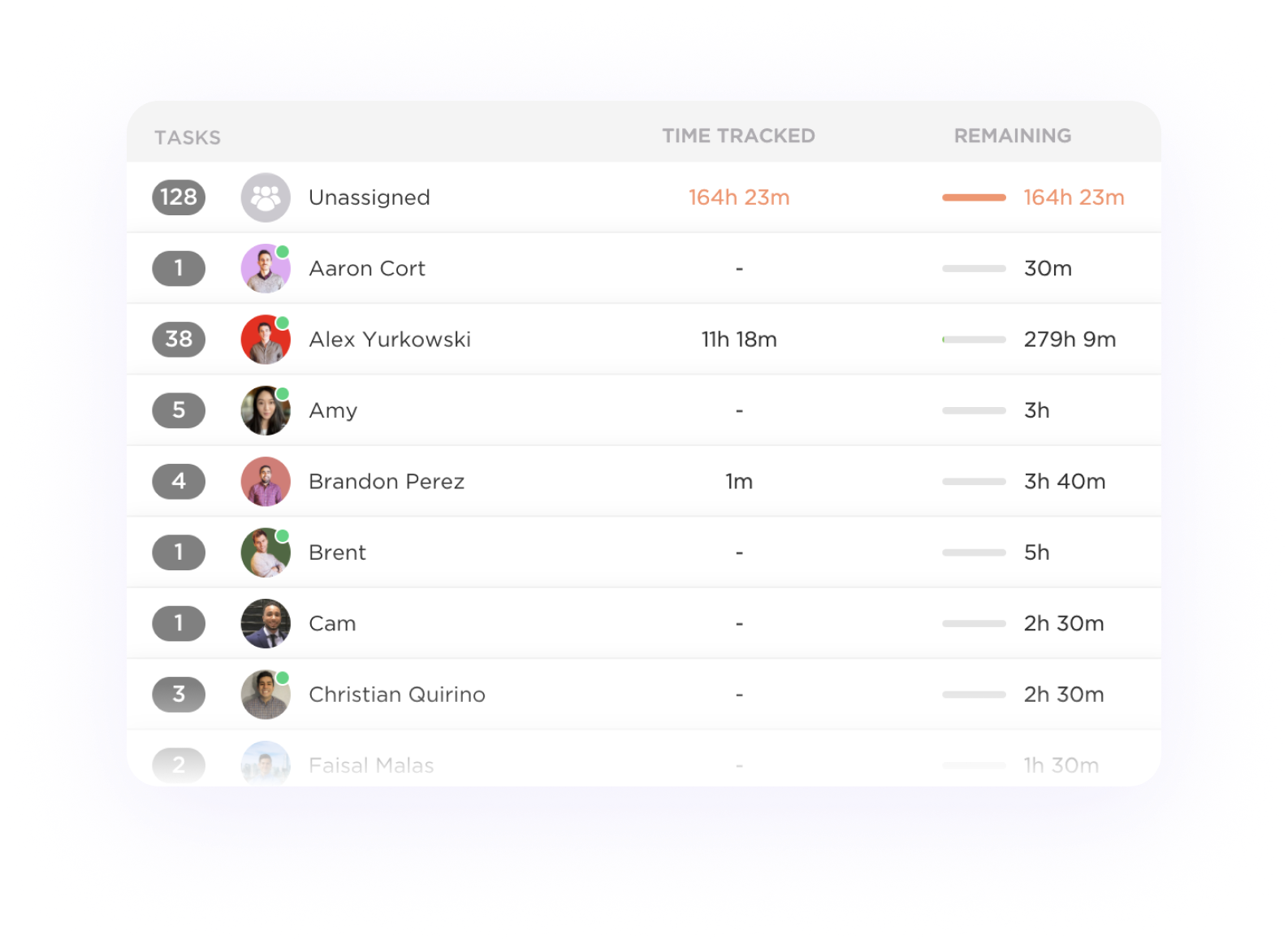

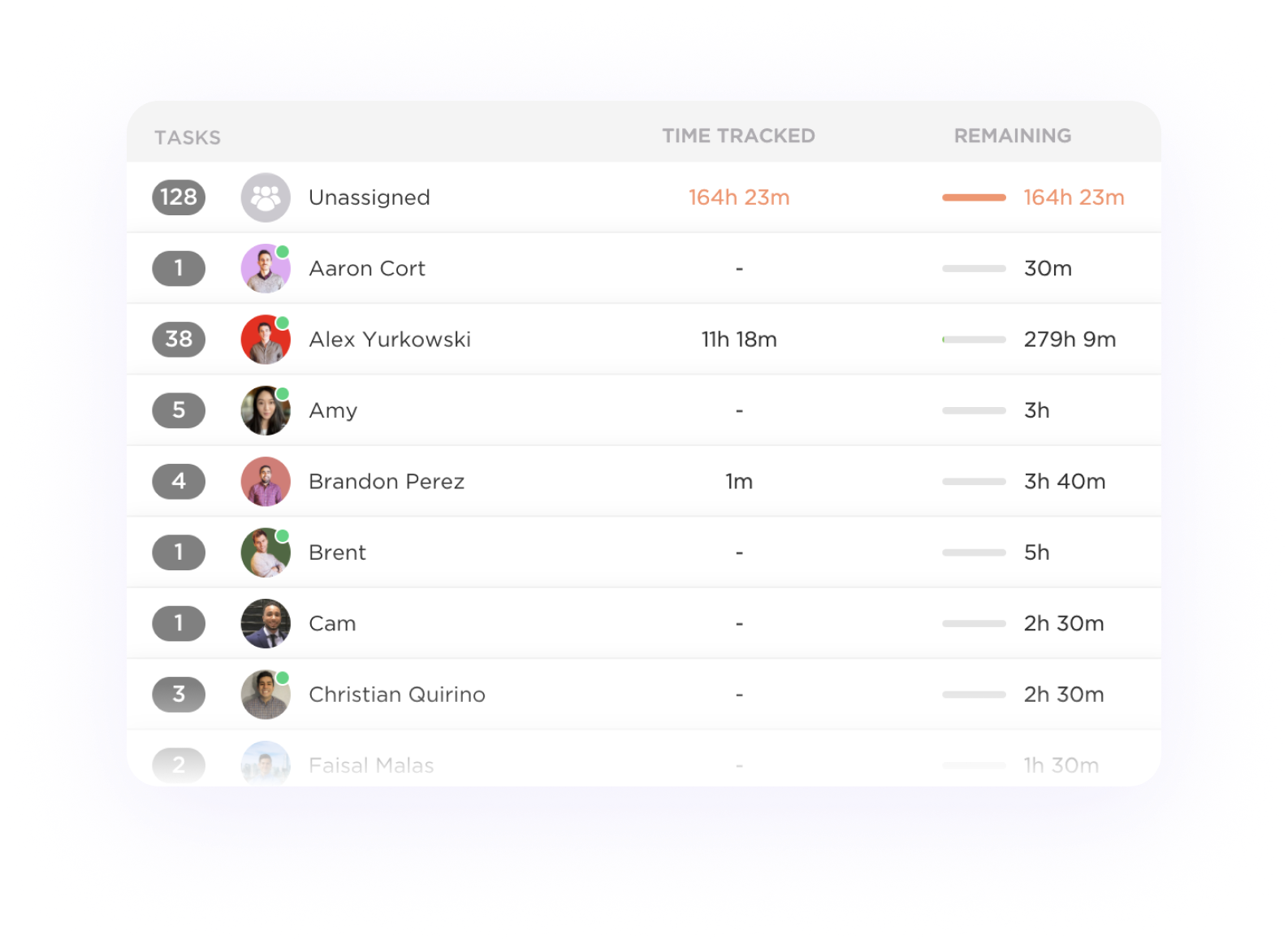

Time Tracked

Never lose track of time again.

Understand how much time groups of tasks take for each person on your team with cumulate time tracking. Add time tracked outside of ClickUp with integrations for Toggl, Harvest, Everhour, and more.

Gantt Charts

Boost productivity and streamline operations with the ultimate time tracking software for Industrial Manufacturers. ClickUp's seamless integration allows you to accurately track time spent on projects, analyze team performance, and optimize workflows for maximum efficiency. Say goodbye to manual time tracking and hello to a smarter way of working with ClickUp. Try it today!

Free forever. No credit card.

Time Tracked

Understand how much time groups of tasks take for each person on your team with cumulate time tracking. Add time tracked outside of ClickUp with integrations for Toggl, Harvest, Everhour, and more.

Time Reporting

See your time entries and filter them in any number of ways to build customized reports. Group time entries together, see estimates, and segment billable and non-billable entries.

Time tracking software can help streamline production processes in an industrial manufacturing setting by providing real-time visibility into employee tasks, identifying bottlenecks, optimizing scheduling, improving resource allocation, and enhancing overall efficiency and productivity.

Key features to consider when selecting a time tracking software for industrial manufacturing include task-based time tracking, job costing capabilities, shift scheduling tools, real-time monitoring of production activities, integration with existing ERP systems, and customizable reporting functionalities.

Yes, time tracking software can integrate with systems like ERP or MES in industrial manufacturing, enabling seamless data flow, improved accuracy in project tracking, streamlined processes, and enhanced overall operational efficiency.