Custom Statuses

Customize your ideal workflow.

Build clear workflows for everything from feature launches to issue tracking. Use templates to save time or create your own to reuse later.

Gantt Charts

Supercharge your productivity as a Machinist with ClickUp, the ultimate task management software that streamlines your workflow, organizes your tasks, and boosts your efficiency. Say goodbye to missed deadlines and incomplete projects as ClickUp empowers you to stay on top of your tasks and take your machining skills to the next level. Try ClickUp now and experience the difference in your productivity!

Free forever. No credit card.

Custom Statuses

Build clear workflows for everything from feature launches to issue tracking. Use templates to save time or create your own to reuse later.

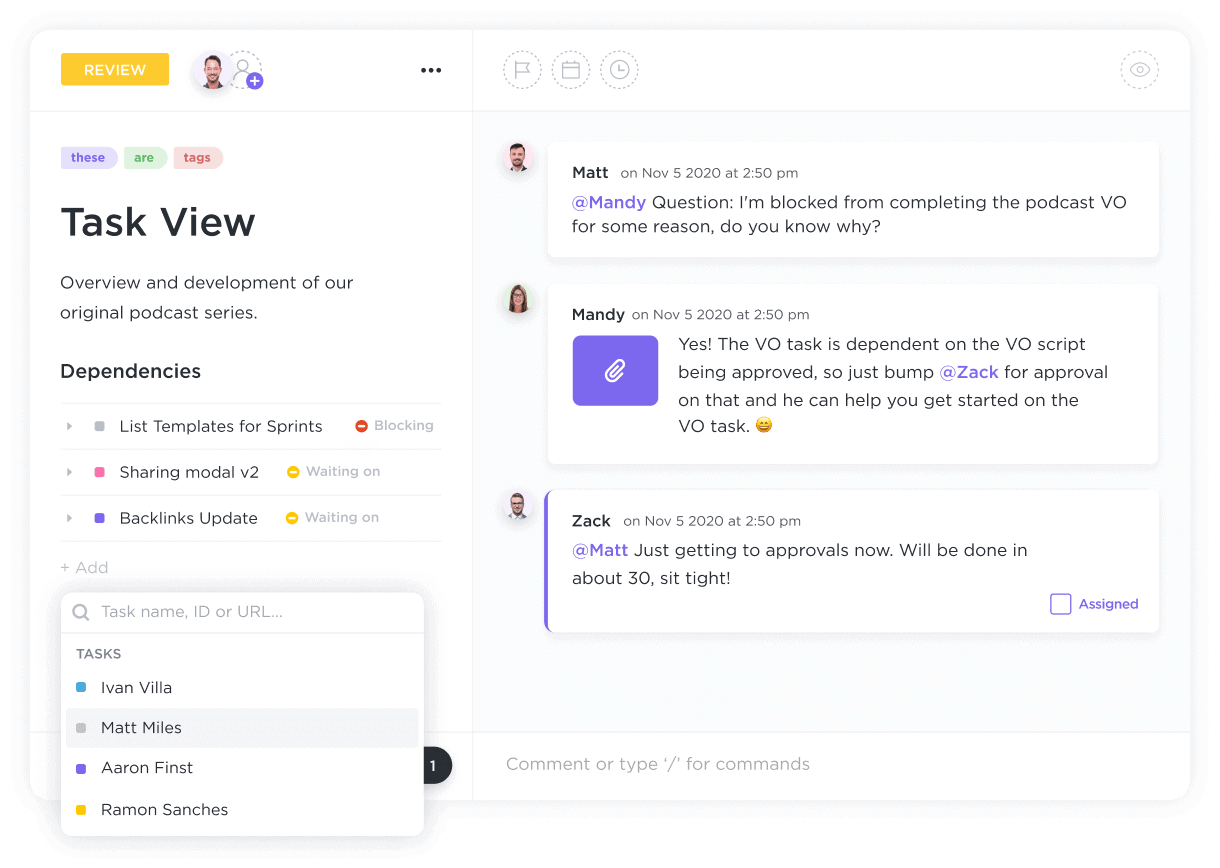

Relationships & Dependencies

Add relationships to tasks to easily jump to related work. Create dependencies to establish a clear order of operations among tasks.

Efficient task management tools can help machinists prioritize their workload based on deadlines, complexity, or dependencies. By scheduling tasks effectively, machinists can ensure that critical jobs are completed on time, optimizing workflow efficiency and meeting production targets.

Task management tools can be used to create and track maintenance and calibration schedules for machines in the workshop. Machinists can set up recurring tasks for routine maintenance, ensuring that equipment is regularly serviced to prevent breakdowns and maintain optimal performance.

By utilizing task management tools, machinists can keep track of inventory levels for raw materials, tools, and supplies. Tasks can be created to reorder materials when stock levels are low, ensuring that machinists have the necessary resources to complete jobs without delays due to material shortages.

Task management tools can assist machinists in creating and implementing quality control tasks and inspection procedures to maintain product quality standards. By setting up tasks for regular inspections and quality checks, machinists can identify and address any issues early in the production process, ensuring consistent quality output.

Key features of task management software that can benefit machinists include task scheduling, priority setting, progress tracking, deadline reminders, and document attachments for detailed instructions or specifications.

Task management software can help machinists prioritize tasks and efficiently manage their workload by providing tools for organizing tasks, setting deadlines, tracking progress, and allocating resources effectively.

Yes, there are task management softwares tailored for machinists that offer integration with industry-specific tools, enhancing workflow efficiency and organization within machining operations.