Activity

Track your progress at every step.

Easily update projects with a simple drag-and-drop action to collaborate amongst your team in real-time. Dynamic progress percentages provide a detailed snapshot.

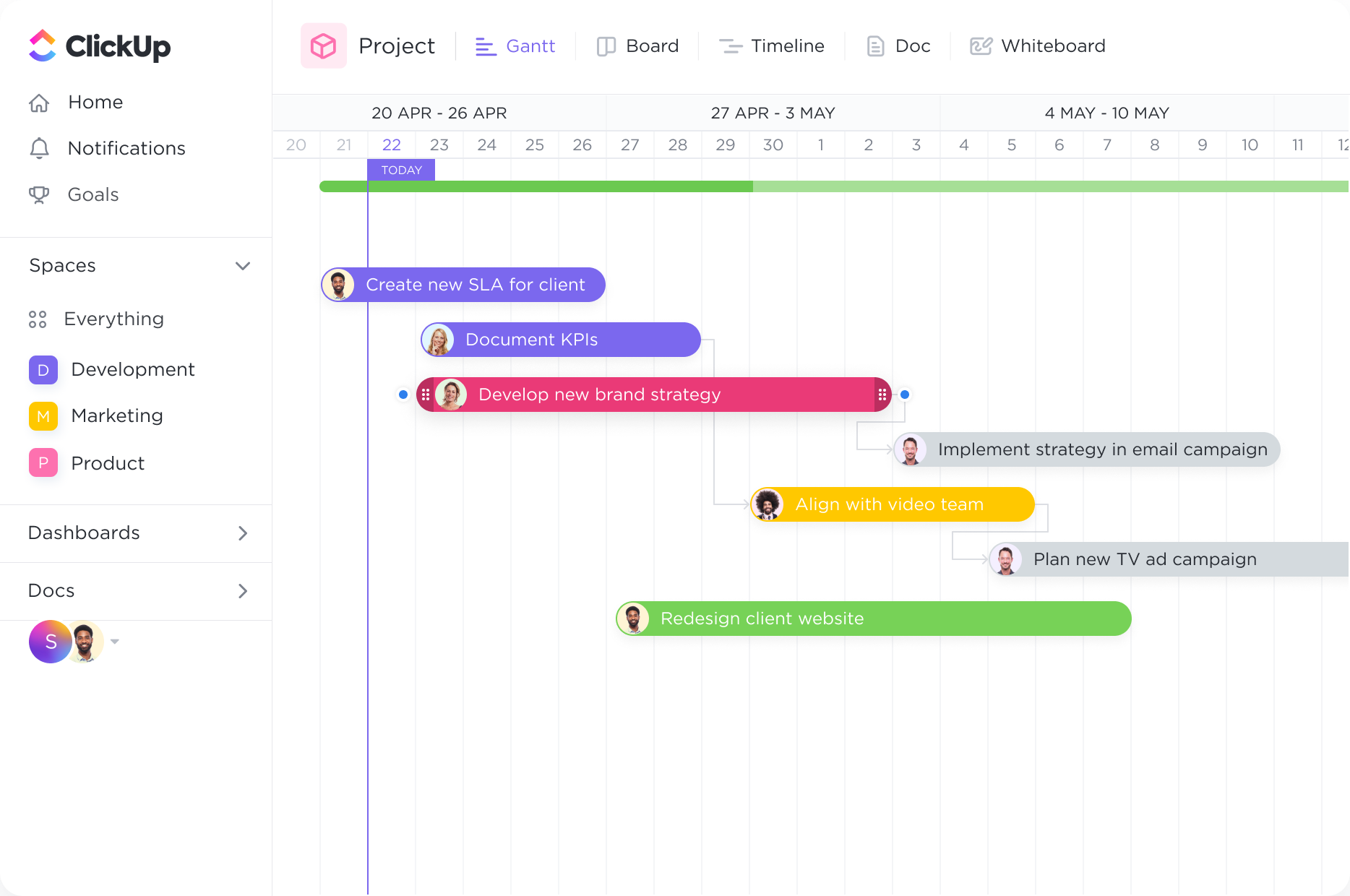

Gantt Charts

Streamline your warehouse operations with ClickUp's powerful Gantt Chart software. Plan, track, and manage your projects with ease, using ClickUp's intuitive interface and robust features. Visualize your tasks, timelines, and dependencies in a single view, ensuring smooth workflow and optimal resource allocation. Take control of your warehouse management with ClickUp's Gantt Chart software and experience seamless efficiency like never before.

Free forever. No credit card.

Activity

Easily update projects with a simple drag-and-drop action to collaborate amongst your team in real-time. Dynamic progress percentages provide a detailed snapshot.

Dependencies

Create tasks and link them with dependencies. Dragging a task with dependencies will automatically reschedule tasks in the chain

Warehouse managers can use Gantt charts to effectively manage inventory levels and plan for replenishment. By visualizing the demand patterns and lead times, they can schedule orders and track the arrival of new stock. This helps prevent stockouts and ensures that the warehouse has the necessary inventory to fulfill customer orders in a timely manner.

Gantt charts can be used to streamline the order fulfillment and shipping process in warehouses. Warehouse managers can allocate tasks to different team members, such as picking, packing, and shipping, and track their progress on the Gantt chart. This enables efficient coordination and ensures that orders are processed and shipped on time.

Optimizing the layout of a warehouse is crucial for maximizing efficiency and minimizing operational costs. Gantt charts can be used to plan and visualize the rearrangement of storage areas, equipment, and workstations. By mapping out the changes and scheduling them on the Gantt chart, warehouse managers can ensure a smooth transition and minimize disruptions to daily operations.

Warehouse managers can use Gantt charts to schedule and track maintenance activities and equipment upgrades. By assigning tasks and setting deadlines on the Gantt chart, they can ensure that regular maintenance is performed to prevent breakdowns and optimize the performance of equipment. Additionally, they can plan for equipment upgrades and schedule them in a way that minimizes downtime.

Managing a large workforce in a warehouse requires careful scheduling and shift planning. Gantt charts can be used to allocate tasks to different employees and schedule their shifts. By visualizing the workload and availability of each employee, warehouse managers can ensure that the right number of staff is scheduled at the right time to meet operational needs.

Gantt charts can be used to track and monitor key performance indicators (KPIs) in a warehouse. Warehouse managers can set milestones and deadlines on the Gantt chart to measure performance against targets. By regularly updating the chart with actual progress, they can identify areas for improvement, make data-driven decisions, and ensure that the warehouse is operating at optimal levels.

A Gantt chart can display the current inventory levels and track when stock needs to be replenished, ensuring that the warehouse manager can effectively manage stock levels and prevent stockouts or overstocking.

A Gantt chart can help warehouse managers schedule and coordinate the timing of receiving and shipping tasks, allowing them to optimize the flow of goods in and out of the warehouse and minimize bottlenecks or delays.

A Gantt chart can track the progress of each order, from receipt to fulfillment, allowing warehouse managers to monitor the status of orders and ensure timely processing and delivery to customers.

A Gantt chart can help warehouse managers allocate resources and plan for labor requirements based on the tasks and activities scheduled, ensuring that the right resources are available at the right time to efficiently manage warehouse operations.

By visualizing the sequence of tasks and activities in a Gantt chart, warehouse managers can easily identify any operational inefficiencies or bottlenecks in the workflow, enabling them to make adjustments and improvements to streamline operations and increase productivity.

A Gantt chart can be shared with stakeholders, such as senior management or customers, to provide visibility into warehouse operations, track progress, and report on key performance indicators, allowing for effective communication and decision-making.

Gantt chart software can help optimize warehouse operations by visually mapping out tasks, timelines, and dependencies. It allows for better resource allocation, identifies potential bottlenecks, and enables efficient scheduling of activities. This improves coordination among team members, streamlines workflow, and ultimately enhances overall efficiency in warehouse operations.

Yes, Gantt chart software can be used to track inventory movement and manage stock levels. By visualizing the timeline of inventory activities, it enables the tracking of stock levels, delivery schedules, and production timelines. This allows for better inventory management, identifying potential bottlenecks, and ensuring timely replenishment of stock. Additionally, it facilitates resource allocation and coordination among teams involved in inventory management, improving efficiency and reducing stockouts or excess inventory.

Yes, Gantt chart software can help you identify bottlenecks in warehouse processes by visually representing the workflow and timelines. It allows you to identify areas where tasks overlap or are delayed, enabling you to adjust task durations, dependencies, and resources in real-time. This helps in finding ways to improve processes and streamline workflow, leading to more efficient warehouse operations.