Overview

Manage all of your projects in one place.

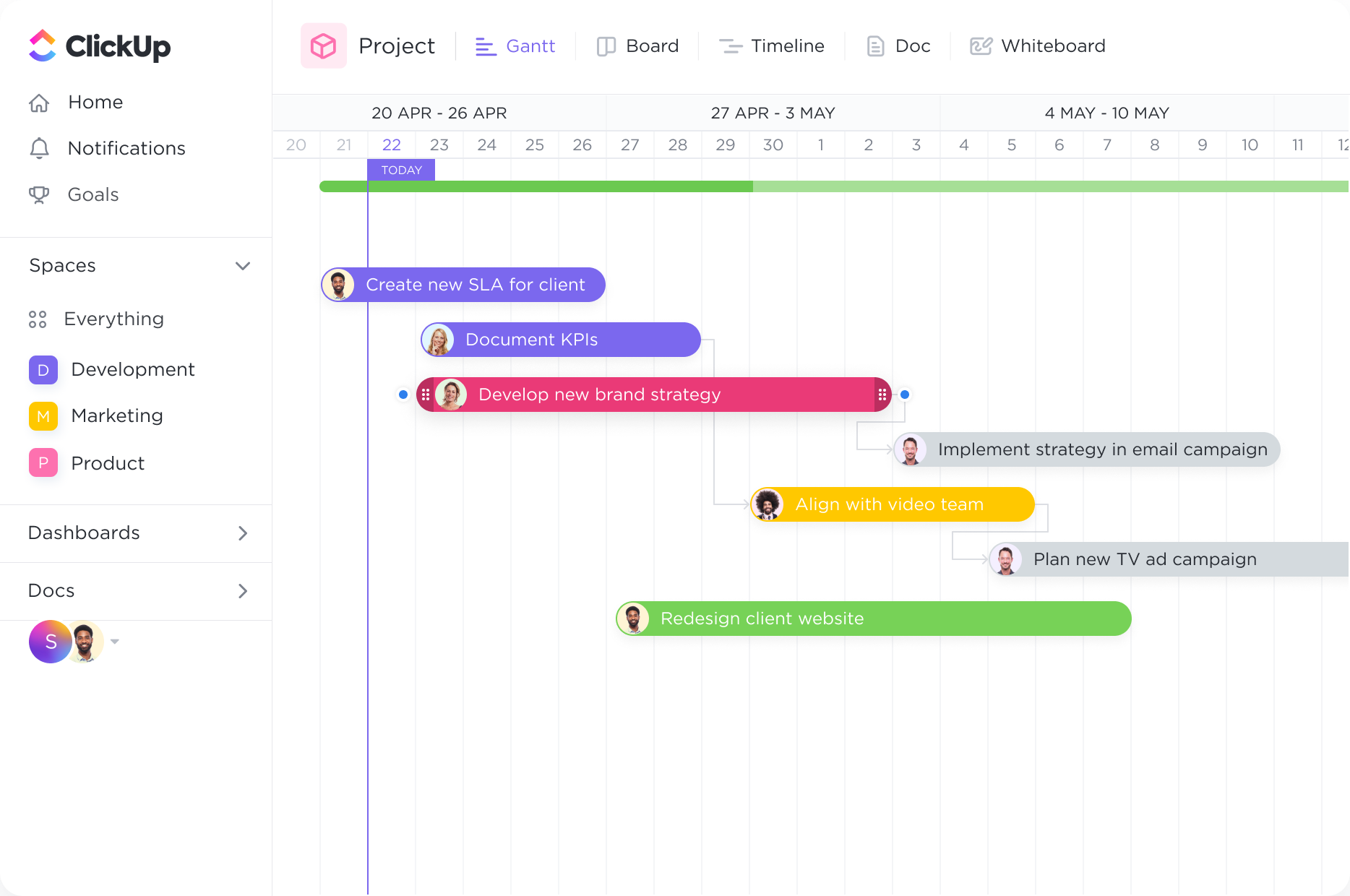

Get a bird's-eye view of all Spaces, Projects, Lists, and tasks in one Gantt chart. With clear coloring options, you can easily see what work is happening and where.

Gantt Charts

Streamline your project management process with ClickUp's powerful Gantt Chart software. Empower machinists to plan, track, and visualize their tasks and projects effortlessly. From assigning tasks to setting deadlines and monitoring progress, ClickUp's intuitive interface ensures seamless collaboration and maximized productivity. Take control of your projects and unleash the full potential of your machinists with ClickUp's tailored Gantt Chart software.

Free forever. No credit card.

Overview

Get a bird's-eye view of all Spaces, Projects, Lists, and tasks in one Gantt chart. With clear coloring options, you can easily see what work is happening and where.

Dependencies

Create tasks and link them with dependencies. Dragging a task with dependencies will automatically reschedule tasks in the chain

In the context of machinists, Gantt charts can be used to plan and schedule production activities. Machinists can visualize the different stages of production, from material acquisition to final product assembly, by using a Gantt chart. This helps them allocate resources effectively, track progress, and ensure that all tasks are completed within the specified timelines.

Gantt charts can also be used to manage and optimize the utilization of machines in a machining workshop. Machinists can schedule different jobs on various machines, ensuring that each machine is utilized efficiently and downtime is minimized. Additionally, Gantt charts can be used to plan and schedule routine maintenance tasks, reducing the risk of machine breakdowns and improving overall productivity.

Efficient management of tools and materials is crucial for machinists. Gantt charts can help machinists plan and schedule the availability of tools and materials required for different production tasks. By visualizing the timeline for tool and material usage, machinists can ensure that they have the necessary resources at each stage of the production process, reducing delays and optimizing workflow.

Maintaining quality standards is essential in machining operations. Gantt charts can be used to schedule quality control and inspection activities at various stages of production. Machinists can allocate time for inspections, ensuring that each product goes through the necessary quality checks before moving to the next phase. This helps identify and address any issues early on, improving the overall quality of the final products.

A Gantt chart can help machinists keep track of multiple projects and their respective timelines, allowing them to prioritize tasks and allocate resources effectively.

Machinists can use a Gantt chart to schedule machine usage and avoid conflicts or overlaps in machine availability, ensuring optimal utilization of machines and minimizing downtime.

A Gantt chart can be used to monitor the availability of materials and tools required for different machining projects, helping machinists plan their work and order necessary supplies in advance.

A Gantt chart can facilitate coordination between machinists and other departments or teams involved in the manufacturing process, enabling smooth handoffs, identifying dependencies, and ensuring timely completion of projects.

By visualizing the sequence of tasks and their durations, a Gantt chart can help machinists identify potential bottlenecks in the workflow, allowing them to take proactive measures to prevent delays and maintain productivity.

A Gantt chart can be shared with clients to provide a clear timeline of when their machining projects will be completed, helping manage client expectations and communicate any potential delays or changes in the schedule.

You can use Gantt chart software to visually plan and schedule machining projects, allocate resources efficiently, and track progress in real-time. It enables you to set dependencies between tasks, identify critical paths, and adjust schedules as needed. This helps you optimize workflow, avoid delays, and ensure timely completion of machining projects.

Gantt chart software can be customized to cater to the needs of machinists by incorporating features such as task dependencies and resource allocation, enabling them to plan and schedule machining operations effectively. It also allows for the visualization of critical paths and bottlenecks, ensuring efficient machine utilization and minimizing downtime. Additionally, it facilitates collaboration among machinists and other team members by providing a centralized platform for communication and real-time updates on project progress.

Yes, Gantt chart software can help optimize the scheduling and sequencing of machining operations by visually representing the workflow, identifying task dependencies, and highlighting potential bottlenecks. It allows for real-time adjustment of task durations and resources, enabling efficient scheduling and sequencing to maximize productivity and minimize downtime.