Timelines

Stay ahead of every deadline.

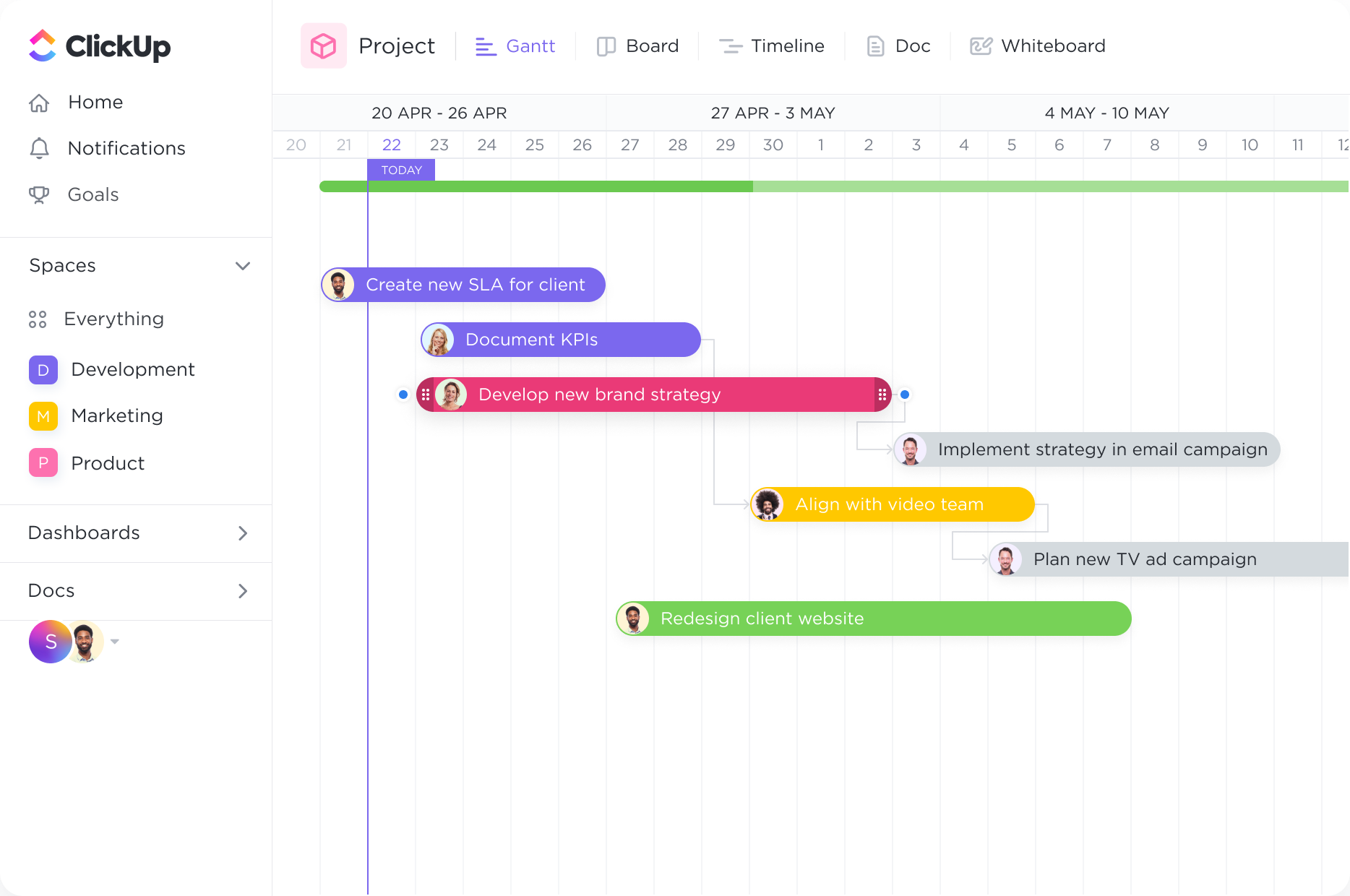

With the Gantt chart's dynamic timeline, you can easily schedule tasks, keep up with project progress, manage deadlines, and handle bottlenecks.

Gantt Charts

Streamline your project management process with ClickUp's powerful Gantt Chart software. Create detailed timelines and schedules, customized specifically for Eyewear Manufacturers. Seamlessly track progress, allocate resources, and meet deadlines with ease. Take control of your projects and maximize efficiency with ClickUp's Gantt Chart software designed for Eyewear Manufacturers.

Free forever. No credit card.

Timelines

With the Gantt chart's dynamic timeline, you can easily schedule tasks, keep up with project progress, manage deadlines, and handle bottlenecks.

Dependencies

Create tasks and link them with dependencies. Dragging a task with dependencies will automatically reschedule tasks in the chain

In eyewear manufacturing, efficient production planning and scheduling are essential to meet customer demands and optimize resources. Gantt charts provide a clear visualization of the production process, allowing manufacturers to plan and allocate tasks, set realistic timelines, and track the progress of each production stage. This helps ensure smooth operations, minimize delays, and meet production targets.

Eyewear manufacturers need to manage their inventory effectively and ensure a steady supply of materials. Gantt charts can be used to track the availability of raw materials, plan procurement activities, and schedule deliveries. By visualizing the inventory and procurement timeline, manufacturers can avoid stockouts, reduce excess inventory, and maintain a streamlined supply chain.

Maintaining high-quality standards is crucial in eyewear manufacturing. Gantt charts can be utilized to schedule and track quality control inspections and testing processes at various stages of production. By integrating quality control tasks into the chart, manufacturers can ensure that each eyewear product undergoes rigorous testing, resulting in superior quality and customer satisfaction.

Eyewear manufacturing involves the use of specialized equipment and machinery. Gantt charts can help schedule routine maintenance, servicing, and calibration activities for these machines. By incorporating equipment maintenance tasks into the chart, manufacturers can prevent unexpected breakdowns, optimize equipment utilization, and ensure uninterrupted production.

Gantt charts are invaluable tools for planning and managing the entire lifecycle of new product development in the eyewear industry. From ideation to design, prototyping, testing, and finally, product launch, Gantt charts provide a comprehensive overview of each stage and its associated tasks. This enables manufacturers to allocate resources, set realistic timelines, and ensure a smooth transition from concept to market-ready eyewear.

Efficient supply chain management is crucial for eyewear manufacturers to deliver products to customers on time. Gantt charts can be used to plan and coordinate various logistics activities, such as transportation, warehousing, and order fulfillment. By visualizing the entire supply chain process, manufacturers can optimize routes, minimize transportation costs, and ensure timely delivery of eyewear products.

A Gantt chart can help eyewear manufacturers track the progress of each production stage, from design and prototyping to manufacturing and quality control. It allows them to allocate resources effectively and ensure that each task is completed on time.

Eyewear manufacturing involves collaboration with various suppliers and vendors. A Gantt chart can help manufacturers coordinate tasks and deadlines with these external parties, ensuring smooth communication and timely delivery of materials and components.

With a Gantt chart, eyewear manufacturers can monitor inventory levels and plan production activities accordingly. It helps them avoid stockouts or excess inventory by aligning production schedules with demand forecasts.

By visualizing the production process in a Gantt chart, manufacturers can identify bottlenecks or areas of inefficiency. This allows them to make informed decisions to optimize workflows, allocate resources more effectively, and improve overall productivity.

Eyewear manufacturers often have specific launch dates and marketing campaigns associated with new products. A Gantt chart can help manage these activities by providing a clear timeline and ensuring that all necessary tasks, such as product photography, marketing materials creation, and advertising, are completed on time.

A Gantt chart can be used to track customer orders, from order placement to delivery. It helps manufacturers ensure that orders are fulfilled in a timely manner and allows them to communicate accurate delivery dates to customers.

Gantt chart software can help eyewear manufacturers by providing a visual representation of project timelines and tasks, allowing for better resource allocation and scheduling. It enables the tracking of production processes, identifies potential bottlenecks, and helps in managing inventory levels. Additionally, it facilitates communication and collaboration among team members, improving overall efficiency and productivity in the manufacturing process.

Gantt chart software can help in managing the production timeline for eyewear manufacturing by visually mapping out the production process, identifying task dependencies and potential bottlenecks. It allows for the allocation of resources and tracking of progress, ensuring timely completion of each manufacturing phase. Additionally, it enables real-time adjustments to the timeline, facilitating effective coordination and communication among team members, leading to improved production efficiency and on-time delivery.

There are several Gantt chart software options available that can be tailored to the needs of eyewear manufacturers. Some software may offer industry-specific features or customization options to accommodate the unique requirements of eyewear manufacturing projects. It is recommended to research and compare different software options to find the one that best suits your specific needs and preferences.