Visualize

Organize and set priorities.

Organize how you see your tasks with quick sorting. Create cascading views with a single click to easily see what important tasks are coming next.

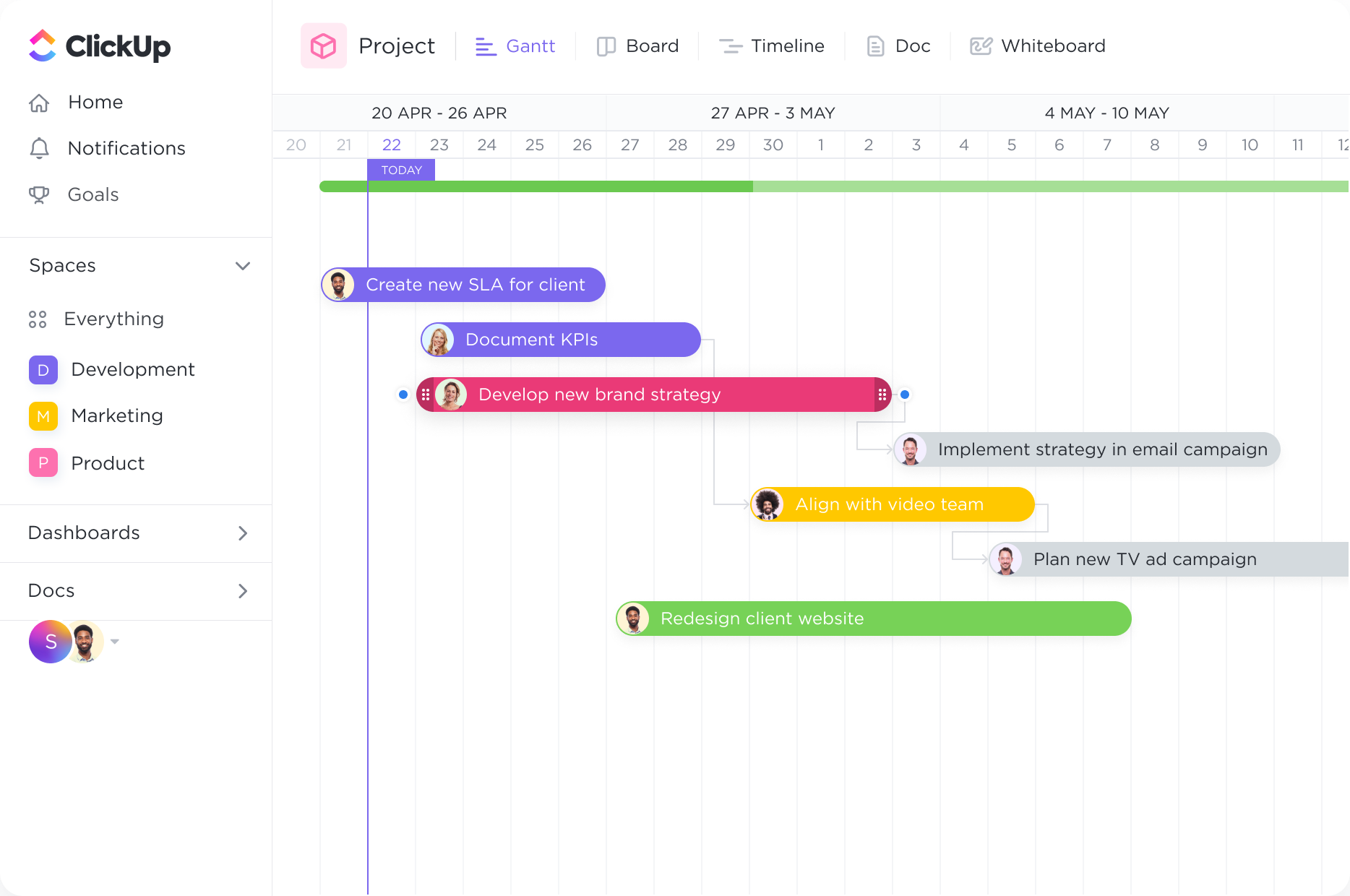

Gantt Charts

Supercharge your project management with ClickUp's revolutionary Gantt Chart software designed specifically for Chemical Manufacturers. Streamline your workflow, track tasks, and visualize deadlines with ease. With ClickUp, you can create custom Gantt Charts that perfectly align with your unique processes, ensuring efficient project execution every step of the way. Take control of your projects and boost productivity with ClickUp's Gantt Chart software today.

Free forever. No credit card.

Visualize

Organize how you see your tasks with quick sorting. Create cascading views with a single click to easily see what important tasks are coming next.

Activity

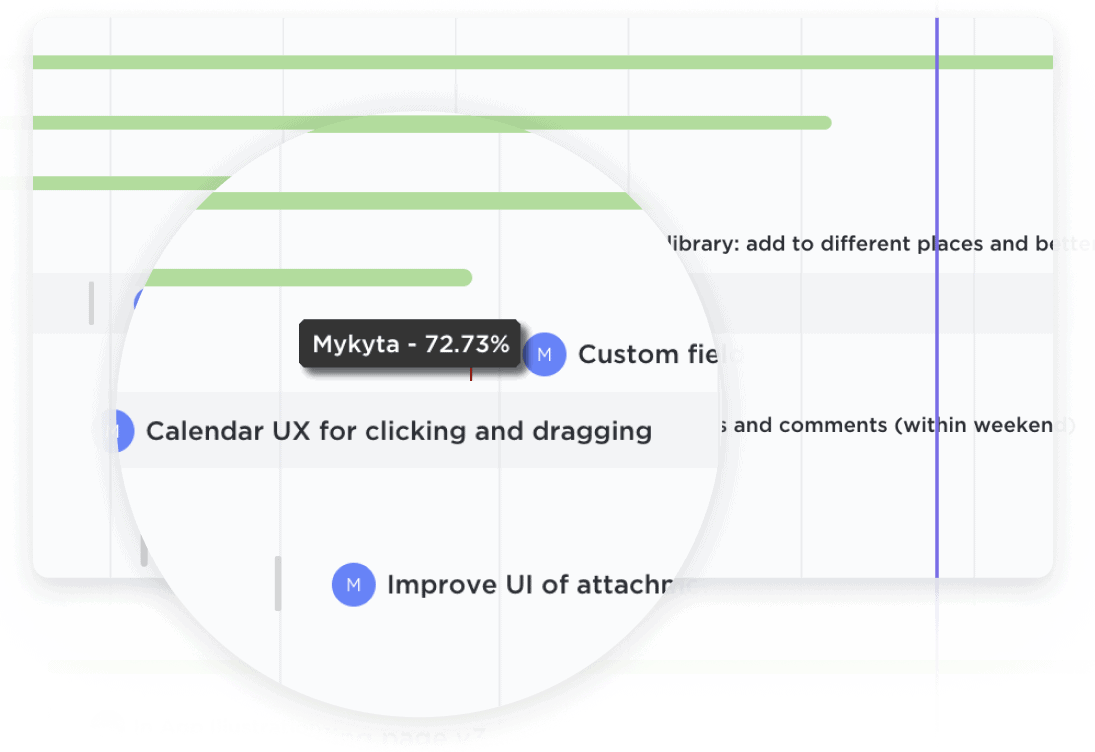

Easily update projects with a simple drag-and-drop action to collaborate amongst your team in real-time. Dynamic progress percentages provide a detailed snapshot.

Gantt charts are invaluable tools for chemical manufacturers when it comes to planning and scheduling production processes. By visualizing the various stages of production, from raw material acquisition to final product delivery, manufacturers can effectively allocate resources, set realistic timelines, and identify potential bottlenecks. This helps ensure smooth operations and timely delivery of products, ultimately enhancing efficiency and customer satisfaction.

Chemical manufacturing involves the allocation of various resources, including personnel, equipment, and raw materials. Gantt charts provide a comprehensive overview of resource availability and utilization, enabling manufacturers to optimize resource allocation and minimize downtime. By effectively managing resources, manufacturers can streamline production, reduce costs, and maximize productivity.

Maintaining quality standards is of utmost importance in the chemical manufacturing industry. Gantt charts can be used to schedule and track quality control activities and testing processes at different stages of production. This ensures that all necessary tests and inspections are conducted, helping to identify and rectify any issues early on. By integrating quality control into the Gantt chart, manufacturers can maintain consistency and uphold product quality.

Regular maintenance and occasional shutdowns are essential for the safe and efficient operation of chemical manufacturing facilities. Gantt charts provide a visual representation of planned maintenance activities, allowing manufacturers to schedule maintenance tasks, allocate resources, and minimize production disruptions. By proactively planning and scheduling maintenance, manufacturers can reduce downtime and extend the lifespan of equipment.

Efficient supply chain management is crucial for chemical manufacturers to ensure a steady flow of raw materials and timely delivery of finished products. Gantt charts can be used to map out the entire supply chain, including procurement, transportation, and distribution processes. This helps manufacturers identify potential delays, optimize logistics, and improve coordination with suppliers and distributors. By visualizing the supply chain, manufacturers can enhance transparency, reduce lead times, and maintain a competitive edge.

A Gantt chart can help chemical manufacturers allocate resources, plan production tasks, and schedule activities in a visual and organized manner. It allows them to see the overall timeline of production and identify any potential bottlenecks or conflicts.

By integrating inventory data into a Gantt chart, chemical manufacturers can monitor their stock levels and ensure that the necessary materials are available at the right time. This helps prevent delays in production due to inventory shortages or overstocking.

Chemical manufacturing often requires regular maintenance and equipment downtime. A Gantt chart can help schedule these activities alongside production tasks, ensuring that maintenance activities do not disrupt the overall production schedule.

Chemical manufacturers must adhere to various compliance and regulatory requirements. A Gantt chart can help track and manage these deadlines, ensuring that necessary permits, certifications, and inspections are completed on time.

With a Gantt chart, chemical manufacturers can visualize the workload and capacity of their resources, such as production lines, machinery, and personnel. This enables them to make informed decisions about resource allocation and avoid overloading or underutilizing resources.

A Gantt chart can be shared with stakeholders and customers to provide a clear overview of production timelines and delivery schedules. This helps manage expectations, improve communication, and foster transparency in the manufacturing process.

You can use Gantt chart software to visually map out the production steps and their dependencies, allowing for better scheduling and resource allocation. It enables you to identify potential bottlenecks and optimize the workflow by adjusting task durations and dependencies. This helps in streamlining the manufacturing processes, improving efficiency, and reducing production time.

Yes, many Gantt chart software options offer integrations with popular project management tools used in the chemical manufacturing industry, allowing for seamless data transfer and collaboration. This integration enables real-time updates, enhances communication, and streamlines project planning and tracking processes, improving overall project management efficiency.

Some best practices for using Gantt chart software in chemical manufacturing to track and manage complex projects include: </p>