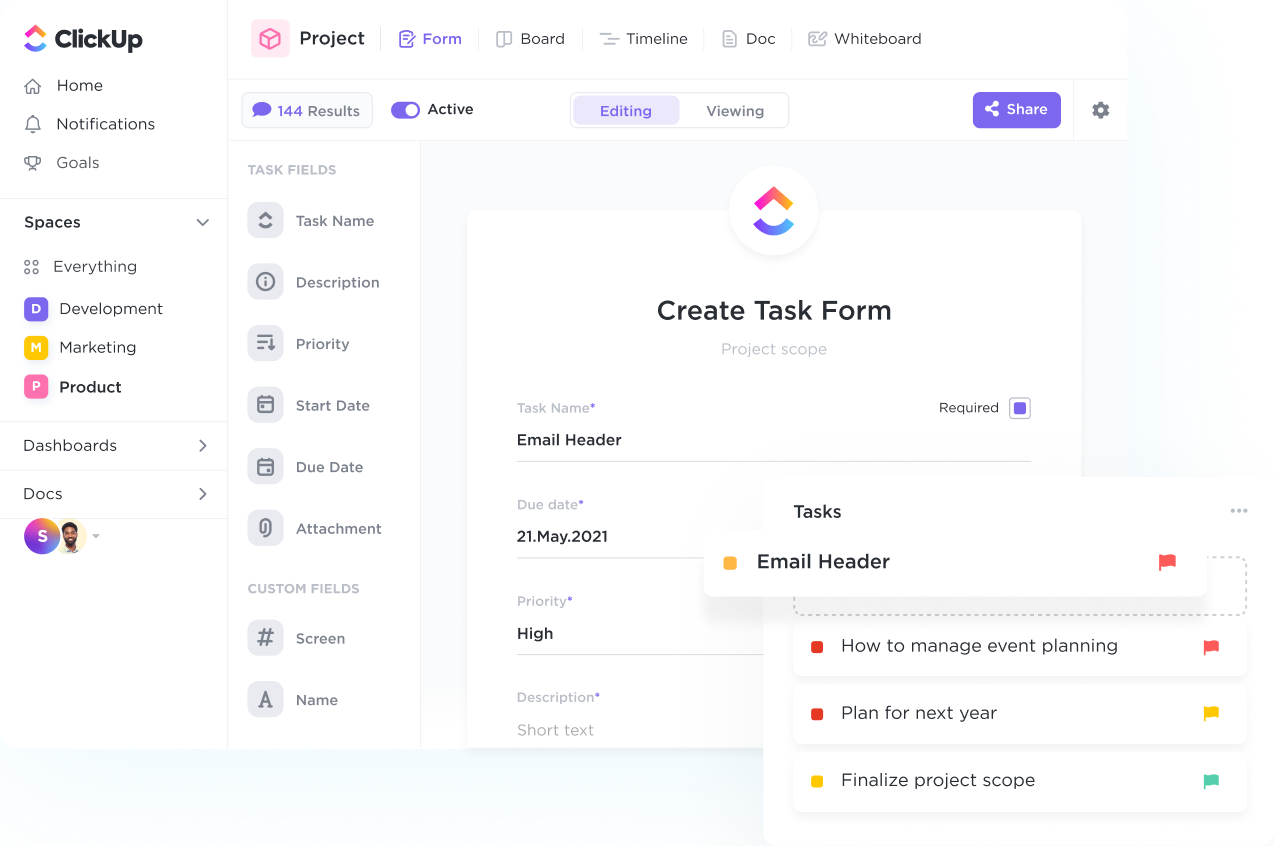

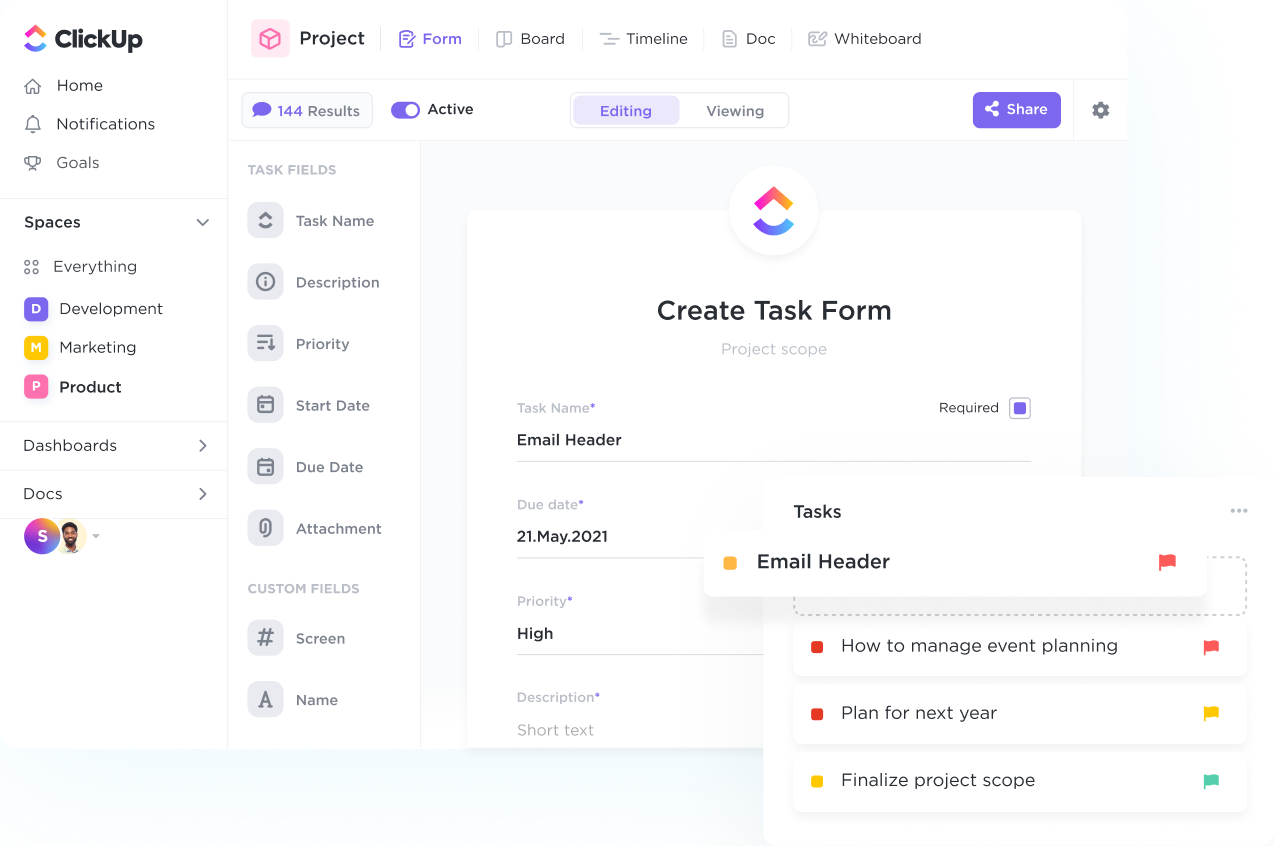

Forms

Onboard customers and collect info in a snap.

Streamline your intake process, organize response data, and automatically create tasks with custom branded Forms powered by conditional logic.

Gantt Charts

Optimize your production management with ClickUp's customizable CRM system. Streamline communication, track projects, and enhance productivity all in one place. Revolutionize your workflow and empower your team to reach new heights with our tailored solution for production managers.

Free forever. No credit card.

Forms

Streamline your intake process, organize response data, and automatically create tasks with custom branded Forms powered by conditional logic.

CRM Views

Manage everything from sales pipelines, customer engagement, and orders with ClickUp's 10+ highly flexible views. Easily track and manage your accounts on a List, Kanban Board, Table view, and more.

A CRM for production managers centralizes all production-related data, including inventory levels, production schedules, supplier information, and quality control metrics. This centralization eliminates the need for manual tracking across multiple systems or spreadsheets, ensuring that all relevant information is easily accessible in one place.

CRMs can help production managers track production costs, budgets, and expenses in real-time. This feature allows for better financial planning, cost control, and the ability to identify areas where costs can be optimized to improve overall profitability.

CRM software can assist production managers in creating production schedules, assigning tasks to team members, and monitoring progress in real-time. By streamlining production processes and optimizing resource utilization, production efficiency can be enhanced, leading to better throughput and reduced lead times.

Automating inventory management through a CRM helps production managers keep track of raw materials, work-in-progress items, and finished goods. By setting up reorder points, tracking stock levels, and managing supplier relationships within the CRM, production managers can ensure smooth operations without the risk of stockouts or overstocking.

CRMs can incorporate quality control measures and compliance checks to ensure that production processes meet industry standards and regulations. By setting up alerts for quality deviations or compliance issues, production managers can take corrective actions promptly, maintaining product quality and regulatory adherence.

Key features of CRM software for production managers include task automation, real-time collaboration, inventory management, production scheduling, resource allocation, and performance analytics for process optimization and efficiency improvements.

CRM software helps production managers by providing real-time visibility into inventory levels, tracking stock movements, generating alerts for low-stock situations, optimizing reorder processes, and enabling efficient inventory management strategies to prevent stockouts and ensure optimal stock levels.

Yes, CRM software can integrate with production management tools or systems to create a unified workflow, streamlining processes, enhancing data visibility, and improving collaboration across teams.