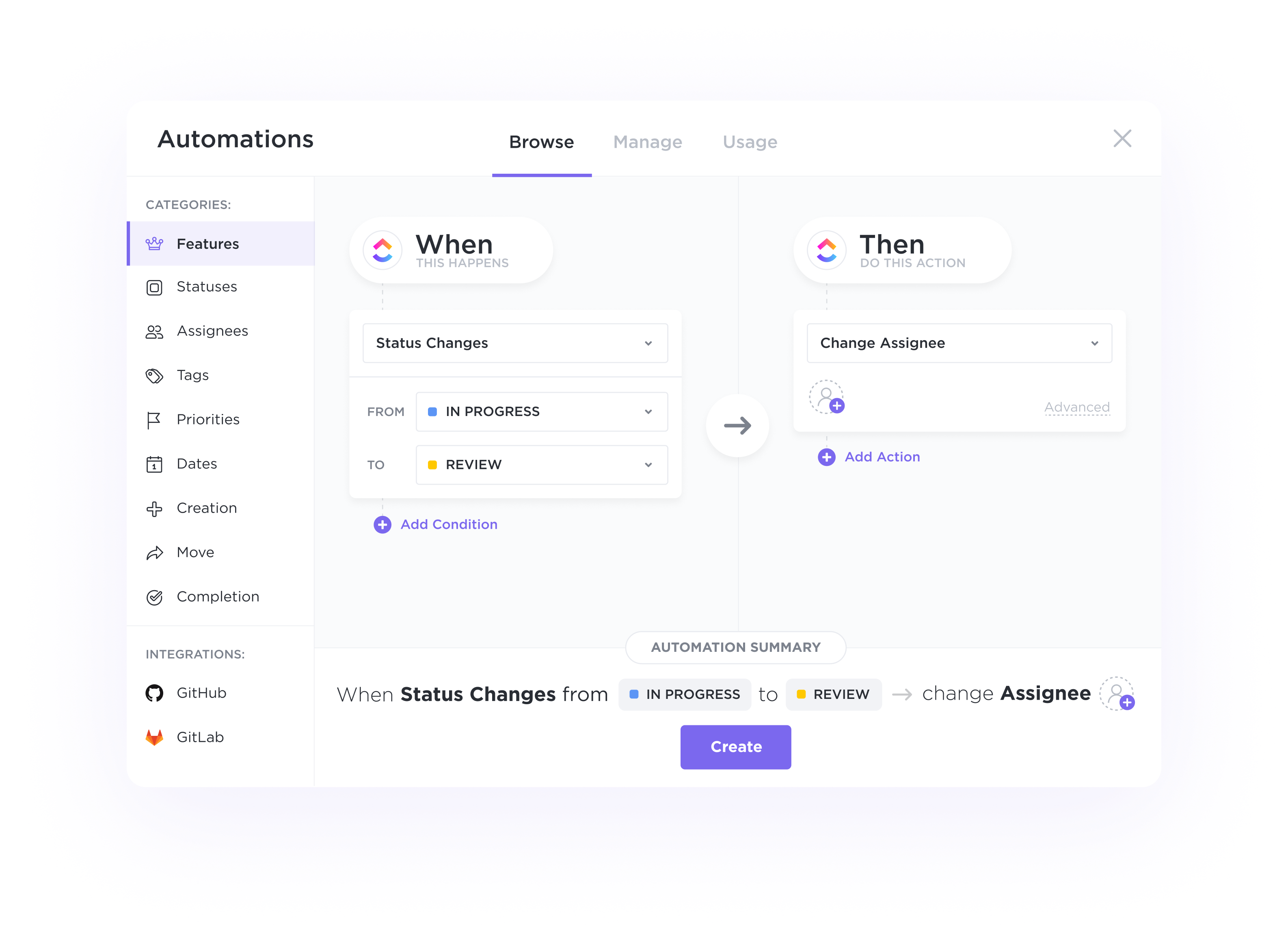

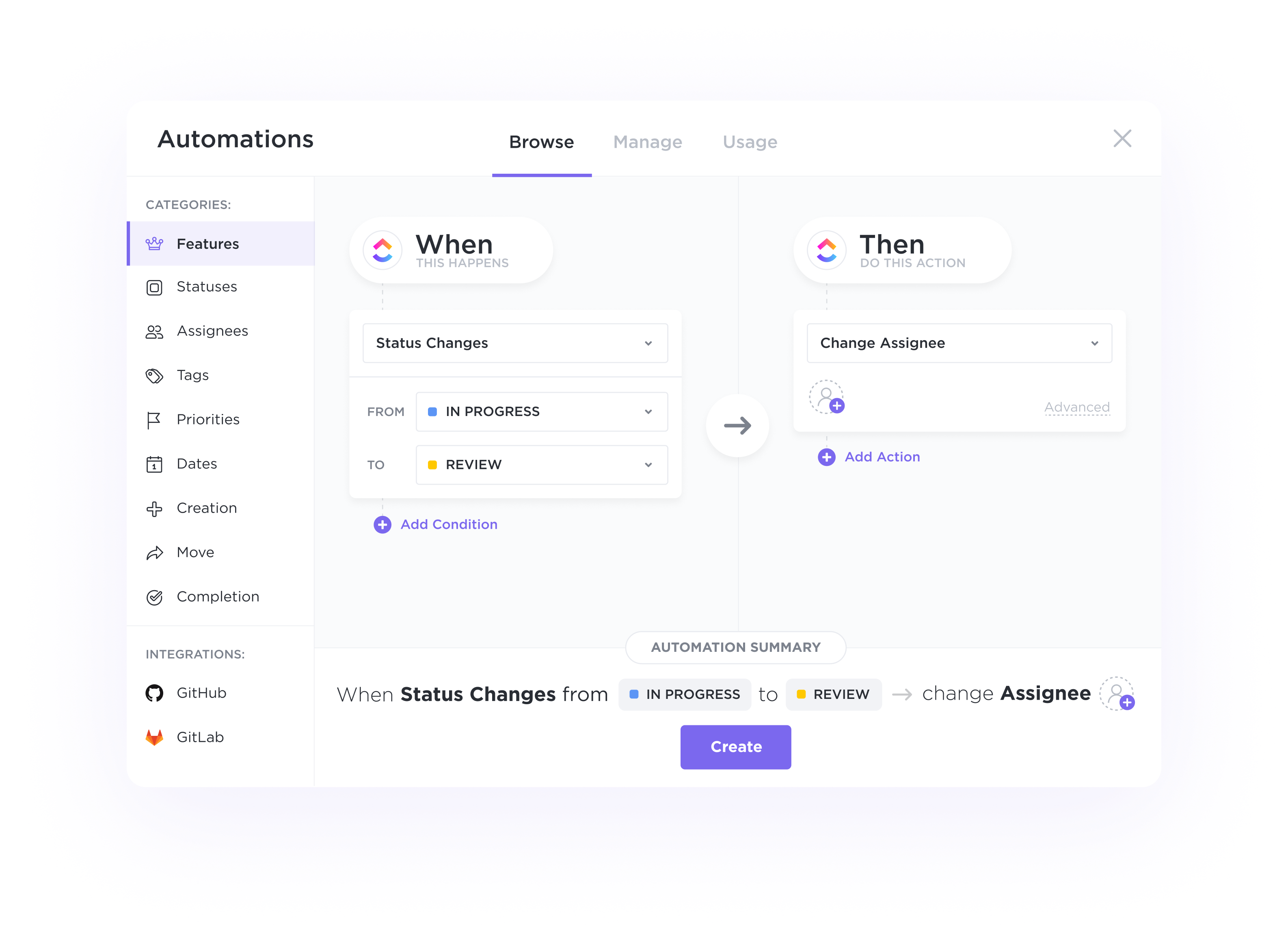

Automations

Automate handoffs, status updates, and more.

Automatically assign tasks for each stage of your pipeline, trigger status updates based on activity, and switch priorities to alert your team on where to focus next.

Gantt Charts

Optimize your customer relationships with ClickUp's customizable CRM system designed specifically for Equipment Operators. Streamline your processes, track interactions effortlessly, and boost productivity with our user-friendly platform. Try ClickUp today and take your customer management to the next level!

Free forever. No credit card.

Automations

Automatically assign tasks for each stage of your pipeline, trigger status updates based on activity, and switch priorities to alert your team on where to focus next.

Email Management

Eliminate silos and fast-track communication by integrating your emails with ClickUp. Collaborate on deals, send project updates to clients, and onboard customers with a single email hub.

A CRM for equipment operators can track the usage history of each piece of equipment, including hours of operation, maintenance schedules, and any reported issues. This centralized information helps in proactive maintenance planning, reducing downtime and increasing equipment longevity.

CRMs can manage the inventory of equipment, track availability, and schedule rentals or deployments efficiently. This ensures that equipment is utilized optimally, prevents double bookings, and helps in planning for maintenance or replacement needs.

By storing safety compliance records and training certifications within the CRM, equipment operators can easily track and manage employee certifications, conduct safety training programs, and ensure that all operators are compliant with regulations. This helps in maintaining a safe work environment.

A CRM can streamline customer inquiries, service requests, and issue resolutions related to equipment operation. By centralizing customer interactions and history, equipment operators can provide better and more personalized customer service, leading to improved customer satisfaction and loyalty.

CRMs can provide insights into equipment utilization trends, performance metrics, and operational efficiency. This data helps equipment operators in making informed decisions about equipment deployment, maintenance schedules, and identifying opportunities for improving overall efficiency.

CRM software can help equipment operators manage their daily tasks more efficiently by providing a centralized platform for scheduling, tracking maintenance activities, monitoring equipment usage, and managing work orders. This streamlines communication, enhances task prioritization, and improves overall operational efficiency.

Yes, there are CRM softwares tailored for equipment operators that focus on tracking maintenance schedules, equipment availability, and other related needs to streamline operations and enhance efficiency.

CRM software can help equipment operators streamline communication with clients and track project progress in real-time by centralizing client information, facilitating seamless communication, and providing real-time project updates and status tracking for improved collaboration and efficiency.