Top AI Prompts for Quality Management

AI Prompts Revolutionizing Quality Management Processes

Ensuring product excellence goes beyond final inspections—it starts with managing every detail throughout production.

Quality management teams juggle audits, compliance reviews, defect tracking, and continuous improvement initiatives—all demanding precise coordination and documentation. AI prompts are now pivotal in streamlining these complex workflows.

Quality teams leverage AI to:

- Quickly identify patterns in quality data and defect reports

- Generate audit summaries, corrective action plans, and inspection checklists

- Interpret regulatory standards and compliance requirements efficiently

- Transform unstructured feedback into prioritized task lists and process maps

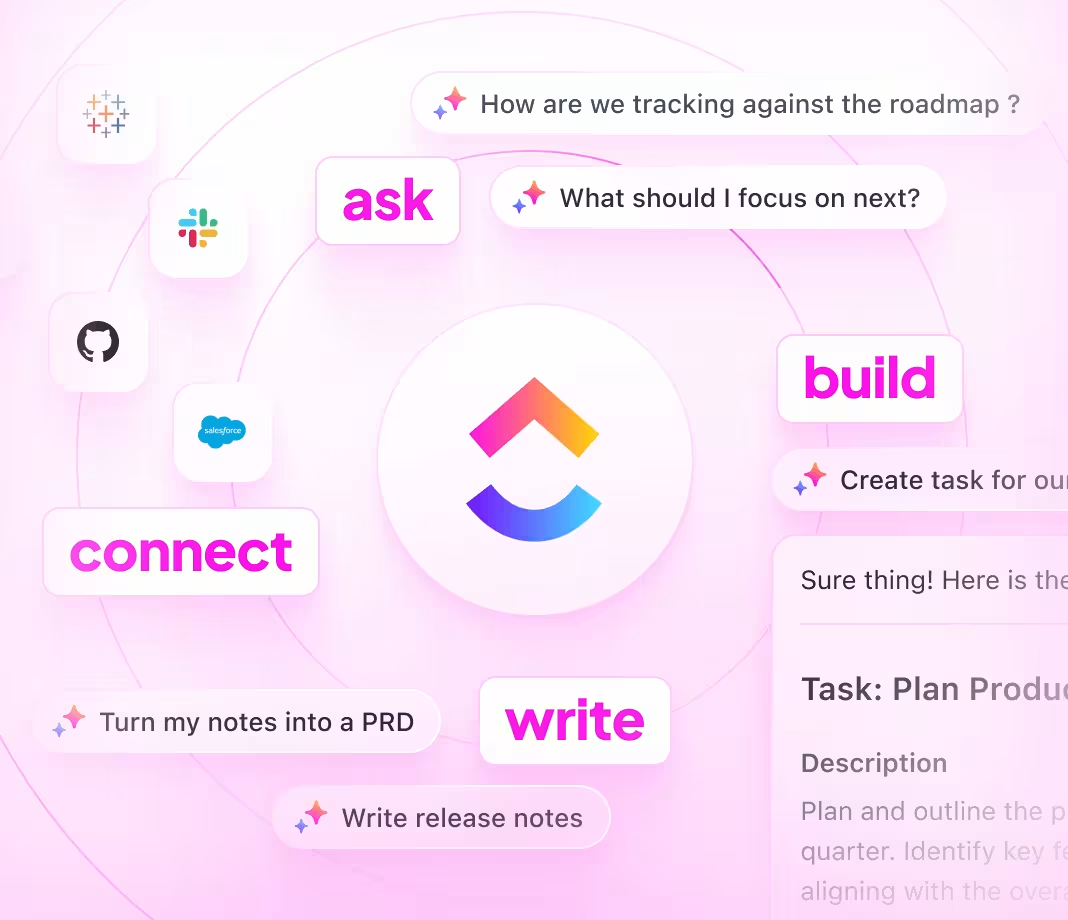

Integrated within familiar tools like documents, dashboards, and project boards, AI in ClickUp Brain acts as a proactive partner—shaping raw quality data into clear, prioritized actions that drive product excellence.

Why ClickUp Brain Stands Apart

Conventional AI Solutions

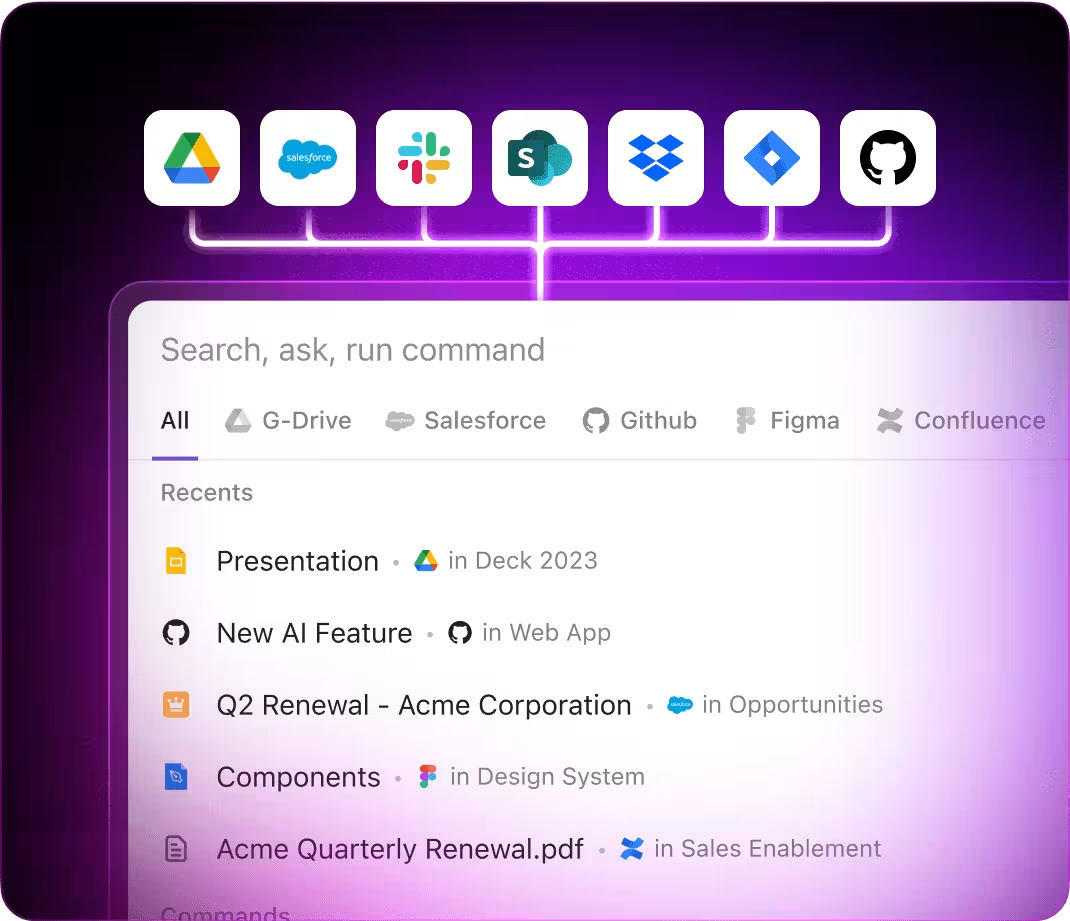

- Constantly toggling between apps to collect information

- Repeating your quality objectives with each query

- Responses that lack relevance to your processes

- Hunting through multiple platforms for a single document

- Interacting with AI that only processes input without insight

- Manually switching between different AI engines

- Merely another add-on in your browser

ClickUp Brain

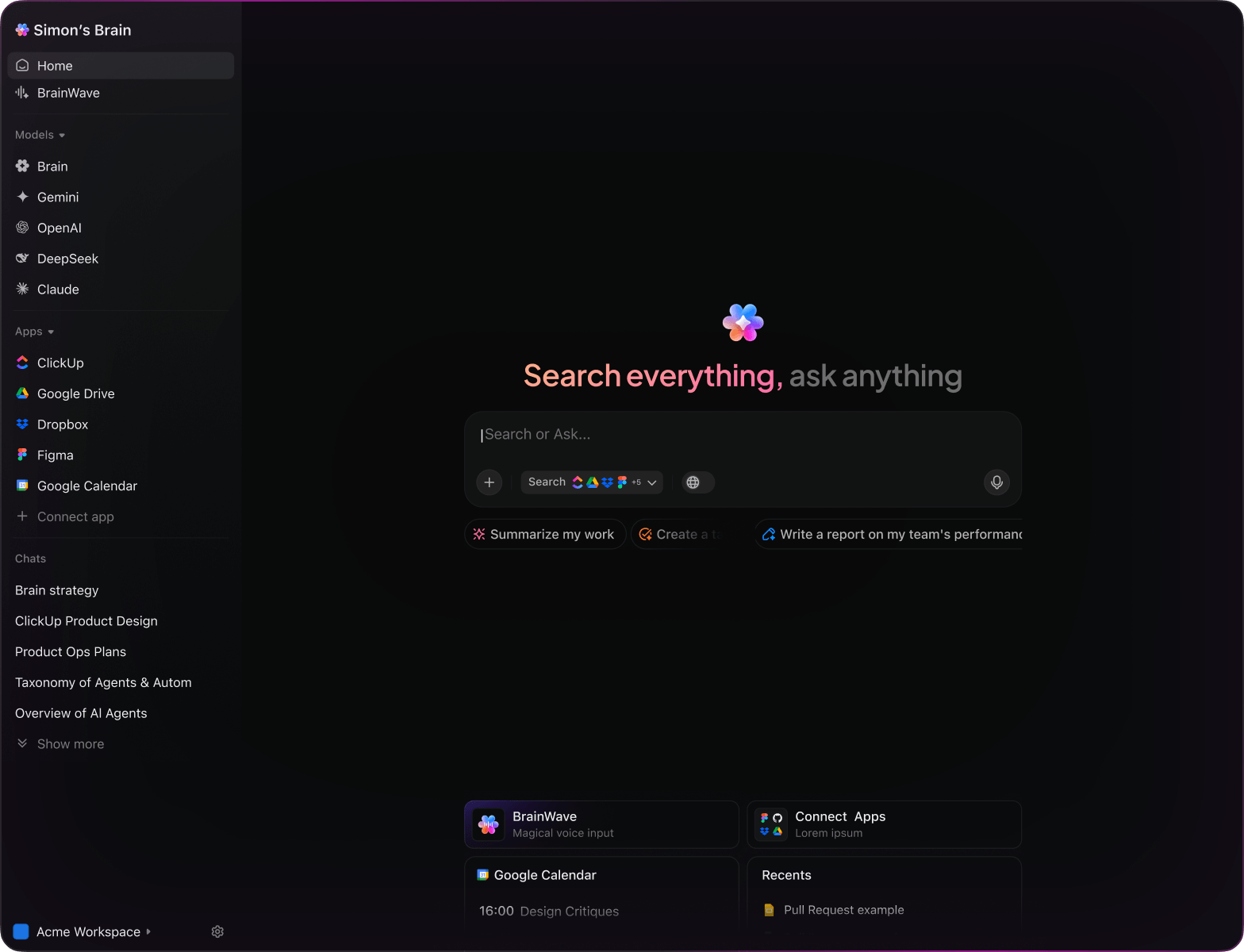

- Deeply understands your quality tasks, documentation, and team progress

- Retains your project history and quality targets

- Provides detailed, context-driven recommendations

- Consolidated search across all your quality management tools

- Hands-free operation with Talk to Text feature

- Automatically selects the optimal AI model: GPT, Claude, Gemini

- Dedicated desktop app for Mac & Windows designed for efficiency

15 Essential AI Prompts for Quality Management Teams

Identify 5 key quality assurance strategies for manufacturing electronics, based on the ‘QA Standards 2025’ document.

ClickUp Brain Behaviour: Analyzes the document’s guidelines and highlights effective QA approaches tailored to electronics production.

What are the latest inspection criteria trends in pharmaceutical packaging under $50K production costs in North America?

ClickUp Brain Behavior: Integrates insights from internal quality reports; Brain Max can supplement with relevant external data if accessible.

Draft a quality control checklist for assembly line audits inspired by ISO 9001 standards. Reference Audit Report #12 and prior compliance notes.

ClickUp Brain Behavior: Extracts key audit points and regulatory references from linked files to create a structured QC checklist.

Summarize defect rate comparisons between Supplier A and Supplier B using our ‘Defect Analysis Q2’ report.

ClickUp Brain Behavior: Pulls tabular data and written observations from internal reports to deliver a concise comparative summary.

List top materials testing methods used in aerospace quality assurance, referencing R&D findings and supplier documentation.

ClickUp Brain Behavior: Reviews internal documents to identify common testing techniques and their effectiveness notes.

From the ‘Calibration Procedures’ document, generate a step-by-step validation checklist for measurement tools.

ClickUp Brain Behavior: Detects procedural steps and compiles them into an actionable checklist within a task or document.

Summarize 3 emerging trends in automated quality inspection from post-2023 research and technology review documents.

ClickUp Brain Behavior: Extracts recurring themes and insights from linked studies and technical notes.

From the ‘Customer Feedback Q1’ report, summarize main quality concerns for product durability.

ClickUp Brain Behavior: Analyzes survey data and feedback to identify prevalent durability issues and user sentiments.

Write clear and engaging quality alert messages for the defect reporting system using the tone guidelines in ‘CommunicationStyle.pdf’.

ClickUp Brain Behavior: References tone and style from the document to craft concise alert copy variations.

Summarize upcoming changes in ISO 13485 standards for medical device quality and their impact on our process documentation.

ClickUp Brain Behavior: Reviews linked compliance documents and highlights key updates relevant to internal workflows.

Generate placement and labeling guidelines for quality control tags, referencing regional compliance documents in our workspace.

ClickUp Brain Behavior: Extracts positioning rules and labeling requirements from internal files to form a compliance checklist.

Create a non-conformance report template using FDA 2025 guidelines and our quality records folder.

ClickUp Brain Behavior: Identifies required report elements from PDF content and organizes them into a structured template.

Compare supplier quality metrics like defect rates and response times across three key vendors using our competitive analysis documents.

ClickUp Brain Behavior: Summarizes documented supplier performance data into a clear, comparative format (table or brief).

What quality management trends are emerging in the food processing industry since 2023?

ClickUp Brain Behavior: Synthesizes trends from internal research notes, industry reports, and uploaded studies.

Summarize main quality control challenges reported in Southeast Asia manufacturing feedback folders (process, materials, inspections).

ClickUp Brain Behavior: Extracts and ranks user-reported issues from surveys, feedback notes, and tagged incident reports.

AI Prompts for Quality Management with ClickUp Brain

Prompts for ChatGPT

Prompts for Gemini

Prompts for Perplexity

Prompts for ClickUp Brain

Transform Initial Thoughts Into Polished Plans

- Convert scattered observations into detailed quality reports swiftly.

- Generate innovative solutions by analyzing previous audits.

- Develop standardized templates that accelerate each review cycle.

Brain Max Boost: Quickly access historical quality data, inspection notes, and compliance documents to guide your upcoming assessments.

Accelerate Quality Management Processes

- Break down detailed quality reviews into manageable tasks.

- Transform inspection feedback into actionable assignments.

- Automatically produce compliance reports and audit summaries without extra effort.

Brain Max Boost: Instantly access historical quality records, defect analyses, or regulatory notes across all projects.

Elevate Every Phase of Quality Management with AI Prompts

Quickly Identify Quality Improvement Areas

Teams spot potential defects sooner, prioritize fixes effectively, and prevent quality bottlenecks.

Enhance Decision-Making with Data-Driven Insights

Make informed choices, reduce compliance risks, and deliver products that exceed standards.

Detect Errors Before They Escalate

Minimizes expensive rework, boosts product reliability, and shortens inspection cycles.

Align Cross-Functional Teams Seamlessly

Improves communication, removes misunderstandings, and accelerates consensus among quality, production, and engineering.

Drive Continuous Quality Innovation

Encourages proactive improvements, fosters best practices, and keeps your processes ahead of industry trends.

Integrated AI Support Within ClickUp Workflows

Transforms AI insights into actionable tasks that advance your quality initiatives efficiently.