Top AI Prompts for Lean Methodology Success

Revolutionizing Lean Methodology with AI Prompts in ClickUp Brain

Implementing Lean principles effectively requires more than just theory—it demands precise coordination and continuous improvement.

From identifying waste to optimizing workflows and tracking metrics, Lean methodology spans numerous activities and documentation. AI prompts are now pivotal in streamlining these processes.

Lean teams leverage AI to:

- Quickly highlight inefficiencies and improvement opportunities

- Generate value stream maps, process flows, and action plans with minimal effort

- Interpret complex data sets and performance reports

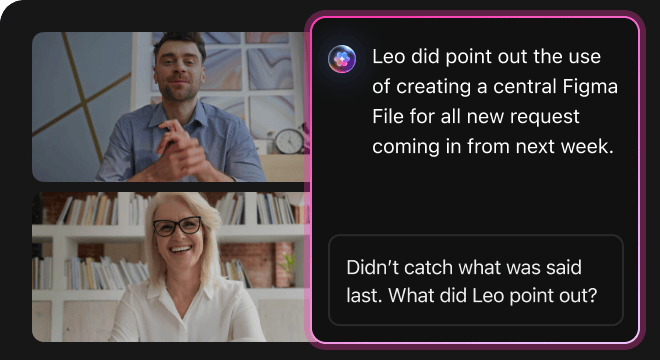

- Transform meeting notes into clear, prioritized task lists and follow-ups

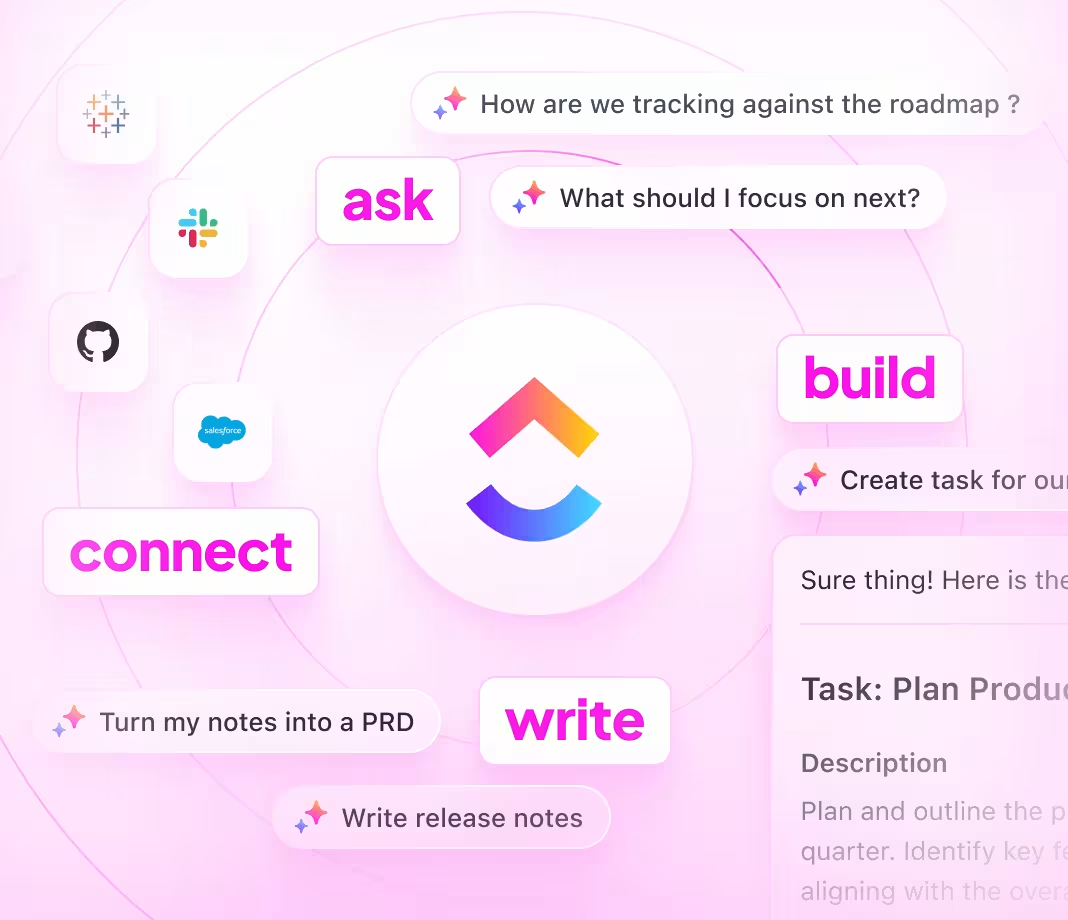

Integrated within familiar tools like documents, boards, and task trackers, AI in ClickUp Brain acts as a proactive partner, converting Lean insights into structured, manageable actions.

Discover Why ClickUp Brain Stands Apart

Standard AI Platforms

- Constantly toggling between apps to collect info

- Repeating your objectives with every request

- Receiving vague, irrelevant replies

- Hunting through numerous systems for a single document

- Engaging with AI that only processes input passively

- Manually switching among different AI engines

- Merely another add-on in your browser

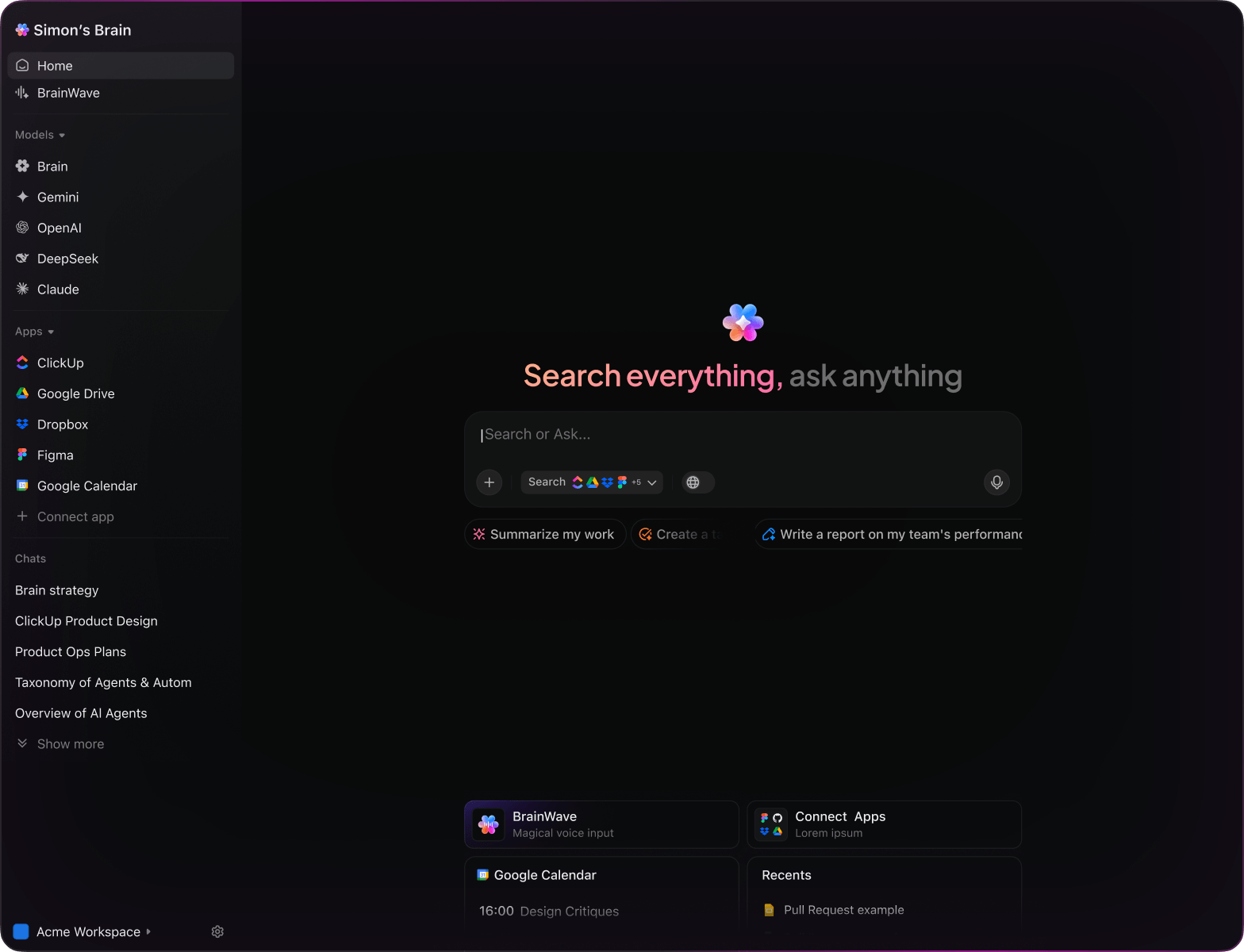

ClickUp Brain

- Deeply connected to your projects, notes, and team activities

- Retains your past interactions and targets

- Provides insightful, context-driven guidance

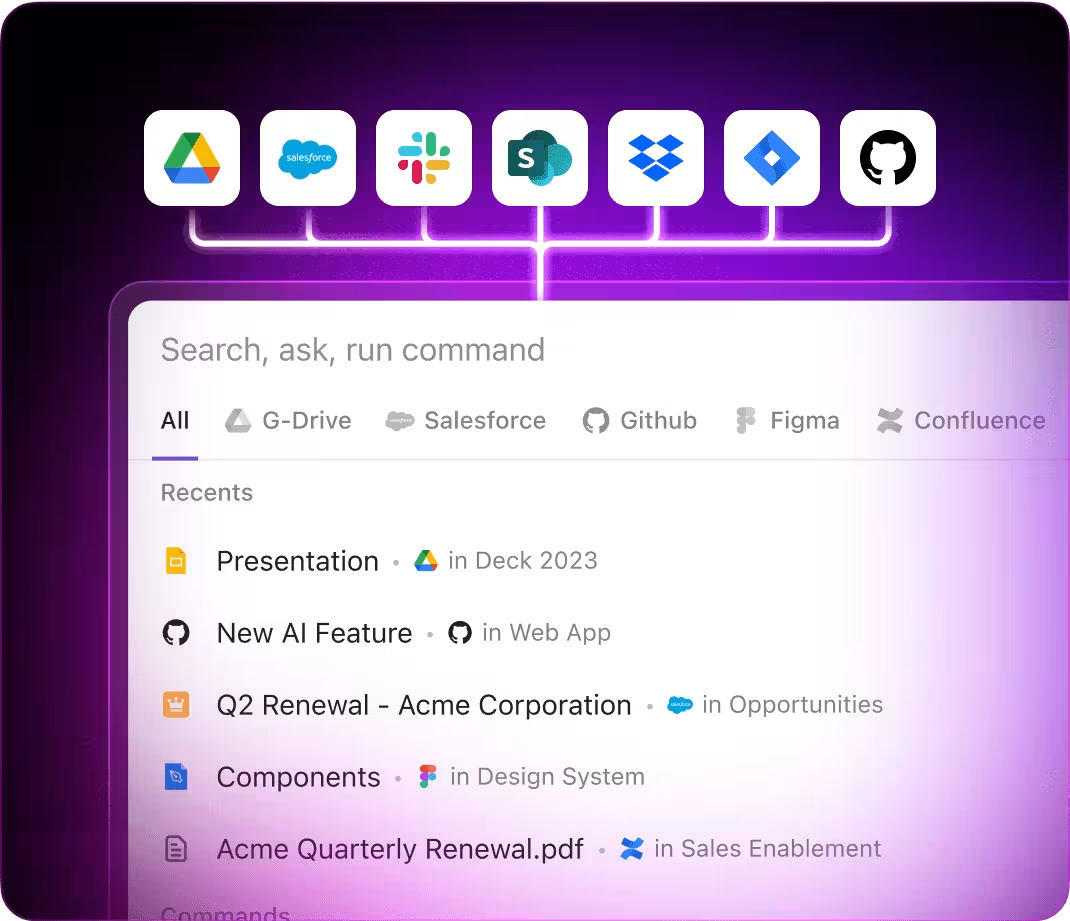

- Searches all your resources in one place

- Responds hands-free with Talk to Text

- Automatically selects optimal AI: GPT, Claude, Gemini

- Dedicated Mac & Windows app designed for efficiency

15 Targeted AI Prompts for Lean Methodology with ClickUp Brain

Identify 5 key value stream mapping approaches tailored for a software development team, based on the ‘Lean Workflow 2024’ document.

ClickUp Brain Behavior: Analyzes linked documents to extract and suggest practical value stream mapping strategies relevant to your context.

What are the latest waste elimination techniques applied in North American manufacturing plants with under $5M revenue?

ClickUp Brain Behavior: Gathers insights from internal reports; Brain Max can supplement with industry data if accessible.

Compose a project charter emphasizing continuous improvement principles, referencing notes from ‘Kaizen Event Planning’ and past retrospectives.

ClickUp Brain Behavior: Extracts key elements from linked files to assemble a focused, actionable project charter.

Summarize lead time and cycle time benchmarks between Line A and Line B using the ‘Production Metrics Q1’ report.

ClickUp Brain Behavior: Pulls quantitative and qualitative data from documents to deliver a concise comparative summary.

Identify top Kanban board setups used in high-performing agile teams, referencing internal case studies and external best practices.

ClickUp Brain Behavior: Scans documents for recurring configurations and their reported effectiveness.

From the ‘QC Procedures’ document, create a detailed checklist aligned with lean quality principles.

ClickUp Brain Behavior: Extracts criteria and translates them into a structured checklist within a task or document format.

Highlight three innovative tools gaining traction in continuous improvement initiatives from recent research and tech reviews post-2023.

ClickUp Brain Behavior: Identifies patterns and key takeaways from linked research and review documents.

From the ‘Employee Survey Q2’ document, summarize main feedback points regarding recent process adjustments.

ClickUp Brain Behavior: Analyzes survey data to detect common sentiments and suggestions.

Write clear, motivating onboarding text for new hires using the tone guidelines in ‘TrainingVoice.pdf’.

ClickUp Brain Behavior: References tone and style cues to generate varied, user-friendly training content.

Outline key OSHA 2024 safety updates and their implications for lean manufacturing floor layouts.

ClickUp Brain Behavior: Extracts and condenses relevant compliance information from internal safety documents; Brain Max can add public updates if available.

Generate detailed placement and dimension standards for 5S zones, referencing company-specific compliance documents.

ClickUp Brain Behavior: Pulls measurements and organizational rules from linked files to create a practical guideline checklist.

Using US manufacturing defect reports and internal quality data, build a structured checklist for root cause analysis.

ClickUp Brain Behavior: Identifies critical factors from PDFs and internal docs, organizing tasks by defect type and severity.

Summarize sustainability and efficiency metrics from Tesla, Toyota, and Ford using competitive analysis reports.

ClickUp Brain Behavior: Condenses comparative data into clear, digestible formats such as tables or briefs.

What lean manufacturing trends have emerged in autonomous vehicle assembly since 2023?

ClickUp Brain Behavior: Synthesizes insights from internal research, industry reports, and concept summaries.

Summarize key operational challenges from feedback on materials handling, layout, and workflows in Southeast Asia factories.

ClickUp Brain Behavior: Extracts and ranks issues from surveys, feedback notes, and tagged tickets for prioritization.

LLMs vs. Workflow Intelligence: How ClickUp Brain Empowers Lean Teams

ChatGPT Lean Prompts

Gemini Lean Prompts

Perplexity Lean Prompts

ClickUp Brain Lean Prompts

Transform Early Concepts into Actionable Plans

- Convert initial observations into clear, actionable project outlines swiftly.

- Generate innovative solutions by analyzing previous iterations.

- Build adaptable templates that accelerate continuous improvement cycles.

Brain Max Boost: Quickly access historical project data, team feedback, and process documents to fuel your next Lean initiative.

Accelerate Lean Methodology Execution

- Break down intricate process reviews into straightforward, actionable items.

- Transform continuous improvement insights into tasks ready for team assignment.

- Automatically create progress summaries and lean metrics reports without extra effort.

Brain Max Boost: Instantly access historical process data, waste analyses, or value stream maps across your projects.

Harness AI Prompts to Elevate Every Phase of Lean Development

Quickly Craft Impactful Solutions

Teams explore innovative approaches rapidly, make informed choices, and avoid analysis paralysis.