Never lose track of time again.

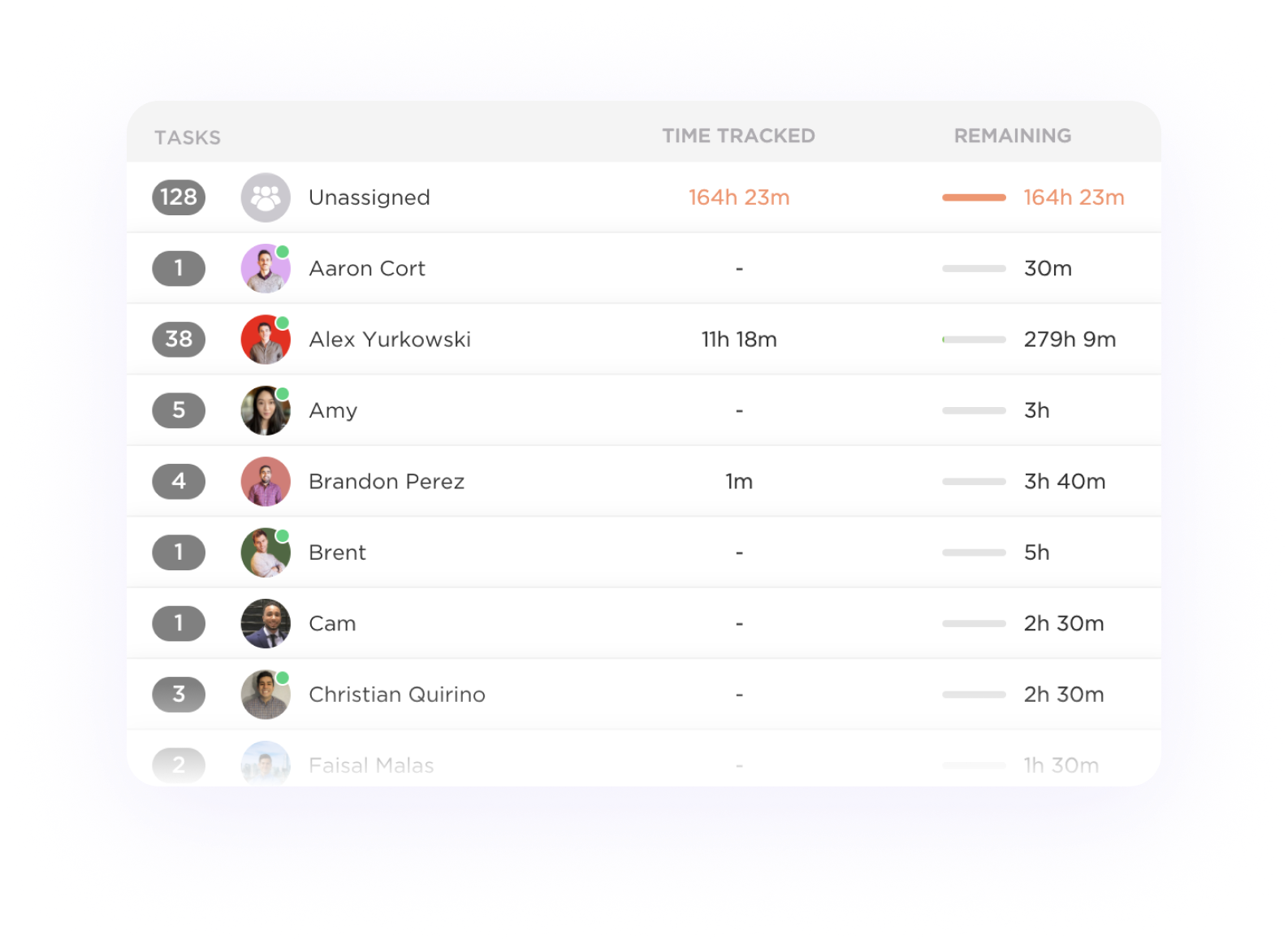

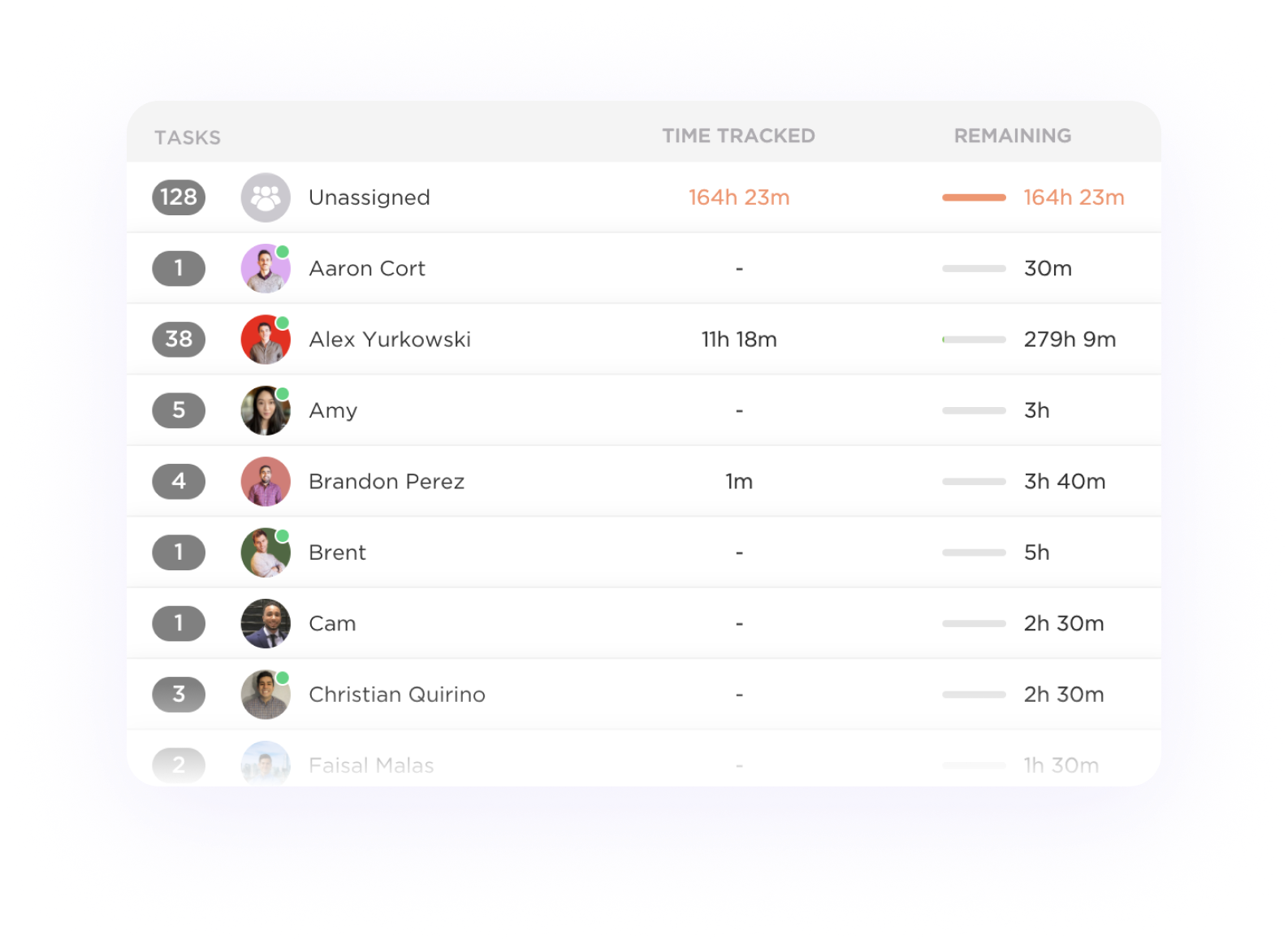

Understand how much time groups of tasks take for each person on your team with cumulate time tracking. Add time tracked outside of ClickUp with integrations for Toggl, Harvest, Everhour, and more.

Boost productivity and efficiency in manufacturing with the ultimate time tracking software integrated seamlessly with ClickUp. Take control of project timelines, monitor progress, and streamline workflows effortlessly. Track time accurately and optimize resource allocation with our powerful tool designed to supercharge your manufacturing processes. Sign up now to revolutionize the way you manage time in your manufacturing projects.

Free forever.

No credit card.

Trusted by the world’s leading businesses

Understand how much time groups of tasks take for each person on your team with cumulate time tracking. Add time tracked outside of ClickUp with integrations for Toggl, Harvest, Everhour, and more.

See your time entries and filter them in any number of ways to build customized reports. Group time entries together, see estimates, and segment billable and non-billable entries.

Time Tracking software allows manufacturers to accurately track the time spent on each production task, from assembly to quality control. This data helps identify bottlenecks, inefficiencies, and areas for improvement in the production process.

By tracking the time spent by each worker on specific tasks or projects, Time Tracking software enables manufacturers to monitor workforce productivity. This data can highlight top performers, identify training needs, and optimize workforce allocation for maximum efficiency.

Time Tracking software can capture the labor hours spent on each product or project, allowing manufacturers to accurately calculate production costs. This information is crucial for pricing strategies, cost control, and profitability analysis.

Time Tracking software provides insights into how long each task or project takes to complete, helping manufacturers create more accurate production schedules. This enables better planning, resource allocation, and meeting delivery deadlines consistently.

Time Tracking software can help monitor adherence to safety protocols and regulations by tracking the time spent on safety training, equipment maintenance, and compliance tasks. This ensures a safer work environment and reduces the risk of accidents or non-compliance issues.

By analyzing time data captured by the software, manufacturers can identify inefficiencies, repetitive tasks, or areas with high downtime. This information is valuable for continuous process improvements, lean manufacturing initiatives, and enhancing overall operational efficiency.

Time tracking software in a manufacturing setting helps improve productivity, project costing accuracy, employee accountability, and resource allocation efficiency.

Time tracking software in manufacturing processes helps improve productivity and efficiency by providing real-time visibility into labor allocation, identifying bottlenecks, optimizing resource utilization, streamlining payroll processes, and enabling data-driven decision-making for process improvements.

Yes, time tracking software can be integrated with other manufacturing software systems to ensure seamless data management and analysis across different processes, enhancing operational efficiency and productivity.