Sync your time into ClickUp.

Connect your favorite time tracking app to ClickUp to sync time tracked directly within ClickUp. Integrate your time tracking with Toggl, Harvest, and many more of today's most popular time tracking apps.

Track every second of your team's productivity effortlessly with the best time tracking software for Food Manufacturers. ClickUp makes it easier than ever to monitor, manage, and optimize your team's time to ensure maximum efficiency and profitability. Start tracking time like a pro today with ClickUp!

Free forever.

No credit card.

Trusted by the world’s leading businesses

Connect your favorite time tracking app to ClickUp to sync time tracked directly within ClickUp. Integrate your time tracking with Toggl, Harvest, and many more of today's most popular time tracking apps.

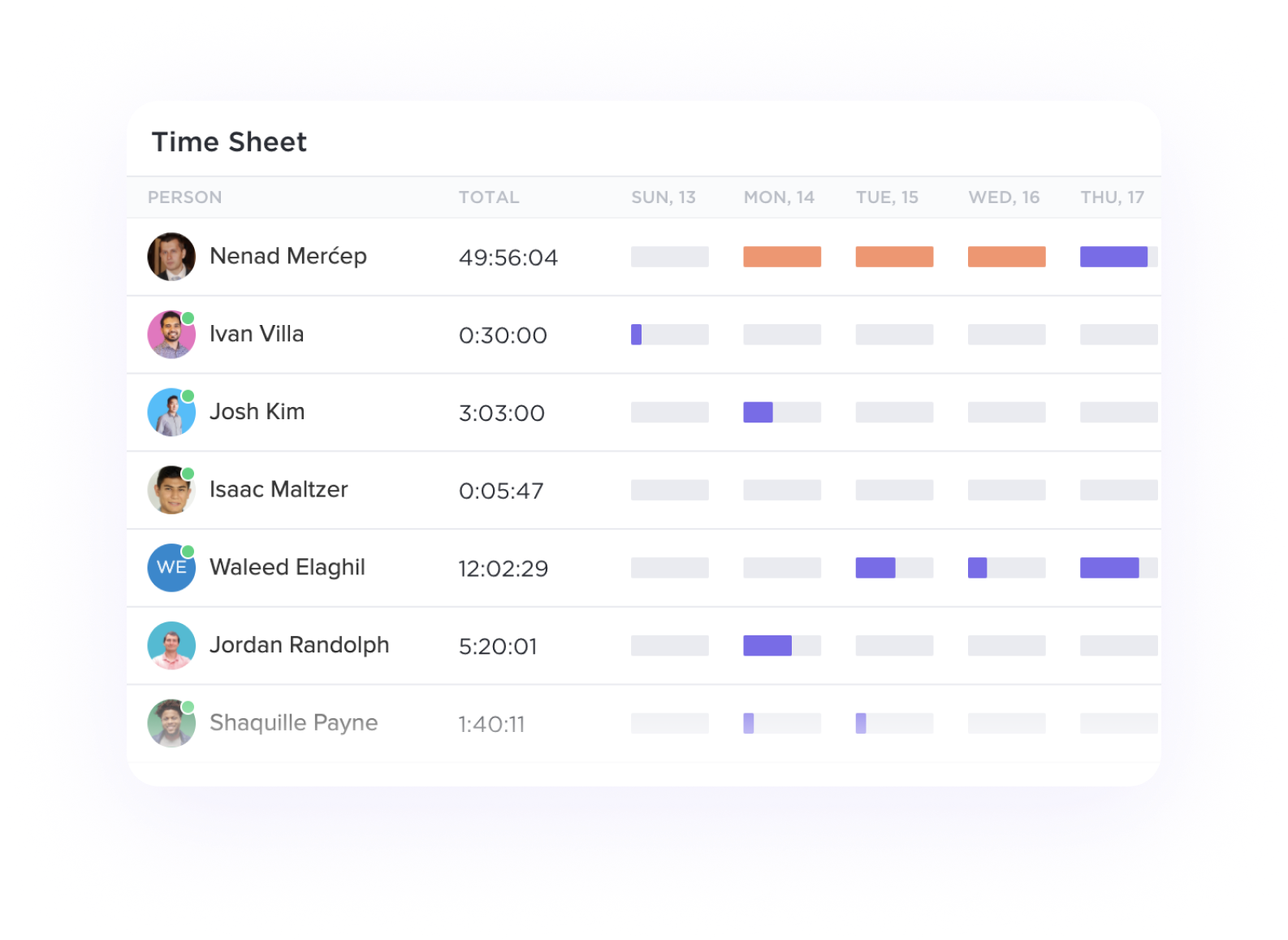

View your time tracked by day, week, month, or any custom range with detailed time sheets. Show time totals grouped by dates and see individual tasks and time entries for a deeper look at where time was spent.

Food manufacturers need to accurately track the time taken at each stage of production to identify bottlenecks, optimize workflows, and improve overall efficiency. Time Tracking software can capture the time spent on various tasks, allowing managers to analyze and streamline production processes.

Food manufacturing is subject to strict regulations regarding production processes, hygiene, and safety standards. Time Tracking software can help in documenting and tracking compliance activities, ensuring that all necessary steps are completed within the required timeframes to meet regulatory requirements.

Food manufacturing often involves shift work to maintain continuous production. Time Tracking software can assist in creating and managing shift schedules, tracking employee work hours, and ensuring adequate coverage during different production phases. This helps in optimizing workforce management and improving productivity.

Equipment breakdowns or maintenance issues can significantly impact production schedules in food manufacturing. Time Tracking software can record downtime incidents, track maintenance activities, and provide insights into equipment utilization rates. This data can help in identifying maintenance needs proactively and minimizing production disruptions.

Understanding the true cost of production is essential for food manufacturers to price products competitively and maintain profitability. Time Tracking software can capture labor hours, machine usage, and other production-related expenses to calculate accurate production costs. This information enables better cost control and pricing strategies.

Accurate tracking of production time can also facilitate better inventory management in food manufacturing. By correlating production time with output volumes, manufacturers can optimize inventory levels, reduce waste, and ensure timely replenishment of raw materials or finished goods.

Time tracking software can help food manufacturers improve production efficiency by accurately tracking employee work hours, identifying bottlenecks in the production process, optimizing resource allocation, and analyzing productivity trends for informed decision-making.

Key features to look for in a time tracking software for food manufacturers include production line tracking, batch and lot traceability, inventory management, compliance with food safety regulations, and integration with scheduling and payroll systems.

Yes, time tracking software can help food manufacturers comply with regulatory requirements by enabling accurate record-keeping of employee work hours, production processes, and sanitation procedures to ensure adherence to industry standards and regulations.