Never lose track of time again.

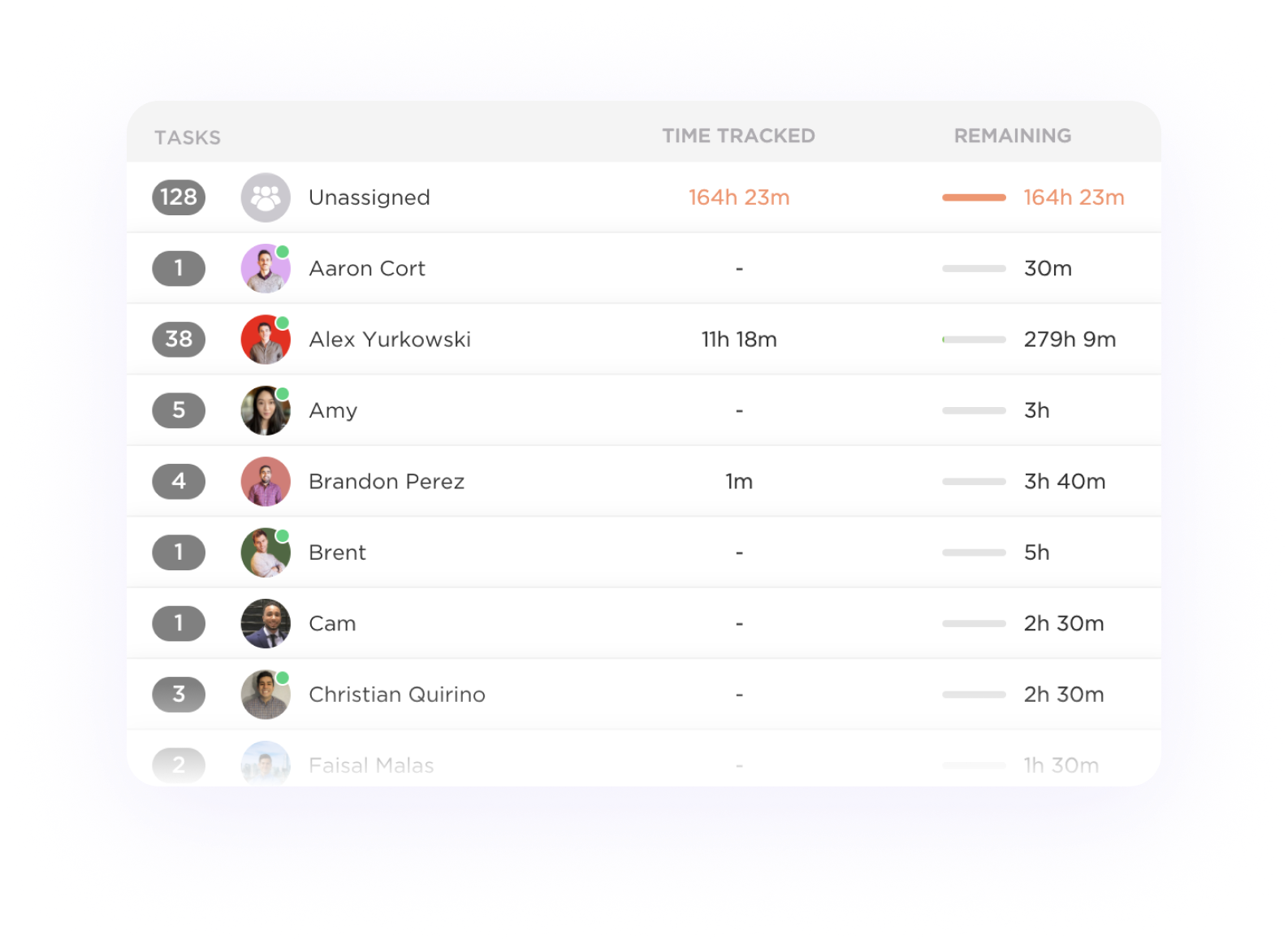

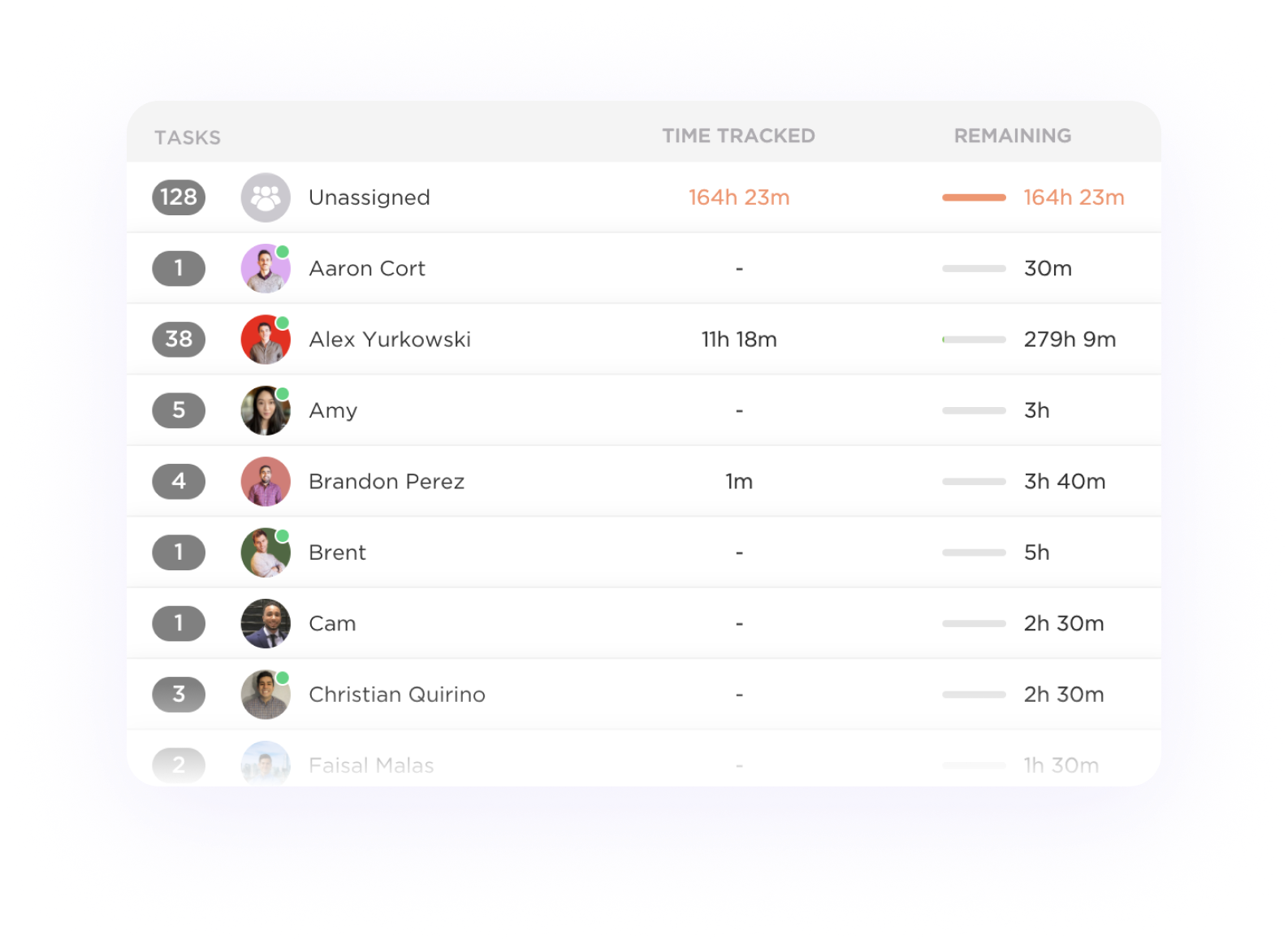

Understand how much time groups of tasks take for each person on your team with cumulate time tracking. Add time tracked outside of ClickUp with integrations for Toggl, Harvest, Everhour, and more.

Boost productivity and streamline operations with the best time tracking software for Chemical Manufacturers, powered by ClickUp. Easily track and manage time spent on projects, analyze employee efficiency, and ensure accurate billing. Take control of your time and resources with ClickUp's innovative time tracking solution.

Free forever.

No credit card.

Trusted by the world’s leading businesses

Understand how much time groups of tasks take for each person on your team with cumulate time tracking. Add time tracked outside of ClickUp with integrations for Toggl, Harvest, Everhour, and more.

See your time entries and filter them in any number of ways to build customized reports. Group time entries together, see estimates, and segment billable and non-billable entries.

Chemical manufacturing involves complex processes that require meticulous tracking of time spent on each task. Time Tracking software can capture and record the time taken for each step in the production process, providing insights into bottlenecks, identifying areas for improvement, and ensuring accurate costing.

Efficient resource allocation is crucial in chemical manufacturing to reduce waste, improve productivity, and meet production targets. Time Tracking software enables managers to monitor resource utilization in real-time, identify underutilized resources, and allocate them effectively to maximize output and minimize costs.

Compliance with stringent regulatory requirements is paramount in the chemical industry. Time Tracking software can help in documenting and timestamping each step of the production process, facilitating compliance audits, ensuring traceability, and demonstrating adherence to regulatory standards.

Chemical manufacturing projects often have strict budgets and timelines. Time Tracking software provides detailed insights into labor costs, project timelines, and resource utilization, allowing for accurate project costing, budget monitoring, and proactive adjustments to ensure projects stay within budget constraints.

Regular maintenance of equipment and facilities is essential in chemical manufacturing to prevent downtime and ensure safety. Time Tracking software can schedule, track, and analyze maintenance activities, including time spent on maintenance tasks, equipment downtime, and maintenance costs, helping in predictive maintenance planning and optimizing maintenance schedules.

Time tracking software can offer chemical manufacturers features such as project tracking for research and development, labor cost tracking for production processes, and resource allocation to optimize operations and ensure accurate cost analysis.

Yes, time tracking software can assist in tracking and managing employee hours and overtime while ensuring compliance with labor regulations specific to the chemical manufacturing industry. It provides accurate records for payroll, monitors work hours to prevent overtime violations, and generates reports to demonstrate adherence to legal requirements.

Time tracking software can enhance project management and productivity in chemical manufacturing plants by providing real-time visibility into tasks, resource allocation, and progress tracking. This enables better scheduling, cost control, and performance evaluation, leading to improved efficiency and timely project completion.