Task Management for Manufacturing Engineers

Purpose-Built Task Management Software for Manufacturing Engineers

Unify your production tasks, oversee project milestones, collaborate effortlessly with your team, and maintain full transparency across every phase of your manufacturing process.

Trusted by the best

The Importance of Task Organization

Why Manufacturing Engineers Depend on Task Management Software

Without a structured system, managing manufacturing projects leads to overlooked steps, dispersed information, and growing disorder — turning routine tasks into major hurdles.

- Production schedules become unclear — making it difficult to monitor completed, ongoing, and pending operations.

- Bill of materials get disorganized — parts lists and specifications scatter across documents and spreadsheets.

- Quality control lapses occur — inconsistent tracking causes defects and repeat inspections.

- Cross-department coordination falters — unclear responsibilities and misaligned timelines slow progress.

- Compliance deadlines are missed — certifications and audits risk delays without automated reminders.

- Progress tracking is opaque — long timelines hide bottlenecks and delays.

- Communication breakdowns happen — fragmented emails and notes prevent team alignment.

- Resource allocation conflicts emerge — equipment and personnel scheduling overlap, causing downtime.

Conventional Methods vs ClickUp

Why Traditional Manufacturing Tools Fall Short

Discover how ClickUp delivers clarity and control beyond standard tools.

Conventional Tools

- Tasks dispersed across spreadsheets, emails, and memory

- Parts lists and specs scattered and duplicated

- Quality checks tracked manually with high error potential

- Team roles and responsibilities unclear

- Compliance deadlines often overlooked

- Documents and communications spread thinly across platforms

ClickUp Task Management

- Centralized tasks with defined statuses and priorities

- Organized BOMs with tags, notes, and attachments

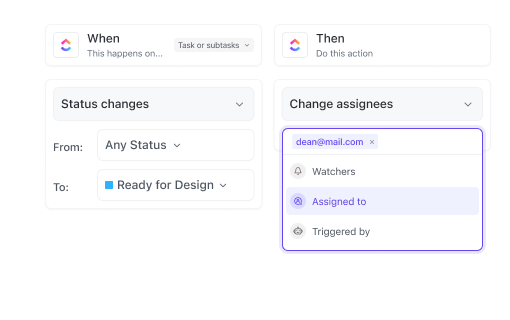

- Automated quality control checklists and templates

- Transparent ownership with live collaboration

- Timely alerts and synced calendars for all deadlines

- Searchable, attached documents for every task

Practical Applications

How Task Management Software Empowers Manufacturing Engineers

See how tracking tasks reduces confusion, minimizes errors, and streamlines production.

#UseCase1

Consolidating Production Data and Documentation

Designs, specs, and process documents stay unified—ClickUp centralizes files with quick search and direct task attachments.

#UseCase2

Maintaining a Clear Audit Trail for Compliance and Quality

Every inspection, adjustment, and approval is logged in ClickUp, ensuring traceability and accountability throughout manufacturing.

#UseCase3

Capturing Real-Time Feedback from Floor Supervisors

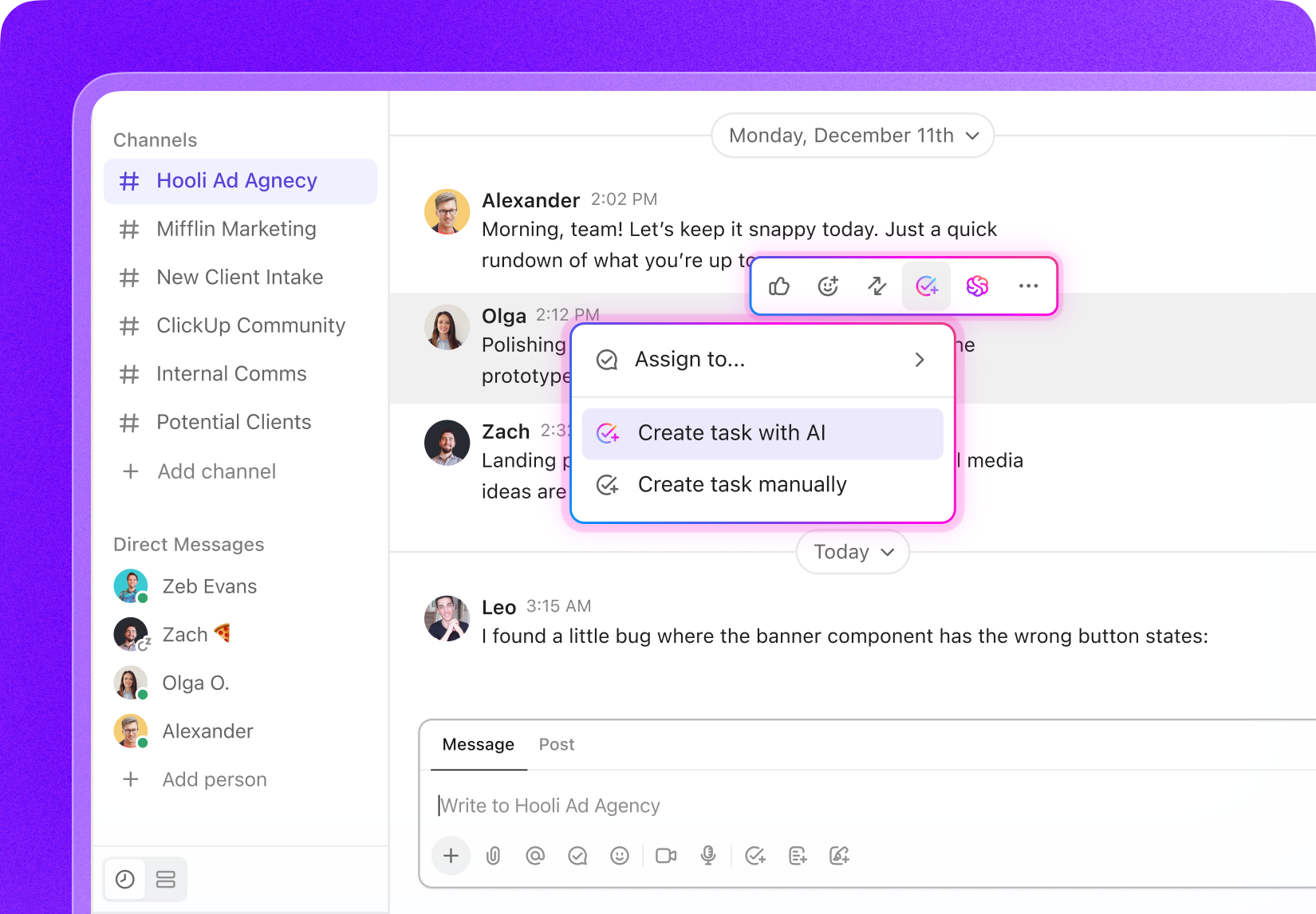

Instant comments, mentions, and update histories keep communication precise and actionable across shifts and teams.

#UseCase4

Preventing Process Deviations in Complex Assemblies

Templates, checklists, and dependencies enforce consistency in assembly steps, reducing defects and rework.

#UseCase5

Tracking Safety Inspections and Regulatory Compliance

Automated reminders and workflow customizations ensure safety protocols and inspections happen on schedule without oversight.

#UseCase6

Mapping Out Detailed Manufacturing Pipelines

Custom statuses and fields visualize each phase of production, helping teams manage dependencies and avoid delays.

#UseCase7

Meeting Product Launch Deadlines without Last-Minute Scrambles

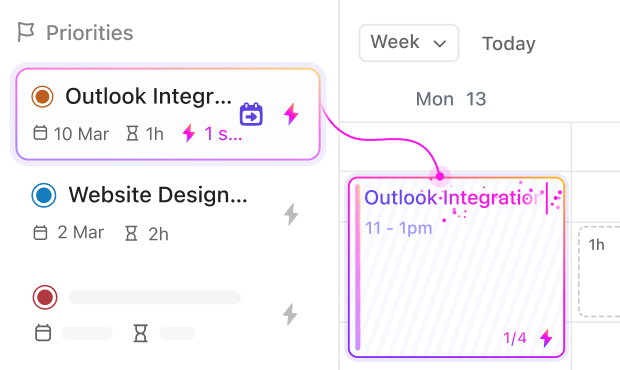

Centralized timelines and task dependencies keep every stakeholder aligned and proactive about delivery dates.

#UseCase8

Reducing Inventory Errors and Duplicate Orders

Track parts usage and orders as tasks with tags and notes to prevent redundancies and stockouts.

#UseCase9

Transforming Shift Meetings into Clear Action Plans

Turn discussions into assigned tasks with checklists and deadlines, ensuring follow-through and accountability.

Key Beneficiaries

Who Benefits Most from ClickUp Task Management

Manufacturing engineers seeking a unified platform to streamline processes and boost productivity.

For Process Engineers

Stay ahead of process optimizations, track experiments, and maintain compliance without juggling multiple tools.

For Quality Assurance Specialists

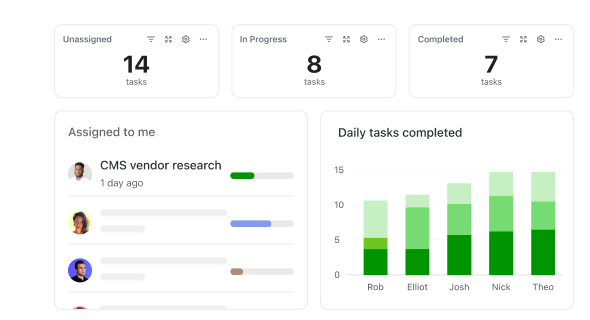

Standardize inspections, monitor defects, and enforce protocols with automated checklists and real-time reporting.

For Production Supervisors

Coordinate teams, manage shift handoffs, and keep production lines running smoothly with clear task assignments.

How ClickUp Supports Manufacturing Engineers

Simplify Your Manufacturing Operations with ClickUp

Integrate task management seamlessly into your production environment.

Centralize Everything

Store literature, datasets, protocols, drafts, and grant docs in one workspace — no more scattered files.

Plan Research in Phases

Break projects into proposal, literature review, experiments, analysis, and writing with task lists and Gantt timelines.

Standardize Experiments & Fieldwork

Use templates and checklists for repeatable, error-free lab or field procedures.

Collaborate Across Teams

Assign tasks to co-authors, lab members, or collaborators. Shared boards and dashboards keep everyone aligned.

Turn Meetings Into Actionable Tasks

Convert supervisor or lab meetings into tasks with owners, checklists, and deadlines.

Stay on Top of Deadlines & Funding

Track grants, conferences, and submissions with automated reminders and calendars.