Task Management for Manufacturing Teams

Manufacturing Task Management Software Designed for Efficiency

Centralize your production tasks, monitor project milestones, collaborate effortlessly with your team, and gain full visibility over every phase of your manufacturing process.

Trusted by the best

Why Manage Manufacturing Tasks

Why Manufacturers Need Robust Task Management Solutions

Handling manufacturing projects without the right system leads to missed deadlines, scattered resources, and operational bottlenecks — turning routine tasks into major challenges.

- Complex production schedules become confusing — tracking what’s completed, pending, or delayed gets difficult.

- Inventory and materials management falters — misplaced orders and duplicated efforts waste time and money.

- Quality control slips through cracks — inconsistent checks lead to defects and rework.

- Team coordination breaks down — unclear responsibilities and miscommunications slow production.

- Compliance deadlines loom unseen — certifications, audits, and safety checks get overlooked.

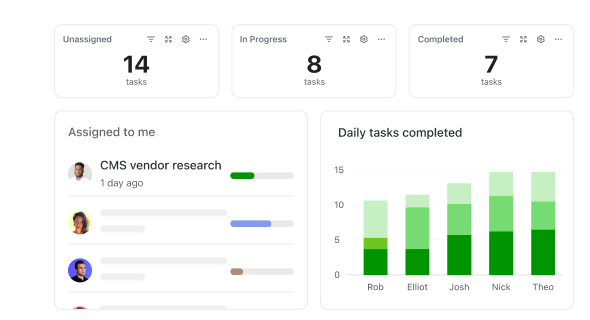

- Progress tracking is unreliable — without clear metrics, project status feels uncertain.

- Communication silos form — emails, calls, and notes scatter vital information.

- Resource conflicts delay output — machinery and labor scheduling overlaps cause downtime.

Conventional Methods vs ClickUp

Why Traditional Manufacturing Tools Fall Short

Discover how ClickUp delivers clarity and control where legacy methods struggle.

Conventional Methods

- Tasks spread over spreadsheets, emails, and verbal instructions

- Inventory data fragmented and outdated

- Manual quality checks prone to errors

- Team roles often unclear, causing delays

- Deadlines and compliance tracked inconsistently

- Files and notes scattered across platforms

ClickUp Task Management

- Unified task lists with real-time statuses and priorities

- Centralized inventory tracking with custom fields

- Standardized quality control templates and checklists

- Clear task ownership with collaborative comments

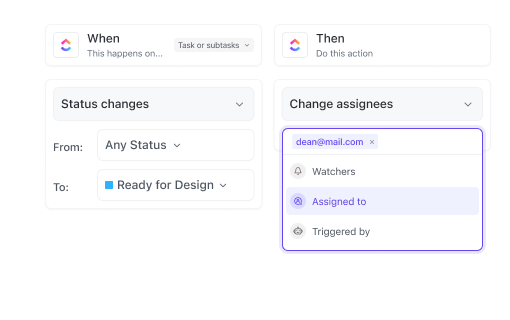

- Automated alerts, synced calendars for deadlines and audits

- Searchable documents linked directly to tasks

Use Cases

Unlocking Manufacturing Excellence with Task Management Software

See how organized task tracking reduces errors, downtime, and miscommunication.

#UseCase1

Eliminating Data Silos Across Production Lines & Teams

Materials lists, work orders, and machine logs stay centralized—ClickUp attaches all files and notes to the relevant tasks for easy access.

#UseCase2

Ensuring Traceability for Quality Assurance and Compliance

Maintain a clear audit trail with timestamps, comments, and document versions so every production step is fully traceable and verified.

#UseCase3

Managing Changing Priorities Without Losing Momentum

Adjust task assignments and timelines flexibly with ClickUp’s real-time updates and notifications to keep production on track.

#UseCase4

Preventing Production Delays Through Automated Workflows

Set dependencies, checklists, and reminders to catch bottlenecks early and maintain consistent output.

#UseCase5

Coordinating Equipment Maintenance and Downtime

Schedule and track maintenance tasks alongside production plans to minimize unexpected equipment outages.

#UseCase6

Streamlining Inventory Replenishment and Order Fulfillment

Track stock levels and automate reorder tasks to avoid shortages and keep the supply chain moving smoothly.

#UseCase7

Meeting Regulatory Deadlines with Confidence

Use custom workflows and reminders to manage certifications, inspections, and compliance deadlines without stress.

#UseCase8

Reducing Manual Errors in Assembly and Packaging

Implement task templates and checklists to standardize processes and ensure accuracy at every step.

#UseCase9

Transforming Team Meetings into Actionable Manufacturing Sprints

Convert meeting discussions into assigned tasks with clear owners, deadlines, and progress tracking.

Key Beneficiaries

Who Benefits Most from ClickUp in Manufacturing

For manufacturing professionals seeking a unified platform to manage complex operations efficiently.

If you’re a Production Manager

ClickUp helps you oversee schedules, coordinate teams, and track output without juggling multiple tools.

If you’re a Quality Assurance Specialist

ClickUp supports standardizing inspections, documenting findings, and ensuring compliance effortlessly.

If you’re a Supply Chain Coordinator

ClickUp streamlines inventory management, order tracking, and supplier communications in one place.

How ClickUp Supports Manufacturing

Optimize Every Phase of Your Production Process

Manage materials, schedules, and teams without switching platforms.

Centralize Everything

Store literature, datasets, protocols, drafts, and grant docs in one workspace — no more scattered files.

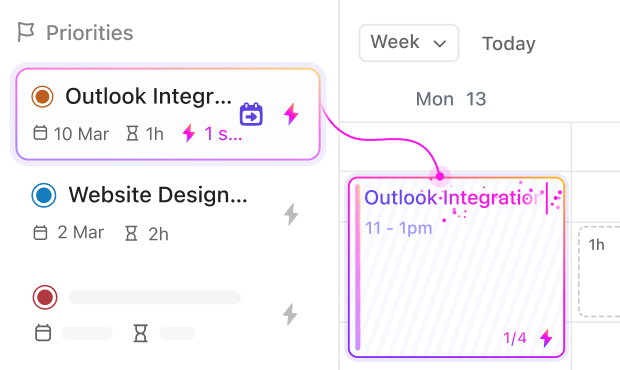

Plan Research in Phases

Break projects into proposal, literature review, experiments, analysis, and writing with task lists and Gantt timelines.

Standardize Experiments & Fieldwork

Use templates and checklists for repeatable, error-free lab or field procedures.

Collaborate Across Teams

Assign tasks to co-authors, lab members, or collaborators. Shared boards and dashboards keep everyone aligned.

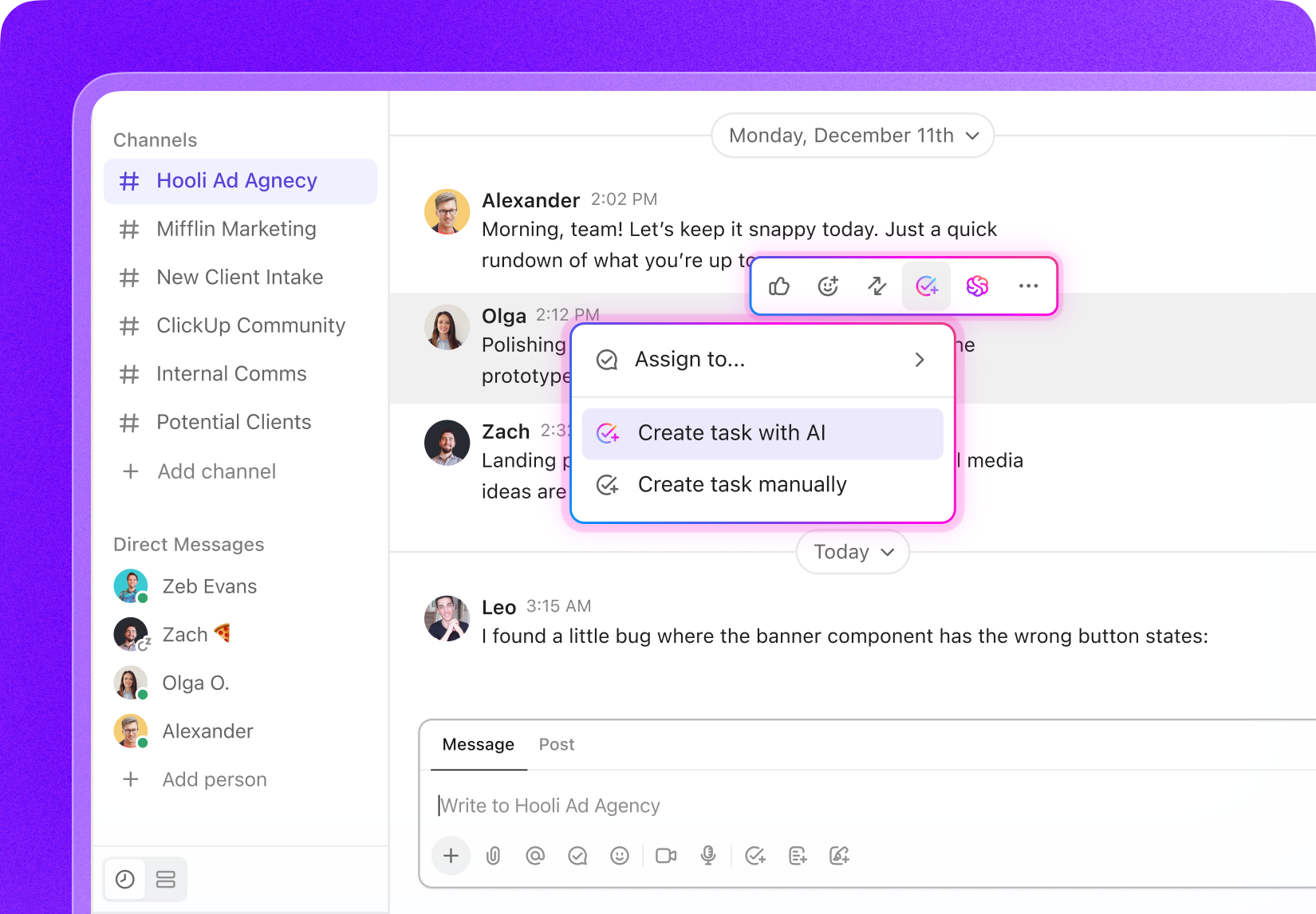

Turn Meetings Into Actionable Tasks

Convert supervisor or lab meetings into tasks with owners, checklists, and deadlines.

Stay on Top of Deadlines & Funding

Track grants, conferences, and submissions with automated reminders and calendars.