Task Management Tailored for Industrial Manufacturing

Task Management Software Designed for Industrial Manufacturers

Unify your production schedules, monitor project milestones, foster seamless team collaboration, and maintain full transparency throughout every manufacturing phase.

Trusted by the world’s leading businesses

The Challenge of Managing Manufacturing Tasks

Why Industrial Manufacturers Need Specialized Task Management

Without a dedicated system, managing manufacturing workflows leads to delays, miscommunication, and operational inefficiencies — making complex projects harder to control.

- Production timelines become blurred — tracking progress across multiple stages is difficult without centralized oversight.

- Inventory and resource tracking falters — scattered data causes shortages or excesses.

- Equipment maintenance schedules get overlooked — risking costly downtime.

- Cross-department coordination suffers — unclear task ownership hampers collaboration.

- Compliance deadlines are missed — regulatory and safety requirements slip through gaps.

- Workflow bottlenecks remain hidden — obstructing continuous improvement efforts.

- Communication gaps increase errors — scattered messaging leads to rework and delays.

- Resource allocation conflicts arise — overlapping demands slow production.

Traditional Methods vs ClickUp

Why Conventional Manufacturing Tools Fall Short

Discover how ClickUp delivers the control and clarity industrial plants need.

Traditional Methods

- Tasks spread across spreadsheets, emails, and paper logs

- Production schedules lack real-time updates

- Manual tracking of equipment maintenance prone to errors

- Team coordination depends on informal communication

- Compliance records scattered and hard to audit

- Resource usage tracked inconsistently across departments

ClickUp Tasks

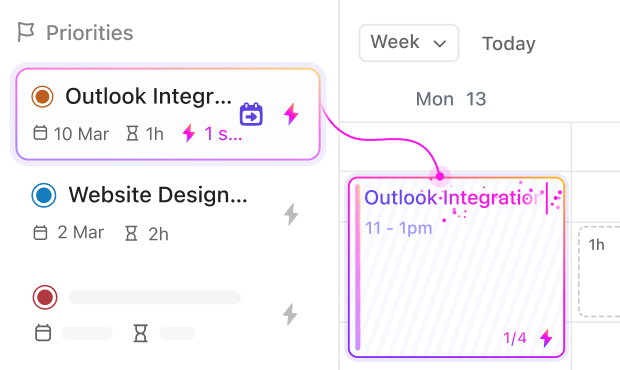

- Centralized task management with clear priorities and statuses

- Dynamic production timelines with real-time visibility

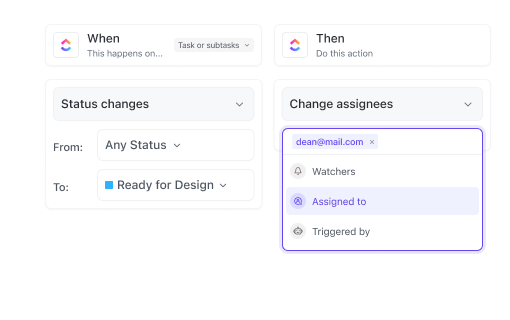

- Automated maintenance reminders and checklists

- Transparent task ownership and collaborative commenting

- Comprehensive audit trails for compliance and safety

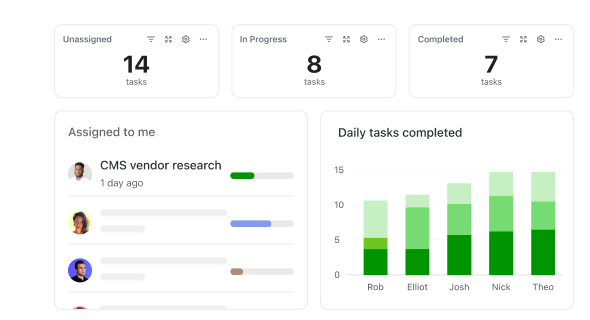

- Unified resource tracking with custom fields and dashboards

Use cases

How Task Management Software Empowers Industrial Manufacturers

See how ClickUp reduces inefficiencies and keeps your production line running smoothly.

Centralizing Production Data Across Teams and Shifts

Eliminate information silos by attaching blueprints, schedules, and quality reports directly to tasks accessible by all stakeholders.

Ensuring Compliance with Industry Regulations and Safety Standards

Maintain detailed logs and automated checklists that guarantee every safety inspection and regulatory step is documented and up to date.

Streamlining Equipment Maintenance and Downtime Tracking

Schedule recurring maintenance with automated alerts to avoid unexpected breakdowns and costly production halts.

Coordinating Cross-Departmental Projects Without Miscommunication

Assign clear responsibilities and track dependencies to keep teams aligned from procurement through assembly to shipping.

Optimizing Inventory and Resource Allocation

Use custom fields and dashboards to monitor material usage and prevent shortages or overstocking.

Accelerating Product Development Cycles

Manage design iterations, testing phases, and launch timelines collaboratively to bring products to market faster.

Tracking Supplier and Vendor Deliverables Efficiently

Centralize communications and deadlines with external partners to ensure timely delivery of components and materials.

Reducing Production Errors Through Standardized Workflows

Leverage templates and checklists to enforce quality standards and minimize human errors on the factory floor.

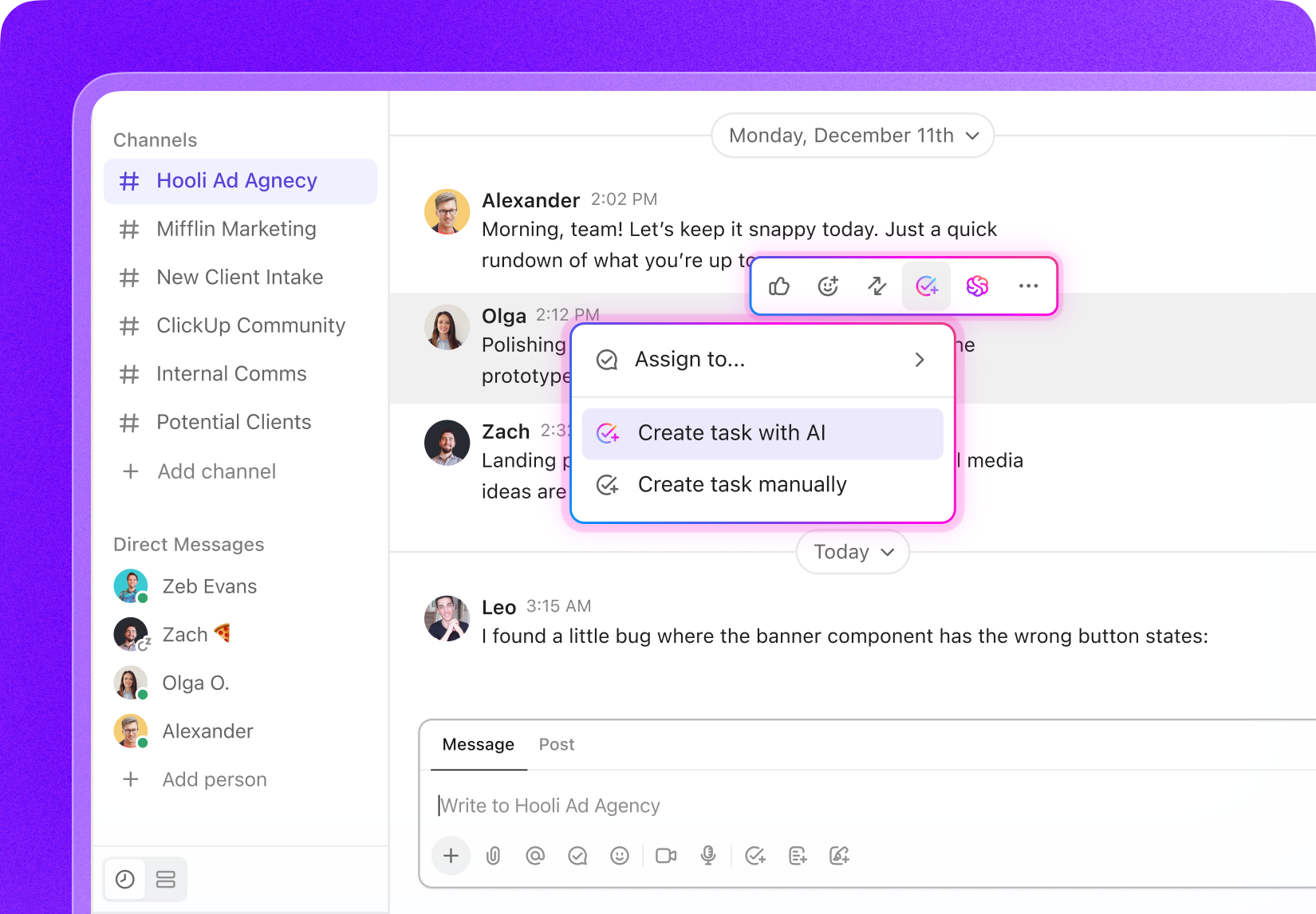

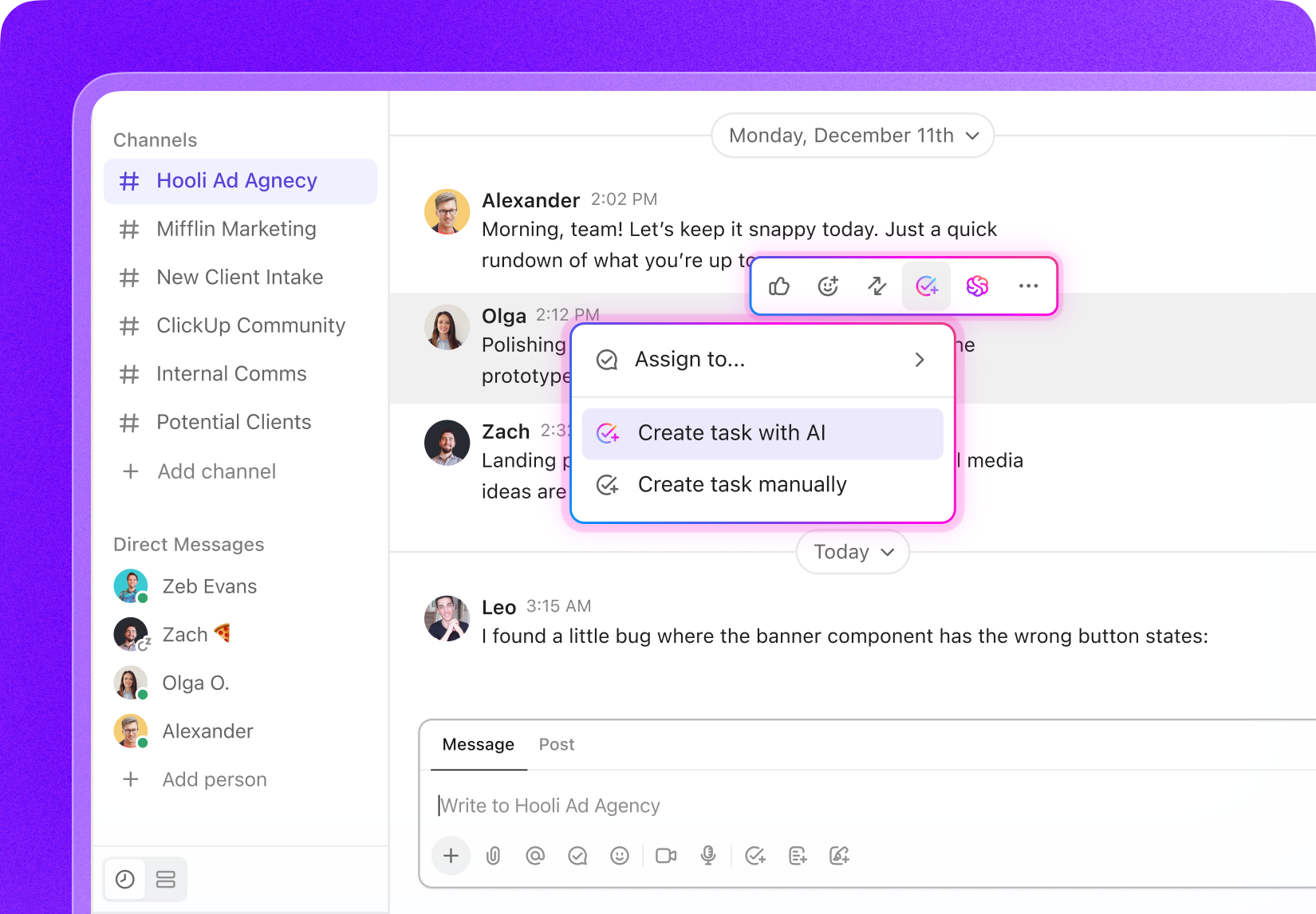

Transforming Daily Standups into Actionable Outcomes

Turn team meetings into assignable tasks with priorities, deadlines, and progress tracking.

Unlock Efficiency at Every Production Stage

From procurement to delivery, keep every process transparent and on schedule.

Key Beneficiaries

Who Benefits Most from ClickUp in Industrial Manufacturing

For manufacturers seeking a unified platform to streamline operations and enhance visibility.

If you’re a Plant Manager

ClickUp helps you oversee production workflows, track equipment status, and coordinate teams without juggling multiple tools.

If you’re a Maintenance Supervisor

ClickUp enables scheduling, tracking, and documenting maintenance tasks to reduce downtime and extend equipment life.

If you’re a Procurement Specialist

ClickUp organizes supplier communications, order tracking, and inventory levels to ensure timely material availability.

How ClickUp Supports Manufacturing Success

How ClickUp Simplifies Complex Industrial Workflows

Manage production, maintenance, and compliance without switching platforms.

Centralize Everything

Store literature, datasets, protocols, drafts, and grant docs in one workspace — no more scattered files.

Plan Research in Phases

Break projects into proposal, literature review, experiments, analysis, and writing with task lists and Gantt timelines.

Standardize Experiments & Fieldwork

Use templates and checklists for repeatable, error-free lab or field procedures.

Collaborate Across Teams

Assign tasks to co-authors, lab members, or collaborators. Shared boards and dashboards keep everyone aligned.

Turn Meetings Into Actionable Tasks

Convert supervisor or lab meetings into tasks with owners, checklists, and deadlines.

Stay on Top of Deadlines & Funding

Track grants, conferences, and submissions with automated reminders and calendars.

Ready to Organize Your Entire Manufacturing Workflow?

Eliminate bottlenecks, ensure compliance, and focus on delivering quality products.