Track your progress at every step.

Easily update projects with a simple drag-and-drop action to collaborate amongst your team in real-time. Dynamic progress percentages provide a detailed snapshot.

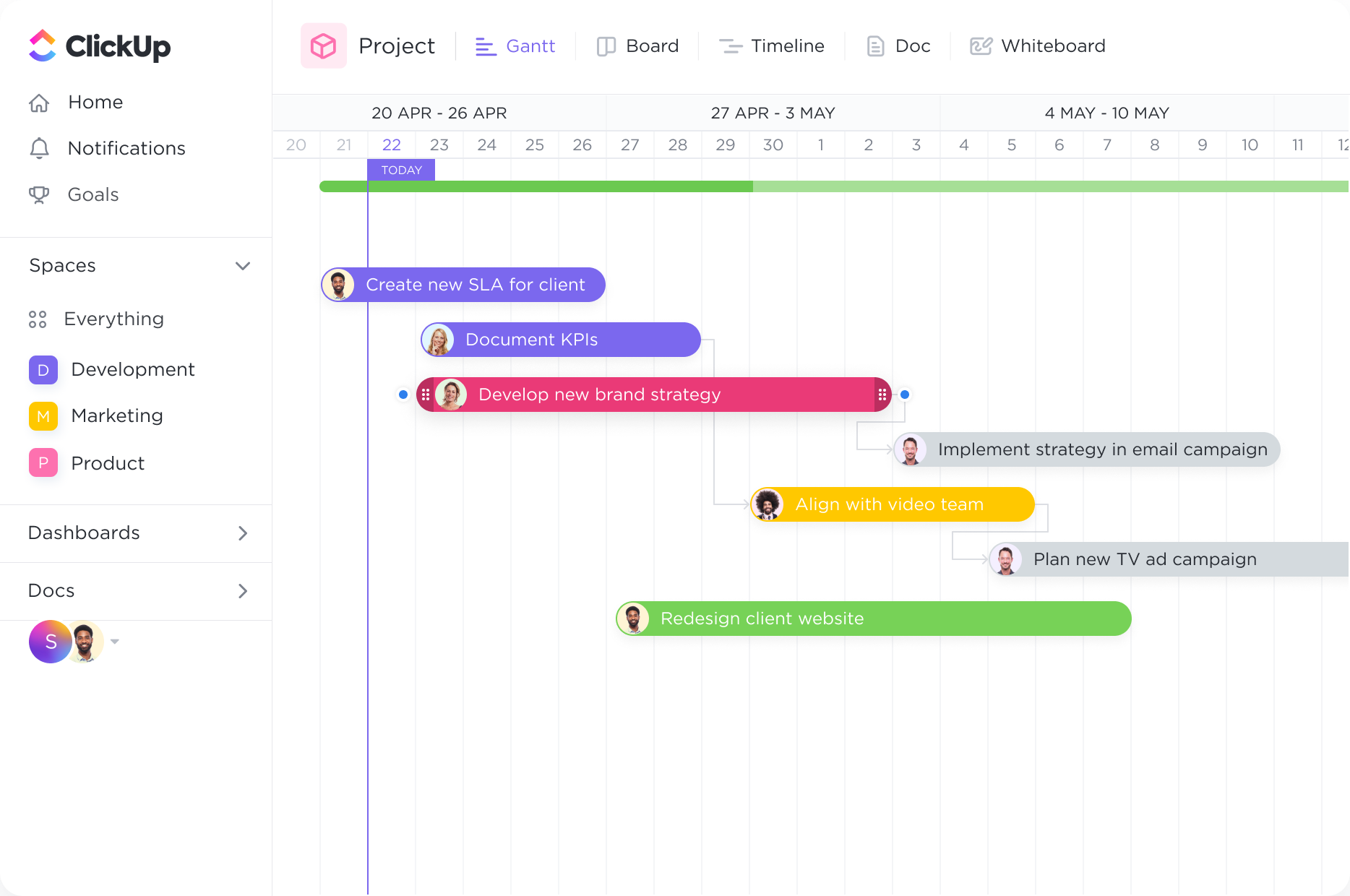

Streamline your project planning and execution with ClickUp's powerful Gantt Chart software. Tailored specifically for Manufacturing Engineers, our intuitive platform allows you to visualize and manage tasks, deadlines, and dependencies with ease. Stay organized, boost productivity, and drive results as you effortlessly plan and track every step of your manufacturing projects. Take control of your projects and experience the power of ClickUp's Gantt Chart software today.

Free forever.

No credit card.

Trusted by the world’s leading businesses

Easily update projects with a simple drag-and-drop action to collaborate amongst your team in real-time. Dynamic progress percentages provide a detailed snapshot.

Organize how you see your tasks with quick sorting. Create cascading views with a single click to easily see what important tasks are coming next.

Manufacturing engineers can utilize Gantt charts to plan and schedule production activities. This includes outlining the sequence of tasks, setting realistic timelines, and identifying dependencies between different stages of the manufacturing process. By visualizing the production plan, engineers can optimize resource allocation, streamline workflows, and ensure efficient utilization of equipment and personnel.

Efficient management of resources is crucial in manufacturing. Gantt charts enable manufacturing engineers to allocate resources effectively by providing a clear overview of resource availability and utilization. This includes personnel, machinery, raw materials, and other assets. By identifying potential bottlenecks or resource conflicts, engineers can make informed decisions to optimize resource allocation and minimize downtime.

Gantt charts can be used to schedule and track quality control and inspection activities throughout the manufacturing process. Engineers can allocate time for inspections at various stages, ensuring that products meet quality standards before proceeding to the next phase. By integrating quality control tasks into the Gantt chart, engineers can maintain a systematic approach to monitoring and improving product quality.

Manufacturing facilities require regular maintenance and occasional equipment upgrades. Gantt charts can help manufacturing engineers plan and schedule these activities to minimize disruptions to production. By incorporating maintenance tasks and equipment upgrades into the chart, engineers can ensure that necessary maintenance is performed on time, preventing unexpected breakdowns and optimizing equipment performance.

Gantt charts can aid manufacturing engineers in managing the complex supply chain involved in manufacturing processes. By visualizing the flow of materials, components, and finished products, engineers can identify potential delays or bottlenecks in the supply chain and take proactive measures to mitigate them. This includes coordinating with suppliers, scheduling deliveries, and ensuring smooth logistics operations.

Manufacturing engineers can use Gantt charts to track and monitor continuous improvement initiatives and process optimization projects. By breaking down improvement tasks into manageable phases and setting timelines, engineers can systematically implement changes and measure their impact on production efficiency. Gantt charts provide a visual representation of improvement efforts, enabling engineers to identify areas for further optimization and drive continuous improvement in manufacturing processes.

You can use Gantt chart software to visually plan and schedule production activities, track progress, and identify bottlenecks or delays in the manufacturing process. It enables you to allocate resources efficiently, adjust task durations and dependencies, and optimize production timelines in real-time. This helps streamline workflow, improve productivity, and ensure timely delivery of products.

Yes, many Gantt chart software programs offer integrations with popular project management tools used by manufacturing engineers, such as Jira, Trello, and Asana. This allows for seamless data transfer and synchronization between the Gantt chart software and other project management tools, enhancing collaboration, efficiency, and visibility across the entire project lifecycle.

Yes, Gantt chart software can help you identify bottlenecks in your manufacturing processes by visually representing the workflow and timelines. It allows for the adjustment of task durations, dependencies, and resources in real-time, enabling teams to quickly identify and address bottlenecks. Furthermore, it facilitates resource allocation optimization by providing a clear overview of resource utilization and availability, ensuring efficient allocation and streamlined workflow adjustments.