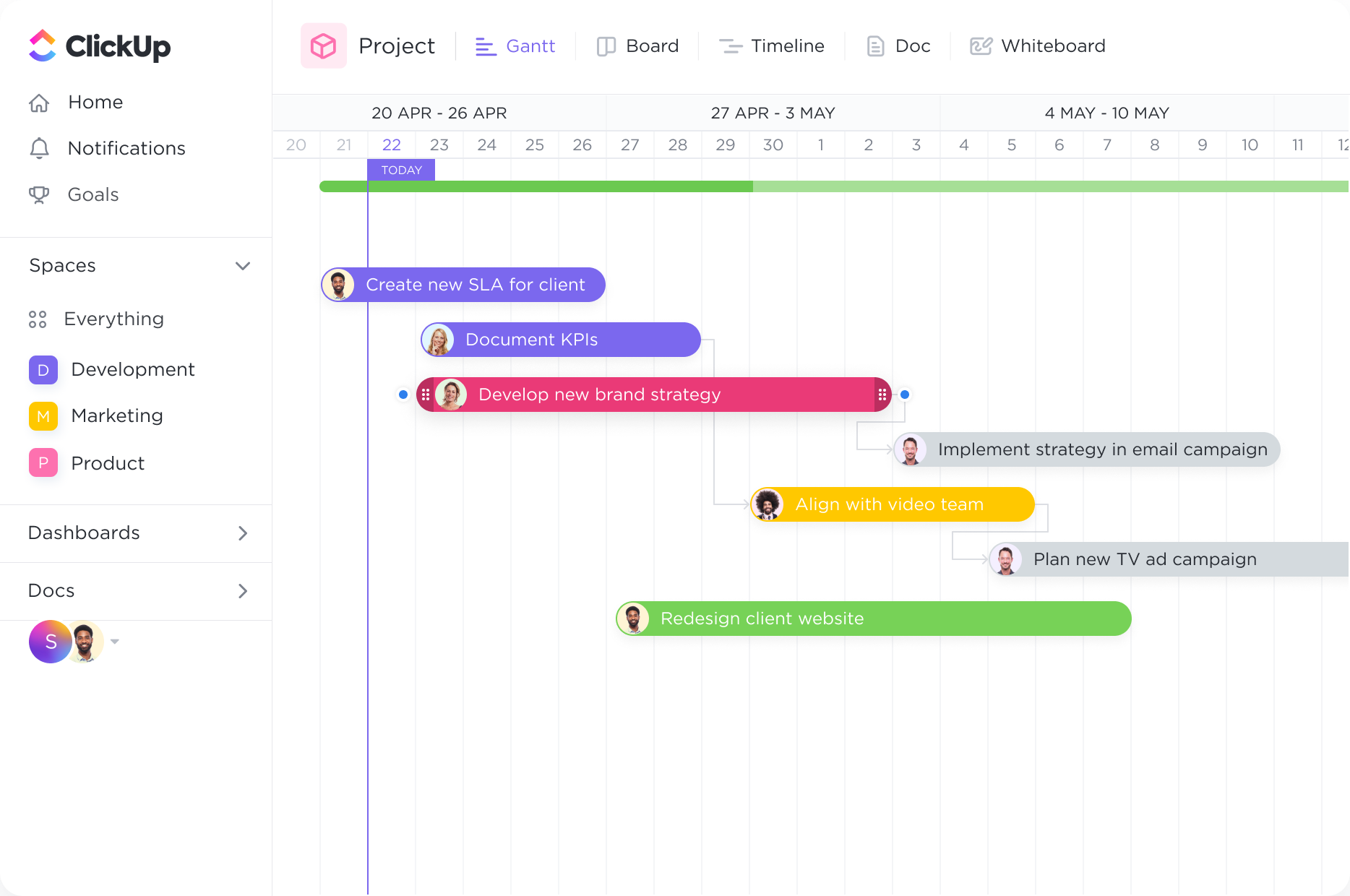

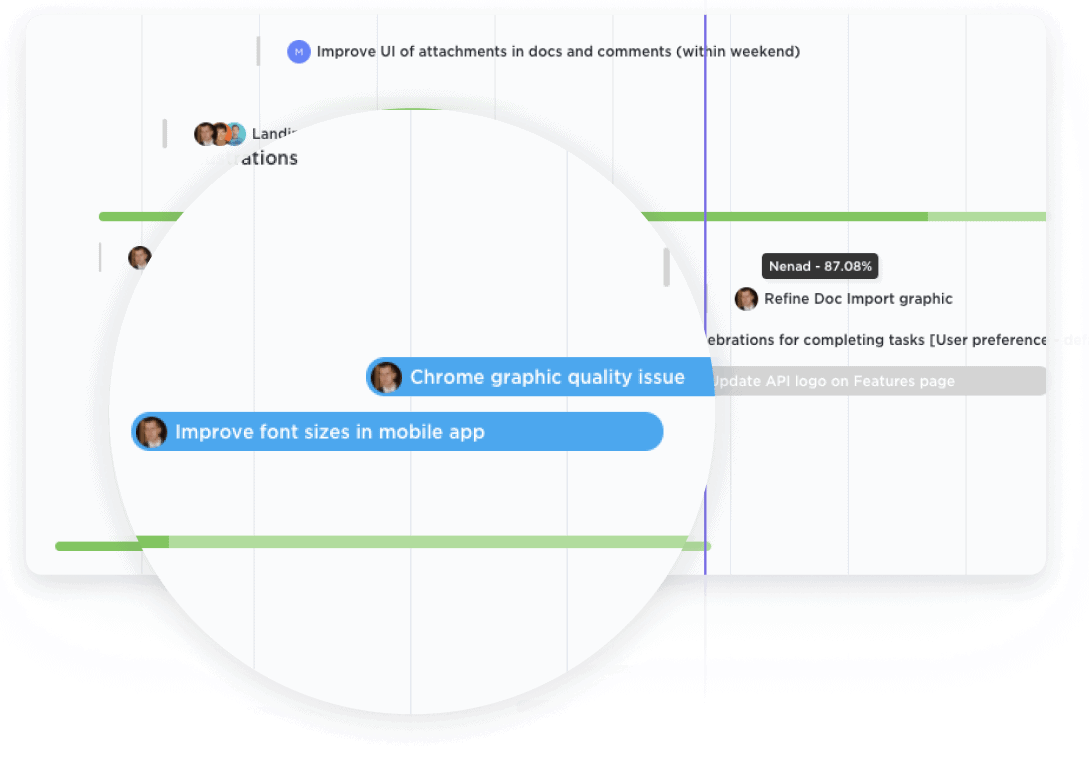

Set task dependencies.

Create tasks and link them with dependencies. Dragging a task with dependencies will automatically reschedule tasks in the chain

Streamline your project management process with ClickUp's powerful Gantt Chart software. Seamlessly plan, organize, and track your industrial manufacturing projects with precision and efficiency. With ClickUp's intuitive interface, you can easily create customized Gantt Charts that align with the unique needs of your industry. Stay on top of deadlines, allocate resources effectively, and ensure smooth project execution, all in one centralized platform. Take control of your project management today and optimize your industrial manufacturing processes with ClickUp's robust Gantt Chart software.

Free forever.

No credit card.

Trusted by the world’s leading businesses

Create tasks and link them with dependencies. Dragging a task with dependencies will automatically reschedule tasks in the chain

Get a bird's-eye view of all Spaces, Projects, Lists, and tasks in one Gantt chart. With clear coloring options, you can easily see what work is happening and where.

Gantt charts are invaluable tools for industrial manufacturers when it comes to planning and scheduling production activities. By visualizing the entire production process, from raw material acquisition to final product delivery, manufacturers can effectively allocate resources, set realistic timelines, and coordinate various tasks and dependencies. This enables them to optimize production efficiency, meet customer demand, and ensure timely delivery of products.

Industrial manufacturers often deal with limited resources and need to allocate them effectively to maximize productivity. Gantt charts provide a clear overview of resource availability and utilization, allowing manufacturers to allocate personnel, equipment, and materials efficiently. By identifying resource bottlenecks and optimizing capacity planning, manufacturers can minimize downtime, reduce costs, and improve overall operational efficiency.

Proper maintenance of equipment is crucial for industrial manufacturers to ensure smooth operations and prevent costly breakdowns. Gantt charts can be used to schedule and track routine maintenance tasks, equipment inspections, and repairs. By visualizing these activities, manufacturers can proactively plan maintenance activities, minimize downtime, and extend the lifespan of their equipment.

Efficient supply chain management is essential for industrial manufacturers to maintain a steady flow of materials and components. Gantt charts can be utilized to track and manage various supply chain activities, such as procurement, inventory management, and logistics. By visualizing the entire supply chain process, manufacturers can identify potential bottlenecks, optimize inventory levels, and ensure timely delivery of materials, reducing production delays and improving customer satisfaction.

Industrial manufacturers often undertake projects for new product development or process improvement. Gantt charts provide a comprehensive view of project timelines, tasks, and dependencies, enabling manufacturers to effectively plan and manage these projects. By breaking down projects into manageable phases, assigning tasks to team members, and tracking progress, manufacturers can ensure that projects are completed on time, within budget, and meet quality standards. Gantt charts also facilitate effective communication and collaboration among team members, improving overall project efficiency.

Gantt chart software can help industrial manufacturers streamline their production processes by providing a visual representation of the production schedule, highlighting dependencies and bottlenecks. It allows for the optimization of resource allocation, efficient coordination of tasks, and real-time tracking of project progress. This enables better planning, scheduling, and decision-making, leading to increased productivity and reduced time-to-market.

Key features to look for in Gantt chart software for industrial manufacturers include the ability to handle complex project dependencies, resource allocation and scheduling, real-time updates and collaboration, integration with other manufacturing software systems, and customizable reporting and analytics capabilities.

Yes, Gantt chart software can be integrated with other project management tools commonly used in the manufacturing industry. This integration allows for seamless data exchange and synchronization, enhancing collaboration and streamlining project planning and execution.