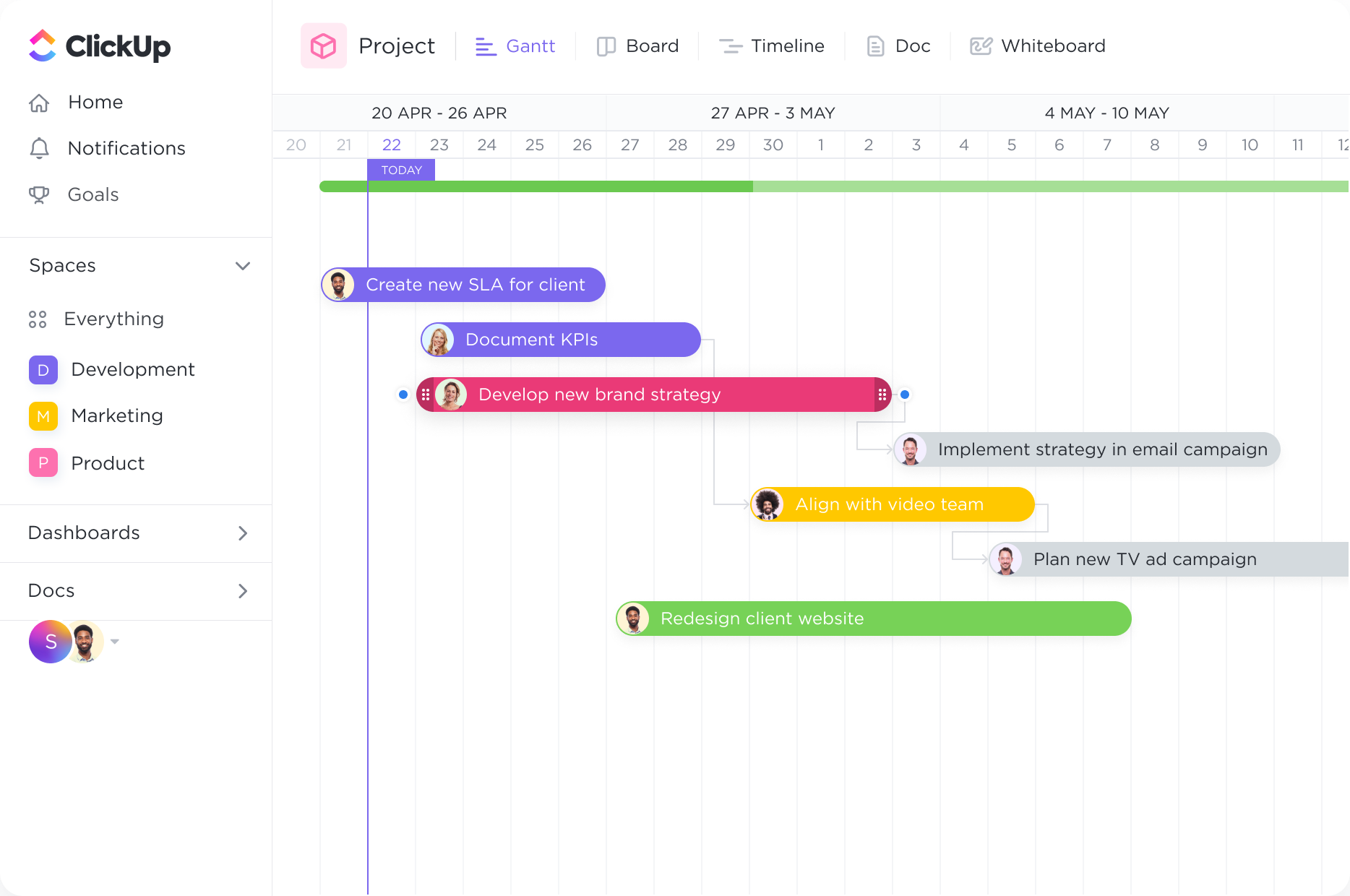

Set task dependencies.

Create tasks and link them with dependencies. Dragging a task with dependencies will automatically reschedule tasks in the chain

Streamline your food manufacturing process with ClickUp's powerful Gantt Chart software. Plan, schedule, and track all your tasks and projects with ease, ensuring that every step of your production line is executed seamlessly. From ingredient sourcing to packaging and distribution, ClickUp's Gantt Chart software empowers food manufacturers to optimize their operations and meet their targets efficiently. Don't let a single deadline go unnoticed - supercharge your productivity and stay ahead of the competition with ClickUp's Gantt Chart software.

Free forever.

No credit card.

Trusted by the world’s leading businesses

Create tasks and link them with dependencies. Dragging a task with dependencies will automatically reschedule tasks in the chain

Organize how you see your tasks with quick sorting. Create cascading views with a single click to easily see what important tasks are coming next.

Food manufacturers often have complex production processes that require careful planning and scheduling. Gantt charts can be used to create a visual representation of the production timeline, including tasks such as ingredient preparation, cooking, packaging, and quality control. This allows manufacturers to optimize their production schedule, ensure efficient use of resources, and meet customer demand while maintaining product quality.

Managing inventory is crucial for food manufacturers to ensure that they have enough raw materials and finished products on hand. Gantt charts can be used to track inventory levels, forecast demand, and plan production accordingly. By visualizing inventory levels alongside production schedules, manufacturers can avoid stockouts, reduce waste, and optimize their supply chain.

Food manufacturers must adhere to strict quality assurance and compliance standards to ensure the safety and quality of their products. Gantt charts can be used to plan and schedule quality control activities, such as inspections, testing, and audits, at various stages of the production process. This helps manufacturers proactively address quality issues, maintain compliance with regulations, and deliver high-quality products to consumers.

Launching new food products involves multiple stages, from research and development to production and marketing. Gantt charts can be used to plan and monitor each stage of the product development process, including concept development, recipe formulation, prototype testing, and commercialization. This allows manufacturers to track progress, allocate resources effectively, and ensure timely product launches.

Food manufacturers rely on a complex network of suppliers, distributors, and logistics partners to source raw materials and deliver finished products. Gantt charts can be used to visualize the entire supply chain, including procurement, transportation, warehousing, and distribution. This helps manufacturers optimize their supply chain operations, identify potential bottlenecks, and ensure on-time delivery to customers.

Gantt Chart software can help food manufacturers by visually representing the production schedule, including tasks, timelines, and dependencies. This allows for better coordination and allocation of resources, ensuring that production runs smoothly and efficiently. It also enables the tracking of progress and identification of potential bottlenecks, allowing for timely adjustments and improved decision-making.

Some key features to look for in Gantt Chart software for food manufacturers include the ability to manage production schedules, track raw material inventory, monitor quality control processes, and integrate with other systems such as ERP or MES. Additionally, features such as batch tracking, traceability, and allergen management can be beneficial for ensuring compliance and efficiency in food manufacturing operations.

Yes, Gantt chart software can help optimize inventory management for food manufacturers by providing a visual representation of production schedules and inventory levels. This allows for better coordination between production and inventory teams, ensuring timely replenishment and reducing stockouts or overstocking. Additionally, Gantt charts enable the identification of potential bottlenecks or delays in the production process, allowing for proactive inventory management and improved efficiency.