Stay ahead of every deadline.

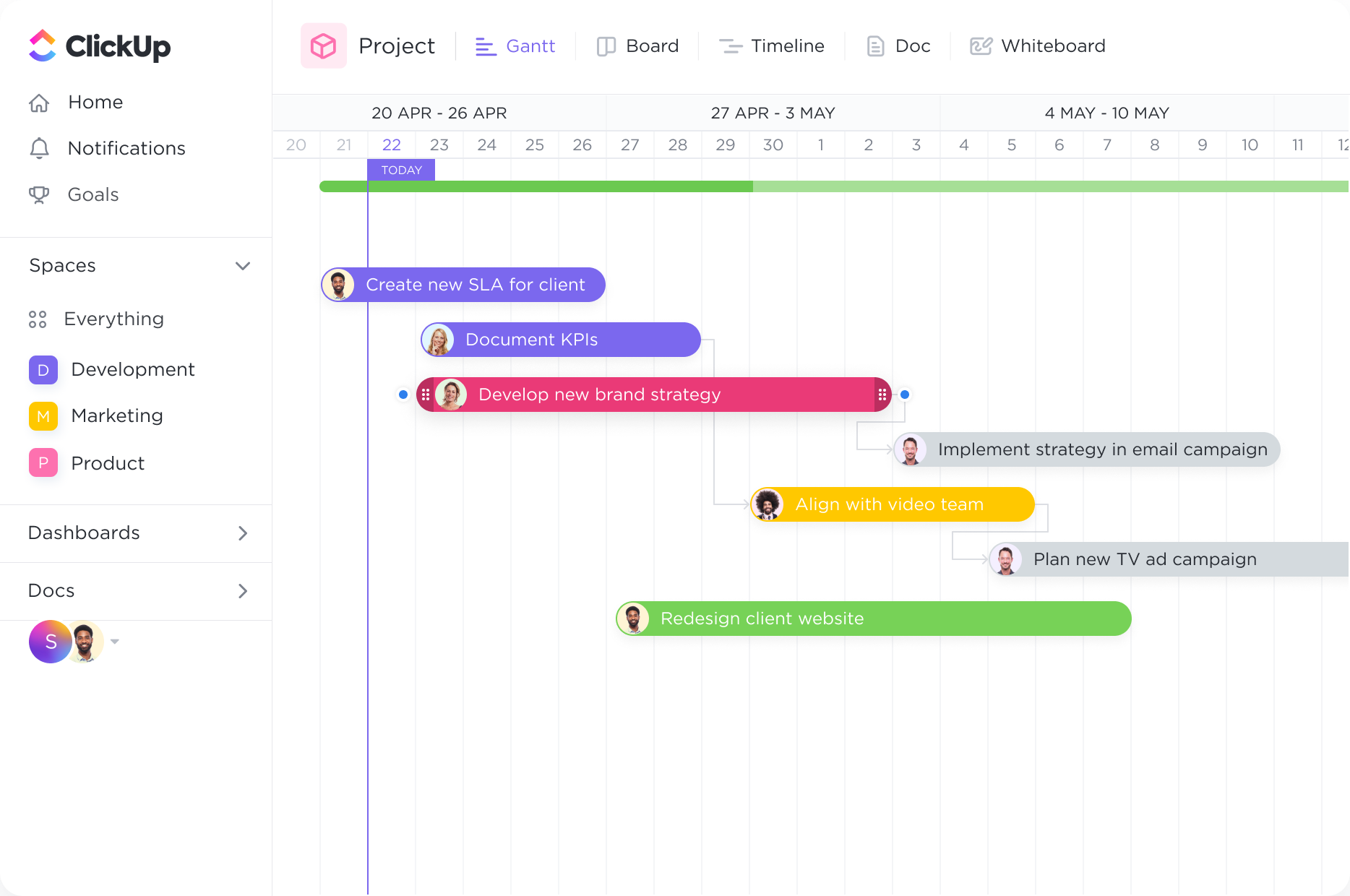

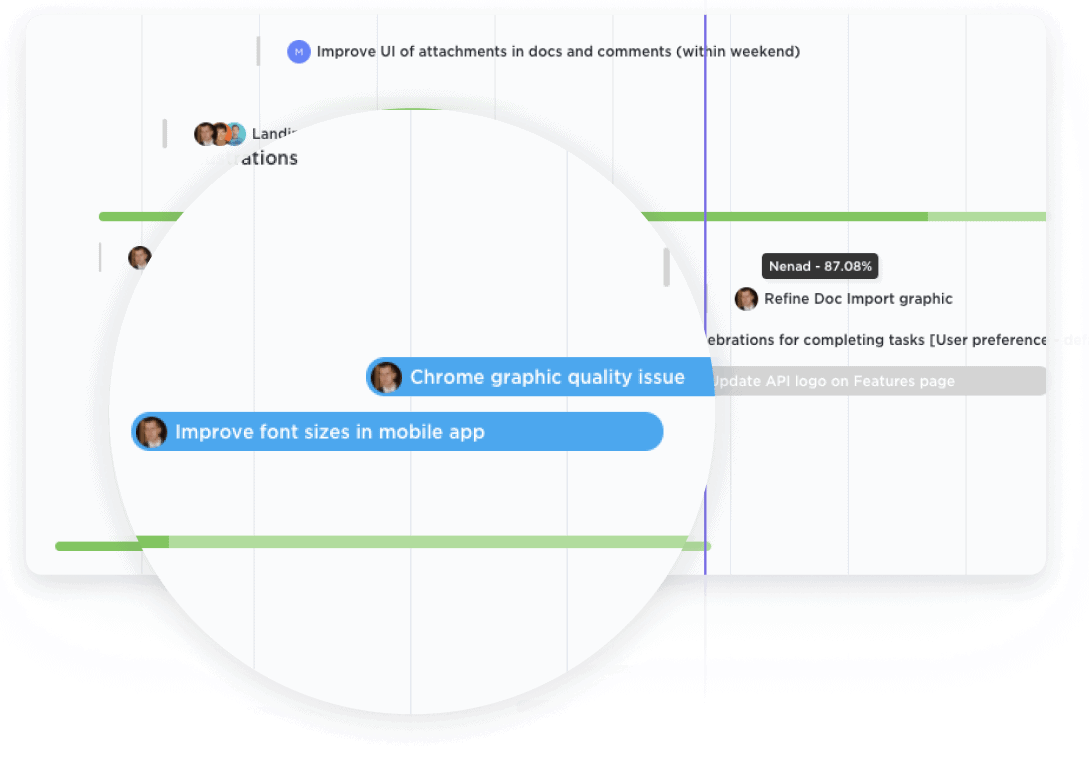

With the Gantt chart's dynamic timeline, you can easily schedule tasks, keep up with project progress, manage deadlines, and handle bottlenecks.

Streamline your project management process and optimize the efficiency of your equipment operators with ClickUp's powerful Gantt Chart software. Visualize tasks, deadlines, and dependencies with ease, empowering your team to stay on track and deliver projects on time. With ClickUp's user-friendly interface and robust features, you can customize Gantt Charts specific to your equipment operators' needs, ensuring seamless coordination and improved productivity. Say goodbye to complex project planning and hello to simplified scheduling with ClickUp's Gantt Chart software.

Free forever.

No credit card.

Trusted by the world’s leading businesses

With the Gantt chart's dynamic timeline, you can easily schedule tasks, keep up with project progress, manage deadlines, and handle bottlenecks.

Get a bird's-eye view of all Spaces, Projects, Lists, and tasks in one Gantt chart. With clear coloring options, you can easily see what work is happening and where.

Gantt charts can be utilized by equipment operators to plan and schedule maintenance and repair tasks for their machinery. By visualizing the timeline and duration of each task, operators can effectively allocate resources and ensure that equipment downtime is minimized. This helps to optimize productivity and prevent unexpected breakdowns, ultimately reducing costs associated with equipment repairs.

Equipment operators often work on large-scale projects that involve multiple tasks and timelines. Gantt charts provide a comprehensive overview of the project, allowing operators to plan and execute tasks in a sequential and efficient manner. By breaking down the project into smaller, manageable phases, operators can track progress, identify dependencies, and ensure that each task is completed on time.

Managing equipment and personnel resources is crucial for equipment operators. Gantt charts enable operators to allocate resources effectively by visualizing the availability and utilization of equipment and personnel. This helps operators avoid overbooking or underutilizing resources, leading to improved efficiency and optimized resource allocation.

Preventive maintenance is essential for equipment longevity and operational efficiency. Gantt charts can assist equipment operators in scheduling and tracking preventive maintenance tasks. By setting up recurring maintenance activities on the chart, operators can ensure that regular inspections, servicing, and replacements are conducted at the appropriate intervals. This proactive approach helps to prevent equipment failures and prolong the lifespan of machinery.

For equipment operators involved in large-scale projects or operations across multiple locations, Gantt charts can be used to plan and manage equipment deployment and logistics. By visualizing the timeline and location of each equipment deployment, operators can coordinate transportation, installation, and setup efficiently. This ensures that equipment is available when and where it is needed, minimizing downtime and optimizing project timelines.

In the fast-paced environment of equipment operation, prioritizing tasks and managing deadlines is crucial. Gantt charts provide a clear visual representation of tasks and their corresponding deadlines, allowing operators to prioritize their work effectively. By having a centralized view of all tasks, operators can identify critical tasks, allocate resources accordingly, and ensure that deadlines are met, enhancing overall productivity and project success.

Gantt chart software can help equipment operators manage their projects more efficiently by providing a visual representation of project timelines and task dependencies. This allows operators to track equipment usage, schedule maintenance, and allocate resources effectively. It also helps identify potential bottlenecks or delays, enabling operators to make timely adjustments and ensure smooth project execution.

Yes, Gantt chart software can track equipment usage and availability by incorporating resource management features. This enables you to assign equipment to specific tasks, monitor its usage, and track availability in real-time. By integrating equipment data into the Gantt chart, you can optimize resource allocation, identify potential conflicts, and ensure that equipment is efficiently utilized throughout the project.

Yes, Gantt chart software can integrate with other tools used by equipment operators, such as maintenance management systems or telematics platforms. This integration allows for seamless data exchange and synchronization, enabling equipment operators to track maintenance schedules, monitor equipment performance, and optimize resource allocation within the Gantt chart software.