Stay ahead of every deadline.

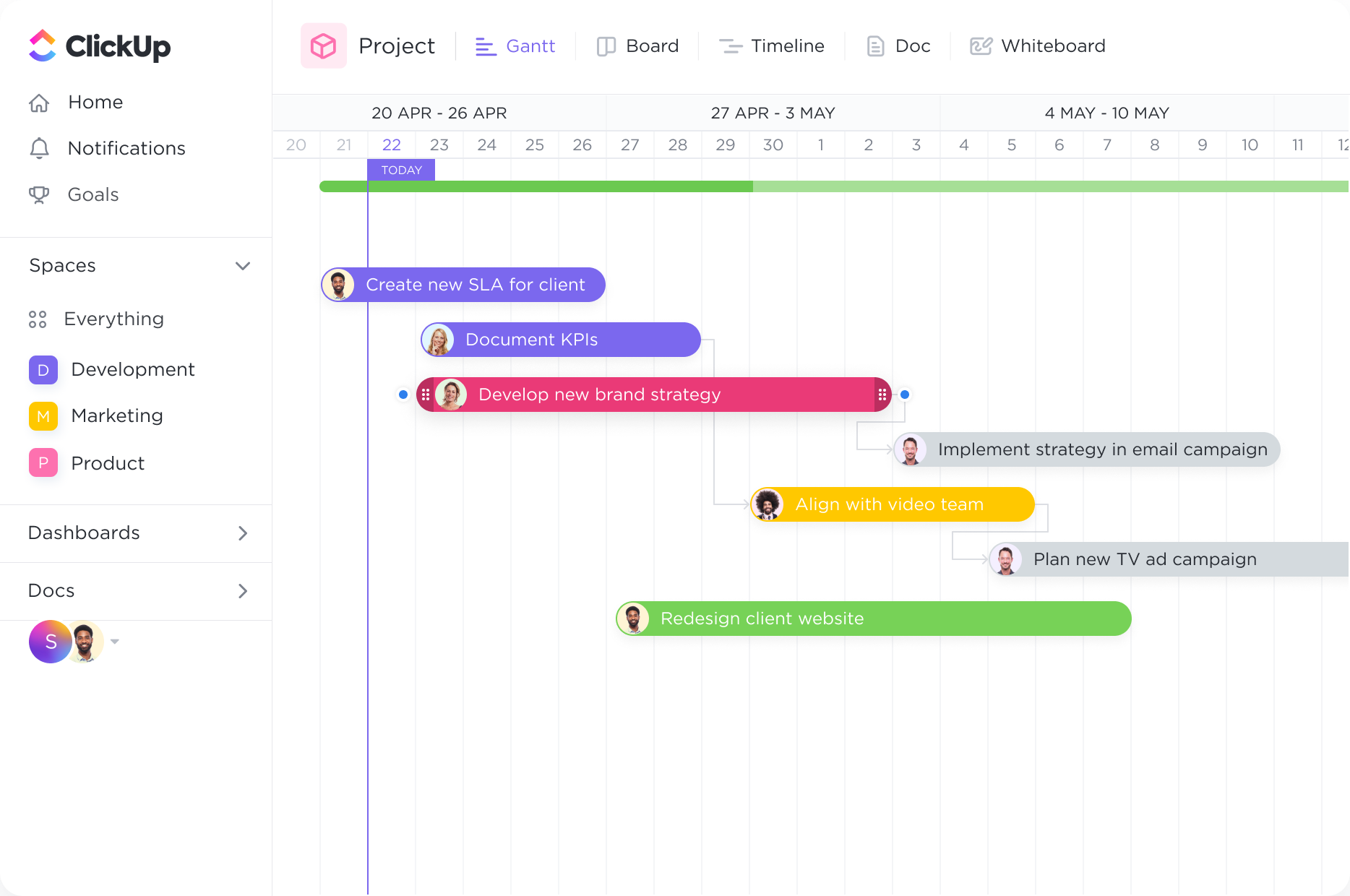

With the Gantt chart's dynamic timeline, you can easily schedule tasks, keep up with project progress, manage deadlines, and handle bottlenecks.

Streamline your project management process with ClickUp's powerful Gantt Chart software. Create dynamic Gantt Charts that are specifically designed for the unique needs of car manufacturers. Plan, track, and manage your projects with ease, utilizing ClickUp's intuitive interface and robust features. Take control of your production timelines and ensure smooth operations from start to finish with ClickUp's tailored Gantt Chart software.

Free forever.

No credit card.

Trusted by the world’s leading businesses

With the Gantt chart's dynamic timeline, you can easily schedule tasks, keep up with project progress, manage deadlines, and handle bottlenecks.

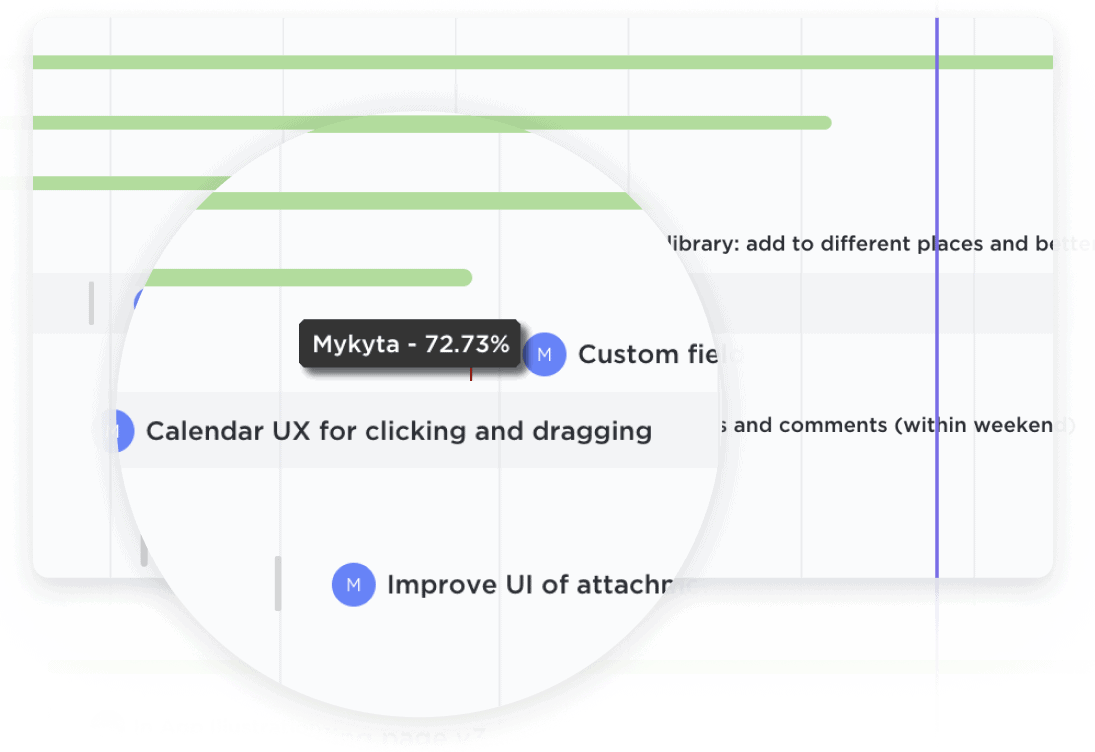

Easily update projects with a simple drag-and-drop action to collaborate amongst your team in real-time. Dynamic progress percentages provide a detailed snapshot.

Car manufacturers rely on efficient production planning and scheduling to meet demand and optimize resources. Gantt charts provide a visual representation of the manufacturing process, including tasks such as component procurement, assembly, testing, and quality control. By utilizing Gantt charts, car manufacturers can effectively allocate resources, track progress, and ensure timely delivery of vehicles to the market.

Managing the complex supply chain is crucial for car manufacturers. Gantt charts enable manufacturers to visualize the various stages of the supply chain, including sourcing raw materials, manufacturing components, and coordinating logistics. By incorporating Gantt charts into their supply chain management, car manufacturers can identify potential bottlenecks, optimize inventory levels, and streamline the flow of materials, ensuring a smooth and efficient production process.

Maintaining and managing equipment is essential for car manufacturers to ensure uninterrupted production and minimize downtime. Gantt charts can be utilized to schedule routine maintenance tasks, track equipment availability, and plan for equipment upgrades or replacements. By using Gantt charts for maintenance and equipment management, car manufacturers can optimize equipment utilization, reduce maintenance costs, and enhance overall operational efficiency.

Car manufacturers are constantly innovating and introducing new models to the market. Gantt charts can be used to plan and monitor all stages of the product development process, from concept design to prototyping, testing, and final production. By utilizing Gantt charts, car manufacturers can ensure that each stage of the development process is completed on time, effectively manage resources, and coordinate cross-functional teams involved in bringing new car models to market.

Gantt chart software can help streamline the production process for car manufacturers by visually mapping out the production timeline and identifying dependencies between tasks. This allows for better coordination and scheduling of manufacturing operations, ensuring efficient use of resources and timely completion of each production stage. Additionally, Gantt charts enable real-time tracking of progress, enabling quick identification and resolution of any bottlenecks or delays in the production process.

When looking for Gantt chart software designed for car manufacturers, key features and functionalities to consider include the ability to manage complex production schedules, track inventory and supply chain management, integrate with other manufacturing systems, provide real-time updates and notifications, and offer customizable reporting and analytics capabilities.

Yes, many Gantt chart software solutions offer integration capabilities with popular project management tools used in the automotive industry, such as Jira, Trello, and Asana. This allows for seamless data transfer and synchronization between systems, enabling teams to leverage the power of Gantt charts while maintaining their existing project management workflows and processes.