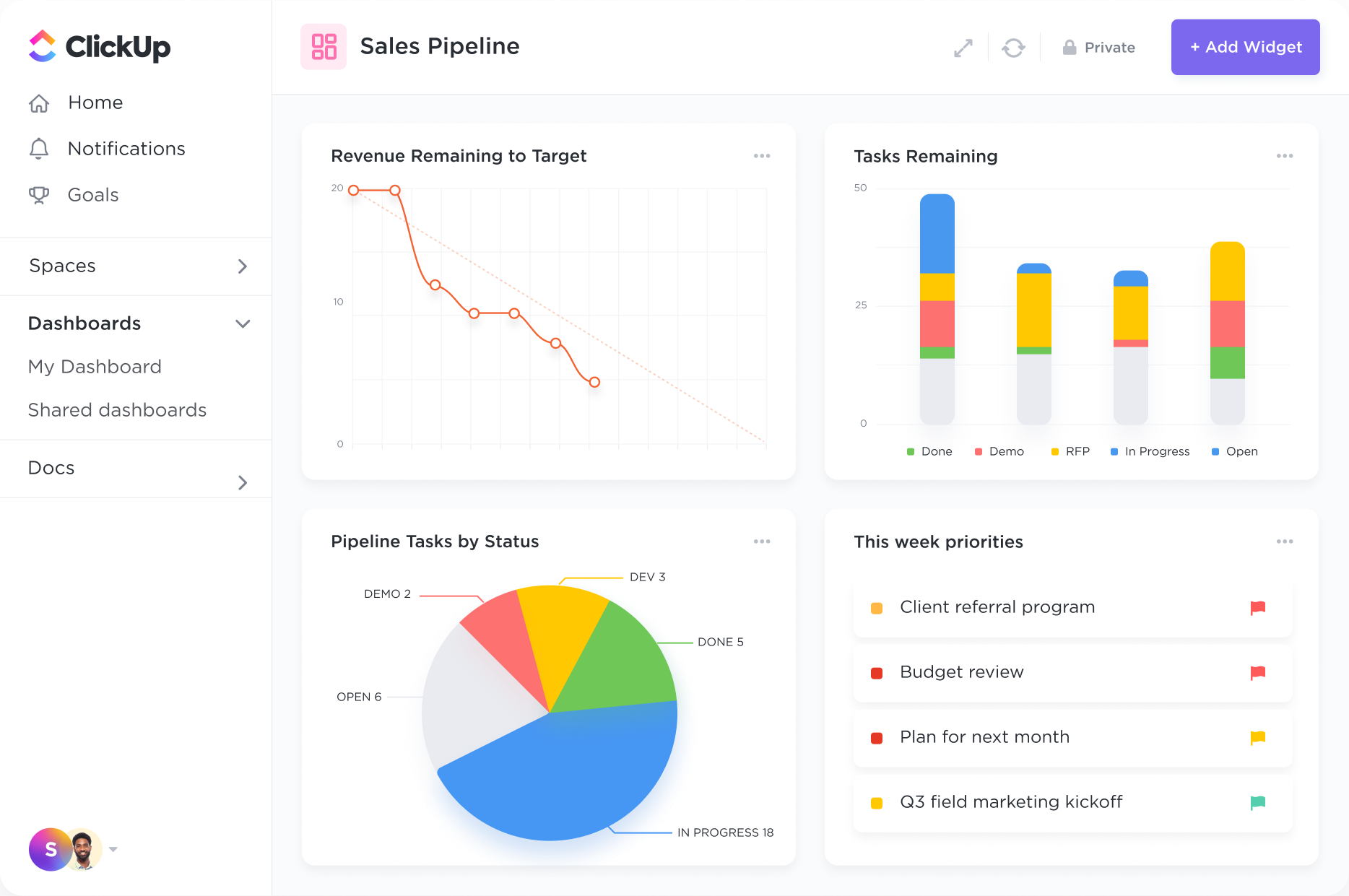

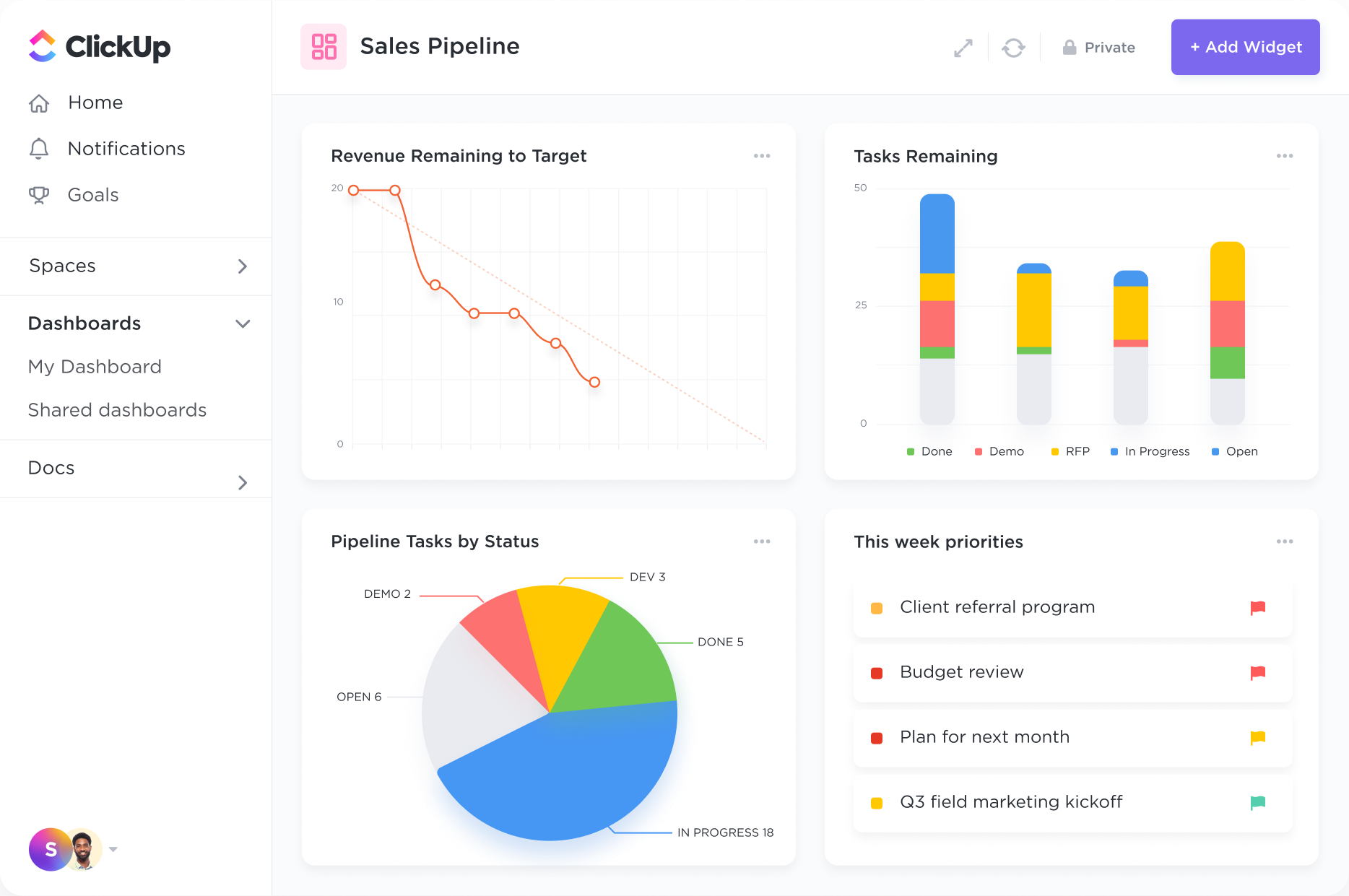

Analyze data for customer insights.

Create high-level views to monitor customer lifetime value, average deal sizes, and more. ClickUp's 50+ Dashboard widgets make it easy to visualize all of your customer data in one place.

Revolutionize your manufacturing business with ClickUp's customizable CRM system. Streamline your customer interactions, track leads, and boost sales effortlessly. Give your team the tools they need to succeed and watch your business thrive with ClickUp's cutting-edge CRM technology.

Free forever.

No credit card.

Trusted by the world’s leading businesses

Create high-level views to monitor customer lifetime value, average deal sizes, and more. ClickUp's 50+ Dashboard widgets make it easy to visualize all of your customer data in one place.

Manage everything from sales pipelines, customer engagement, and orders with ClickUp's 10+ highly flexible views. Easily track and manage your accounts on a List, Kanban Board, Table view, and more.

CRM software can improve the manufacturing process by enhancing customer relationship management, facilitating order and inventory management, streamlining production scheduling, and enabling data-driven decision-making for operational efficiency and better customer service.

When selecting a CRM software for manufacturing, consider features like inventory management, order tracking, customer service ticketing, production scheduling, and integration with manufacturing systems for a comprehensive solution tailored to the industry.

Yes, CRM software can help with inventory management in the manufacturing industry by providing real-time visibility into inventory levels, streamlining order processing, optimizing supply chain logistics, and improving production planning based on customer demand.